Jul . 27, 2024 11:16 Back to list

Cost Analysis for Boring Submersible Pump Installation and Maintenance in Various Applications

Understanding the Costs of Submersible Pump Boring

Submersible pump boring is a crucial process in extracting groundwater from depths that traditional pumps cannot reach. It involves drilling a borehole, installing a submersible pump, and ensuring that the entire system operates efficiently. While the utility of submersible pump systems is widely recognized, understanding the costs associated with submersible pump boring is essential for individuals and organizations looking to invest in this water extraction method.

Initial Costs

The initial costs of submersible pump boring can vary significantly based on several factors, including the depth of the water table, the geological conditions, and the specific equipment used. Typically, a borehole can range from a few hundred to several thousand dollars to drill. For instance, a shallow well might cost around $1,500 to $3,000, while deeper wells can reach $15,000 or more.

Drill Rig and Equipment

The type of drilling equipment also impacts the overall expense. Contractors need to choose between different types of rigs, such as rotary or percussion drilling rigs. Rotary drilling tends to be more expensive due to its efficiency and capability to penetrate tougher geological formations. Additionally, the cost of the drilling bits, casing, and other materials necessary for completing the borehole can add to the overall expenditure.

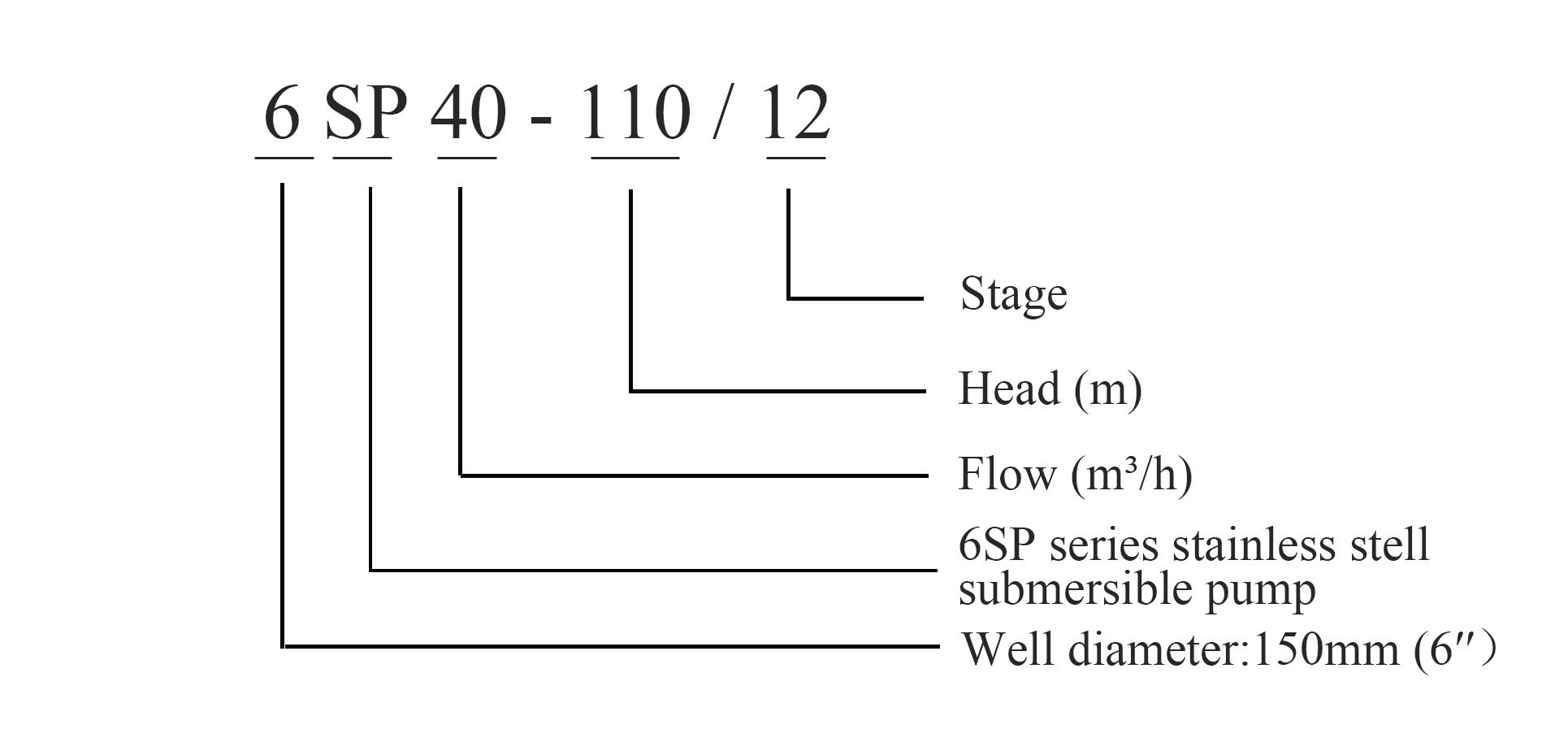

Cost of the Submersible Pump

Once the borehole is drilled, the cost of the submersible pump itself must be considered. These pumps come in various sizes, capacities, and efficiencies, and the price can range from $300 to over $5,000, depending on the specifications and brand. Higher-capacity models that can lift water from greater depths will typically incur higher costs, but they may provide better long-term value through increased efficiency.

submersible pump boring cost

Installation and Labor Costs

Labor costs are another significant factor in the overall expense of installing a submersible pump system. The installation process requires skilled technicians who can handle the complexities of electrical connections and ensure that the pump is set up properly within the borehole. On average, labor costs can range from $500 to $2,000, depending on the complexity of the installation and the local labor rates.

Maintenance Costs

After installation, ongoing maintenance is essential to ensure the longevity and efficiency of the submersible pump system. Routine checks, cleaning, and potential repairs should be factored into the total cost of ownership. Maintenance costs can vary but budgeting for around 5-10% of the initial installation cost on an annual basis is a reasonable guideline.

Conclusion

In summary, while the initial outlay for submersible pump boring can be significant, understanding the cumulative costs can help in making informed decisions. Factors such as drilling depth, geological conditions, equipment choices, and installation labor all play essential roles in the total expenditure. Additionally, factoring in maintenance costs will provide a clearer picture of the long-term financial commitment required.

Investing in a submersible pump system can be an excellent decision for those looking to access groundwater efficiently. However, it's crucial to conduct thorough research and obtain multiple quotes from contractors to ensure you are getting the best value for your investment. Furthermore, considering the potential savings in energy costs and increased water accessibility can help justify the initial expense, ultimately making submersible pump boring an economically viable solution for water extraction needs.

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater World

NewsJul.01,2025

-

Submersible Pond Pump: The Hidden Guardian of Water Landscape Ecology

NewsJul.01,2025

-

Stainless Well Pump: A Reliable and Durable Pumping Main Force

NewsJul.01,2025

-

Stainless Steel Submersible Pump: An Efficient and Versatile Tool for Underwater Operations

NewsJul.01,2025

-

Deep Well Submersible Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Deep Water Well Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail -

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail -

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail