Dec . 04, 2024 08:37 Back to list

Understanding the Function and Applications of Submersible Pumps in Various Industries

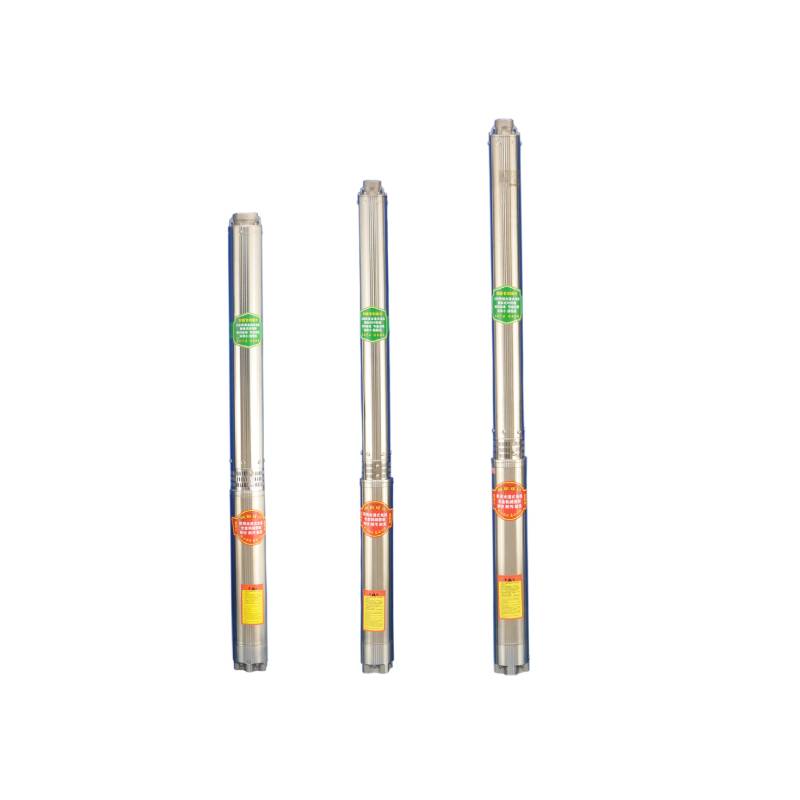

What is a Submersible Pump?

A submersible pump is a type of pump that is designed to be submerged in fluid, typically water. These pumps are widely used in various applications, including groundwater extraction, sewage treatment, and even in some industrial processes. Their unique design and functionality make them ideal for pumping fluids from depths that other pumps may struggle with.

Design and Operation

The fundamental principle behind a submersible pump is its ability to push fluid to the surface rather than drawing it up, as is the case with many other types of pumps. A submersible pump consists of a motor and pump section that is hermetically sealed within a casing. This design allows it to operate effectively when submerged.

The motor of a submersible pump is typically sealed and cooled by the fluid it is submerged in, enhancing its efficiency and lifespan. The pump is connected to a discharge pipe that carries the fluid to the surface. When the motor is activated, it powers an impeller which creates pressure and pushes the fluid upwards.

Applications of Submersible Pumps

Submersible pumps are utilized in a vast array of applications, largely due to their efficiency and effectiveness in moving fluids from beneath the surface

1. Groundwater Extraction One of the most common uses of submersible pumps is in wells to extract groundwater for drinking, irrigation, or other purposes. These pumps can handle the challenges of being submerged deep in a well while maintaining high efficiency.

2. Sewage and Wastewater Management Submersible pumps are often used for sewage or wastewater removal in municipal and industrial systems. They handle solids and debris efficiently, making them suitable for applications where traditional pumps might fail.

3. Drainage Systems In construction and mining, submersible pumps are deployed to remove water from flooded areas or excavations. Their ability to work underwater makes them indispensable for such applications.

4. Aquaculture Submersible pumps are widely used in aquaculture systems to circulate water, ensuring that aquatic life experiences optimal conditions for growth and survival.

5. Firefighting Some firefighting systems use submersible pumps to draw water from lakes, ponds, or fountains in case of emergencies.

Advantages of Submersible Pumps

what is a submersible pump

There are numerous benefits to using submersible pumps. Some of the key advantages include

1. Efficiency Submersible pumps can be more efficient than other types because they do not create a vacuum to lift fluid. Instead, they push fluid directly, which requires less energy.

2. Less Noise Because they are submerged, submersible pumps produce less noise than surface pumps, making them more suitable for residential areas.

3. Compact Design These pumps generally occupy less space compared to traditional pumps, making them ideal for situations where space is limited.

4. Reduced Risk of Priming Issues Unlike surface pumps that require priming to function effectively, submersible pumps are always primed due to their submerged nature.

Considerations When Choosing a Submersible Pump

When selecting a submersible pump for a specific application, several factors should be considered

1. Total Dynamic Head (TDH) Understanding the height that the pump needs to lift water and the friction losses in the pipe is crucial for efficient operation.

2. Fluid Characteristics The type of fluid being pumped (clean water, sewage, sludge, etc.) will influence the choice of pump materials and design features.

3. Power Source Most submersible pumps operate on electricity, but alternative energy sources may be required depending on the location or application.

4. Installation Environment The pump should be suitable for the conditions in which it will be used, including temperature, depth, and potential for corrosive substances.

Conclusion

Submersible pumps are an essential technology in a wide range of industries and applications. Their efficient design, ability to function underwater, and versatile capabilities make them a favored choice for handling various fluids. Understanding their operation, advantages, and appropriate applications ensures that users can maximize their potential benefits, making them a reliable solution for fluid management needs.

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater World

NewsJul.01,2025

-

Submersible Pond Pump: The Hidden Guardian of Water Landscape Ecology

NewsJul.01,2025

-

Stainless Well Pump: A Reliable and Durable Pumping Main Force

NewsJul.01,2025

-

Stainless Steel Submersible Pump: An Efficient and Versatile Tool for Underwater Operations

NewsJul.01,2025

-

Deep Well Submersible Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Deep Water Well Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail -

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail -

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail