stu . 16, 2024 05:02 Back to list

submersible oil pump

Understanding Submersible Oil Pumps An Essential Component in Oil Extraction

In the oil and gas industry, the extraction of hydrocarbons from underground reservoirs is a complex process that demands robust and reliable equipment. One of the key components in this process is the submersible oil pump. Known for its efficiency and effectiveness, this type of pump has become an indispensable tool in modern oil extraction operations.

What is a Submersible Oil Pump?

A submersible oil pump is a device that is submerged directly in the fluid it is pumping, whether that be crude oil, water, or other liquids. Unlike traditional pumps that are located above the ground, submersible pumps are designed to work underwater, enhancing their efficiency in moving fluids from deep wells or reservoirs to the surface. They operate on the principle of converting rotational kinetic energy into hydrodynamic energy, allowing them to effectively transport oil and other fluids through pipelines.

How Do Submersible Oil Pumps Work?

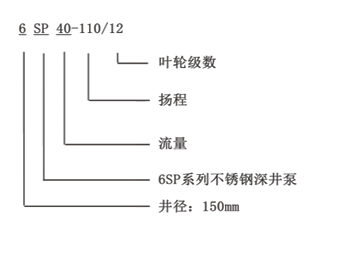

The operation of a submersible oil pump involves a series of components working together harmoniously. At its core, the pump consists of a motor that drives an impeller. When the motor spins, the impeller generates a pressure difference that draws the fluid into the pump and forces it upward through a discharge head. The design of the impeller and the overall pump structure is crucial for optimizing flow rates and minimizing energy consumption.

Most submersible pumps are constructed from durable materials such as stainless steel or high-quality plastics to withstand the corrosive nature of crude oil. The entire assembly is sealed and designed to prevent any leakage, ensuring that the pumping operation is safe and efficient.

Advantages of Submersible Oil Pumps

The use of submersible oil pumps comes with a multitude of advantages

submersible oil pump

1. Efficiency Since submersible pumps work underwater, they can lift fluids more efficiently than surface pumps, resulting in lower operational costs.

2. Space-saving These pumps do not require extensive above-ground installations, which is especially beneficial in remote locations where space is limited.

3. Versatility Submersible oil pumps are suitable for a variety of fluids, making them highly versatile in different extraction scenarios.

4. Reliability Designed to withstand harsh conditions, submersible pumps have a long operational lifespan, reducing the need for frequent maintenance or replacements.

5. Reduced noise Being submerged in fluid, these pumps operate relatively quietly, which can be an advantage in sensitive areas.

Key Considerations in Deployment

While submersible oil pumps have many advantages, several factors must be considered before deployment. The depth of the well, the viscosity of the oil, and the total dynamic head (TDH) are critical in selecting the right pump. Additionally, regular maintenance is essential to ensure optimal performance, as accumulated debris and wear can affect pump efficiency.

Conclusion

Submersible oil pumps play a crucial role in the efficient extraction of oil from deep underground reservoirs. Their ability to operate underwater, combined with their efficiency and reliability, makes them a preferred choice in the oil and gas industry. As the demand for oil continues to grow, advancements in submersible pump technology will undoubtedly continue to improve their performance, ensuring they remain a valuable component in the energy sector for years to come. Understanding the intricacies of these pumps not only enhances operational efficiency but also contributes to more sustainable practices within the industry.

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater World

NewsJul.01,2025

-

Submersible Pond Pump: The Hidden Guardian of Water Landscape Ecology

NewsJul.01,2025

-

Stainless Well Pump: A Reliable and Durable Pumping Main Force

NewsJul.01,2025

-

Stainless Steel Submersible Pump: An Efficient and Versatile Tool for Underwater Operations

NewsJul.01,2025

-

Deep Well Submersible Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Deep Water Well Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail -

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail -

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail