This series of fountain pump is a special fountain pump developed by our factory. The pump motor core is made of high quality cold rolled silicon steel, which makes the pump more efficient, has good magnetic conductivity, and does not produce heat when starting frequently. The two ends of the motor rotor are equipped with alloy copper sleeves with water as lubricant. Stainless steel bushings replace ball bearings, avoiding the problems of easy rust of ball bearings and burnout of motor due to lack of oil and wear. Most suitable for music fountain, all models can be used horizontally.

1, phepelo ea matla: mekhahlelo e meraro AC 380V (mamello + / - 5%), 50HZ (mamello + / - 1%).

2, boleng ba metsi:

(1) water temperature is not higher than 20 °C;

(2) litaba tsa litšila tse tiileng (karolelano ea boima) ha e kholo ho feta 0.01%;

(3) PH boleng (pH) 6.5-8.5;

(4) hydrogen sulfide content ha e kholo ho feta 1.5mg/L;

(5) chloride ion content ha e kholo ho feta 400mg/L.

3, motlakase o koetsoe kapa o tletse metsi a nang le metsi, pele o sebelisoa, mochine o kenang ka tlas'a metsi o lokela ho tlala metsi a hloekileng, ho thibela ho tlala leshano, ebe o tiisa ente ea metsi, liboutu tsa ho lokolloa ha moea, ho seng joalo ha lia lumelloa ho sebelisoa.

4, pompo e ka tlas'a metsi e tlameha ho qoelisoa ka ho feletseng ka metsing, botebo ba ho qoela ha bo kholo ho feta 70m, tlase ea pompo e ka tlas'a metsi ho tloha botebong ba seliba ha e ka tlaase ho 3m.

5, phallo ea metsi a seliba e lokela ho khona ho kopana le phallo ea metsi a pompo ea submersible le ts'ebetso e tsoelang pele, phallo ea metsi a pompo ea submersible e lokela ho laoloa ka makhetlo a 0.7 - 1.2 ho phallo e lekantsoeng.

6, seliba se lokela ho otloloha, pompo e ka tlas'a metsi e ke ke ea sebelisoa kapa ea lahleloa, e sebelisoa feela e otlolohileng.

7, pompo ea submersible e tlameha ho ts'oaroa le thapo ho latela litlhoko, le sesebelisoa sa ts'ireletso sa kantle ho moroalo o boima.

8, pompo e thibetsoe ka thata ntle le mochini oa tlhahlobo oa metsi o se nang mojaro

| Mohlala | Phallo (m3/h) | Hlooho (m) |

Rotatingspeed (fetola/ ntlha) |

Pompo ea metsi(%) | Sethala bophara (mm) |

E sebetsa hantle bophara(mm) |

E lekantsoe power(KW) |

E lekantsoe motlakase (V) |

E lekantsoe jwale (A) |

Monyetla (%) | power factorcosφ | Yuniti Radial Maximu size(mm) |

Ela hloko | |||||||||

| 250QJ50-40 | 50 | 40 | 2875 | 72 | 80 | 250hodimo | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 233 | ||||||||||

| 250QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | |||||||||||||||||

| 250QJ50-80 | 80 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ50-100 | 100 | 22 | 47.9 | 83.0 | 0.84 | |||||||||||||||||

| 250QJ50-120 | 120 | 25 | 53.8 | 84.0 | 0.84 | |||||||||||||||||

| 250QJ50-140 | 140 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ50-160 | 160 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ50-200 | 200 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ50-240 | 240 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ50-280 | 280 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ50-320 | 320 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ50-400 | 400 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ50-440 | 440 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ63-40 | 63 | 40 | 2875 | 74 | 80 | 250hodimo | 11 | 380 | 25.8 | 79.0 | 0.82 | 233 | ||||||||||

| 250QJ63-60 | 60 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ63-80 | 80 | 22 | 47.9 | 83.0 | 0.84 | |||||||||||||||||

| 250QJ63-100 | 100 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ63-120 | 120 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ63-160 | 160 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ63-200 | 200 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ63-220 | 220 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ63-260 | 260 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ63-300 | 300 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ63-360 | 360 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ80-20 | 80 | 20 | 2875 | 75 | 100 | 250hodimo | 7.5 | 380 | 18.0 | 78.0 | 0.81 | 233 | ||||||||||

| 250QJ80-40 | 40 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 250QJ80-60 | 60 | 22 | 47.9 | 83.0 | 0.84 | |||||||||||||||||

| 250QJ80-80 | 80 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ80-100 | 100 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ80-120 | 120 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ80-160 | 80 | 160 | 2875 | 75 | 100 | 250hodimo | 55 | 380 | 114.3 | 86.0 | 0.85 | 233 | ||||||||||

| 250QJ80-180 | 180 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ80-200 | 200 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ80-240 | 240 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ80-280 | 280 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ100-18 | 100 | 18 | 2875 | 75 | 100 | 250hodimo | 7.5 | 380 | 18.0 | 78.0 | 0.81 | 233 | ||||||||||

| 250QJ100-36 | 36 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 250QJ100-54 | 54 | 25 | 53.8 | 84.0 | 0.84 | |||||||||||||||||

| 250QJ100-72 | 72 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ100-90 | 90 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ100-108 | 108 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ100-126 | 126 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ100-144 | 144 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ100-162 | 162 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ100-198 | 198 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ100-216 | 216 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-16 | 125 | 16 | 2875 | 76 | 125 | 250hodimo | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 233 | ||||||||||

| 250QJ125-32 | 32 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ125-48 | 48 | 25 | 53.8 | 84.0 | 0.84 | |||||||||||||||||

| 250QJ125-64 | 64 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ125-80 | 80 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ125-96 | 96 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ125-112 | 112 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ125-128 | 128 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-160 | 160 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-176 | 176 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-192 | 192 | 110 | 219.6 | 87.5 | 0.87 | |||||||||||||||||

| 250QJ140-15 | 140 | 15 | 2875 | 76 | 125 | 250hodimo | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 233 | ||||||||||

| 250QJ140-30 | 30 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ140-45 | 45 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ140-60 | 60 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ140-75 | 45 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ140-90 | 90 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ140-105 | 140 | 105 | 2875 | 76 | 125 | 250hodimo | 63 | 380 | 131.0 | 86.0 | 0.85 | 233 | ||||||||||

| 250QJ140-120 | 120 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ140-150 | 150 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ140-165 | 165 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ140-180 | 180 | 110 | 219.6 | 87.5 | 0.87 | |||||||||||||||||

| 250QJ200-20 | 200 | 20 | 2875 | 75 | 150 | 250hodimo | 18.5 | 380 | 40.8 | 82.0 | 0.84 | 233 | ||||||||||

| 250QJ200-40 | 40 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ200-60 | 60 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ200-80 | 80 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ200-100 | 100 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ200-120 | 120 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ200-140 | 140 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, ho latela lipehelo tsa phahamiso ea pompo, mefuta e fapaneng ea ts'ebeliso ea phallo, ho thibela phallo e tlase kapa matla a ho pompa a phahamiso e phahameng, matla a ho pompa le likarolo tse ling tsa moaparo, moroalo o moholo oa koloi o chesitsoe.

6, after the pump down the well, the measurement of the motor to the ground insulation resistance should not be less than 100M, after the start to observe the voltage and current, check the motor winding insulation, whether in line with the requirements; pump storage location temperature if less than freezing point, should be dry the motor cavity water, prevent the motor cavity water ice damage caused by low temperature.

The introduction and structure of this pump product mainly include pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor part is mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand ring, water inlet section, lead cable and other components. The main characteristics of this pump product include the use of water-cooled wet submersible three-phase asynchronous motor, the motor cavity is filled with clean water to cool the motor and lubricate the bearing, the pressure regulating diaphragm at the bottom is used to adjust the expansion and contraction pressure difference of the internal water caused by the change of the temperature rise of the motor. In order to prevent the sand particles in the well water from entering the motor, two oil seals are installed on the upper end of the motor shaft extension, and the sand ring is installed to form a sand prevention structure. In order to avoid the pump shaft jumping at startup, the pump shaft and the motor shaft are connected together through the coupling, and the thrust bearing is installed at the lower part of the motor. The motor and pump bearing lubrication adopts water lubrication. The stator winding of the motor adopts high quality submersible motor winding, with high insulation performance. The pump adopts computer CAD design, simple structure and superior technical performance.

(1) Tokisetso pele ho ho kenya:

1. Lekola hore na pompo e ka tlas'a metsi e kopana le maemo a ts'ebeliso le boholo bo boletsoeng bukeng ea tataiso.

2. Ho sebelisa obiect e boima e nang le bophara bo lekanang le bophara bo boholo ba ka ntle ba pompo e ka tlas'a metsi, lekanya hore na inneldiameter ea seliba e ka lumellana le pompo e ka tlas'a metsi, 'me u lekanye hore na botebo ba seliba bo finyella litlhoko tsa ho kenya.

3. Lekola hore na seliba se hloekile le hore na metsi a seliba a litšila. Le ka mohla u se ke ua sebelisa pompo ea motlakase e ka tlas'a metsi ho hlatsoa seretse sa pompo ea welor le metsi a lehlabathe ho qoba tšenyo ea pele ho nako ea pompo ea motlakase e ka tlase ho metsi.

4. Sheba hore na boemo ba letlapa la ho kenya welhead le loketse le hore na le khona ho mamella boleng ba yuniti kaofela.

5. Sheba hore na likarolo tsa pompo tse ka tlas'a metsi li phethehile 'me li kentsoe ka nepo ho ea ka setšoantšo sa kopano se bukeng ea litaelo Tlosa skrine ea sefe 'me u potolohe sekopanyi ho bona hore na se potoloha ka mokhoa o bonolo.

6. Hlakola sekoti sa metsi 'me u tlatse lesoba la motlakase ka metsi a hloekileng, a sa cheng (hlokomela. etsa bonnete ba hore u se tlatse), ebe u tiisa sekheo sa metsi. Kamora lihora tse 12 tsa ente ea metsi, khanyetso ea enjene ha ea lokela ho ba ka tlase ho 150M Q ha e lekantsoe ka tafole ea 500V e sisinyehang.

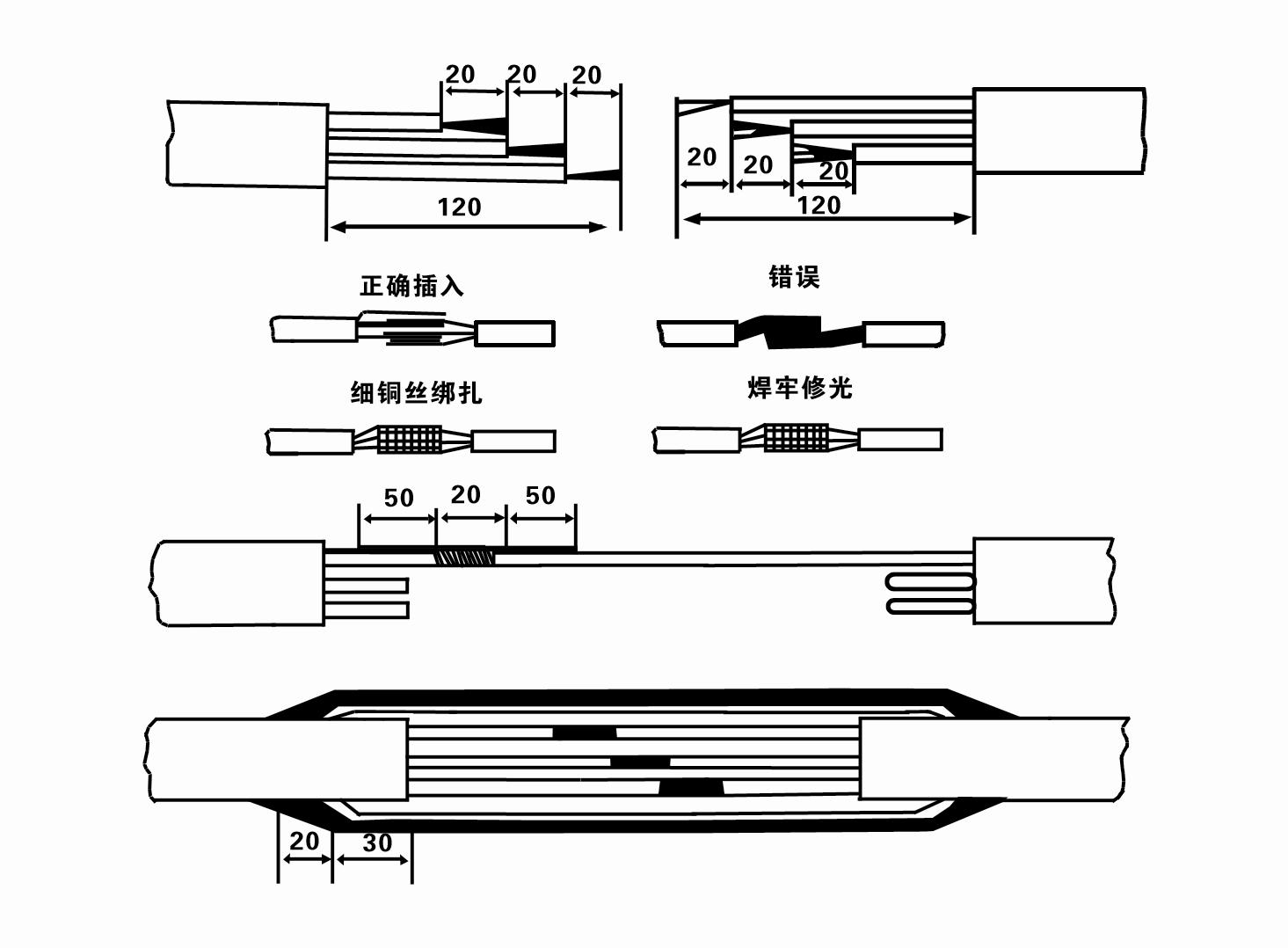

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Sets'oants'o sa ts'ebetso ea terata ea cable e kenyellelitsoeng ka tsela e latelang:

8. Sebelisa multimeter ho hlahloba hore na lithapo tsa mekhahlelo e meraro li hokahane le hore na ho hanyetsa ha DC ho batla ho leka-lekana.

9. Lekola hore na matla a potoloho le a transformer a tletse, ebe o hokahanya sesebelisoa sa ts'ireletso ea overload kapa lisebelisoa tsa ho qala. Sheba Tafole ea 2 bakeng sa mefuta e ikhethileng, ebe u tšela bakete ea metsi ka har'a pompo ea metsi ho tsoa sebakeng sa pompo ea metsi ho tlotsa li-bearings tsa rabara ka har'a pompo, ebe u beha pompo ea motlakase e ka tlas'a metsi e otlolohile ebile e tsitsitse. Qala (e seng ho feta motsotsoana) 'me u hlahlobe hore na tataiso ea tsamaiso e lumellana le letšoao la ho tsamaisa. Haeba ho se joalo, fapanyetsana lihokelo leha e le life tse peli tsa mohala oa mekhahlelo e meraro. Ebe u kenya filthara 'me u itokisetse ho theohela selibeng. Haeba e sebelisoa liketsahalong tse khethehileng (tse kang liforo, liforo, linōka, matangoana, matangoana, joalo-joalo), pompo ea motlakase e tlameha ho thehoa ka mokhoa o tšepahalang.

(2) Lisebelisoa le lisebelisoa tsa ho kenya:

1. Para e le 'ngoe ea liketane tse phahamisang lithane tse fetang tse peli.

2. Tripod e nang le bophahamo bo otlolohileng bo sa feteng limithara tse 'nè.

3. Liropo tse peli tse leketlileng (lithapo tsa terata) tse ka jarang boima ba lithane tse fetang e le 'ngoe (li ka jara boima ba sete e felletseng ea lipompo tsa metsi).

4. Kenya lipara tse peli tsa li-clamp (li-splints).

5. Li-wrenches, lihamore, screwdrivers, lisebelisoa tsa motlakase le lisebelisoa, joalo-joalo.

(3) Ho kenya pompo ea motlakase:

1. Setšoantšo sa ho kenya pompo ea motlakase e ka tlas'a metsi e bontšoa ho Setšoantšo sa 2. Litekanyo tse khethehileng tsa ho kenya li bontšoa ho Lethathamo la 3 "Lethathamo la Litekanyo tsa ho Kenyeletsoa ha Pompo ea Motlakase ea Submersible".

2. Lipompo tsa motlakase tse ka tlas’a metsi tse nang le hlooho e ka tlaase ho limithara tse 30 li ka phahamisoa ka ho toba selibeng ho sebelisa liphaepe le lithapo tsa terata kapa lithapo tse ling tsa hemp tse ka khonang ho jara boima bo feletseng ba mochine kaofela, lipeipi tsa metsi, le metsi a liphaephe.

3. Lipompo tse nang le hlooho ea limithara tse fetang 30 li sebelisa liphaephe tsa tšepe, 'me tatellano ea ho kenya e tjena:

① Sebelisa clamp ho tiisa ntlha e ka holimo ea karolo ea pompo ea metsi (enjene le pompo ea metsi li se li hokahantsoe ka nako ena), e phahamise ka ketane e leketlileng, 'me butle-butle e e tlamelle ka selibeng ho fihlela u Beha thipa holim'a seliba ebe u tlosa ketane e leketlileng.

② Sebelisa para e 'ngoe ea li-clamp ho tlamella phala, u e phahamise ka ketane e leketlileng e bolelele ba lisenthimithara tse 15 ho tloha flange, 'me u e theole butle. Pakeng tsa peipi flange le pompo flange Beha pete ea rabara sebakeng 'me u tiise phala 'me u pompe ka ho lekana ka liboutu, linate le lihlatsoana tsa selemo.

③ Phahamisa pompo e ka tlas'a metsi hanyenyane, tlosa sekoti karolong e ka holimo ea pompo ea metsi, tlamella thapo ka thata peiping ea metsi ka tepi ea polasetiki, 'me u e tlamele butle ho fihlela Sekoti se behoa selibeng.

④ Sebelisa mokhoa o tšoanang ho fasa lipeipi tsohle tsa metsi selibeng.

⑤Ka mor'a hore thapo e etellang pele e hokahane le sesebelisoa sa taolo, e hokahane le phepelo ea motlakase ea mekhahlelo e meraro.

(4) Lintho tseo u lokelang ho li ela hloko nakong ea ho kenya:

1. Haeba ketsahalo ea jamming e fumanoa nakong ea ho pompa, fetola kapa u hule phala ea metsi ho hlōla ntlha ea ho jamming. Haeba mehato e fapaneng e ntse e sa sebetse, ka kopo U se ke ua qobella pompo hore e theohe ho qoba tšenyo ea pompo ea motlakase e ka tlas'a metsi le seliba.

2. Nakong ea ho kenya, pente ea rabara e lokela ho behoa ka lehlakoreng la phala e 'ngoe le e' ngoe 'me e tiisetsoe ka tsela e tšoanang.

3. Ha pompo ea metsi e theoleloa ka selibeng, e lokela ho behoa bohareng ba phala ea seliba ho thibela pompo ho matha leboteng la seliba nako e telele, ho etsa hore pompo e thothomele le motor e fiele le ho chesa. .

4. Etsa qeto ea botebo ba pompo ea metsi ho ea tlaase ho seliba ho ea ka lehlabathe le phallang le maemo a silt a seliba. U se ke ua pata pompo ka seretseng. Sebaka ho tloha pompong ea metsi ho ea tlase ho seliba hangata ha se ka tlase ho limithara tse 3 (sheba setšoantšo sa 2).

5. Botebo ba ho kena ha metsi ba pompo ea metsi ha boa lokela ho ba tlase ho limithara tse 1-1.5 ho tloha boemong ba metsi a matla ho ea ho node ea metsi (sheba setšoantšo sa 2). Ho seng joalo, li-bearings tsa pompo ea metsi li ka senyeha habonolo.

6. Phahamiso ea pompo ea metsi e ke ke ea ba tlase haholo. Ho seng joalo, belofo ea heke e hloka ho kenngoa pompong ea metsi ea seliba ho laola phallo ea pompo sebakeng sa phallo e lekantsoeng ho thibela enjene hore e se ke ea tlala le ho cha ka lebaka la likhahla tse kholo tsa phallo.

7. Ha pompo ea metsi e ntse e sebetsa, tlhahiso ea metsi e lokela ho ba e tsoelang pele esita le, hona joale e lokela ho ba e tsitsitseng (tlas'a maemo a sebetsang a lekantsoeng, ka kakaretso ha a na ho feta 10% ea hona joale e lekantsoeng), 'me ha hoa lokela ho ba le ho thothomela kapa lerata. Haeba ho na le ntho e sa tloaelehang, mochine o lokela ho emisoa ho fumana sesosa le ho o felisa.

8. Ha u kenya, ela hloko boemo ba mohala oa motlakase oa motlakase (sheba setšoantšo sa 2). Ha phala ea metsi e le phala ea tšepe, e etelle pele ho tloha ho clamp ea seliba; ha phala ea metsi e le phala ea polasetiki, e etelle pele ho tloha letšoao la motheo la pompo ea motlakase.

After the installation of the underwater pump, the insulation resistance and three-phase continuity of the switch face should be rechecked, and the connection between the instrument and the start device should be checked for any errors. If there is no problem, you can start to test the machine. After the start, observe whether the indication readings of each instrument are correct. If the rated voltage and current specified on the nameplate are exceeded, observe whether the pump has noise or vibration. If everything is normal, it can be put into operation. After the first operation of the pump for four hours, the motor should be shut down and tested for thermal insulation resistance quickly. Its value should not be less than 0.5 megaohm. After stopping the pump, it should be restarted after an interval of five minutes to prevent the water column in the pipeline from completely reversing and causing the motor to burn out due to excessive current. After the pump is put into normal operation, in order to prolong its service life, it is necessary to check regularly whether the supply voltage, running current and insulation resistance are normal. If the following conditions are found, the machine should be shut down immediately to eliminate the fault: the current exceeds 20% under rated working conditions; the dynamic water level drops to the inlet section, resulting in intermittent drainage; the underwater pump becomes violently vibrating or making noise; the supply voltage is lower than 340 volts; a fuse is blown out; the water pipe is damaged; the motor's thermal insulation resistance to the earth is less than 0.5 megaohm. The sequence of disassembly is: untie the cable fastening, remove the pipeline part, remove the line protection plate, screw down the water discharge bolt and discharge all the water in the motor chamber, remove the filter and loosen the coupling fixing screw of the motor shaft. The sequence of disassembly of the pump is: (see Figure 1) inlet section, impeller, guide housing, impeller, check the valve body. When removing the impeller, use special tools to loosen the taper sleeve of the impeller. Avoid bending the pump shaft and damaging the components throughout the process. The disassembly process of the motor is: (see Figure 1) put the motor on the platform, and remove the bolts, base, shaft head lock nut, thrust plate, key, lower guide plate (transverse bolt), bearing seat, screw knife seat from the bottom of the motor in order (take care not to damage the winding), and finally remove the connecting part and the upper guide bearing seat. Before assembling the unit, the rust and dirt of each part should be cleaned, and the sealant should be applied to each mating surface and fastener, and then assembled in reverse order of disassembly (the movement of the motor shaft after assembly is about one millimeter). After assembly, the coupling should be rotated flexibly and put on the filter for test. Once a year, or if less than a year of operation but has been immersed for two years, the underwater electric pump must be disassembled for maintenance in accordance with Article 5 and replace worn parts to ensure the normal operation and durability of the pump.

1, ntša metsi ka har'a mokoti oa motlakase (haholo-holo mariha ho thibela motlakase hore o se ke oa hatsela), 'me u tlame mohala hantle.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, tšebeliso ea nako e telele e lokela ho ela hloko thibelo ea mafome ea lipompo tsa submersible.

- Impeller

- Sleeve sa Shaft

- Mokotla oa rabara

-

Lesale la ho tiisa

01 Ho noa metsi a seliba se tebileng

02 Phepelo ea metsi e phahameng

03 phepelo ea metsi thabeng

04 metsi a tora

05 Ho nosetsa ka temo

06 ho nosetsa serapeng

07 ho noa metsi a noka

08 metsi a malapeng