Rhag . 10, 2024 11:20 Back to list

10/2 submersible pump wire

Understanding Submersible Pump Wires Importance and Specifications

Submersible pumps play a crucial role in numerous applications, primarily in water extraction from wells, drainage of flooded areas, and even in boosting water pressure in various systems. However, the effectiveness and safety of these pumps significantly depend on the quality and specifications of the wires used to power them. In this article, we will delve into the essential aspects of submersible pump wiring, discussing materials, installation, and maintenance considerations.

What is a Submersible Pump?

A submersible pump is a device designed to operate underwater. It consists of a sealed motor and a pump in a single assembly that is submerged in the fluid it is meant to pump. The design prevents the motor from overheating and allows for efficient fluid movement. Common uses include groundwater extraction, wastewater treatment, and irrigation systems.

Importance of Submersible Pump Wires

The wires that connect to submersible pumps are vital for several reasons

1. Safety Submersible pump wires are specifically designed to handle the challenges associated with underwater installations. They must be insulated to prevent electrical shorts and protect against moisture, chemicals, and other environmental factors.

2. Efficiency Properly rated wires ensure that the electric current can travel to the pump with minimal resistance, maintaining the pump's efficiency and performance. Undersized or improperly insulated wires can lead to energy loss, overheating, and potential pump failure.

3. Durability Given the harsh conditions submersible pumps operate in, the wires must be robust enough to resist corrosion and wear over time. This includes exposure to water, sediment, and possibly aggressive chemicals found in sewage or industrial applications.

Specifications of Submersible Pump Wires

When selecting wires for submersible pumps, several specifications must be considered

10/2 submersible pump wire

1. Material The most commonly used materials are copper and aluminum. Copper wires are favored due to their superior conductivity, making them more efficient for power transmission. However, they are also more expensive than aluminum, which is lighter and resistant to corrosion but not as conductive.

2. Insulation The insulation material is critical for wire durability and performance. Common insulations include PVC (polyvinyl chloride) and XLPE (cross-linked polyethylene). PVC is economical but may not withstand extreme temperatures, while XLPE offers greater flexibility and better protection against heat and moisture.

3. Gauge Size The gauge size of the wire is another vital factor, as it must accommodate the pump's amperage draw. A wire that is too thin for the load can overheat and fail, so it is essential to consult the pump’s specifications to choose the correct gauge.

4. Water Resistance Submersible pump wires must be rated for underwater use. Look for wires that are specifically labeled as submersible and have a water-resistant rating. They should also be resistant to UV degradation if they will be exposed above water at any point.

5. Temperature Rating The wires should be rated for the temperature conditions they will encounter. Pumps in deeper waters may experience colder temperatures, while pumps in industrial settings may be exposed to high temperatures.

Installation Considerations

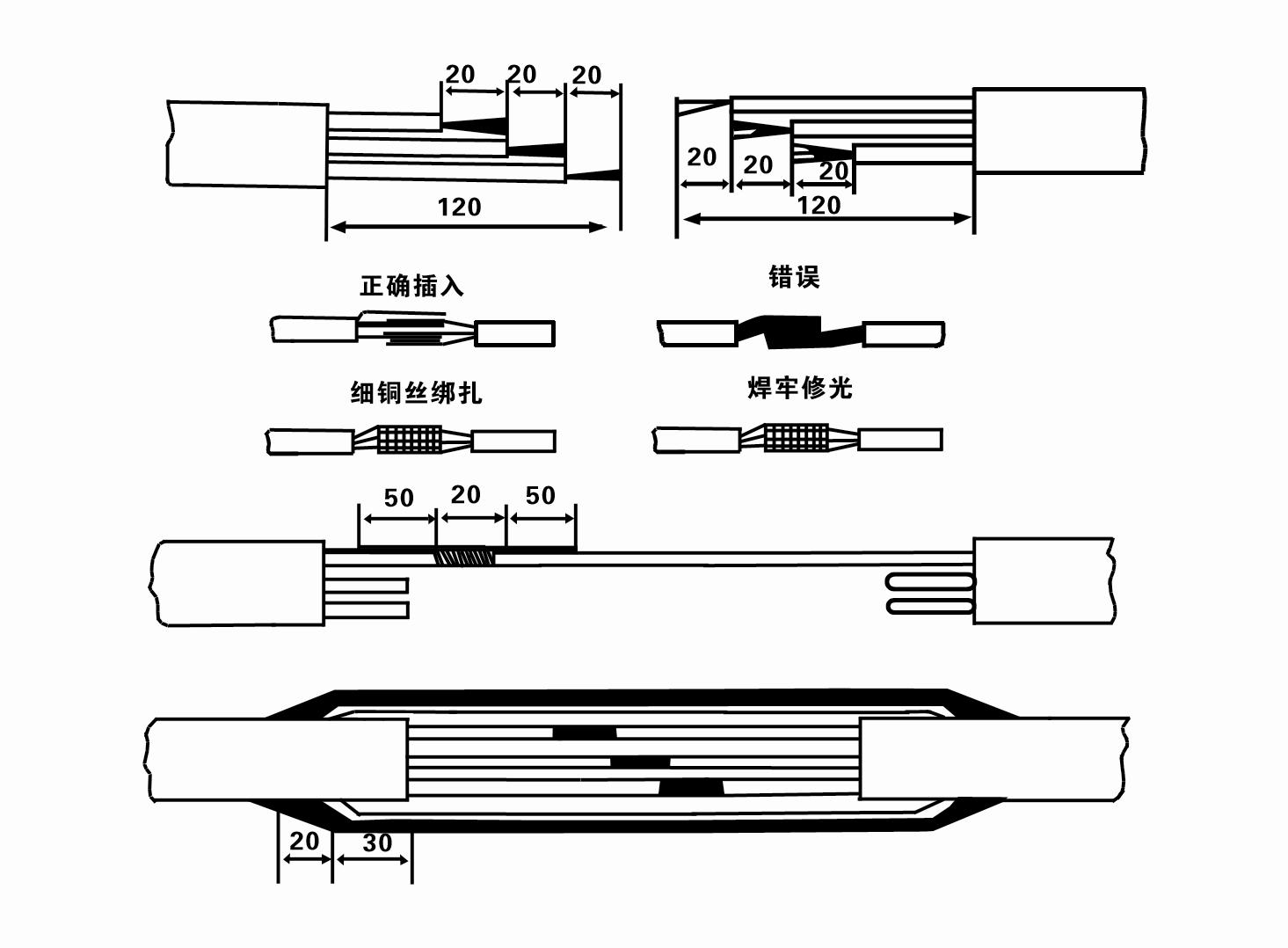

Proper installation is paramount in ensuring the longevity and effectiveness of submersible pump wires. Make sure that connections are secure and use appropriate junction boxes to protect wiring from moisture. It’s advisable to keep the wiring as short as possible to minimize voltage drop, which can impede performance.

Maintenance Tips

Regular maintenance can prolong the life of submersible pump wires. This includes checking for any signs of wear, corrosion, or damage, and ensuring airtight seals around junctions to prevent moisture intrusion. Conducting regular inspections will help identify potential issues before they escalate into costly repairs.

Conclusion

In conclusion, submersible pump wires are a critical component that must not be overlooked. Their specifications, material choices, and proper installation play significant roles in the pump's operation and longevity. Whether installing a new pump or maintaining an existing system, understanding the importance of high-quality wiring will ultimately lead to more efficient and safer submersible pumping operations. Always consult with a professional when in doubt, ensuring that your installations meet industry standards and safety regulations.

-

Water Pumps: Solutions for Every Need

NewsJul.30,2025

-

Submersible Well Pumps: Reliable Water Solutions

NewsJul.30,2025

-

Stainless Steel Water Pumps: Quality and Durability

NewsJul.30,2025

-

Powerful Water Pumps: Your Solution for Efficient Water Management

NewsJul.30,2025

-

Oil vs Water Filled Submersible Pumps: Which is Better?

NewsJul.30,2025

-

Deep Well Pumps: Power and Reliability

NewsJul.30,2025

-

Water Pumps: Solutions for Every NeedWhen it comes to handling dirty water, the dirty water pump is a must-have.Detail

Water Pumps: Solutions for Every NeedWhen it comes to handling dirty water, the dirty water pump is a must-have.Detail -

Submersible Well Pumps: Reliable Water SolutionsWhen it comes to ensuring a reliable water supply, submersible well pumps are a top choice.Detail

Submersible Well Pumps: Reliable Water SolutionsWhen it comes to ensuring a reliable water supply, submersible well pumps are a top choice.Detail -

Stainless Steel Water Pumps: Quality and DurabilityWhen it comes to choosing a water pump, the stainless steel water pump price is a crucial factor.Detail

Stainless Steel Water Pumps: Quality and DurabilityWhen it comes to choosing a water pump, the stainless steel water pump price is a crucial factor.Detail