Jan . 09, 2025 10:39 Back to list

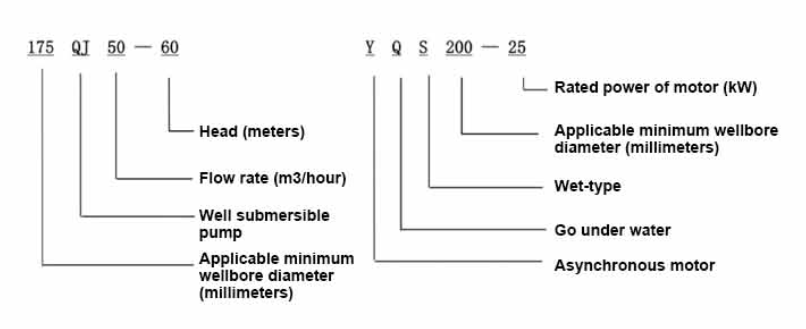

175QJ Deep Well Submersible Pump

Installing a deep well submersible pump can be a transformative upgrade for both residential and commercial water systems. This type of pump is essential for extracting water from deep underground and is known for its efficiency and reliability. Drawing from years of experience in the field and a deep understanding of this technology, the following expert guide offers valuable insights into the installation process, potential challenges, and tips for optimizing pump performance.

A particularly pivotal aspect of installing a deep well submersible pump lies in the proper management of wiring. For reliable operation, submersible pumps use waterproof cables which are specially designed to resist long-term exposure to moisture. Secure the wiring along the supply pipe at regular intervals using cable ties to prevent tangling during installation. In addition, using a control box is vital as it manages the pump’s functions and protects the unit from voltage drops or spikes that could lead to malfunctions or reduced lifespan. After installation, initial testing is crucial. Allow the pump to run for several hours while observing its performance. This can help identify any immediate issues such as leaks or electrical problems. Pay attention to the flow rate and water pressure. If these are not aligning with the specifications, reevaluate the pump’s placement or check for obstructions in the piping. To maintain optimal performance and prolong the lifespan of a deep well submersible pump, regular maintenance is vital. Scheduled inspections should include checking the electrical wiring for wear, ensuring the pressure switch is set correctly, and monitoring for sediment build-up in the pump’s intake screen, which could hinder water flow. Water quality should also be tested, as high mineral content can lead to scaling and corrosion, potentially damaging the pump over time. In regions with hard water, installing a water softener can be beneficial. In conclusion, the successful installation of a deep well submersible pump requires meticulous planning and execution. By following these expert recommendations and adhering to safety protocols, users can optimize the efficiency and longevity of their water systems. With proper care and maintenance, a high-quality deep well submersible pump is an investment that can provide reliable water supply for years. As with all major installations, consulting with experienced professionals is invaluable, ensuring both the safety and efficiency of the system.

A particularly pivotal aspect of installing a deep well submersible pump lies in the proper management of wiring. For reliable operation, submersible pumps use waterproof cables which are specially designed to resist long-term exposure to moisture. Secure the wiring along the supply pipe at regular intervals using cable ties to prevent tangling during installation. In addition, using a control box is vital as it manages the pump’s functions and protects the unit from voltage drops or spikes that could lead to malfunctions or reduced lifespan. After installation, initial testing is crucial. Allow the pump to run for several hours while observing its performance. This can help identify any immediate issues such as leaks or electrical problems. Pay attention to the flow rate and water pressure. If these are not aligning with the specifications, reevaluate the pump’s placement or check for obstructions in the piping. To maintain optimal performance and prolong the lifespan of a deep well submersible pump, regular maintenance is vital. Scheduled inspections should include checking the electrical wiring for wear, ensuring the pressure switch is set correctly, and monitoring for sediment build-up in the pump’s intake screen, which could hinder water flow. Water quality should also be tested, as high mineral content can lead to scaling and corrosion, potentially damaging the pump over time. In regions with hard water, installing a water softener can be beneficial. In conclusion, the successful installation of a deep well submersible pump requires meticulous planning and execution. By following these expert recommendations and adhering to safety protocols, users can optimize the efficiency and longevity of their water systems. With proper care and maintenance, a high-quality deep well submersible pump is an investment that can provide reliable water supply for years. As with all major installations, consulting with experienced professionals is invaluable, ensuring both the safety and efficiency of the system.

Latest news

-

submersible-sump-pump-auto-drainage-for-crawlspaces

NewsAug.22,2025

-

solar-powered-stainless-steel-submersible-well-pump-setup

NewsAug.22,2025

-

stainless-steel-well-pump-flow-rate-optimization

NewsAug.22,2025

-

water-filled-submersible-pump-fish-farm-oxygenation

NewsAug.22,2025

-

submersible-pump-in-aquaculture-and-fish-farming

NewsAug.22,2025

-

deep-well-submersible-pump-for-drought-areas

NewsAug.22,2025

-

submersible-sump-pump-auto-drainage-for-crawlspacesCrawlspaces, those narrow areas beneath homes, are prone to water accumulation due to leaks, groundwDetail

submersible-sump-pump-auto-drainage-for-crawlspacesCrawlspaces, those narrow areas beneath homes, are prone to water accumulation due to leaks, groundwDetail -

solar-powered-stainless-steel-submersible-well-pump-setupHarnessing solar energy to power stainless steel submersible well pumps is a sustainable and coDetail

solar-powered-stainless-steel-submersible-well-pump-setupHarnessing solar energy to power stainless steel submersible well pumps is a sustainable and coDetail -

stainless-steel-well-pump-flow-rate-optimizationIn various applications like agriculture, domestic water supply, and industrial use, the flow rate oDetail

stainless-steel-well-pump-flow-rate-optimizationIn various applications like agriculture, domestic water supply, and industrial use, the flow rate oDetail