Aug . 22, 2024 16:50 Back to list

How Does a Well Pump Work: Well Water Basics

An introduction to well pump systems which explains the mechanics behind jet and submersible pumps as well as basic knowledge, maintenance, and troubleshooting information.

According to a survey done by the US Census American Housing Survey, an estimated 13 million across the United States use private wells as their source of water (EPA).

Modern private well water systems have come leaps and bounds in efficiency and reliability as compared to older methods of ancient and even recent history.

And while the establishment of municipal water systems will continue to provide water to hundreds of thousands and even millions of people in larger cities, there are undeniable advantages to owning a private well system for those in more remote areas and for the homestead owner.

Understanding the Groundwater Beneath You

Before understanding how a well water system works, it's best to understand where the water comes from.

Groundwater is the water found beneath the Earth’s surface which is renewed via precipitation when rainwater or water from other forms of precipitation moves downward to fill up the cracks or spaces in soil and rocks. Groundwater makes up almost all the water on Earth except ocean water and frozen water, accounting for around 95% of all freshwater.

Lakes, rivers, and other surface water make up 3% of all freshwater. The renewal of groundwater depends on various environmental conditions. Groundwater naturally undergoes filtration, but it can get contaminated when it encounters the earth’s surface. Thus, groundwater needs to be protected from pollutants (NGWA).

Aquifers

Water exists underground in what are known as aquifers. Aquifers consist of layers of rock and soil that allow water to flow through their small pores. Groundwater can move from one aquifer to another. In general, groundwater follows permeable pathways within individual aquifers from the point of recharge to the point of discharge.

When a well is dug, drilled, or bored, the sole purpose is to reach far enough into the aquifer so that water can be accessed and pumped out. Because the location of aquifers and the amount of water in them are rough estimates at best, it is difficult to be certain exactly where and how deep and well needs to be dug.

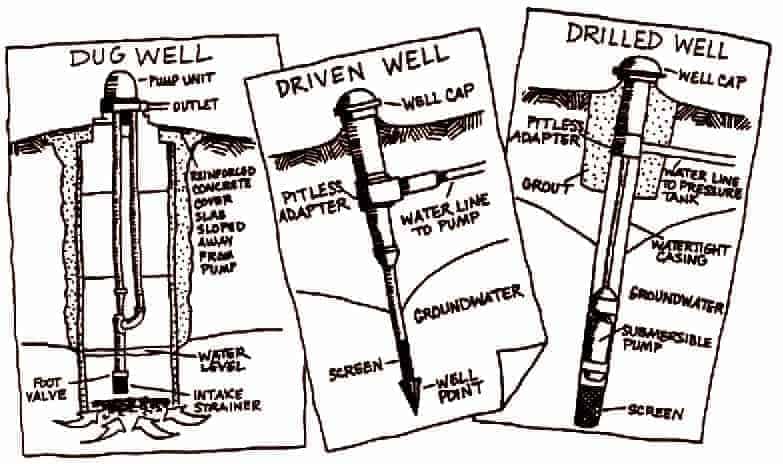

Most Common Types of Wells

In order for groundwater to be accessed from the surface, the surface of the earth needs to be dug deep enough so that it reaches the aquifer. The hole that is created is known as a well. The three most common types of wells are drilled wells, driven wells, and dug wells.

Drilled Well

Most modern wells are drilled wells. These wells are constructed by cable tools (percussion) or rotary (air or hydraulic) drilling machines, usually mounted on carriages, trucks, or trailers.

Most modern wells are drilled wells. These wells are constructed by cable tools (percussion) or rotary (air or hydraulic) drilling machines, usually mounted on carriages, trucks, or trailers.

Drilled wells penetrating unconsolidated material, which consists of granular material such as sand, gravel, and clay, require casing and a screen to prevent sediment from flowing in, which can result in a collapse. The space around the casing also needs to be sealed with grouting material, as water draining toward the outside of the casing from the surface can contaminate the water in the well.

The grouting material can be made up of either neat cement or bentonite clay. Residential drilled wells can go as shallow as 10-60 feet and as deep as 1,000 feet. Some industrial wells exceed depths of 3,000 feet (900 meters).

Driven Well

Driven wells are relatively simple to construct and reasonably priced. These types of wells are dug vertically by driving a small-diameter pipe into shallow water-bearing sand or gravel.

A screen well point is usually attached to the bottom of the casing before driving to allow water to enter yet keep the water-bearing formation in place.

Driven wells are typically around 30 feet deep when driven by hand and 50 feet deep when driven by machine. Thus, they can only tap shallow water and can be easily contaminated by nearby surface sources as they draw water from aquifers near the surface.

Dug Well

Dug wells were historically dug by hand shovel or backhoe below the water table until the water coming in surpassed the digger’s bailing rate. The hole was then lined with stones, brick, or tile to prevent the well from collapsing.

Dug wells were historically dug by hand shovel or backhoe below the water table until the water coming in surpassed the digger’s bailing rate. The hole was then lined with stones, brick, or tile to prevent the well from collapsing.

Modern dug wells are dug by power equipment and are usually lined with concrete tiles. These wells typically have large diameters, exposing a large area to the aquifer, and they can go deeper beneath the water table than hand-dug wells. Dug wells can obtain water from less-permeable materials such as fine sand or clay. However, they are shallow and lack continuous casing, which makes them prone to contamination from nearby surface sources. If the water table drops below the well bottom during a drought, dug wells may go dry.

Most modern wells are drilled as water can be accessed at much greater depths. However, dug wells are still constructed, and driven wells are still common where geological conditions are suitable.

200QJ Deep Well Submersible Pump

Well Water System Design and Components

The Well Pump

The well pump, or water pump, is the heart of the system. It is what pumps water upward and into the household or designated water system. The two most popular types of pumps used today are jet pumps and submersible pumps. Both pumps rely on centrifugal force in order to force water upward. Spinning rotors, known as impellers, create a vacuum that forces water upward through the well casing and into the distribution system. The type of pump required for a well system would depend on the depth of the well and the amount of water required for the household.Jet pumps are placed above ground and lift water from the ground through a suction pipe which creates a vacuum with an impeller that drives water through a small nozzle. Because jet pumps use water to pump water, they first need to be primed with flowing water.

Shallow well jet pumps are used for wells that go down to a depth of 25 feet, while deep well jet pumps typically go down 150 feet. Deeper wells would require a submersible pump (McDonald).

Submersible pumps have a much wider range in depth and can be used in wells as shallow as 25 feet and as deep as 400 feet. As the name implies, submersible pumps are submerged deep in the well, just under the water level. Most of its energy is dedicated to pushing water upward rather than sucking water from above, as in the case of jet pumps.

Submersible pumps are cylindrical in shape, housing the pump motor and a series of impellers that drives water up the pump into the drop pipe. Because of their efficiency, durability, and versatility in well depth, most modern well systems use submersible pumps over any other pump (McDonald).

Pressure Tank

Pressure tanks are used to maintain water pressure throughout the distribution system and to store a reserve water supply so as to relieve the pump of continuous usage. The sizes range from around 40 gallons for domestic use to 21,000 gallons or more for industrial use. In conventional pressure tanks, pressure is created by pumping water into the tank until the air in the tank is compressed to typically 40, 50, or 60 psi (pounds per square inch). An air compressor ensures that the air pressure is maintained. When the valve is opened via a tap, the air pressure in the tank forces water out of the tank and into the pipes for distribution.

Pressure Switch & Control Box

Well pumps, especially submersible pumps, are not meant for around-the-clock usage. Continuous usage would cause unnecessary wear on the pumping mechanism and would rack additional electricity costs. The pressure switch and the control box work in conjunction with the pressure tank to measure the water pressure in the well system so that the pump is only used when the water pressure drops below a certain level.

Typical well systems have a water pressure range of 40-60 psi. When the water pressure drops below 40 psi, the pressure switch turns the pump on, bringing the water pressure back up within range. When the water pressure is at an adequate level, the pressure switch turns the pump back off.

Casing

Well casing, usually made of carbon steel, stainless steel, or polyvinyl chloride (PVC), is a tube-shaped structure placed in a well to maintain the well opening spanning from the target groundwater to the land surface. The casing prevents dirt from contaminating the water and keeps excess water out of the well. It also keeps out contaminants from less desirable groundwater. Some may use concrete, fiberglass, or asbestos cement to build well casing. However, the choice of material depends on the geologic formation. For example, steel is used where hard rock lies underground.

Well Cap

Well caps are placed on top of well casings to keep out debris, insects, and small animals. They are usually made of aluminum or plastic, and they include a vented screen to equalize the pressure difference between the inside and outside of the well when water is pumped from the well. To prevent overflows from contaminating the well, the cap should extend past the flood level.

Well Screen

Well screens are filtering devices attached to the bottom of the well casing to prevent excess sediment from contaminating the well. Continuous slots, slotted pipes, and perforated pipes are the most popular well screens used. Well screens are built to suit the geologic condition with specified openings and holes to match the screen filtering capability. They are also designed to be placed within the saturated portion of the aquifer to prevent damage if the groundwater elevation drops.

Pitless Adapter

Older well systems required that a large pit be dug so that pipes remain far enough underground so that they wouldn't freeze during wintertime. But the pit design has proven to be quite hazardous and prone to contamination.

The modern pitless design allows for the casing to reach all the way up to the ground level. Pitless adapters are connectors that provide a sanitary seal between the well casing and the waterline. They are connected to the well casing below the frost line to divert water horizontally, preventing the water from freezing. A check valve may be fitted below the adapter to prevent water from flowing back into the well.

Mechanics Behind How a Well Water Pump Works

While jet pumps and submersible pumps are very different in design and mechanics, the concept behind their purpose is the same: pump water from the ground into the designated water system for usage. In explaining the mechanics behind how water is pumped from the ground and distributed throughout the system, we'll use the following setup as an example:

A private residence has a drilled well with a submersible pump in a pitless adapter setup, with a pressure tank and pressure switch inside the house.

- Most pressure tanks have a pressure range of 40 psi to 60 psi. When the water pressure is within this range (as indicated by the pressure gauge), the water pump is turned off, as there is a sufficient amount of water currently available in the system. For practical purposes, PSI can, in fact, be thought of in terms of the current volume of water rather than the actual pressure (more volume = higher pressure).

- As water is used throughout the house, whether it be from the sink, shower, dishwasher, or washing machine, the water pressure in the tank will naturally drop.

- When the pressure gauge indicates that the water pressure in the tank has dropped below the minimum range of 40 psi, the pressure switch will signal the pump to turn on.

- Some 200 feet below the ground, impellers in the submersible pump begin to spin rapidly, pushing water upward through the casing and through the pitless adapter.

- As the water is forced through the waterline and into the house, the pressure tank begins to fill gradually, as indicated by the pressure gauge.

- Just as the pressure tank reaches the maximum psi of 60, the pressure switch will signal the pump to turn off, ceasing the flow of water into the system. The pressure will remain at this level until more water is used, and it eventually drops. Once it drops below 40 psi, the pump kicks on, and the cycle starts over.

Things to Consider Before Starting a Well Water Pump System

When either purchasing a home with a current well system in place or scouting the area for a place to build, it is best to be familiar with the land beforehand.

- Ask about other homeowners' wells in the area and whether they've had much success or trouble with their own system.

- Ask authorities about the condition of the groundwater in the region and how deep they expect a well needs to be drilled or whether the water level is known to be particularly low at certain times of the year.

- Be aware of the climate: rainfall, snow, flooding, and other things that may potentially cause problems for the well.

- Be aware of nearby factories or other factors that may pose a contamination risk.

Acquire all Necessary Permits

Each state and region will have its own required permits that would need to be applied for before well construction can begin, so do the research and be sure to have all of them. In most cases, contractors won't begin construction without all of the necessary permits.

Choose the Best Location for the Well Site

The location of the well is one of the most critical factors in determining its long-term success and cleanliness. While choosing the best place for the most water yield is largely an estimate, choosing the best place for the least risk for contamination is much easier to determine.

- A rule of thumb is to always have the well site at a higher level of ground rather than a lower level of ground. In areas with heavy rainfall, rainwater will carry contaminants for the ground floor as it runs downhill. If the well site is in a low-basin area where rainwater collects, there is a high risk that contaminants can enter the groundwater through the well.

- If the home has a septic tank, always choose a well site that is at a higher ground level than the septic tank location and at a significant distance. Septic tanks always have the potential to leak, so it's better that the contaminants move away from the well site rather than toward it.

- Choose a location that has some distance between objects or places that can potentially disrupt or contaminate the well, such as barns, livestock pens, streams or creeks, and septic tanks.

The Determine the Amount of Water the Household will Need

Knowing how much water your household will need will make it easier to determine the type of set you'll need. The average American uses 60-100 gallons of water per day which includes drinking, bathing, and washing clothes and dishes (NebGuide). Since well pumps vary in efficiency – measured in GPH (gallons per hour), calculating the average amount of water that your household will use can help determine the best type of well pump and pressure tank for your system.

Well Water System Troubleshooting, Maintenance, and Testing

Additional tests should be performed for production rate, the static water level – the distance from the ground level to the top of the water in the well, and drawdown – the difference between the static water level and the level of water during pumping. These tests derive information that can be used to forecast the long-term yield of the well. Most households require a yield of 6 to 12 gallons per minute.

Additional Practical Considerations and Tips

- Don’t try to service your own well. Consult qualified professional water well system contractors instead

- Practice preventive maintenance, which is less costly in the long run

- Do your homework before getting a well-maintenance check-up or service

- Keep away hazardous chemicals such as fertilizer, pesticides, and motor oil

- Always use certified water well drillers and pump installers

- Regularly inspect the well cover or well cap to ensure it is in good shape

- Maintain proper separation between your well, waste systems, and chemical storage facilities

Well Water Benefits and Advantages

The upfront cost of drilling and installation may prove to be a large financial investment, but for those dedicated to a more permanent homesteading lifestyle, it is an investment well worth the cost. Unlike homeowners in large cities who pay for monthly tap water service, homeowners who access water from their well system owe nothing – groundwater is literally free.

Other than the cost of the initial installation service and parts, the only expense a well owner would need to be aware of is maintenance costs and the use of electricity required to power the pump.

Independence

By relying on your own private access to groundwater, you eliminate the need for a municipal service to treat and distribute water to your home. While city tap water services adhere to strict sanitation guidelines, much of the beneficial minerals in groundwater are removed. Furthermore, additional chemicals, such as fluoride, are often added to the water supply without the public's consent.

In extreme cases, hundreds of miles of aging city water pipes and infrastructure can corrode long before a replacement plan is in place. As in the case of Flint, Michigan, thousands of residents suffered from illnesses due to a contaminated water supply (Glenza, 2018). With a privately owned well, the supply is entirely in the owner's control.

Health Benefits

Water from the ground has undergone nature's most stringent purification process. After being thoroughly distilled through evaporation and precipitation, water flows through underground aquifers collecting minerals as it passes through layers of rock.

These minerals, such as magnesium, calcium, and sodium, are necessary for basic human function and add a natural, pleasant taste to the water. During its strict purification process, city water services often remove more of the beneficial minerals than what's necessary, leaving behind nutrient-deficient, bland-tasting water.

Conclusion

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater World

NewsJul.01,2025

-

Submersible Pond Pump: The Hidden Guardian of Water Landscape Ecology

NewsJul.01,2025

-

Stainless Well Pump: A Reliable and Durable Pumping Main Force

NewsJul.01,2025

-

Stainless Steel Submersible Pump: An Efficient and Versatile Tool for Underwater Operations

NewsJul.01,2025

-

Deep Well Submersible Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Deep Water Well Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail -

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail -

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail