The variable frequency winding design ensures the motor's long-term smooth conversion operation between 1HZ-50HZ, energy saving and longer service life. This product stands out for its advanced technology and efficient performance, which can achieve energy-saving and environmentally friendly operation, while ensuring the stability and reliability of the motor for long-term use. Not only that, its design makes the product with a longer life, bringing more value to users. Whether in home applications or industrial fields, this motor can provide you with excellent performance to meet a variety of needs.

1,Power supply: three-phase AC 380V (tolerance + / - 5%), 50HZ (tolerance + / - 1%).

2, càileachd uisge:

(1) water temperature is not higher than 20 °C;

(2) chan eil susbaint neo-chunbhalachd cruaidh (co-mheas mòr) nas àirde na 0.01%;

(3) PH luach (pH) 6.5-8.5;

(4) Chan eil susbaint hydrogen sulfide nas àirde na 1.5mg / L;

(5) Chan eil susbaint ion clorid nas àirde na 400mg / L.

3, the motor is a closed or water-filled wet structure, before use the submersible motor cavity must be full of clean water, to prevent false full, and then tighten the water injection, air release bolts, otherwise not allowed to use

4, the submersible pump must be completely submerged in the water, the diving depth is not greater than 70m, the bottom of the submersible pump from the bottom of the well is not less than 3m.

5, bu chòir gum biodh sruth uisge an tobair comasach air coinneachadh ri toradh uisge pumpa submersible agus obrachadh leantainneach, bu chòir smachd a chumail air toradh uisge pumpa fon uisge aig 0.7 - 1.2 uair an t-sruth ìre.

6, bu chòir don tobar a bhith dìreach, chan urrainnear am pumpa submersible a chleachdadh no a dhumpadh, dìreach cleachdadh dìreach.

7, feumaidh am pumpa submersible a bhith air a mhaidseadh leis a’ chàball a rèir nan riatanasan, agus an inneal dìon cus cuideim taobh a-muigh.

8, the pump is strictly prohibited without water no-load test machine.

| Modail | Sruth (m3/h) | Ceann (m) |

Luas rothlach (atharrachadh/puing) |

Pumpa uisge (%) | Ar-a-mach trast-thomhas (mm) |

Gu math iomchaidh trast-thomhas (mm) |

Rangaichte cumhachd (KW) |

Rangaichte bholtaids (V) |

Rangaichte sruth (A) |

Èifeachdas motair (%) | power factorcosφ | Aonad Meud radial (mm) |

Facal | |||||||||

| 135QJ5-34 | 5 | 34 | 2850 | 40 | 135gu h-àrd | 1.5 | 380 | 4.23 | 128 | |||||||||||||

| 135QJ5-51 | 51 | 2.2 | 6.03 | |||||||||||||||||||

| 135QJ5-68 | 68 | 3 | 8.01 | |||||||||||||||||||

| 135QJ5-85 | 85 | 4 | 10.53 | |||||||||||||||||||

| 135QJ5-102 | 102 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ5-119 | 119 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ5-240 | 240 | 11 | 26.28 | |||||||||||||||||||

| 135QJ5-280 | 5 | 280 | 2850 | 40 | 135gu h-àrd | 13 | 380 | 30.87 | 128 | |||||||||||||

| 135QJ5-320 | 320 | 15 | 35.62 | |||||||||||||||||||

| 135QJ10-24 | 10 | 24 | 2850 | 50 | 135gu h-àrd | 1.5 | 380 | 4.23 | 128 | |||||||||||||

| 135QJ10-32 | 32 | 2.2 | 6.03 | |||||||||||||||||||

| 135QJ10-48 | 48 | 3 | 8.01 | |||||||||||||||||||

| 135QJ10-56 | 56 | 4 | 10.53 | |||||||||||||||||||

| 135QJ10-72 | 72 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ10-80 | 80 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ10-104 | 104 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ10-120 | 120 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ10-136 | 136 | 9.2 | 22.7 | |||||||||||||||||||

| 135QJ10-180 | 180 | 11 | 26.28 | |||||||||||||||||||

| 135QJ10-210 | 210 | 13 | 30.87 | |||||||||||||||||||

| 135QJ10-240 | 240 | 15 | 35.62 | |||||||||||||||||||

| 135QJ10-300 | 300 | 18.5 | 43.12 | |||||||||||||||||||

| 135QJ15-36 | 15 | 36 | 2850 | 50 | 135gu h-àrd | 2.2 | 380 | 6.03 | 128 | |||||||||||||

| 135QJ15-39 | 39 | 3 | 8.01 | |||||||||||||||||||

| 135QJ15-46 | 46 | 4 | 10.53 | |||||||||||||||||||

| 135QJ15-52 | 52 | 4 | 10.53 | |||||||||||||||||||

| 135QJ15-59 | 59 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ15-65 | 65 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ15-78 | 78 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ15-91 | 91 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ15-104 | 104 | 9.2 | 22.7 | |||||||||||||||||||

| 135QJ15-120 | 120 | 11 | 26.28 | |||||||||||||||||||

| 135QJ15-142 | 142 | 13 | 30.87 | |||||||||||||||||||

| 135QJ15-162 | 162 | 15 | 35.62 | |||||||||||||||||||

| 135QJ15-200 | 200 | 18.5 | 43.12 | |||||||||||||||||||

| 135QJ20-16 | 20 | 16 | 2850 | 50 | 135above | 2.2 | 380 | 6.03 | 128 | |||||||||||||

| 135QJ20-24 | 24 | 3 | 8.01 | |||||||||||||||||||

| 135QJ20-32 | 32 | 4 | 10.53 | |||||||||||||||||||

| 135QJ20-40 | 40 | 4 | 10.53 | |||||||||||||||||||

| 135QJ20-48 | 48 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ20-56 | 56 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ20-64 | 64 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ20-72 | 72 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ20-80135QJ20-100 | 80 | 9.2 | 22.7 | |||||||||||||||||||

| 100 | 11 | 26.28 | ||||||||||||||||||||

| 135QJ20-120 | 120 | 13 | 30.87 | |||||||||||||||||||

| 135QJ20-136 | 136 | 15 | 35.62 | |||||||||||||||||||

| 135QJ20-168135QJ25-12 | 168 | 18.5 | 43.12 | |||||||||||||||||||

| 25 | 12 | 2850 | 65 | 135gu h-àrd | 2.2 | 380 | 6.03 | 128 | ||||||||||||||

| 135QJ25-18 | 18 | 3 | 8.01 | |||||||||||||||||||

| 135QJ25-24 | 24 | 4 | 10.53 | |||||||||||||||||||

| 135QJ25-30 | 30 | 4 | 10.53 | |||||||||||||||||||

| 135QJ25-36 | 36 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ25-48 | 48 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ25-60 | 60 | 9.2 | 22.7 | |||||||||||||||||||

| 135QJ25-82 | 82 | 11 | 26.28 | |||||||||||||||||||

| 135QJ25-97 | 97 | 13 | 30.87 | |||||||||||||||||||

| 135QJ25-110 | 110 | 15 | 35.62 | |||||||||||||||||||

| 135QJ25-130 | 130 | 18.5 | 43.12 | |||||||||||||||||||

| 135QJ32-24 | 32 | 24 | 2850 | 80 | 135gu h-àrd | 4 | 380 | 10.53 | 128 | |||||||||||||

| 135QJ32-30 | 30 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ32-42 | 42 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ32-54 | 54 | 9.2 | 22.7 | |||||||||||||||||||

| 135QJ32-68 | 68 | 11 | 26.28 | |||||||||||||||||||

| 135QJ32-80 | 80 | 13 | 30.87 | |||||||||||||||||||

| 135QJ32-92 | 92 | 15 | 35.62 | |||||||||||||||||||

| 135QJ32-104 | 104 | 18.5 | 43.12 | |||||||||||||||||||

| 135QJ40-46 | 40 | 46 | 2850 | 80 | 135gu h-àrd | 11 | 380 | 26.28 | 128 | |||||||||||||

| 135QJ40-54 | 54 | 13 | 30.87 | |||||||||||||||||||

| 135QJ40-62 | 62 | 15 | 35.62 | |||||||||||||||||||

| 135QJ40-84 | 84 | 18.5 | 43.12 | |||||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, gu teann a rèir ullachaidhean an lioft pumpaidh, raon cleachdaidh sruthadh, gus casg a chuir air sruthadh ìosal no feachd pumpaidh àrdachaidh, giùlan smeòrach agus pàirtean eile den chaitheamh, loisg an cus luchd motair 6, às deidh a’ phump sìos an tobar, cha bu chòir tomhas an motair gu dìon insulation na talmhainn a bhith nas lugha na 100M, às deidh tòiseachadh a bhith a’ cumail sùil air an bholtadh agus an t-sruth, thoir sùil air insulation lùbach motair, ge bith an ann a rèir nan riatanasan; bu chòir teòthachd àite stòraidh pumpa ma tha e nas ìsle na reothadh, a bhith tioram an uisge cuibhle motair, casg a chuir air milleadh deigh uisge cavity motair air adhbhrachadh le teòthachd ìosal.

The pump parts are mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor parts are mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand discharging ring, water inlet section, and lead cable.

Am measg prìomh fheartan an toraidh tha:

The main characteristic of the product is that the pump is a water-immersed three-phase asynchronous motor, and the motor cavity is full of water for cooling the motor and lubricating the bearing. The pressure regulating diaphragm at the bottom of the motor is used to adjust the expansion-contraction pressure difference of the water inside the body caused by the change of temperature. At the same time, in order to prevent the sand particles in the well water from entering the motor, two oil seals are installed at the end of the motor shaft, and the sand discharging ring is installed to form a sand control structure. In order to prevent the pump shaft from beating when starting up, the pump shaft and the motor shaft are connected by a coupling, and the thrust bearing is installed at the bottom of the motor. In addition, the motor and the pump bearing are water-lubricated, and the stator winding of the motor uses high-quality submersible motor winding to ensure high insulation performance. The overall design is made of computer CAD, with simple structure and superior technical performance.

(1) Ag ullachadh mus stàladh:

1. Dèan cinnteach a bheil am pumpa fon uisge a’ coinneachadh ris na cumhaichean cleachdaidh agus an raon a tha air a shònrachadh san leabhar-làimhe.

2. A’ cleachdadh inneal trom le trast-thomhas co-ionann ris an trast-thomhas a-muigh as àirde den phump a tha fon uisge, tomhais an urrainn dha trast-thomhas a-staigh an tobair a bhith a’ freagairt air a’ phumpa fon uisge, agus tomhas a bheil doimhneachd an tobair a’ coinneachadh ri riatanasan an stàlaidh.

3. Dèan cinnteach a bheil toll an tobair glan agus a bheil uisge an tobair turbid. Na cleachd pumpa dealain fon uisge gu bràth gus poll pumpa welor agus uisge gainmhich a nighe gus milleadh ro-luath air a’ phump dealain fon uisge a sheachnadh.

4. Dèan cinnteach a bheil suidheachadh a’ chlamp stàlaidh welhead freagarrach agus an urrainn dha seasamh ri càileachd an aonaid gu lèir

5. Dèan cinnteach a bheil na pàirtean pumpa fon uisge coileanta agus air an stàladh ceart a rèir an diagram cruinneachaidh san leabhar-làimhe Thoir air falbh an scrion sìoltachain agus cuairteachadh a’ chàraid gus faicinn a bheil e a ’tionndadh gu sùbailte

6. Unscrew an sgriubha uisge agus lìon a’ chuas motair le uisge glan, neo-chreimneach (nota. bi cinnteach gun cuir thu a-steach e), agus an uairsin teannachadh an sgriubha uisge. Às deidh 12 uair de in-stealladh uisge, cha bu chòir an aghaidh insulation an motair a bhith nas ìsle na 150M Q nuair a thèid a thomhas le clàr crathadh 500V.

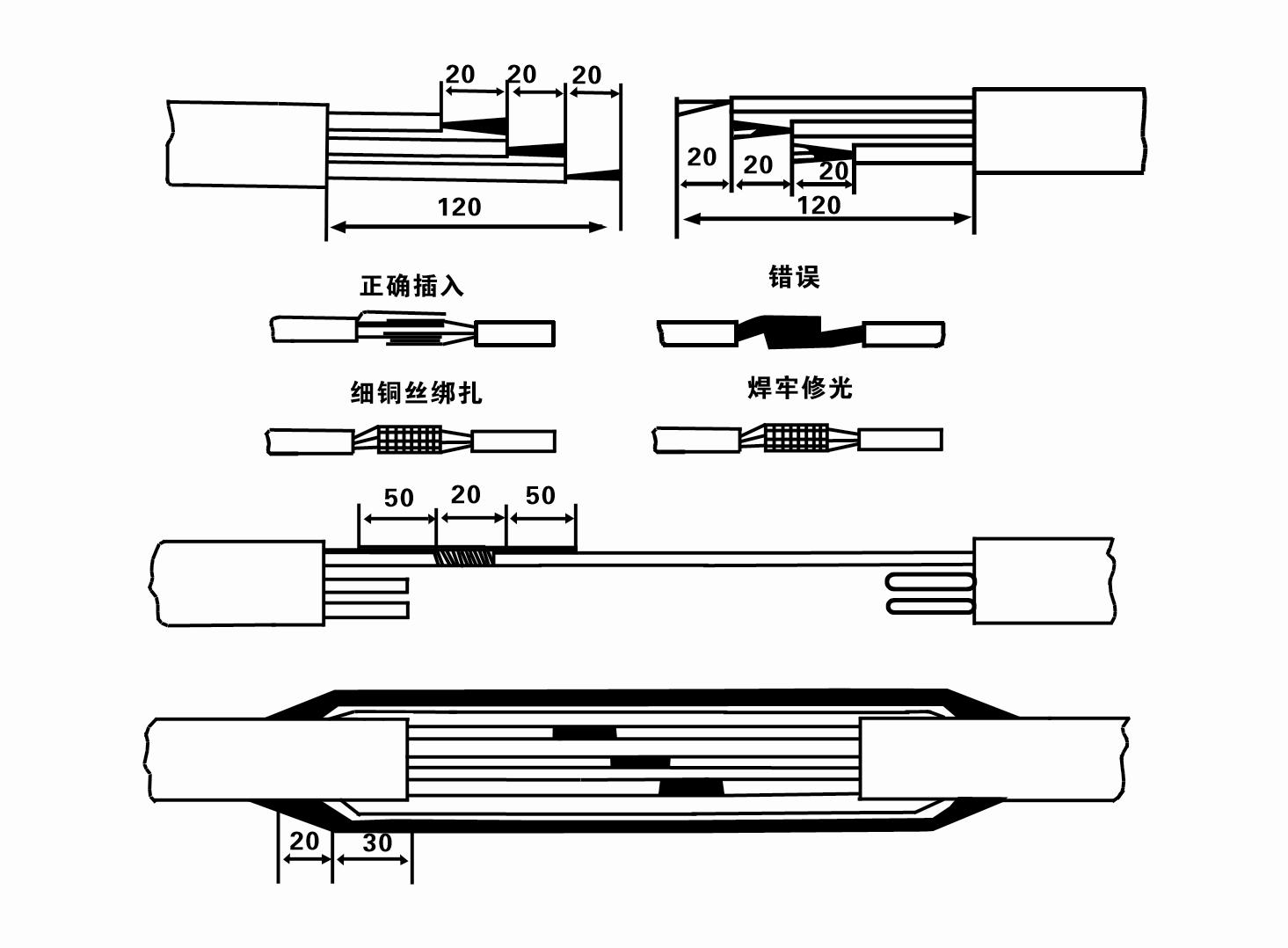

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Tha an diagram pròiseas sreangadh càball ceangailte mar a leanas:

8. Cleachd multimeter gus dèanamh cinnteach a bheil na h-uèirichean trì-ìrean ceangailte agus a bheil an aghaidh DC timcheall air cothromach.

9. Dèan cinnteach a bheil cus luchd air a’ chuairt agus comas an cruth-atharrachaidh, agus an uairsin ceangail an tionndadh dìon cus cuideim no an uidheamachd tòiseachaidh. Faic Clàr 2 airson modalan sònraichte, agus an uairsin dòirt bucaid uisge a-steach don phump uisge bhon ionad pumpa uisge gus na giùlan rubair a lubricadh anns a’ phump, agus an uairsin cuir am pumpa dealain fon uisge gu dìreach agus gu seasmhach.Start (gun a bhith nas fhaide na aon diog). agus dèan cinnteach a bheil an stiùireadh stiùiridh co-chòrdail ris an t-soidhne stiùiridh. Mura h-eil, suaip dà cheangail den chàball trì-ìre.Then stàlaich an criathrag agus ullaich airson a dhol sìos an tobar. Ma thèid a chleachdadh aig amannan sònraichte (leithid dìgean, dìgean, aibhnichean, lochan, lòin, msaa), feumaidh am pumpa dealain a bhith air a chuir air bhonn gu h-earbsach.

(2) Uidheam agus innealan stàlaidh:

1. Aon phaidhir de shlabhraidhean togail airson barrachd air dà thunna.

2. Tripod le àirde dìreach nach eil nas lugha na ceithir meatairean.

3. Dà ròp crochte (ròpaichean uèir) as urrainn cuideam nas motha na aon tunna a ghiùlan (faodaidh cuideam seata iomlan de phumpaichean uisge a ghiùlan).

4. Stàlaich dà phaidhir de clamps (splints).

5. Wrenches, ùird, screwdrivers, innealan dealain agus ionnstramaidean, msaa.

(3) Stàladh pumpa dealain:

1. Tha an diagram stàlaidh den phump dealain submersible air a shealltainn ann am Figear 2. Tha na tomhasan stàlaidh sònraichte air an sealltainn ann an Clàr 3 "Liosta de mheudan stàlaidh a' phump dealain fon uisge".

2. Faodar pumpaichean dealain fon uisge le ceann nas lugha na 30 meatair a thogail gu dìreach a-steach don tobar le bhith a’ cleachdadh phìoban agus ròpaichean uèir no ròpannan hemp eile as urrainn làn chuideam an inneil gu lèir, pìoban uisge, agus uisge anns na pìoban a ghiùlan.

3. Bidh pumpaichean le ceann nas motha na 30 meatair a 'cleachdadh pìoban stàilinn, agus tha an sreath stàlaidh mar a leanas:

① Cleachd clamp gus ceann shuas pàirt a’ phump uisge a chlampadh (tha am pumpa motair is uisge air a cheangal aig an àm seo), tog e le slabhraidh crochte, agus ceangail gu slaodach a-steach don tobar gus an cuir thu an clamp air ceann an tobair agus thoir air falbh an slabhraidh crochte.

② Cleachd paidhir clamps eile gus pìob a chlampadh, tog e le slabhraidh crochte 15 cm air falbh bhon flange, agus lughdaich e gu slaodach. Eadar flange pìoba agus flange pumpa Cuir am pasgan rubair na àite agus teannachadh a’ phìob agus am pumpa gu cothromach le boltaichean, cnothan agus nigheadairean earraich.

③ Tog beagan am pumpa fon uisge, thoir air falbh an clamp air ceann shuas a’ phump uisge, ceangail an càball gu daingeann ris a’ phìob uisge le teip plastaig, agus ceangail sìos e gu slaodach gus an tèid an clamp a chuir aig ceann an tobair.

④ Cleachd an aon dòigh airson a h-uile pìob uisge a cheangal a-steach don tobar.

⑤ Às deidh don chàball luaidhe a bhith ceangailte ris an suidse smachd, tha e ceangailte ris an t-solar cumhachd trì ìrean.

(4) Rudan ri thoirt fa-near aig àm an stàlaidh:

1. Ma lorgar iongantas jamming tron phròiseas pumpaidh, tionndaidh no tarraing am pìob uisge gus faighinn thairis air a’ phuing jamming. Mura h-eil grunn cheumannan ag obair fhathast, feuch nach toir thu air a’ phump sìos gus milleadh a sheachnadh air a’ phump dealain fon uisge agus an tobar.

2. Rè an stàladh, bu chòir ceap rubair a chuir aig flange gach pìoba agus a theannachadh gu cothromach.

3. Nuair a thèid am pumpa uisge a leigeil a-steach don tobar, bu chòir a chuir ann am meadhan pìob an tobair gus casg a chuir air a ’phump bho bhith a’ ruith an-aghaidh balla an tobair airson ùine mhòr, ag adhbhrachadh gum bi am pumpa a ’crith agus an motair a’ sguabadh agus a losgadh .

4. Obraich a-mach doimhneachd a' phump uisge gu bonn an tobair a rèir suidheachadh gainmhich is eabar an tobair. Na cuir a-steach am pumpa san eabar. Mar as trice chan eil an astar bhon phump uisge gu bonn an tobair nas lugha na 3 meatairean (faic Figear 2).

5. Cha bu chòir doimhneachd inntrigidh uisge a’ phump uisge a bhith nas lugha na 1-1.5 meatairean bhon ìre uisge fiùghantach chun nód uisge a-steach (faic Figear 2). Rud eile, dh ’fhaodadh na giùlan pumpa uisge a bhith air am milleadh gu furasta.

6. Chan urrainn togail a' phump uisge a bhith ro ìosal. Rud eile, feumar bhalbhaichean geata a chuir a-steach air loidhne-phìoban uisge ceann an tobair gus smachd a chumail air sruthadh a’ phump aig a’ phuing sruthadh ìre gus casg a chuir air a’ motair a bhith air a luchdachadh cus agus a losgadh a-mach air sgàth ìrean sruth mòr.

7. Nuair a bhios am pumpa uisge a 'ruith, bu chòir an toradh uisge a bhith leantainneach agus eadhon, bu chòir an sruth a bhith seasmhach (fo chumhachan obrach comharraichte, mar as trice gun a bhith nas fhaide na 10% den t-sruth), agus cha bu chòir crith no fuaim a bhith ann. Ma tha ana-cainnt sam bith ann, bu chòir stad a chuir air an inneal gus faighinn a-mach an adhbhar agus cuir às dha.

8. Nuair a bhios tu a’ stàladh, thoir aire do shuidheachadh an uèir talmhainn motair (faic Figear 2). Nuair a tha am pìob uisge na phìob stàilinn, stiùir e bhon chlamp ceann tobair; nuair a tha am pìob uisge na phìob plastaig, stiùir e bho chomharra bunaiteach a’ phump dealain.

- 1.After the submersible pump is installed, check the insulation resistance and three-phase conduction from the switch again, check whether the instrument and the connection of the start equipment are wrong, if there is no problem, the trial machine can be started, and after the start, observe whether the indicator readings of the instrument exceed the rated voltage and current specified on the nameplate, observe whether the pump has noise and vibration phenomenon, and put into operation if everything is normal.

- 2. After the first operation of the pump for four hours, the motor should be stopped to test the thermal insulation resistance quickly, and its value should not be less than 0.5 megaohm.

- 3. After the pump is stopped, it should be started after five minutes to prevent the water column in the pipe from being completely reflowed and causing the motor to burn out due to excessive current.

- 4. Our pump is designed to provide efficient, reliable and lasting pumping solutions.After normal operation, in order to prolong the service life of the pump, it is necessary to check the power supply voltage, running current and insulation resistance regularly to ensure that they are normal.

- If the following conditions are found, the machine should be shut down immediately to eliminate the fault:

- - the current exceeds 20% under the rated working conditions;

- - the dynamic water level drops to the inlet section, resulting in intermittent drainage;

- - the submersible pump vibrates violently or emits noisy sounds;

- - the power supply voltage is lower than 340 volts;

- - one phase of a fuse is blown out;

- - the water pipe is damaged;

- - the thermal insulation resistance of the motor to the ground is less than 0.5 megaohm.

- The steps of disassembling the unit include unlocking the cable holder, taking off the pipe part, removing the line protection plate, rotating the drain screw and emptying all the water in the motor chamber, taking out the filter and loosening the screw of the coupling fixed to the motor shaft.Unscrew the bolt connecting the water inlet section and the motor, and separate the pump and the motor (note that the unit should be placed horizontally when separating to prevent the bending of the pump shaft).

- 5. The disassembly sequence of the pump includes: water inlet part, impeller, shunt shell, impeller, check valve body.When removing the impeller, use a special tool to loosen the cone sleeve fixing the impeller.During the disassembly process, avoid bending the pump shaft and damaging various parts.The disassembly process of the motor includes: placing the motor on the platform, and then removing the nuts on the studs, base, shaft head lock nut, thrust plate, key, lower guide rail, bearing seat and bolt from the bottom of the motor, then removing the rotor (be careful not to damage the winding), and finally removing the connecting parts and upper guide bearing seat. Before assembling the unit, it is necessary to clean the rust and dirt of each part, and apply sealant on each mating surface and fastener, and then assemble it in the opposite order of disassembly.After assembly, the coupling should be flexibly rotated, and then the filter should be put on to test the machine. Our pump products are designed to provide superior performance and reliability to meet your pumping needs.

- 6. Submersible pumps operating every year, or less than a year of operation but the submersible time has reached two years, should be taken out of the well according to the 5th dismantled maintenance, replacement of worn parts.

1, cuir a-mach an uisge anns a’ chuas motair (gu sònraichte sa gheamhradh gus casg a chuir air an motair bho reothadh), agus ceangail an càball gu math.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, bu chòir cleachdadh fad-ùine aire a thoirt do chasg meirge bho phumpaichean fon uisge.

- Impeller

- Muinchille shaft

- Muinchill rubair

- Cearcall ròin

01 Tobar uisge domhainn

02 Solar uisge àrd

03 solar uisge beinne

04 tùr uisge

05 Uisgeachadh àiteachais

06 uisgeachadh gàrraidh

07 toirt a-steach uisge aibhne

08 uisge dachaigheil