Nov . 23, 2024 11:18 Back to list

deep well submersible pump installation

Installation of Deep Well Submersible Pumps A Comprehensive Guide

Deep well submersible pumps are essential for various applications, from irrigation and municipal water supply to industrial use. Their ability to lift water from significant depths makes them an invaluable asset in many regions, particularly those with limited access to surface water. Proper installation of these pumps is crucial for ensuring efficient operation and longevity. This guide outlines the steps involved in the installation of deep well submersible pumps.

1. Site Preparation

Before initiating the installation process, it’s essential to assess the site where the deep well will be located. Factors such as soil type, groundwater levels, and environmental considerations should be evaluated. A geotechnical survey may be necessary to understand the subsurface conditions and determine the best approach for drilling the well.

The area should also be cleared of debris, and access should be provided for equipment and personnel. It is advisable to have a designated location for storing the pump and all accompanying materials.

2. Drilling the Well

The next step involves drilling the well to reach the desired depth where the water table is located. This process can be performed using various drilling techniques, such as rotary drilling or cable tool drilling. The choice of method depends on factors like the geological conditions, the diameter of the well, and the equipment available.

During drilling, it is crucial to monitor the well’s diameter and depth to ensure it aligns with the specifications of the submersible pump. Once the target depth is reached, the well must be properly cleaned to remove any drilling cuttings and debris that may affect pump operation.

3. Installing the Well Casing

After drilling the well, a casing is installed to prevent the well from collapsing and to protect the groundwater from contamination. The casing is typically made from high-quality PVC or steel, which is resistant to corrosion and other environmental factors.

The casing should extend above the ground level to prevent surface water from entering the well. Ensure that the casing is properly sealed at the top to provide protection against insects, debris, and other contaminants.

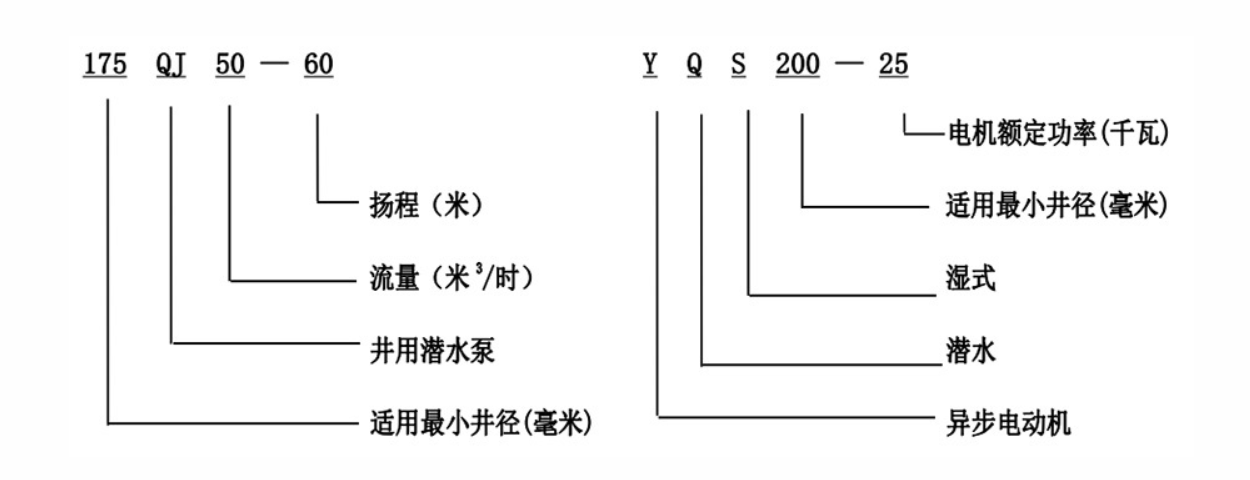

4. Selecting the Submersible Pump

Selecting the right submersible pump is critical for efficient operation. Factors to consider include the well’s depth, the desired flow rate, and the specific characteristics of the water being pumped (such as temperature and chemical composition).

deep well submersible pump installation

It is also essential to ensure the pump is compatible with the power supply available, whether it is electric or other energy sources. Consulting a professional or referring to manufacturer specifications can aid in making an informed selection.

5. Pump Installation

With the well casing in place and the pump selected, the installation can commence. Lower the submersible pump into the well using a hoisting system, ensuring that it is positioned at the appropriate depth. The pump should be submerged deep enough to prevent cavitation and ensure a steady flow of water.

Once the pump is in place, secure it to the well casing using appropriate clamps or brackets. This step is essential to prevent any movement that could cause damage to the pump or filtration systems.

6. Electrical Wiring and Controls

After the pump is installed, the next step involves connecting it to the power supply. This process should be performed by a qualified electrician to ensure safety and adherence to local electrical codes. Proper wiring is crucial to prevent any electrical failures or hazards.

Additionally, install controls and monitoring systems that will allow for easy operation and maintenance of the pump. Considerations should include pressure switches, float switches, and any automation systems that may be desired for remote operation.

7. Testing and Maintenance

Once everything is installed, conduct a thorough test of the system to ensure proper operation. Check for leaks, verify that the pump engages and discharges water effectively, and monitor for any unusual sounds or vibrations.

Establishing a regular maintenance schedule is essential to ensure the longevity of the pump and its efficiency. This includes inspecting electrical connections, cleaning filters, and checking for signs of wear and tear.

Conclusion

Installing a deep well submersible pump requires careful planning, precise execution, and regular maintenance. By following these steps, you can ensure that your installation will provide reliable service for years to come, delivering the water needed for your specific application efficiently and effectively. Always consult with professionals when in doubt, as proper installation is key to maximizing the pump's performance and lifespan.

-

Submersible Well Pumps Buying Guide

NewsMay.14,2025

-

Submersible Sump, Dirty Water, Borehole Pumps Demystified

NewsMay.14,2025

-

Stainless Steel Submersible Pumps Superior Performance

NewsMay.14,2025

-

High Flow Submersible Well Pumps Essential Features

NewsMay.14,2025

-

Choosing the Best Stainless Well Pump

NewsMay.14,2025

-

A Comparison of Submersible Pumps Filled with Water and Oil

NewsMay.14,2025

-

Submersible Well Pumps Buying GuideReliable access to clean water is fundamental for residential, agricultural, and commercial operations, making the selection of an appropriate well pump system one of the most important infrastructure decisions.Detail

Submersible Well Pumps Buying GuideReliable access to clean water is fundamental for residential, agricultural, and commercial operations, making the selection of an appropriate well pump system one of the most important infrastructure decisions.Detail -

Submersible Sump, Dirty Water, Borehole Pumps DemystifiedThe world of water management has undergone a technological revolution, with advanced pumping systems now offering unprecedented efficiency and reliability across diverse applications.Detail

Submersible Sump, Dirty Water, Borehole Pumps DemystifiedThe world of water management has undergone a technological revolution, with advanced pumping systems now offering unprecedented efficiency and reliability across diverse applications.Detail -

Stainless Steel Submersible Pumps Superior PerformanceModern water extraction and fluid handling systems demand equipment capable of withstanding harsh environments while maintaining peak efficiency.Detail

Stainless Steel Submersible Pumps Superior PerformanceModern water extraction and fluid handling systems demand equipment capable of withstanding harsh environments while maintaining peak efficiency.Detail