Dec . 14, 2024 00:34 Back to list

Safe and Efficient Submersible Pumps for Hazardous Environments and Explosion Protection

Understanding Explosion-Proof Submersible Pumps

In industries where flammable materials are present, safety is of paramount importance. One of the critical components that ensure operational safety in such environments is the explosion-proof submersible pump. These pumps are specifically designed to operate under hazardous conditions, providing reliable performance while minimizing the risk of ignition of flammable vapors, gases, or dust. In this article, we delve into the features, applications, and importance of explosion-proof submersible pumps.

What Are Explosion-Proof Submersible Pumps?

Explosion-proof submersible pumps are specialized devices that are submerged in liquids to pump them from one location to another. The explosion-proof designation means that these pumps can contain an internal explosion and prevent the ignition of hazardous materials surrounding the pump. This is crucial in industries such as oil and gas, chemicals, mining, and wastewater management, where the presence of volatile substances is common.

The construction of these pumps includes robust materials and sealing mechanisms designed to withstand extreme conditions. Essential components such as the motor, housing, and electrical connections are designed to prevent the escape of sparks or hot gases that could ignite surrounding flammable substances.

Key Features

1. Sealing and Enclosure The pumps are built with high-grade materials and designed to be watertight and vapor-tight. This is achieved through the use of hermetically sealed enclosures, minimizing the risk of ignition due to external elements.

2. Thermal Management Explosion-proof submersible pumps often come with advanced thermal management systems that prevent overheating. This is particularly important as excessive heat can lead to failure and potentially cause an explosion.

3. Variable Speed Options Many explosion-proof pumps offer variable speed capabilities that allow operators to adjust the flow rate as needed, which can help to further minimize hazard risks, especially in fluctuating operational conditions.

4. Certification and Compliance These pumps must meet strict industry standards and certifications, such as the ATEX (ATmosphères EXplosibles) and UL (Underwriters Laboratories) standards. These certifications ensure that the equipment is safe for use in hazardous environments.

Applications

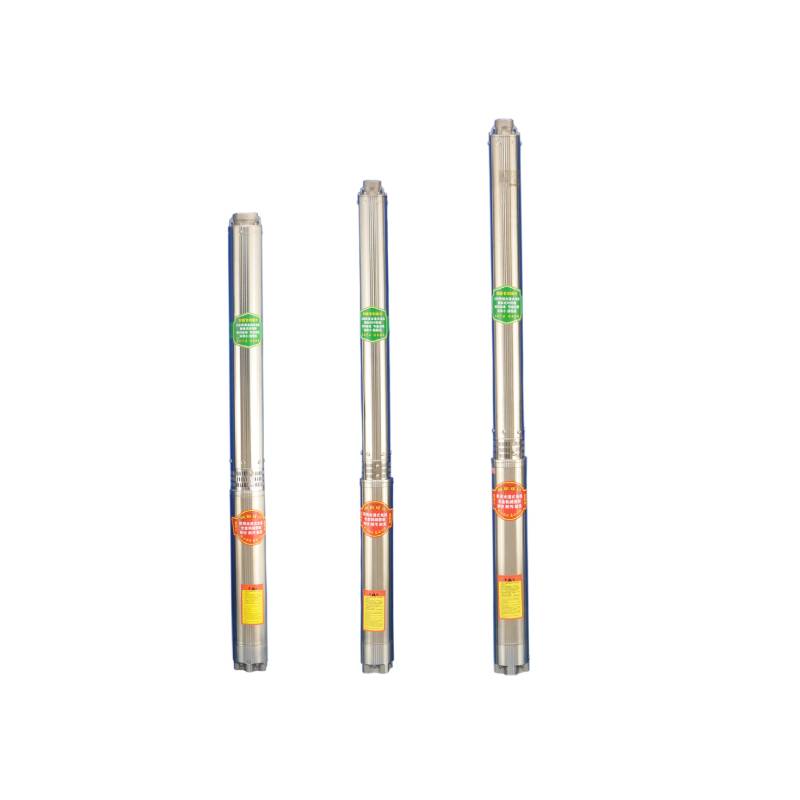

explosion proof submersible pump

Explosion-proof submersible pumps are utilized in a variety of sectors

1. Oil and Gas Industry In extracting oil from underground wells, the risk of igniting flammable gases is significant. Submersible pumps are used in offshore and onshore drilling operations to safely transport fluids.

2. Chemical Manufacturing The handling of volatile chemicals poses a risk of explosion. These pumps are used for transferring chemicals safely within production facilities.

3. Wastewater Treatment In wastewater treatment plants, submersible pumps help manage sewage and other hazardous waste, ensuring that materials are moved effectively without creating hazardous conditions.

4. Mining Mining operations often encounter flammable gases and must manage water from underground sources. Explosion-proof pumps are essential to maintain safety while efficiently removing water and other by-products.

Importance of Explosion-Proof Submersible Pumps

The significance of explosion-proof submersible pumps cannot be overstated. They play a crucial role in ensuring safety, preventing accidents, and maintaining operational efficiency in industries handling hazardous materials. By minimizing the risk of ignition, these pumps protect both personnel and equipment, contributing to overall workplace safety.

Additionally, the economic implications are substantial. Accidents due to equipment failure can lead to costly downtime, legal liabilities, and damage to the organization’s reputation. By investing in reliable explosion-proof equipment, businesses can safeguard their operations against these risks.

Conclusion

In conclusion, explosion-proof submersible pumps are essential tools in various industries where hazardous materials are present. Their specialized design, safety features, and compliance with industry standards make them vital for preventing explosions and ensuring safe operations. As industries continue to evolve and face new challenges, the role of these pumps in promoting safety and efficiency will undoubtedly remain significant. Understanding the importance of investing in suitable equipment is key to fostering a safer working environment.

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater World

NewsJul.01,2025

-

Submersible Pond Pump: The Hidden Guardian of Water Landscape Ecology

NewsJul.01,2025

-

Stainless Well Pump: A Reliable and Durable Pumping Main Force

NewsJul.01,2025

-

Stainless Steel Submersible Pump: An Efficient and Versatile Tool for Underwater Operations

NewsJul.01,2025

-

Deep Well Submersible Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Deep Water Well Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail -

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail -

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail