Ago . 18, 2024 02:56 Back to list

Efficient Solutions for Deep Well Pump Piping Systems and Installation Techniques

Understanding Deep Well Pump Pipes An Essential Component for Water Extraction

Deep well pump pipes are crucial elements in the infrastructure of water extraction systems, particularly in agricultural, industrial, and municipal applications. These pipes facilitate the efficient movement of water from aquifers deep underground to the surface, ensuring a reliable supply of water for various uses. This article delves into the significance of deep well pump pipes, their materials, construction, and maintenance considerations.

The Importance of Deep Well Pump Pipes

Deep well pump pipes serve as the conduits through which water is drawn from significant depths, often reaching hundreds of feet below the surface. The primary role of these pipes is to transport water efficiently while maintaining its quality and preventing contamination. In areas where surface water is scarce or unreliable, deep well systems provide a critical resource. They also play a pivotal role in irrigation, supporting agriculture in regions where rainfall is insufficient.

Materials and Design

Deep well pump pipes are typically constructed from various materials, each chosen for its durability and compatibility with specific water conditions. Common materials include stainless steel, PVC (polyvinyl chloride), and HDPE (high-density polyethylene).

- Stainless Steel Known for its strength and resistance to corrosion, stainless steel is often used in environments with harsh water conditions. Its longevity makes it a popular choice despite its higher cost. - PVC Lightweight and resistant to chemical damage, PVC pipes are commonly used in shallow to moderately deep wells. They are often preferred for their ease of installation and lower cost. - HDPE This plastic material is flexible, resistant to environmental stress, and can adapt to shifting soil conditions. HDPE pipes are increasingly becoming a favorite in deep well installations due to their durability and resistance to corrosion.

deep well pump pipe

When designing deep well pump systems, considerations such as pipe diameter, wall thickness, and the type of pump used are essential

. These factors influence the flow rate, efficiency, and longevity of the system.Installation and Maintenance

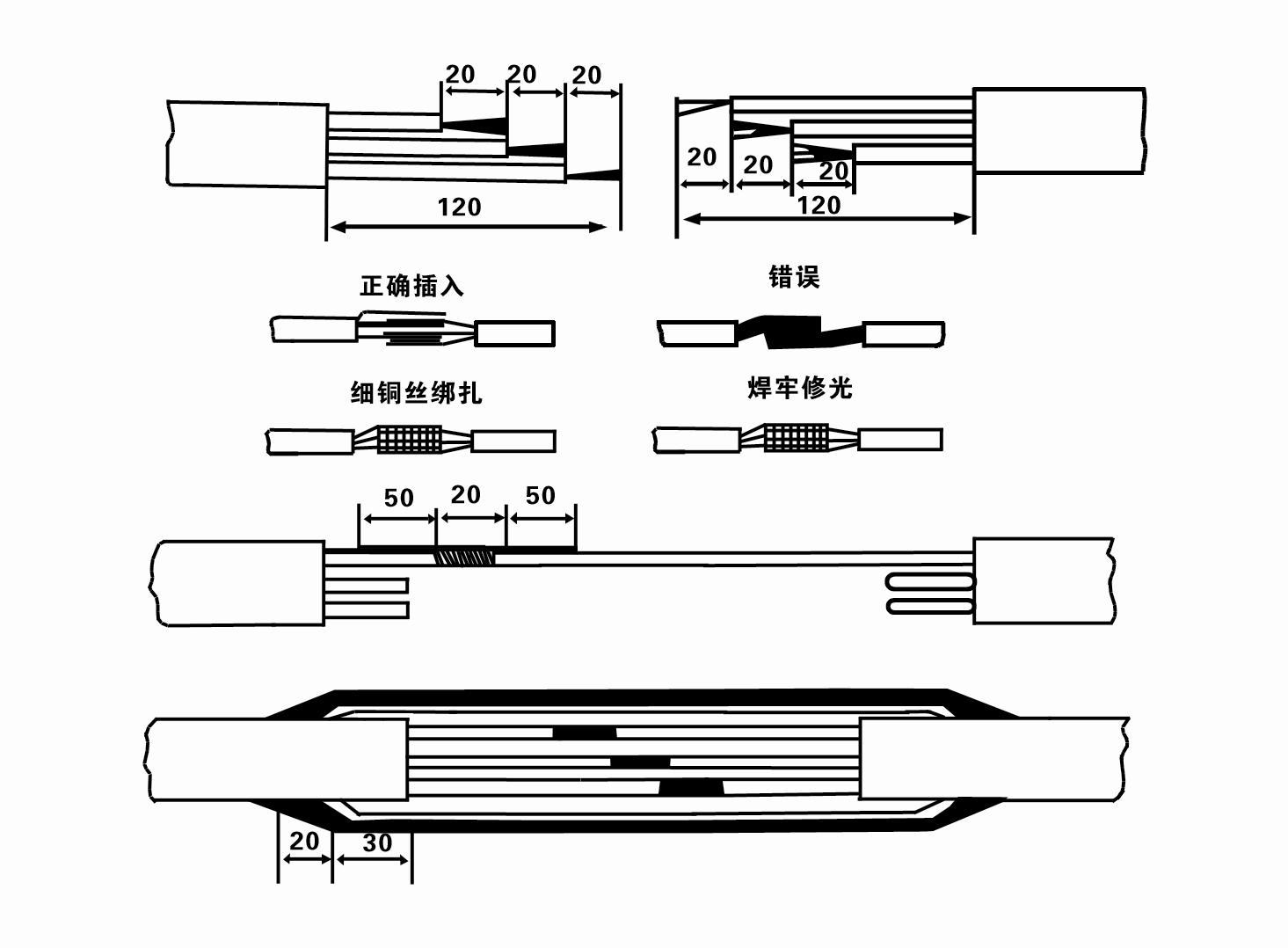

The installation of deep well pump pipes requires careful planning and skilled labor. Professionals must consider the geological conditions, depth of the aquifer, and the type of pump being used. The goal is to ensure that the system operates efficiently while minimizing potential complications such as clogging or collapse.

Maintenance is equally critical to ensure the longevity and effectiveness of the deep well pump system. Regular inspections are necessary to check for leaks, corrosion, or blockages. It is also essential to monitor the water quality periodically to detect any contamination issues that may arise from environmental factors or aging infrastructure.

Conclusion

In conclusion, deep well pump pipes are indispensable for effective water extraction from underground aquifers. They not only enable the reliable supply of water for various applications but also contribute to the overall sustainability of water resources. As technology advances, the materials and designs of these pipes continue to evolve, promising even greater efficiency and durability. Proper installation and maintenance practices will ensure that these systems continue to function reliably, meeting the water needs of communities and industries alike. Understanding the significance and functionality of deep well pump pipes is vital for anyone involved in water management, agriculture, or infrastructure development.

-

Water Filled Submersible PumpA water filled submersible pump is engineered for optimal cooling, eco-friendliness, and high efficiency, especially in applications involving clean or slightly sandy water.Detail

Water Filled Submersible PumpA water filled submersible pump is engineered for optimal cooling, eco-friendliness, and high efficiency, especially in applications involving clean or slightly sandy water.Detail -

The Ultimate Solution for CleanWhen it comes to efficient water delivery from underground or submerged sources, a submersible pump stands as the go-to solution for homes, farms, ponds, and industrial sites.Detail

The Ultimate Solution for CleanWhen it comes to efficient water delivery from underground or submerged sources, a submersible pump stands as the go-to solution for homes, farms, ponds, and industrial sites.Detail -

SS Submersible PumpA ss submersible pump (short for stainless steel submersible pump) is the premium choice for environments that demand durability, corrosion resistance, and long-term performance.Detail

SS Submersible PumpA ss submersible pump (short for stainless steel submersible pump) is the premium choice for environments that demand durability, corrosion resistance, and long-term performance.Detail