سبتمبر . 14, 2024 00:45 Back to list

Submersible Water Pump Problems and Solutions | Expert Guide

Common Submersible Water Pump Problems and Solutions

Submersible water pumps are vital components in various applications, including residential drainage, irrigation, and industrial water systems. However, like any mechanical equipment, they can experience issues that may hinder their performance. Understanding the common problems and their solutions can help maintain optimal operation and extend the lifespan of these pumps. Here are several common submersible water pump problems and their corresponding solutions.

1. Pump Won't Start

One of the frequent issues users encounter is that the submersible pump fails to start. This problem can stem from several factors, including power supply issues, tripped circuit breakers, or faulty switches. To troubleshoot this issue, first, ensure that the power supply is functioning correctly. Check the circuit breaker to see if it has tripped and reset it if necessary. If the power supply is fine but the pump still won’t operate, inspect the float switch, which can get stuck or malfunction. Cleaning or replacing the switch may resolve the problem.

Another common problem is a significant reduction in water flow. This can occur due to clogs in the intake screen, impeller blockage, or wear over time. To address low flow, begin by inspecting the intake screen for any debris or sediment that could be obstructing water flow. Clean the screen regularly to prevent blockages. If the impeller is damaged or worn out, it may need replacement. Regular maintenance can significantly reduce the occurrence of such issues.

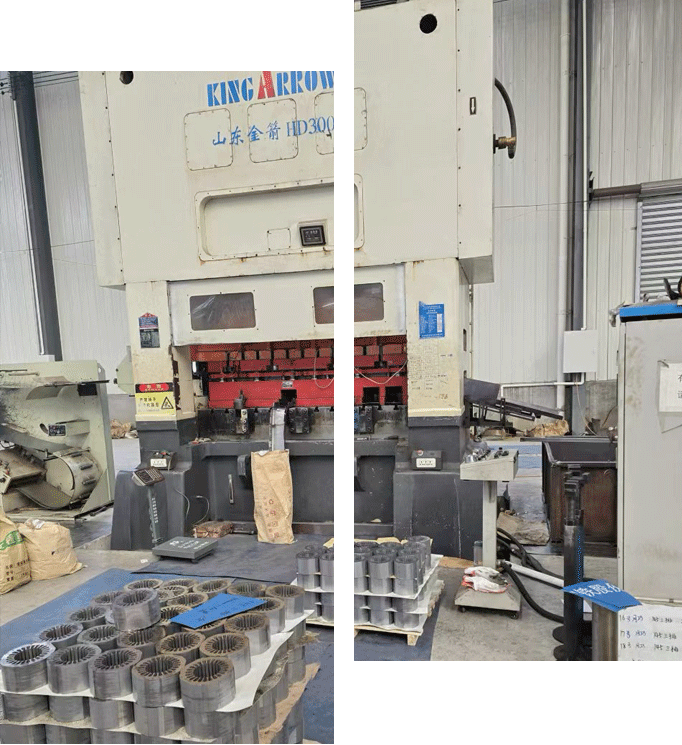

submersible water pump problems and solutions

3. Overheating

Overheating is a critical issue that can lead to permanent damage if not addressed promptly. Submersible pumps can overheat for various reasons, including running dry, excessive operational time, or inadequate cooling. To prevent overheating, ensure that the pump is fully submerged during operation. If the pump is continuously stopping and starting, consider adjusting the float switch or checking for clogging. Additionally, allowing the pump to operate for extended periods without breaks can cause it to overheat; monitor performance and provide regular operational breaks.

4. Unusual Noises

If the pump is emitting unusual noises, it may indicate a mechanical issue or misalignment. Common sounds include grinding or rattling, suggesting that internal components have become loose or worn. To troubleshoot this, first ensure the pump is securely mounted and not vibrating excessively. If the issue persists, consider inspecting the internal components for damage or wear and consulting a professional if needed.

Conclusion

Proper maintenance and timely troubleshooting of submersible water pumps can prevent many common problems and ensure consistent operation. Regular checks on power supply, cleaning intake screens, and monitoring for unusual noises will help keep the pump in excellent working condition. By being proactive and addressing issues promptly, users can maximize the efficiency and lifespan of their submersible water pumps.

-

submersible-sump-pump-auto-drainage-for-crawlspaces

NewsAug.22,2025

-

solar-powered-stainless-steel-submersible-well-pump-setup

NewsAug.22,2025

-

stainless-steel-well-pump-flow-rate-optimization

NewsAug.22,2025

-

water-filled-submersible-pump-fish-farm-oxygenation

NewsAug.22,2025

-

submersible-pump-in-aquaculture-and-fish-farming

NewsAug.22,2025

-

deep-well-submersible-pump-for-drought-areas

NewsAug.22,2025

-

submersible-sump-pump-auto-drainage-for-crawlspacesCrawlspaces, those narrow areas beneath homes, are prone to water accumulation due to leaks, groundwDetail

submersible-sump-pump-auto-drainage-for-crawlspacesCrawlspaces, those narrow areas beneath homes, are prone to water accumulation due to leaks, groundwDetail -

solar-powered-stainless-steel-submersible-well-pump-setupHarnessing solar energy to power stainless steel submersible well pumps is a sustainable and coDetail

solar-powered-stainless-steel-submersible-well-pump-setupHarnessing solar energy to power stainless steel submersible well pumps is a sustainable and coDetail -

stainless-steel-well-pump-flow-rate-optimizationIn various applications like agriculture, domestic water supply, and industrial use, the flow rate oDetail

stainless-steel-well-pump-flow-rate-optimizationIn various applications like agriculture, domestic water supply, and industrial use, the flow rate oDetail