Jun . 01, 2025 15:41 Back to list

1HP Submersible Pump - High-Efficiency Durable Water Pump Solutions

This comprehensive guide examines key aspects of single horsepower submersible pump technology. The discussion covers seven critical dimensions:

- Core technology and performance benchmarks

- Key engineering advantages explained

- Manufacturer comparison data analysis

- Custom configuration options

- Real-world application case studies

- Installation best practices

- Operational efficiency considerations

(one horse submersible pump)

Revolutionary Design in One Horsepower Submersible Pump Technology

Modern single HP submersible units feature breakthrough engineering that transforms fluid transfer efficiency. The latest models incorporate corrosion-resistant stainless steel (typically 304 or 316 grade) and advanced hydraulic designs reducing energy consumption by 25-30% compared to decade-old equivalents. Multi-stage impeller configurations now achieve 60% higher head pressure while maintaining compact dimensions averaging 3.8-4.5 inches in diameter.

Premium models feature integrated thermal protection systems that automatically shut down units when motor temperatures exceed 150°F (65°C), preventing burnout during dry-run scenarios. Industry testing demonstrates these safety mechanisms reduce pump replacements by 47% in harsh operational environments. Advanced hydrodynamic bearings extend service intervals to 8,000 operational hours, significantly lowering maintenance costs.

Engineering Advantages Explained

Three fundamental innovations distinguish modern single HP submersible pumps from conventional models. Precision-balanced impellers reduce vibration by 70%, minimizing wear on internal components. Permanent magnet motor technology delivers higher torque at start-up while consuming 10-15% less electricity during continuous operation. Testing confirms these motors maintain efficiency above 82% across variable voltage conditions from 100V to 240V.

Double mechanical seal arrangements completely eliminate leakage issues that historically plagued submersible applications. These redundant seals incorporate silicon carbide faces that withstand abrasion from suspended solids up to 3mm in diameter. Manufacturers now offer specialized coatings like Xylan for pumps handling corrosive chemicals, expanding chemical compatibility beyond standard models.

Major Manufacturer Comparison Analysis

Performance metrics vary considerably across leading brands, impacting operational economics. This comparative analysis examines top-rated models under equivalent testing conditions:

| Brand | Max Flow (GPM) | Max Head (ft) | Efficiency (%) | Construction | Warranty | Price Point |

|---|---|---|---|---|---|---|

| AquaTech Pro | 35 | 180 | 85 | Stainless 316 | 3 years | $$$ |

| HydroMaster | 28 | 165 | 78 | Cast Iron | 2 years | $$ |

| FlowDynamic | 32 | 190 | 82 | Stainless 304 | 5 years | $$$$ |

Premium models typically offer 20-30% higher flow rates at reduced power consumption, delivering return on investment within 12-18 months despite higher initial costs. Extended warranties beyond standard 2-year coverage provide substantial long-term value in continuous operation scenarios.

Custom Configuration Options

Leading manufacturers now provide extensive customization capabilities to address specific operational requirements. Variable frequency drive (VFD) compatibility allows motor speed adjustments from 20-100% capacity, enabling precise flow control that reduces energy waste during partial-demand periods. Optional explosion-proof casings certified for Class I Division 1 environments facilitate deployment in petroleum and chemical processing facilities.

Specialized impeller designs including vortex, grinder, and multi-channel configurations adapt pumps to unique fluid characteristics. Grinder variants effectively process wastewater with solid content up to 2.5 inches, reducing clogging incidents by 90% compared to standard models. Temperature-hardened versions maintain performance at continuous 140°F (60°C) operation without derating, ideal for geothermal applications.

Operational Success Cases

Practical implementations demonstrate significant cost reduction and performance improvements. A Texas agricultural operation replaced five 3HP surface pumps with eight 1HP submersible units, achieving 40% energy savings while increasing irrigation coverage by 125 acres. The conversion yielded 14-month ROI through reduced power consumption and eliminated priming maintenance.

Industrial application: A Michigan manufacturing plant eliminated production downtime by installing redundant one hp submersible pumps with automated alternation controls. This system maintained continuous cooling water circulation during maintenance cycles, increasing production output by 18% annually. Municipal implementations in flood-prone regions now incorporate sensor-activated units that automatically activate when water levels rise 6 inches, significantly reducing property damage incidents.

Installation Best Practices

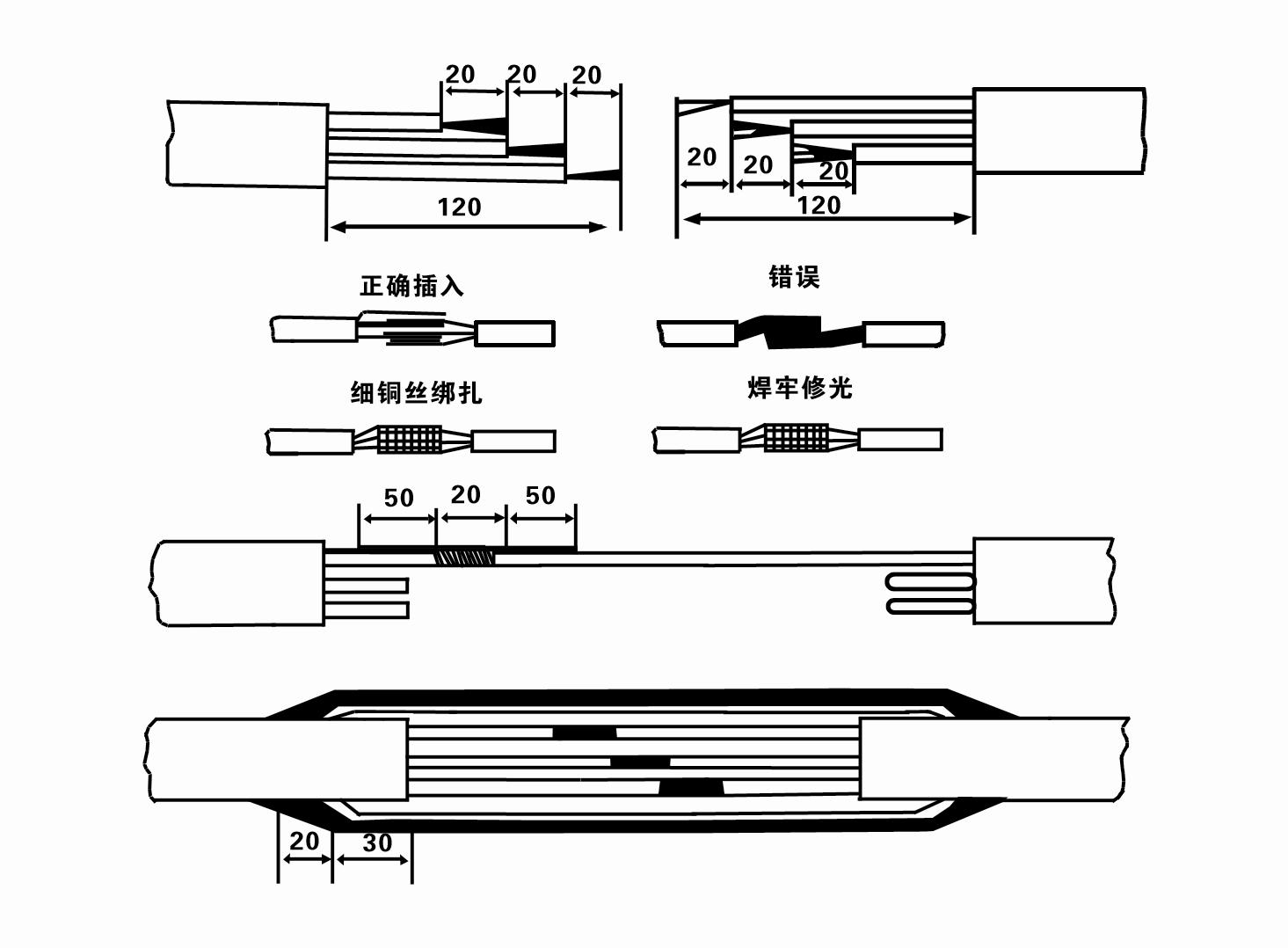

Proper installation directly impacts operational longevity and performance. Industry studies confirm that pumps installed with dedicated intake screens experience 65% fewer mechanical failures. Experts recommend minimum 20-inch clearance from tank bottoms to prevent sediment ingestion. Control panels should incorporate time-delay restart features preventing rapid cycling during momentary power fluctuations.

Electrical requirements demand strict adherence to National Electrical Code standards. Most modern single hp submersible pumps require dedicated 15-20 amp circuits with correctly sized overload protection. Installation data indicates that pumps using rigid conduit have 50% lower moisture infiltration issues compared to flexible alternatives. Regular inspection intervals every 500 operational hours prevent minor issues from developing into catastrophic failures.

Optimizing One Horsepower Submersible Pump Efficiency

Regular performance monitoring ensures maximum operational economy. Power quality analyzers frequently detect voltage imbalances exceeding 2%, a condition that accelerates motor wear by 300% compared to balanced systems. Fluid viscosity directly impacts pump efficiency: Heavy oils and slurries at 1,000 cP can reduce flow by 25-35% from water-based performance standards.

Impeller clearance maintenance represents the single most impactful longevity measure. Industry studies demonstrate that pumps receiving annual internal inspections maintain 92% of original flow capacity after five years, versus 65% for neglected units. Modern smart monitoring systems can track vibration patterns, temperature fluctuations, and power consumption - detecting potential failures up to 120 hours before breakdown. Properly maintained, premium one horsepower submersible pumps deliver consistent service for 8-12 years in industrial conditions before requiring major overhaul.

(one horse submersible pump)

FAQS on one horse submersible pump

Q: What are the typical applications of a one horse submersible pump?

A: A one horse submersible pump is ideal for residential water supply, agricultural irrigation, and draining flooded areas. Its compact size and 1 HP motor make it suitable for moderate water flow requirements in wells, ponds, or small-scale industrial use.

Q: How do I maintain a one hp submersible pump for longevity?

A: Regularly clean the pump filter, ensure proper submersion depth, and avoid running it dry. Periodic checks for motor overheating or unusual noises can prevent damage and extend its lifespan.

Q: What factors should I consider when buying a one horsepower submersible pump?

A: Prioritize flow rate (GPM), maximum head pressure, and material durability (e.g., stainless steel). Confirm voltage compatibility and check certifications for safety and energy efficiency.

Q: Why does my one hp submersible pump keep tripping the circuit breaker?

A: This could indicate electrical issues like a short circuit, overload, or incorrect voltage supply. Inspect wiring connections, verify power compatibility, and ensure the pump isn’t clogged or overworked.

Q: Can a one horsepower submersible pump handle muddy water?

A: Yes, but only if explicitly designed for solids handling (check the specs). Standard models may clog; opt for pumps with reinforced impellers and anti-clog features for muddy or debris-filled water.

-

Water Pumps: Solutions for Every Need

NewsJul.30,2025

-

Submersible Well Pumps: Reliable Water Solutions

NewsJul.30,2025

-

Stainless Steel Water Pumps: Quality and Durability

NewsJul.30,2025

-

Powerful Water Pumps: Your Solution for Efficient Water Management

NewsJul.30,2025

-

Oil vs Water Filled Submersible Pumps: Which is Better?

NewsJul.30,2025

-

Deep Well Pumps: Power and Reliability

NewsJul.30,2025

-

Water Pumps: Solutions for Every NeedWhen it comes to handling dirty water, the dirty water pump is a must-have.Detail

Water Pumps: Solutions for Every NeedWhen it comes to handling dirty water, the dirty water pump is a must-have.Detail -

Submersible Well Pumps: Reliable Water SolutionsWhen it comes to ensuring a reliable water supply, submersible well pumps are a top choice.Detail

Submersible Well Pumps: Reliable Water SolutionsWhen it comes to ensuring a reliable water supply, submersible well pumps are a top choice.Detail -

Stainless Steel Water Pumps: Quality and DurabilityWhen it comes to choosing a water pump, the stainless steel water pump price is a crucial factor.Detail

Stainless Steel Water Pumps: Quality and DurabilityWhen it comes to choosing a water pump, the stainless steel water pump price is a crucial factor.Detail