Aug . 31, 2024 14:55 Back to list

v6 submersible pump

Understanding V6 Submersible Pumps

Submersible pumps are essential devices used in various applications, ranging from residential water supply systems to industrial processes. Among the different types available, the V6 submersible pump has gained popularity due to its efficient design and versatility. This article explores the features, advantages, and applications of the V6 submersible pump.

Features of V6 Submersible Pumps

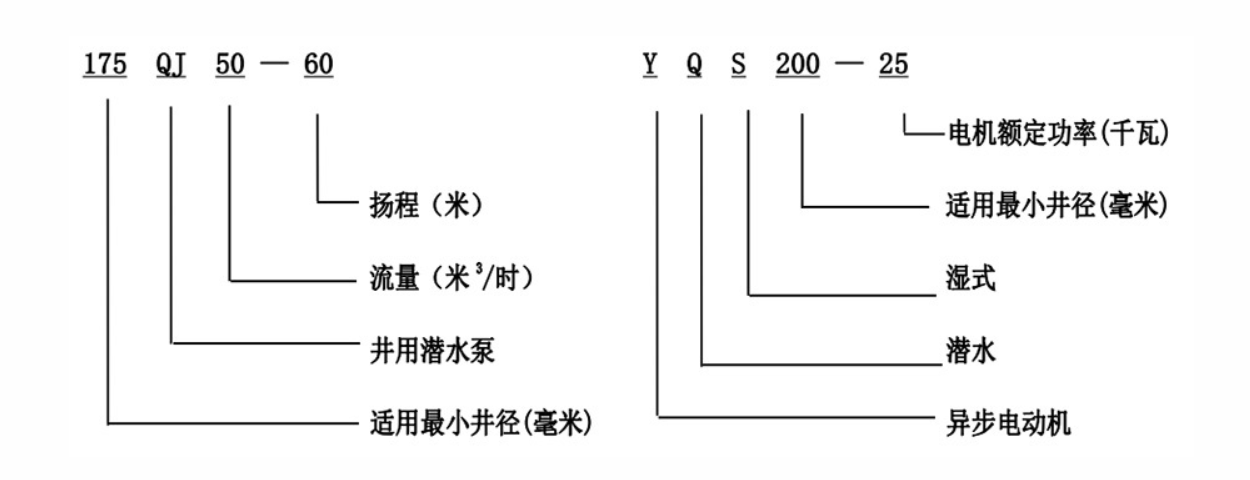

The V6 submersible pump is characterized by its 6-inch diameter casing, which allows it to be installed in 6-inch or larger boreholes. This type of pump typically features a multi-stage design, which enhances its efficiency and makes it capable of lifting water from considerable depths. The pump is submersible, meaning it operates underwater, which reduces the need for additional components like priming systems and ensures quiet operation.

Materials used in the construction of V6 pumps are often chosen for their durability and resistance to corrosion. Stainless steel is commonly used for key components, while thermoplastic materials can be found in the impellers. These materials ensure that the pump can withstand various environmental conditions, including exposure to corrosive substances in groundwater or seawater.

Advantages of Using V6 Submersible Pumps

One of the primary advantages of V6 submersible pumps is their high efficiency. The multi-stage design optimizes the hydraulic performance, allowing for better flow rates and head pressure. This efficiency translates to lower energy consumption, making them an environmentally friendly option.

v6 submersible pump

Another significant benefit is their compact size and ease of installation. V6 pumps can be installed in narrow boreholes, making them ideal for residential well systems or deep well applications, where space may be limited. Moreover, since the pump remains submerged, it helps in cooling the motor and prolongs its operational life.

Maintenance is relatively straightforward, as submersible pumps are designed to operate submerged without the need for additional external components. Routine checks mostly involve inspecting the electrical connections and ensuring that there are no blockages in the pump intake.

Applications of V6 Submersible Pumps

V6 submersible pumps are used widely across different sectors. In agricultural settings, they are utilized for irrigation purposes, ensuring that crops receive the adequate water supply needed for optimal growth. Additionally, they find applications in municipal water systems for supplying drinking water to communities.

In industrial settings, these pumps are employed for dewatering operations, as well as transferring chemicals and wastewater. Their robust design makes them suitable for handling various types of fluids, thereby enhancing their usability across multiple sectors.

In conclusion, the V6 submersible pump is a reliable and efficient solution for various fluid movement needs. Its unique features, combined with its versatility and ease of use, make it a valuable asset in both residential and industrial applications. As technology continues to advance, we can expect even more improvements in the efficiency and performance of submersible pumps like the V6, further enhancing their role in modern water management systems.

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater World

NewsJul.01,2025

-

Submersible Pond Pump: The Hidden Guardian of Water Landscape Ecology

NewsJul.01,2025

-

Stainless Well Pump: A Reliable and Durable Pumping Main Force

NewsJul.01,2025

-

Stainless Steel Submersible Pump: An Efficient and Versatile Tool for Underwater Operations

NewsJul.01,2025

-

Deep Well Submersible Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Deep Water Well Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail -

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail -

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail