Oct . 06, 2024 17:34 Back to list

submersible deep well pump installation

Installation of Submersible Deep Well Pumps A Comprehensive Guide

Submersible deep well pumps are a crucial component in providing reliable water supply for agricultural, industrial, and residential applications. Their ability to operate submerged underwater makes them particularly efficient for deep wells, as they can draw water from significant depths. However, the installation process of these pumps requires careful planning and execution to ensure optimal performance and longevity. In this article, we will guide you through the essential steps and considerations for a successful installation.

1. Pre-Installation Preparation

Prior to installing a submersible pump, it’s vital to conduct thorough research and gather information about the specific requirements of the installation site. This includes understanding the depth of the well, the diameter of the casing, and the water quality. A well survey may be necessary to determine the static water level, dynamic water level, and the yield of the well. Collecting these data points will help in selecting the appropriate pump model that meets the system demand efficiently.

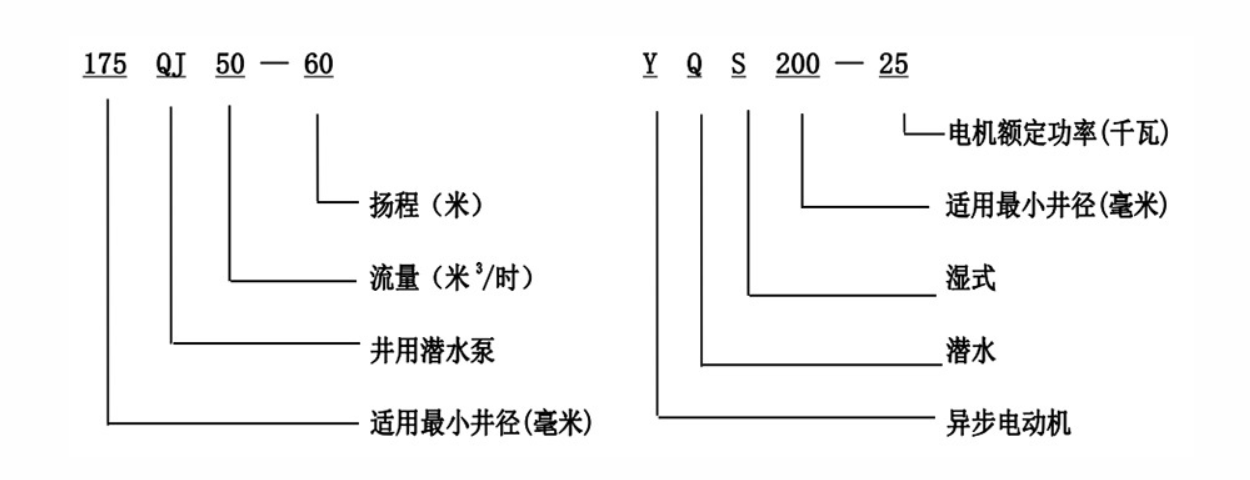

2. Choosing the Right Pump

Selecting the right submersible pump is critical for effective installation. There are various factors to consider, such as the flow rate, total dynamic head (TDH), and voltage specifications. Pumps come in different sizes and capacities, so it’s crucial to match the pump’s output with the specific needs of your system. Consulting with a professional or manufacturer can assist in making the best choice for your situation.

3. Gathering Necessary Tools and Materials

Before beginning the installation, ensure you have all required tools and materials at hand. Basic tools include wrenches, pliers, a torque wrench, and a cable cutter. Additionally, you may need a hoist or well cap for lifting the pump into place, and PVC or stainless steel pipes for connecting the pump to the surface. Safety gear, including gloves and eye protection, is also recommended to protect against potential hazards during installation.

4. Installation Steps

submersible deep well pump installation

The installation process can generally be broken down into several critical steps

- Lowering the Pump Carefully lower the submersible pump into the well using a hoist. Ensure that the pump is positioned properly and not subjected to unnecessary strain on the electrical cables or discharge pipes. - Connecting the Discharge Pipe Once the pump is in place, connect the discharge pipe to ensure that water can flow from the pump to the surface. Tighten the connections securely to prevent leaks.

- Electrical Connections Attach the electrical cable to the pump, following the manufacturer’s wiring instructions. It’s essential to ensure that all connections are waterproof and secured to prevent any electrical faults.

- Testing the Pump Before fully sealing the well, perform a test run to check for any issues. Monitor the pump’s operation for unusual noises, vibrations, or other irregularities. Ensure that the water flows smoothly and meets the expected yield.

5. Finalizing Installation

Once testing is complete, finalize the installation by sealing the wellhead and ensuring that all safety measures are in place. This may include securing the power supply and ensuring all components are protected from environmental factors.

Conclusion

Installing a submersible deep well pump can be a straightforward process if approached methodically. With proper preparation, the right equipment, and adherence to safety practices, you can ensure that your pump operates efficiently for years to come. Always consult with professionals when needed, and consider regular maintenance checks to extend the lifespan of your pump system. With these guidelines, you can enjoy a reliable water supply tailored to your specific needs.

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater World

NewsJul.01,2025

-

Submersible Pond Pump: The Hidden Guardian of Water Landscape Ecology

NewsJul.01,2025

-

Stainless Well Pump: A Reliable and Durable Pumping Main Force

NewsJul.01,2025

-

Stainless Steel Submersible Pump: An Efficient and Versatile Tool for Underwater Operations

NewsJul.01,2025

-

Deep Well Submersible Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Deep Water Well Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail -

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail -

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail