Aug . 18, 2024 06:31 Back to list

Durable Steel Submersible Pumps for Efficient Water Management Solutions

The Steel Submersible Pump A Robust Solution for Submerged Applications

The steel submersible pump has emerged as a vital component in various industrial and municipal applications, demonstrating unparalleled efficiency and durability in environments where other pump types may fail. Submersible pumps, by their very design, operate underwater, immersing their entire apparatus beneath the liquid's surface. This unique feature allows them to handle diverse tasks, from dewatering to sewage management, and they are particularly favored in scenarios where space is limited.

Construction and Advantages

One of the most significant advantages of steel submersible pumps is their robust construction. Steel is renowned for its strength and resistance to corrosion, especially when treated with coatings or alloys designed to withstand harsh environmental conditions. This makes steel submersible pumps particularly suitable for applications involving abrasive or corrosive materials, such as wastewater treatment, mining operations, and even oil and gas extraction. The durability of steel ensures that these pumps can operate effectively over extended periods, leading to lower maintenance costs and reduced downtime.

In addition to their strength, steel submersible pumps are engineered to be energy-efficient. The design typically includes a streamlined impeller and motor configuration, which allows for optimal fluid dynamics and energy consumption. As industries continuously seek to reduce their carbon footprints and operational expenses, the energy efficiency of steel submersible pumps becomes an attractive proposition.

Applications

Steel submersible pumps are versatile tools utilized in a wide range of applications. In municipal settings, they effectively manage sewage and stormwater systems, preventing flooding and ensuring that wastewater is adequately handled. Their ability to operate submerged allows them to be installed in various locations, from residential basements to deep wells.

steel submersible pump

In the agricultural sector, these pumps are essential for irrigation systems. They draw water from deep aquifers to supply crops with the necessary hydration, facilitating food production even in arid regions. Moreover, in industrial contexts, steel submersible pumps play a crucial role in dewatering operations in mines and construction sites, where managing water levels is critical for safety and operational efficiency.

Considerations for Selection

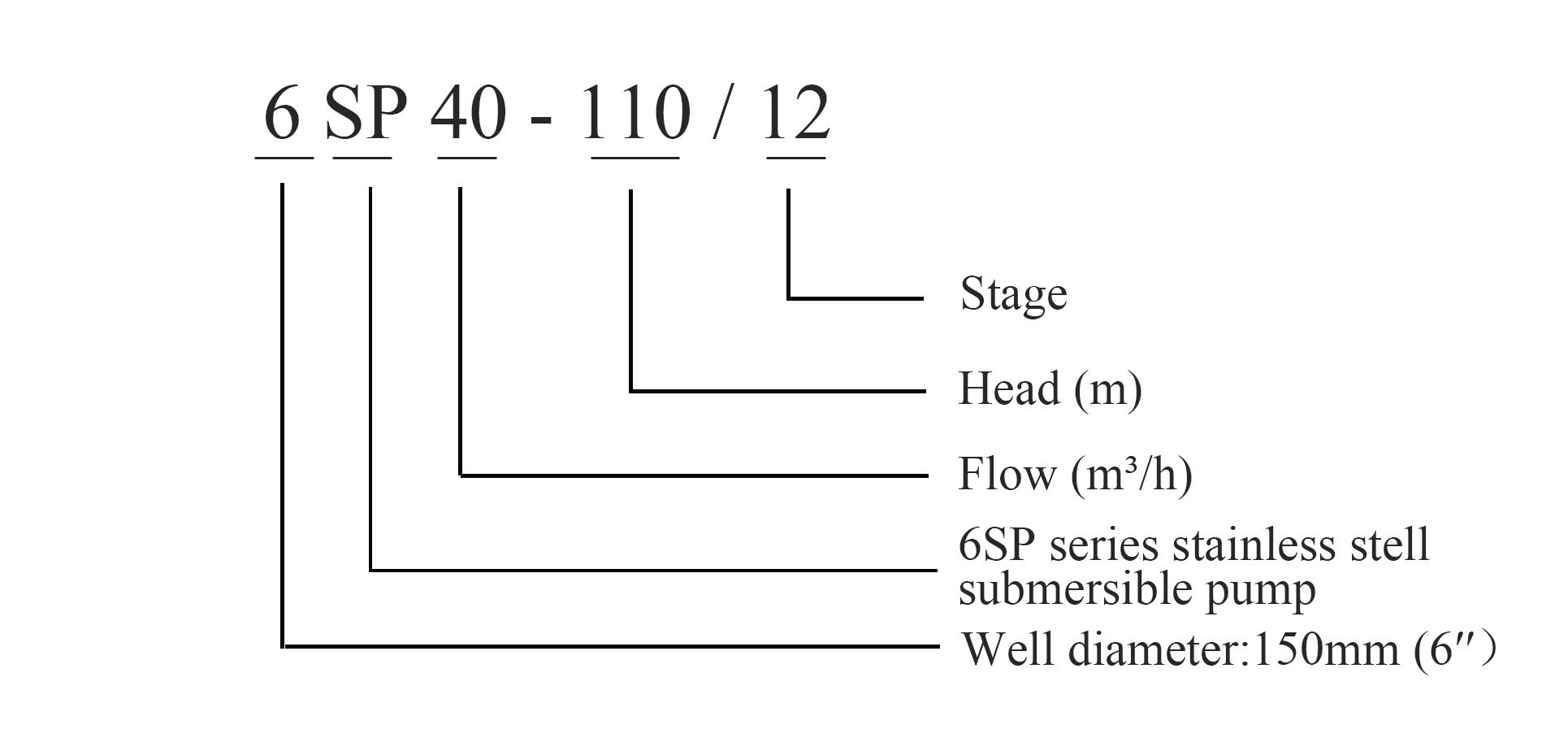

When selecting a steel submersible pump, several factors must be considered to ensure optimal performance. The specific application, required flow rate, and depth of operation are essential aspects to address. Additionally, the type of fluid—whether it is clean water, sewage, or industrial waste—will also influence the choice of pump.

Another crucial aspect is the pump's motor power. A pump that is too powerful can lead to unnecessary energy consumption, while one that is underpowered may fail to meet the required performance standards. Therefore, working with an experienced supplier or engineer to determine the right specifications is paramount.

Conclusion

In summary, the steel submersible pump stands out as a robust and efficient solution for a multitude of submerged applications. Its durable construction, energy efficiency, and versatility make it an indispensable tool across various industries, from municipal infrastructure to agricultural demands. As technology advances, the development of more efficient and sustainable pumping solutions will continue to enhance the role of steel submersible pumps in ensuring that our water management systems remain reliable and effective in an ever-changing world. Embracing such innovations will be key as we move toward a more sustainable future, where water management is increasingly crucial.

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater World

NewsJul.01,2025

-

Submersible Pond Pump: The Hidden Guardian of Water Landscape Ecology

NewsJul.01,2025

-

Stainless Well Pump: A Reliable and Durable Pumping Main Force

NewsJul.01,2025

-

Stainless Steel Submersible Pump: An Efficient and Versatile Tool for Underwater Operations

NewsJul.01,2025

-

Deep Well Submersible Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Deep Water Well Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail -

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail -

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail