Jun . 05, 2025 08:29 Back to list

Reliable Submersable Water Pump for Sump, Pool & Home Drainage

- Fundamentals and technological advancements in submersible pumping systems

- Critical performance metrics analyzed through comparative data tables

- Market differentiation among leading manufacturers explored

- Application-specific solutions with customized configurations

- Detailed industrial case studies demonstrating efficiency gains

- Maintenance protocols for extended operational longevity

- Selection methodology and future industry developments

(submersable water pump)

Innovations Driving Modern Submersible Water Pump Technology

Contemporary submersible water pumps represent substantial advancements over traditional pumping systems. Engineered to operate while fully submerged, these units leverage hydraulic principles that significantly increase energy transfer efficiency. Premium models demonstrate 20-30% better power utilization compared to surface pumps according to Hydraulic Institute studies. Modern submersible pool pump configurations feature corrosion-resistant composite materials like reinforced thermoplastic compounds that withstand pool chemicals while reducing component degradation.

Thermal management innovations include integrated cooling jackets surrounding motor assemblies, maintaining optimal operating temperatures below 140°F even during continuous operation. Leading industrial-grade submersible sump pump units incorporate redundant sealing systems with triple-lip mechanical seals and moisture-detection sensors that trigger automatic shutdown before critical failures occur. Variable-frequency drives now enable precise flow control from 10-100% capacity, delivering exact hydraulic requirements without energy waste.

Performance Benchmark Analysis

Comparison metrics reveal substantial performance differentials across pump categories. Industrial operators prioritize flow rate stability under pressure, while residential users value operational silence. The following performance data illustrates key operational parameters:

| Parameter | Residential Sump | Commercial Water | High-Performance Pool |

|---|---|---|---|

| Max Flow Rate (GPM) | 50-60 | 120-250 | 80-100 |

| Pressure Head (ft) | 20-30 | 65-100 | 50-70 |

| Power Consumption (kW) | 0.5-1 | 3-7.5 | 1.5-3 |

| Continuous Duty (hrs) | 72 max | Unlimited | 16-20 |

| Noise Level (dB) | 40-45 | 65-75 | 48-52 |

| Optimal Solids Handling (mm) | 10-15 | 35-50 | 5 max |

Performance variances stem from specialized engineering: pool circulation units prioritize chemical compatibility and particle-free operation, while dewatering pumps emphasize solids-handling capabilities up to 50mm particulate diameter. High-pressure models achieve discharge pressures exceeding 90psi for deep-well applications and multi-story buildings.

Manufacturer Solutions Analysis

Key manufacturers provide differentiated solutions within specific performance brackets. Franklin Electric's industrial-grade submersible water pumps feature heavy-duty cast stainless steel components suitable for abrasive slurry applications, while Grundfos incorporates precision-controlled permanent magnet motors that adapt power consumption to actual flow demands.

Hayward residential systems offer specialized features: redundant float-switch systems with battery backups that activate during power outages, critical for basement flood prevention. Pentair's commercial submersible pool pump range includes self-cleaning impellers that prevent debris accumulation, extending service intervals by 50-70% compared to conventional designs. Premium manufacturers universally incorporate hardened mechanical seals using silicon carbide or ceramic faces that extend mean time between failures beyond 20,000 operational hours.

Application-Specific Implementation

Effective system design requires matching pump specifications to hydraulic demands. Municipal water supply implementations utilize multistage deep-well units engineered for 400-600ft total dynamic head requirements. These feature reinforced column pipes supporting thrust loads exceeding 9,000 lbf and specialized shaft alignment systems preventing vibration-induced failures.

Agricultural implementations follow distinctly different specifications, prioritizing cost-efficient pumping for extended periods. High-flow drainage pumps incorporate oversized floatation surfaces preventing sediment accumulation in irrigation ponds. Marine installations demand specialized encapsulation eliminating galvanic corrosion pathways, utilizing sacrificial anodes and dielectric couplings rated for saltwater exposure. Custom controls integration enables remote tank-level monitoring with automated activation thresholds.

Operational Validation Studies

Performance metrics collected from industrial deployments demonstrate significant efficiency improvements. A beverage processing facility in Wisconsin documented 19% monthly energy reduction after upgrading to variable-speed submersible water pump systems, recovering upgrade costs within 14 months through reduced consumption. Municipal wastewater treatment plants achieved 82% reduction in clogging incidents through adoption of vortex impeller technology, decreasing maintenance labor requirements by 240 hours annually per pump station.

A coastal recreational facility eliminated saltwater infiltration damage to pool equipment by implementing fully encapsulated submersible pool pump systems with triple redundancy. After 36 months of operation, the facility reported zero corrosion-related failures despite continuous exposure to salt air environments. Irrigation applications in California's Central Valley demonstrated 12-15% improved water distribution uniformity through pressure-compensating submersible units.

Maintenance Protocols

Operational longevity directly corresponds to preventive maintenance execution. Quarterly inspections should verify seal integrity through thermal imaging analysis detecting abnormal temperature variances exceeding 15% across seal faces. Vibration spectra should be captured annually using portable analyzers, comparing results against baseline signatures to identify impeller imbalance or bearing deterioration.

Performance documentation should include bi-annual efficiency testing verifying flow rates, discharge pressures and power consumption against factory curves. Electrical systems require insulation resistance measurements documenting at least 100 megohm resistance to ground at operating temperature. Manufacturers typically recommend complete seals replacement at 16,000 operational hours regardless of failure signs. Proper impeller clearance adjustment prevents recirculation wear extending hydraulic component lifespan.

Selection Criteria for Submersible Water Pump Applications

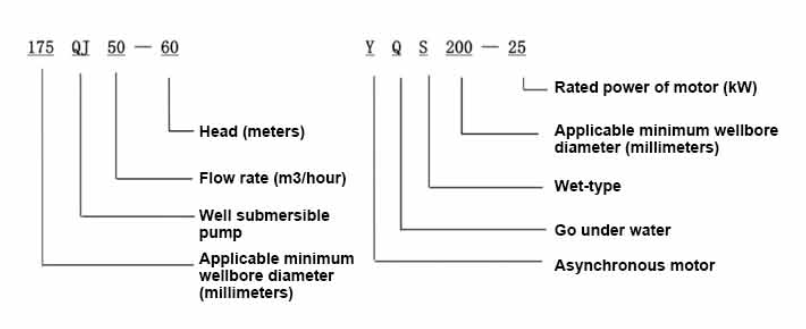

System integrators must evaluate multiple selection parameters before implementation. The primary selection factor remains the hydraulic operating point matching pump performance curves. Engineers should calculate net positive suction head (NPSH) requirements ensuring adequate submersion depth preventing cavitation conditions. Physical installation constraints frequently determine casing diameter limitations, especially in deep-well applications where borehole diameters restrict pump dimensions.

Future industry developments include wider adoption of intelligent monitoring systems that automatically record operating parameters and forecast maintenance requirements. Premium submersible sump pump models now incorporate IoT connectivity providing real-time alerts regarding abnormal operations. Material advancements continue expanding chemical compatibility boundaries, with new polymer compounds offering superior resistance to solvents and hydrocarbons. As energy regulations evolve, variable frequency drives will become standard across all commercial applications, enabling adaptive pumping solutions that optimize consumption based on instantaneous demand.

(submersable water pump)

FAQS on submersable water pump

Q: How does a submersable water pump work?

A: A submersable water pump operates fully underwater, using an electric motor to drive an impeller. This creates suction that draws water into the pump housing and expels it through a discharge pipe. Its sealed design prevents electrical hazards and allows efficient water movement in wells, ponds, or flood-prone areas.

Q: What is the main purpose of a submersable sump pump?

A: A submersable sump pump removes accumulated water from basements or crawl spaces to prevent flooding. Installed in a sump basin, it automatically activates when water reaches a critical level. Its submerged operation reduces noise and efficiently handles debris-laden water.

Q: Why choose a submersable pool pump over other types?

A: Submersable pool pumps are ideal for quick draining or winterizing pools as they operate directly in water. They eliminate priming issues and handle leaves/debris better than external pumps. Their portability also simplifies temporary tasks like spot-cleaning or vacuuming.

Q: Can a submersable water pump handle dirty water?

A: Yes, certain submersable water pumps feature vortex or grinder impellers designed for muddy or sediment-filled water. Always check the pump's solids-handling capacity (e.g., particle size in millimeters) before use. Avoid submerging non-clog models in thick sludge to prevent motor damage.

Q: What safety precautions are vital for submersable pool pumps?

A: Never operate the pump without complete submersion, as this may overheat the motor. Ensure GFCI protection for electrical connections to prevent shocks. Regularly inspect the power cord and seals for wear, and always unplug before handling to avoid injury.

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater World

NewsJul.01,2025

-

Submersible Pond Pump: The Hidden Guardian of Water Landscape Ecology

NewsJul.01,2025

-

Stainless Well Pump: A Reliable and Durable Pumping Main Force

NewsJul.01,2025

-

Stainless Steel Submersible Pump: An Efficient and Versatile Tool for Underwater Operations

NewsJul.01,2025

-

Deep Well Submersible Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Deep Water Well Pump: An Efficient 'Sucker' of Groundwater Sources

NewsJul.01,2025

-

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail

Submersible Water Pump: The Efficient 'Power Pioneer' of the Underwater WorldIn the field of hydraulic equipment, the Submersible Water Pump has become the core equipment for underwater operations and water resource transportation due to its unique design and excellent performance.Detail -

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail

Submersible Pond Pump: The Hidden Guardian of Water Landscape EcologyIn courtyard landscapes, ecological ponds, and even small-scale water conservancy projects, there is a silent yet indispensable equipment - the Submersible Pond Pump.Detail -

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail

Stainless Well Pump: A Reliable and Durable Pumping Main ForceIn the field of water resource transportation, Stainless Well Pump has become the core equipment for various pumping scenarios with its excellent performance and reliable quality.Detail