velj . 14, 2025 13:39 Back to list

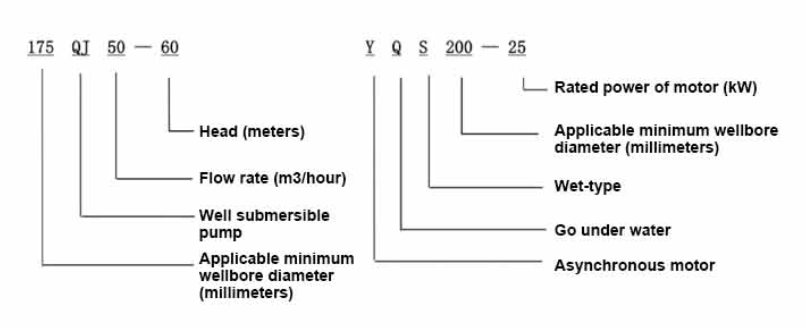

3in submersible well pump

Selecting the right wire for your submersible pump is an essential task that ensures system efficiency, reliability, and safety. Especially when it involves a 10/2 submersible pump wire, understanding its unique characteristics and applications can greatly improve your installation results. With years of industry experience, I'm here to share crucial insights into this specialized area of submersible pump wire selection and installation.

Moreover, emphasize the criticality of aligning the wire purchase with local electrical codes and standards. Consulting with licensed professionals not only guarantees code compliance but also provides peace of mind regarding the installation integrity and safety. Many regions have specific mandates that dictate the allowable wire types and installation methodologies, which if neglected, could lead to costly regulatory infringements. Trustworthiness is built through sharing genuine user experiences and authoritative references. Testimonials that review performance over time, focus on long-term efficiency gains, and discuss customer support interactions can create a strong trust foundation for prospective users. Likewise, referencing industry standards, safety organization endorsements, and manufacturer guidelines adds credibility to your claims while instilling confidence in consumers about their purchasing decision. As part of the journey towards optimal performance of your electrical systems, becoming informed about potential product innovations and developments is vital. Breakthroughs in smart technology, enhanced materials, and eco-friendly manufacturing practices can shape the future landscape of submersible pump wires. Staying informed about these developments and possibly integrating new technologies can elevate the efficiency and sustainability of present systems. In drawing this insightful guide to a close, the role a 10/2 submersible pump wire plays in the broader context of pump installations cannot be understated. Standing at the intersection of practical engineering and electrical efficiency, making informed decisions about this component fosters not just system excellence but also contributes to broader energy conservation efforts. If chosen and installed with precision and forethought, the 10/2 submersible pump wire becomes an invaluable asset, ensuring your pump operates smoothly, safely, and economically for years to come.

Moreover, emphasize the criticality of aligning the wire purchase with local electrical codes and standards. Consulting with licensed professionals not only guarantees code compliance but also provides peace of mind regarding the installation integrity and safety. Many regions have specific mandates that dictate the allowable wire types and installation methodologies, which if neglected, could lead to costly regulatory infringements. Trustworthiness is built through sharing genuine user experiences and authoritative references. Testimonials that review performance over time, focus on long-term efficiency gains, and discuss customer support interactions can create a strong trust foundation for prospective users. Likewise, referencing industry standards, safety organization endorsements, and manufacturer guidelines adds credibility to your claims while instilling confidence in consumers about their purchasing decision. As part of the journey towards optimal performance of your electrical systems, becoming informed about potential product innovations and developments is vital. Breakthroughs in smart technology, enhanced materials, and eco-friendly manufacturing practices can shape the future landscape of submersible pump wires. Staying informed about these developments and possibly integrating new technologies can elevate the efficiency and sustainability of present systems. In drawing this insightful guide to a close, the role a 10/2 submersible pump wire plays in the broader context of pump installations cannot be understated. Standing at the intersection of practical engineering and electrical efficiency, making informed decisions about this component fosters not just system excellence but also contributes to broader energy conservation efforts. If chosen and installed with precision and forethought, the 10/2 submersible pump wire becomes an invaluable asset, ensuring your pump operates smoothly, safely, and economically for years to come.

Latest news

-

Water Pumps: Solutions for Every Need

NewsJul.30,2025

-

Submersible Well Pumps: Reliable Water Solutions

NewsJul.30,2025

-

Stainless Steel Water Pumps: Quality and Durability

NewsJul.30,2025

-

Powerful Water Pumps: Your Solution for Efficient Water Management

NewsJul.30,2025

-

Oil vs Water Filled Submersible Pumps: Which is Better?

NewsJul.30,2025

-

Deep Well Pumps: Power and Reliability

NewsJul.30,2025

-

Water Pumps: Solutions for Every NeedWhen it comes to handling dirty water, the dirty water pump is a must-have.Detail

Water Pumps: Solutions for Every NeedWhen it comes to handling dirty water, the dirty water pump is a must-have.Detail -

Submersible Well Pumps: Reliable Water SolutionsWhen it comes to ensuring a reliable water supply, submersible well pumps are a top choice.Detail

Submersible Well Pumps: Reliable Water SolutionsWhen it comes to ensuring a reliable water supply, submersible well pumps are a top choice.Detail -

Stainless Steel Water Pumps: Quality and DurabilityWhen it comes to choosing a water pump, the stainless steel water pump price is a crucial factor.Detail

Stainless Steel Water Pumps: Quality and DurabilityWhen it comes to choosing a water pump, the stainless steel water pump price is a crucial factor.Detail