The product adopts special waterproof wire design, which can realize long-term stable conversion operation of the motor within the frequency range of 1HZ-50HZ. The frequency conversion winding design not only makes the frequency conversion deep well pump more energy saving, but also prolongs its service life. The motor winding adopts special water-resistant conductors that are resistant to high frequency impact, pulse peak voltage impact and high temperature aging, with excellent characteristics and stability.

The product is powered by three-phase AC 380V power supply, 50HZ frequency, suitable for the environment with harsh water quality conditions. Specific requirements include water temperature below 20 °C, solid impurities content is not greater than 0.01%, PH value is 6.5-8.5, hydrogen sulfide content is not greater than 1.5mg/L, chloride ion content is not greater than 400mg/L. The product adopts closed or water immersion structure of the motor, before use to ensure that the pump is fully filled with water, no-load test run is strictly prohibited. The pump must be completely immersed in water, not more than 70m water depth, water source to meet the requirements of the pump water output and continuous operation. In addition, the well must be vertical, the pump can only be used vertically. The wiring should be supported according to the requirements, and equipped with external overload protection device. This series of requirements to ensure the efficient and stable operation of the product, suitable for all kinds of special environment of the pump demand.

| ຕົວແບບ | ກະແສ (ມ3/ຊມ) | ຫົວ (ມ) |

ຄວາມໄວຫມຸນ (ປ່ຽນ/ຈຸດ) |

ປ້ຳນ້ຳ(%) | ຂາອອກ ເສັ້ນຜ່າສູນກາງ (ມມ) |

ນຳໃຊ້ໄດ້ດີ ເສັ້ນຜ່າສູນກາງ(ມມ) |

ໃຫ້ຄະແນນ power(KW) |

ໃຫ້ຄະແນນ ແຮງດັນ(V) |

ໃຫ້ຄະແນນ ປັດຈຸບັນ(A) |

ປະສິດທິພາບລົດຈັກ (%) | power factorcosφ | ໜ່ວຍ Radial Maximu ຂະໜາດ(ມມ) |

ຂໍ້ສັງເກດ | |||||||||

| 250QJ50-40 | 50 | 40 | 2875 | 72 | 80 | 250ຂ້າງເທິງ | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 233 | ||||||||||

| 250QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | |||||||||||||||||

| 250QJ50-80 | 80 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ50-100 | 100 | 22 | 47.9 | 83.0 | 0.84 | |||||||||||||||||

| 250QJ50-120 | 120 | 25 | 53.8 | 84.0 | 0.84 | |||||||||||||||||

| 250QJ50-140 | 140 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ50-160 | 160 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ50-200 | 200 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ50-240 | 240 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ50-280 | 280 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ50-320 | 320 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ50-400 | 400 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ50-440 | 440 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ63-40 | 63 | 40 | 2875 | 74 | 80 | 250ຂ້າງເທິງ | 11 | 380 | 25.8 | 79.0 | 0.82 | 233 | ||||||||||

| 250QJ63-60 | 60 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ63-80 | 80 | 22 | 47.9 | 83.0 | 0.84 | |||||||||||||||||

| 250QJ63-100 | 100 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ63-120 | 120 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ63-160 | 160 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ63-200 | 200 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ63-220 | 220 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ63-260 | 260 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ63-300 | 300 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ63-360 | 360 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ80-20 | 80 | 20 | 2875 | 75 | 100 | 250ຂ້າງເທິງ | 7.5 | 380 | 18.0 | 78.0 | 0.81 | 233 | ||||||||||

| 250QJ80-40 | 40 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 250QJ80-60 | 60 | 22 | 47.9 | 83.0 | 0.84 | |||||||||||||||||

| 250QJ80-80 | 80 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ80-100 | 100 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ80-120 | 120 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ80-160 | 80 | 160 | 2875 | 75 | 100 | 250ຂ້າງເທິງ | 55 | 380 | 114.3 | 86.0 | 0.85 | 233 | ||||||||||

| 250QJ80-180 | 180 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ80-200 | 200 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ80-240 | 240 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ80-280 | 280 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ100-18 | 100 | 18 | 2875 | 75 | 100 | 250ຂ້າງເທິງ | 7.5 | 380 | 18.0 | 78.0 | 0.81 | 233 | ||||||||||

| 250QJ100-36 | 36 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 250QJ100-54 | 54 | 25 | 53.8 | 84.0 | 0.84 | |||||||||||||||||

| 250QJ100-72 | 72 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ100-90 | 90 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ100-108 | 108 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ100-126 | 126 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ100-144 | 144 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ100-162 | 162 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ100-198 | 198 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ100-216 | 216 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-16 | 125 | 16 | 2875 | 76 | 125 | 250ຂ້າງເທິງ | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 233 | ||||||||||

| 250QJ125-32 | 32 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ125-48 | 48 | 25 | 53.8 | 84.0 | 0.84 | |||||||||||||||||

| 250QJ125-64 | 64 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ125-80 | 80 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ125-96 | 96 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ125-112 | 112 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ125-128 | 128 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-160 | 160 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-176 | 176 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-192 | 192 | 110 | 219.6 | 87.5 | 0.87 | |||||||||||||||||

| 250QJ140-15 | 140 | 15 | 2875 | 76 | 125 | 250ຂ້າງເທິງ | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 233 | ||||||||||

| 250QJ140-30 | 30 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ140-45 | 45 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ140-60 | 60 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ140-75 | 45 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ140-90 | 90 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ140-105 | 140 | 105 | 2875 | 76 | 125 | 250ຂ້າງເທິງ | 63 | 380 | 131.0 | 86.0 | 0.85 | 233 | ||||||||||

| 250QJ140-120 | 120 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ140-150 | 150 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ140-165 | 165 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ140-180 | 180 | 110 | 219.6 | 87.5 | 0.87 | |||||||||||||||||

| 250QJ200-20 | 200 | 20 | 2875 | 75 | 150 | 250ຂ້າງເທິງ | 18.5 | 380 | 40.8 | 82.0 | 0.84 | 233 | ||||||||||

| 250QJ200-40 | 40 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ200-60 | 60 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ200-80 | 80 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ200-100 | 100 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ200-120 | 120 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ200-140 | 140 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, ຢ່າງເຂັ້ມງວດອີງຕາມການສະຫນອງການຍົກ pump, ລະດັບການໄຫຼຂອງການນໍາໃຊ້, ເພື່ອປ້ອງກັນການໄຫຼຕ່ໍາຫຼືແຮງສູບຍົກສູງ, ຮັບຜິດຊອບ thrust ແລະພາກສ່ວນອື່ນໆຂອງການສວມໃສ່, ການ overload motor ໄດ້ຖືກໄຟໄຫມ້.

6, after the pump down the well, the measurement of the motor to the ground insulation resistance should not be less than 100M, after the start to observe the voltage and current, check the motor winding insulation, whether in line with the requirements; pump storage location temperature if less than freezing point, should be dry the motor cavity water, prevent the motor cavity water ice damage caused by low temperature.

The pump parts are mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body and so on; the motor part mainly includes base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand discharging ring, water inlet section, cable lead, etc. The main characteristic of the product is that the motor is a water-filled wet submersible three-phase asynchronous motor, the motor cavity is filled with water, used to cool the motor and lubricate the bearing; the pressure regulating diaphragm at the bottom is used to adjust the expansion and contraction pressure difference of the internal water caused by the change of the temperature rise of the motor. In order to prevent the sand particles in the well water from entering the motor, two sand sealing rings are installed on the upper end of the motor shaft extension, and a sand discharging ring is installed to form a sand prevention structure. To prevent the pump shaft from jumping when starting up, the pump shaft is connected with the motor shaft through a coupling, and the thrust bearing is installed on the lower part of the motor. The motor and pump bearing adopt water lubrication technology, and the stator winding of the motor adopts high quality submersible motor winding with high insulation performance. The pump is designed by computer CAD, with simple structure and excellent technical performance.

(1) ການກະກຽມກ່ອນການຕິດຕັ້ງ:

1. ກວດເບິ່ງວ່າປັ໊ມ submersible ຕອບສະຫນອງເງື່ອນໄຂການນໍາໃຊ້ແລະຂອບເຂດທີ່ລະບຸໄວ້ໃນຄູ່ມື.

2. ການນໍາໃຊ້ obiect ຫນັກທີ່ມີເສັ້ນຜ່າກາງເທົ່າກັບເສັ້ນຜ່າກາງນອກສູງສຸດຂອງປັ໊ມ submersible, ວັດແທກວ່າ inneldiameter ຂອງ wellbore ສາມາດເຫມາະກັບ pump submersible ໄດ້, ແລະວັດແທກວ່າຄວາມເລິກຂອງດີຕອບສະຫນອງຄວາມຕ້ອງການການຕິດຕັ້ງ.

3. ກວດເບິ່ງວ່າອ່າງນ້ຳນັ້ນສະອາດບໍ່ ແລະ ນ້ຳຂອງນ້ຳກໍ່ມີຄວາມຂຸ່ນຫຼືບໍ່. ຢ່າໃຊ້ປັ໊ມໄຟຟ້າ submersible ເພື່ອລ້າງຂີ້ຕົມແລະນ້ໍາຊາຍຂອງ welor pump ເພື່ອຫຼີກເວັ້ນຄວາມເສຍຫາຍກ່ອນໄວອັນຄວນຂອງປັ໊ມໄຟຟ້າ submersible.

4. ກວດເບິ່ງວ່າຕໍາແໜ່ງຂອງຕົວຍຶດຕິດສະຫວັດແມ່ນເຫມາະສົມຫຼືບໍ່ ແລະ ມັນສາມາດທົນກັບຄຸນນະພາບຂອງເຄື່ອງທັງໝົດໄດ້ຫຼືບໍ່.

5. ກວດເບິ່ງວ່າອົງປະກອບຂອງປັ໊ມ submersible ຄົບຖ້ວນສົມບູນແລະຕິດຕັ້ງຢ່າງຖືກຕ້ອງຕາມແຜນຜັງການປະກອບໃນຄູ່ມື, ເອົາຫນ້າຈໍການກັ່ນຕອງອອກແລະຫມຸນທໍ່ເຊື່ອມຕໍ່ເພື່ອເບິ່ງວ່າມັນ rotates ຍືດຫຍຸ່ນ.

6. ຖອດສະກູນ້ຳອອກ ແລະ ຕື່ມນ້ຳທີ່ສະອາດ, ບໍ່ມີສານກັດກ່ອນ (ໝາຍເຫດ, ໝຸນມັນອອກ), ຈາກນັ້ນບີບອັດສະກູໃຫ້ແໜ້ນ. ຫຼັງຈາກ 12 ຊົ່ວໂມງຂອງການສີດນ້ໍາ, ຄວາມຕ້ານທານ insulation ຂອງມໍເຕີບໍ່ຄວນຫນ້ອຍກ່ວາ 150M Q ເມື່ອວັດແທກກັບຕາຕະລາງສັ່ນ 500V.

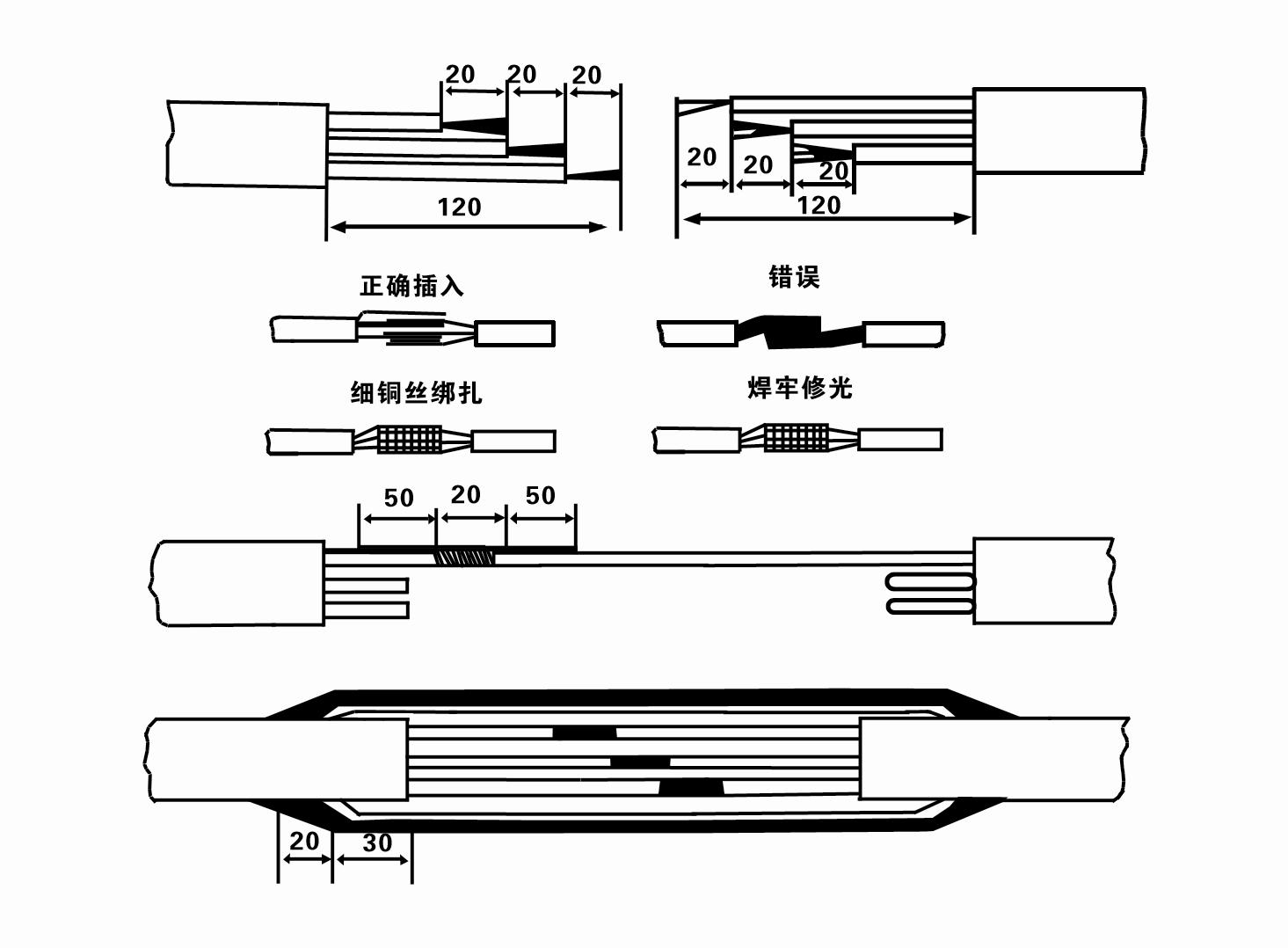

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

ແຜນວາດຂະບວນການສາຍສາຍໄຟທີ່ຕິດຄັດມາມີດັ່ງນີ້:

8. ໃຊ້ມັນຕິມິເຕີເພື່ອກວດເບິ່ງວ່າສາຍໄຟສາມເຟດຖືກເຊື່ອມຕໍ່ຫຼືບໍ່ແລະວ່າຄວາມຕ້ານທານ DC ແມ່ນປະມານສົມດູນຫຼືບໍ່.

9. ກວດເບິ່ງວ່າວົງຈອນແລະຄວາມອາດສາມາດຂອງຫມໍ້ແປງແມ່ນ overloaded, ແລະຫຼັງຈາກນັ້ນເຊື່ອມຕໍ່ສະຫຼັບປ້ອງກັນ overload ຫຼືອຸປະກອນເລີ່ມຕົ້ນ. ເບິ່ງຕາຕະລາງ 2 ສໍາລັບແບບຈໍາລອງສະເພາະ, ແລະຫຼັງຈາກນັ້ນເອົາຖັງນ້ໍາເຂົ້າໄປໃນປັ໊ມນ້ໍາຈາກປ່ຽງປ່ຽງນ້ໍາເພື່ອຫລໍ່ລື່ນລູກປືນຢາງໃນປັ໊ມ, ແລະຫຼັງຈາກນັ້ນວາງປັ໊ມໄຟຟ້າ submersible ຕັ້ງຊື່ແລະສະຫມໍ່າສະເຫມີ. ເລີ່ມຕົ້ນ (ບໍ່ເກີນຫນຶ່ງວິນາທີ). ແລະກວດເບິ່ງວ່າທິດທາງການຊີ້ນໍາແມ່ນສອດຄ່ອງກັບເຄື່ອງຫມາຍການຊີ້ນໍາຫຼືບໍ່. ຖ້າບໍ່ແມ່ນ, ແລກປ່ຽນສອງຕົວເຊື່ອມຕໍ່ຂອງສາຍໄຟສາມເຟດ. ຫຼັງຈາກນັ້ນ, ຕິດຕັ້ງຕົວກອງແລະກະກຽມທີ່ຈະລົງໄປໃນນ້ໍາດີ. ຖ້າໃຊ້ໃນໂອກາດພິເສດ (ເຊັ່ນ: ຮ່ອງ, ຄອງ, ແມ່ນໍ້າ, ໜອງ, ໜອງ, ແລະອື່ນໆ), ປັ໊ມໄຟຟ້າຕ້ອງມີພື້ນຖານທີ່ເຊື່ອຖືໄດ້.

(2) ອຸປະກອນການຕິດຕັ້ງແລະເຄື່ອງມື:

1. ຄູ່ຂອງຕ່ອງໂສ້ຍົກສໍາລັບຫຼາຍກ່ວາສອງໂຕນ.

2. Tripod ທີ່ມີຄວາມສູງຕັ້ງບໍ່ຫນ້ອຍກວ່າສີ່ແມັດ.

3. ເຊືອກຫ້ອຍສອງອັນ (ສາຍເຊືອກ) ທີ່ສາມາດຮັບນ້ຳໜັກໄດ້ຫຼາຍກວ່າໜຶ່ງໂຕນ (ສາມາດຮັບນ້ຳໜັກໄດ້ຂອງປ້ຳນ້ຳຄົບຊຸດ).

4. ຕິດຕັ້ງສອງຄູ່ຂອງ clamps (splint).

5. wrenches, hammers, screwdrivers, ເຄື່ອງມືໄຟຟ້າແລະເຄື່ອງມື, ແລະອື່ນໆ.

(3) ການຕິດຕັ້ງປໍ້າໄຟຟ້າ:

1. ແຜນວາດການຕິດຕັ້ງຂອງປັ໊ມໄຟຟ້າ submersible ແມ່ນສະແດງຢູ່ໃນຮູບ 2. ຂະຫນາດການຕິດຕັ້ງສະເພາະແມ່ນສະແດງຢູ່ໃນຕາຕະລາງ 3 "ລາຍການຂະຫນາດການຕິດຕັ້ງຂອງປັ໊ມໄຟຟ້າ Submersible".

2. ປັ໊ມໄຟຟ້າໃຕ້ນໍ້າທີ່ມີຫົວບໍ່ເກີນ 30 ແມັດ ສາມາດຍົກນໍ້າໃສ່ນໍ້າສ້າງໄດ້ໂດຍກົງ ໂດຍໃຊ້ສາຍທໍ່ ແລະສາຍເຊືອກ ຫຼືເຊືອກເຊືອກອື່ນໆ ທີ່ສາມາດຮັບນໍ້າໜັກໄດ້ທັງໝົດຂອງເຄື່ອງຈັກ, ທໍ່ນໍ້າ ແລະນໍ້າໃນທໍ່.

3. ປໍ້າທີ່ມີຫົວຫຼາຍກວ່າ 30 ແມັດ ໃຊ້ທໍ່ເຫຼັກ, ແລະ ລຳດັບການຕິດຕັ້ງມີດັ່ງນີ້:

①ໃຊ້ຕົວຍຶດເພື່ອມັດສ່ວນເທິງຂອງປ້ຳນ້ຳ (ມໍເຕີແລະປ້ຳນ້ຳໄດ້ເຊື່ອມຕໍ່ກັນແລ້ວໃນເວລານີ້), ຍົກມັນດ້ວຍຕ່ອງໂສ້ຫ້ອຍ, ແລະຄ່ອຍໆມັດມັນເຂົ້າໄປໃນນ້ຳສ້າງຈົນກວ່າເອົາຕົວຍຶດໃສ່ຫົວນ້ຳສ້າງ ແລະເອົາສາຍຮັດອອກ. ຕ່ອງໂສ້ຫ້ອຍ.

② ໃຊ້ຕົວຍຶດອີກຄູ່ເພື່ອຍຶດທໍ່, ຍົກມັນດ້ວຍຕ່ອງໂສ້ຫ້ອຍ 15 ຊຕມຈາກຫນ້າແປນ, ແລະຫຼຸດລົງຊ້າໆ. ລະຫວ່າງປ່ຽງທໍ່ ແລະປ່ຽງປ່ຽງ ວາງແຜ່ນຢາງໃສ່ບ່ອນ ແລະຮັດທໍ່ ແລະປ້ຳໃຫ້ສະເໝີກັນດ້ວຍບານປະຕູ, ແກ່ນໝາກໄມ້ ແລະເຄື່ອງຊັກພາກຮຽນ spring.

③ ຍົກປັ໊ມ submersible ເລັກນ້ອຍ, ເອົາ clamp ຢູ່ເທິງສຸດຂອງປັ໊ມນ້ໍາ, ມັດສາຍກັບທໍ່ນ້ໍາຢ່າງແຫນ້ນຫນາດ້ວຍ tape ພາດສະຕິກ, ແລະຄ່ອຍໆມັດມັນລົງຈົນກ່ວາ clamp ໄດ້ຖືກວາງໄວ້ທີ່ຫົວ wellhead.

④ ໃຊ້ວິທີດຽວກັນເພື່ອມັດທໍ່ນ້ຳທັງໝົດໃສ່ໃນນ້ຳສ້າງ.

⑤ຫຼັງຈາກສາຍໄຟສາຍອອກໄດ້ເຊື່ອມຕໍ່ກັບສະວິດຄວບຄຸມ, ມັນເຊື່ອມຕໍ່ກັບການສະຫນອງພະລັງງານສາມເຟດ.

(4) ສິ່ງທີ່ຄວນສັງເກດໃນລະຫວ່າງການຕິດຕັ້ງ:

1. ຖ້າພົບເຫັນປະກົດການຕິດຂັດໃນລະຫວ່າງຂະບວນການສູບນ້ໍາ, ໃຫ້ຫັນຫຼືດຶງທໍ່ນ້ໍາເພື່ອເອົາຊະນະຈຸດຕິດຂັດ. ຖ້າມາດຕະການຕ່າງໆຍັງບໍ່ໄດ້ຜົນ, ກະລຸນາຢ່າບັງຄັບປັ໊ມລົງເພື່ອຫຼີກເວັ້ນການເສຍຫາຍຂອງປັ໊ມໄຟຟ້າ submersible ແລະນ້ໍາດີ.

2. ໃນລະຫວ່າງການຕິດຕັ້ງ, ຄວນວາງແຜ່ນຢາງຢູ່ຫນ້າແປນຂອງທໍ່ແຕ່ລະອັນແລະແຫນ້ນແຫນ້ນຢ່າງເທົ່າທຽມກັນ.

3. ເມື່ອປ້ຳນ້ຳລົງໃນນ້ຳສ້າງຄວນວາງໄວ້ກາງທໍ່ນ້ຳດີ ເພື່ອບໍ່ໃຫ້ປ້ຳແລ່ນໄປຕຳກັບຝານ້ຳສ້າງເປັນເວລາດົນ ເຮັດໃຫ້ປ້ຳສັ່ນສະເທືອນ ແລະ ມໍເຕີຈະກວາດ ແລະໄໝ້ໄດ້. .

4. ກໍານົດຄວາມເລິກຂອງປັ໊ມນ້ໍາລົງລຸ່ມຂອງດີອີງຕາມການໄຫຼຂອງດິນຊາຍແລະ silt ຂອງດີ. ຢ່າຝັງປັ໊ມໃນຕົມ. ໄລຍະຫ່າງຈາກປັ໊ມນ້ໍາໄປຫາລຸ່ມຂອງນ້ໍາໂດຍທົ່ວໄປແມ່ນບໍ່ຫນ້ອຍກວ່າ 3 ແມັດ (ເບິ່ງຮູບ 2).

5. ຄວາມເລິກຂອງນໍ້າເຂົ້າຂອງປໍ້ານໍ້າຄວນຈະບໍ່ຫນ້ອຍກວ່າ 1-1.5 ແມັດຈາກລະດັບນໍ້າແບບເຄື່ອນໄຫວໄປຫາທໍ່ນໍ້າເຂົ້າ (ເບິ່ງຮູບ 2). ຖ້າບໍ່ດັ່ງນັ້ນ, bearings pump ນ້ໍາອາດຈະໄດ້ຮັບຄວາມເສຍຫາຍໄດ້ຢ່າງງ່າຍດາຍ.

6. ການຍົກຂອງປັ໊ມນ້ໍາບໍ່ສາມາດຕ່ໍາເກີນໄປ. ຖ້າບໍ່ດັ່ງນັ້ນ, ປ່ຽງປະຕູຕ້ອງໄດ້ຮັບການຕິດຕັ້ງໃສ່ທໍ່ນ້ໍາ wellhead ເພື່ອຄວບຄຸມການໄຫຼຂອງປັ໊ມຢູ່ທີ່ຈຸດການໄຫຼທີ່ຖືກຈັດອັນດັບເພື່ອປ້ອງກັນບໍ່ໃຫ້ມໍເຕີໂຫລດເກີນແລະໄຟໄຫມ້ເນື່ອງຈາກອັດຕາການໄຫຼຂະຫນາດໃຫຍ່.

7. ໃນເວລາທີ່ປັ໊ມນ້ໍາກໍາລັງແລ່ນ, ຜົນຜະລິດນ້ໍາຄວນຈະຢ່າງຕໍ່ເນື່ອງແລະແມ້ກະທັ້ງ, ປະຈຸບັນຄວນຈະມີຄວາມຫມັ້ນຄົງ (ພາຍໃຕ້ເງື່ອນໄຂການເຮັດວຽກທີ່ມີການຈັດອັນດັບ, ໂດຍທົ່ວໄປແລ້ວບໍ່ເກີນ 10% ຂອງກະແສໄຟຟ້າທີ່ຖືກຈັດອັນດັບ), ແລະບໍ່ຄວນມີການສັ່ນສະເທືອນຫຼືສຽງລົບກວນ. ຖ້າມີຄວາມຜິດປົກກະຕິ, ຄວນຢຸດເຄື່ອງເພື່ອຫາສາເຫດແລະລົບລ້າງມັນ.

8. ເມື່ອຕິດຕັ້ງ, ໃຫ້ເອົາໃຈໃສ່ກັບການຕັ້ງຄ່າຂອງສາຍດິນມໍເຕີ (ເບິ່ງຮູບ 2). ເມື່ອທໍ່ນ້ໍາເປັນທໍ່ເຫລໍກ, ນໍາພາມັນອອກຈາກທໍ່ນ້ໍາດີ; ໃນເວລາທີ່ທໍ່ນ້ໍາເປັນທໍ່ພາດສະຕິກ, ນໍາພາມັນຈາກເຄື່ອງຫມາຍພື້ນດິນຂອງປັ໊ມໄຟຟ້າ.

- 1.After the submersible pump is installed, check the insulation resistance and three-phase conduction from the switch again, check whether the instrument and the connection of the start 2.equipment are wrong, if there is no problem, the trial machine can be started, and observe whether the indicator readings of the instrument exceed the rated voltage and current specified on 3.the nameplate after the start, and observe whether the pump has noise and vibration phenomenon, and put into operation if everything is normal.

- 4.After the first operation of the pump for four hours, the motor should be shut down to test the thermal insulation resistance quickly, and its value should not be less than 0.5 megaohm.

- 5.After the pump is shut down, it should be started after five minutes to prevent the water column in the pipe from being completely reflowed and causing excessive motor current and burnout.

- 6.After the pump is put into normal operation, in order to prolong its service life, it is necessary to check whether the supply voltage, working current and insulation resistance are normal regularly. If the following conditions are found, the pump should be shut down immediately to troubleshoot.

- 1 In the rated condition, the current exceeds 20%.

- 2 ລະດັບນ້ໍາແບບເຄື່ອນໄຫວຫຼຸດລົງໄປຫາພາກສ່ວນນ້ໍາ inlet, ເຮັດໃຫ້ນ້ໍາ interrupted.

- 3 ປັ໊ມ submersible ມີການສັ່ນສະເທືອນຫຼືສຽງດັງ.

- 4 ແຮງດັນການສະຫນອງແມ່ນຕ່ໍາກວ່າ 340 volts.

- 5 ຟິວໄຟໄໝ້ໝົດ.

- 6 ທໍ່ນ້ໍາປະປາເສຍຫາຍ.

- 7 The motor's thermal insulation resistance is lower than 0.5 megaohm.

- Unit disassembly:

- 1 Untie the cable tie, remove the pipeline part, and remove the wire plate. 2 screw down the water bolt, put the water in the motor chamber.

- 3 ເອົາການກັ່ນຕອງອອກ, ວ່າງ screw ຄົງທີ່ກ່ຽວກັບ coupling ເພື່ອແກ້ໄຂ shaft motor.

- 4 ໝຸນສະລັອດທີ່ເຊື່ອມຕໍ່ສ່ວນນ້ຳເຂົ້າກັບມໍເຕີ, ແລະແຍກປ້ຳອອກຈາກມໍເຕີ (ໃຫ້ຄວາມສົນໃຈກັບເບາະຫົວໜ່ວຍໃນເວລາທີ່ແຍກອອກ, ເພື່ອປ້ອງກັນການບິດເບືອນຂອງປ້ຳປ້ຳ).

- 5 ລໍາດັບ disassembly ຂອງປັ໊ມແມ່ນ: (ເບິ່ງຮູບ 1) ພາກສ່ວນ inlet ນ້ໍາ, impeller, diversion shell, impeller ...... ກວດເບິ່ງ valve body, ເມື່ອຖອນ impeller, ໃຊ້ເຄື່ອງມືພິເສດເພື່ອພວນແຂນຮູບຈວຍຂອງຄົງທີ່. impeller ທໍາອິດ, ແລະຫຼີກເວັ້ນການ bending ແລະ bruising shaft pump ໃນຂະບວນການ disassembly ໄດ້.

- 6 ຂັ້ນຕອນການຖອດມໍເຕີຄື: (ເບິ່ງຮູບ 1) ວາງມໍເຕີຢູ່ເທິງເວທີ, ແລະເອົາແກ່ນເປືອກອອກ, ໂຄນ, ແກນລັອກຫົວ shaft, ແຜ່ນ thrust, ກະແຈ, ບ່ອນນັ່ງ bearing ຄູ່ມືຕ່ໍາແລະ bolt ຫົວສອງຈາກລຸ່ມສຸດຂອງ. motor ແລະເຮັດໃຫ້ການ, ແລະຫຼັງຈາກນັ້ນເອົາອອກ rotor (ເອົາໃຈໃສ່ບໍ່ໃຫ້ທໍາລາຍຊຸດສາຍ) ແລະສຸດທ້າຍເອົາພາກສ່ວນເຊື່ອມຕໍ່ແລະບ່ອນນັ່ງ bearing ຄູ່ມືເທິງ.

- 7 ການປະກອບຫນ່ວຍ: ກ່ອນທີ່ຈະປະກອບ, rust ແລະຝຸ່ນຂອງພາກສ່ວນຄວນໄດ້ຮັບການອະນາໄມ, ແລະຫນ້າການປະສົມພັນແລະ fasteners ເຄືອບດ້ວຍ sealant, ແລະຫຼັງຈາກນັ້ນປະກອບໃນຄໍາສັ່ງກົງກັນຂ້າມຂອງ disassembly (shaft motor ຍ້າຍຂຶ້ນແລະລົງຫຼັງຈາກປະກອບປະມານຫນຶ່ງ. millimeter), ຫຼັງຈາກການປະກອບ, coupling ຄວນມີຄວາມຍືດຫຍຸ່ນ, ແລະຫຼັງຈາກນັ້ນເຄື່ອງທົດສອບຫນ້າຈໍການກັ່ນຕອງ. ປັ໊ມ submersible ຈະຖືກເອົາອອກຈາກຂຸມສໍາລັບການຮື້ແລະບໍາລຸງຮັກສາຕາມມາດຕາ 5 ຫຼັງຈາກການດໍາເນີນງານ 1 ປີ, ຫຼືຫນ້ອຍກວ່າຫນຶ່ງປີຂອງການດໍາເນີນງານແຕ່ໃຊ້ເວລາ 2 ປີ, ແລະພາກສ່ວນທີ່ສວມໃສ່ຈະຖືກປ່ຽນແທນ.

In order to ensure the long-term use and stable performance of submersible electric pump, we have launched a convenient and practical product. The product has a unique design, easy operation, and is perfect for various application scenarios. After use, remember to discharge all the water in the electric pump, especially in winter, so as not to freeze the motor. Wind the cable and bundle it. Store it in an environment without corrosive substances and gases, and keep the temperature below 40 °C. In addition, if you do not use it for a long time, you should pay attention to prevent the submersible electric pump from rusting. Choose our products to make your work more convenient and efficient.

- ແຮງດັນ

- ແຂນ Shaft

- ເສອແຂນຢາງ

-

ວົງການຜະນຶກ

01 ການດູດນ້ໍາດີ

02 ນ້ຳປະປາສູງ

03 ນ້ຳປະປາພູເຂົາ

04 ຫໍນ້ຳ

05 ຊົນລະປະທານກະສິກຳ

06 ຊົນລະປະທານສວນ

07 ການນໍາໃຊ້ນ້ໍາ

08 ນ້ໍາພາຍໃນ