jan . 20, 2025 16:37 Back to list

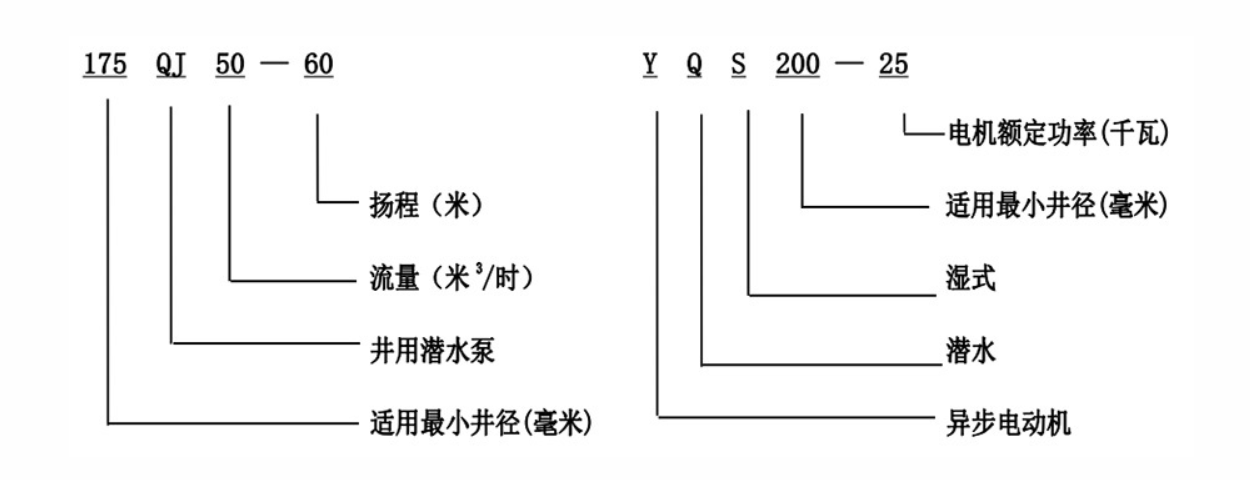

175QJ Deep Well Submersible Pump

Repairing a deep well submersible pump requires a keen understanding of the equipment, a strong grasp of the mechanics involved, and a methodical approach to troubleshooting. The process usually begins with diagnosing the issue. Common problems include electrical failures, mechanical blockages, or physical damage to the pump itself. Experience in handling such equipment is essential, as it helps swiftly identify and address these issues.

Replacing damaged parts requires thorough knowledge of the pump's construction. It's advisable to refer to the manufacturer's manual for guidance on parts replacement. Using genuine replacement parts is critical for maintaining the pump's performance and reliability. Preventive maintenance dramatically extends the lifecycle of a submersible pump. Regular inspections of the electrical systems can preempt failures, while ensuring the pump’s immediate environment is free from large particles can prevent physical blockages. Scheduled servicing, similar to that of HVAC systems, allows for diagnosis of potential issues before they escalate into major malfunctions. Working with a certified technician or an experienced professional in submersible pumps increases trustworthiness, as these experts bring authoritative knowledge that significantly enhances repair success rates. An expert's role extends beyond mere repair; they offer insights into optimizing pump performance and energy efficiency, aspects crucial for reducing operational costs. Engaging with knowledgeable forums or communities dedicated to submersible pump maintenance can also be beneficial. Such platforms offer anecdotal advice and professional opinions that can provide innovative solutions for complex issues. Sharing experiences within these communities not only aids individual learning but collectively broadens the understanding of submersible pump maintenance and repair. Ultimately, resolving issues with deep well submersible pumps combines experience, expertise, and a willingness to learn. Each repair is an opportunity to build on existing knowledge and contribute to a broader comprehension of best practices in the field, enhancing both personal expertise and community trustworthiness.

Replacing damaged parts requires thorough knowledge of the pump's construction. It's advisable to refer to the manufacturer's manual for guidance on parts replacement. Using genuine replacement parts is critical for maintaining the pump's performance and reliability. Preventive maintenance dramatically extends the lifecycle of a submersible pump. Regular inspections of the electrical systems can preempt failures, while ensuring the pump’s immediate environment is free from large particles can prevent physical blockages. Scheduled servicing, similar to that of HVAC systems, allows for diagnosis of potential issues before they escalate into major malfunctions. Working with a certified technician or an experienced professional in submersible pumps increases trustworthiness, as these experts bring authoritative knowledge that significantly enhances repair success rates. An expert's role extends beyond mere repair; they offer insights into optimizing pump performance and energy efficiency, aspects crucial for reducing operational costs. Engaging with knowledgeable forums or communities dedicated to submersible pump maintenance can also be beneficial. Such platforms offer anecdotal advice and professional opinions that can provide innovative solutions for complex issues. Sharing experiences within these communities not only aids individual learning but collectively broadens the understanding of submersible pump maintenance and repair. Ultimately, resolving issues with deep well submersible pumps combines experience, expertise, and a willingness to learn. Each repair is an opportunity to build on existing knowledge and contribute to a broader comprehension of best practices in the field, enhancing both personal expertise and community trustworthiness.

Latest news

-

Water Pumps: Solutions for Every Need

NewsJul.30,2025

-

Submersible Well Pumps: Reliable Water Solutions

NewsJul.30,2025

-

Stainless Steel Water Pumps: Quality and Durability

NewsJul.30,2025

-

Powerful Water Pumps: Your Solution for Efficient Water Management

NewsJul.30,2025

-

Oil vs Water Filled Submersible Pumps: Which is Better?

NewsJul.30,2025

-

Deep Well Pumps: Power and Reliability

NewsJul.30,2025

-

Water Pumps: Solutions for Every NeedWhen it comes to handling dirty water, the dirty water pump is a must-have.Detail

Water Pumps: Solutions for Every NeedWhen it comes to handling dirty water, the dirty water pump is a must-have.Detail -

Submersible Well Pumps: Reliable Water SolutionsWhen it comes to ensuring a reliable water supply, submersible well pumps are a top choice.Detail

Submersible Well Pumps: Reliable Water SolutionsWhen it comes to ensuring a reliable water supply, submersible well pumps are a top choice.Detail -

Stainless Steel Water Pumps: Quality and DurabilityWhen it comes to choosing a water pump, the stainless steel water pump price is a crucial factor.Detail

Stainless Steel Water Pumps: Quality and DurabilityWhen it comes to choosing a water pump, the stainless steel water pump price is a crucial factor.Detail