The product adopts special water-resistant wire for motor winding, with excellent characteristics such as high frequency shock resistance, pulse peak voltage shock resistance and high temperature aging resistance. The frequency conversion winding design ensures the motor to operate smoothly between 1Hz and 50Hz for a long time, making the frequency conversion deep well pump more energy saving and longer service life.

We are honored to introduce our products, this product provides three-phase AC 380V power supply (tolerance of ± 5%), 50HZ voltage (tolerance of ± 1%). At the same time, our products require strict water quality requirements: water temperature is not higher than 20 °C; solid impurities content (mass ratio) is not greater than 0.01%; PH value (pH) is 6.5-8.5; hydrogen sulfide content is not greater than 1.5mg/L; chloride ion content is not greater than 400mg/L. The motor adopts closed or water-filled wet structure, which must be filled with clean water before use to prevent empty. Tighten the water charging and deflating bolts before use, otherwise, it is not allowed to use. The submersible pump must be completely immersed in water to work, the immersion depth shall not exceed 70 meters, and the distance between the bottom of the submersible pump and the bottom of the well shall not be less than 3 meters. The well water flow shall meet the output and continuous operation requirements of the submersible pump, and the output of the submersible pump shall be controlled at 0.7-1.2 times of the rated flow. The well must be vertical, and the submersible pump can not be used horizontally or inverted, but only vertically. The submersible pump must be equipped with cables according to requirements, and is equipped with external overload protection devices. It is strictly prohibited to conduct no-load tests on the pump without water. Our products guarantee to provide you with high quality and stable performance, while meeting your needs to ensure safe and reliable.

| Chitsanzo | Kuyenda (m3/h) | Mutu (m) |

Rotatingspeed (kusintha / mfundo) |

Pampu (%) | Chotuluka awiri (mm) |

Zokwanira bwino awiri (mm) |

Adavoteledwa power(KW) |

Adavoteledwa voteji (V) |

Adavoteledwa panopa (A) |

Kuchita bwino (%) | power factorcosφ | Chigawo Kukula kwa Radial Maximu (mm) |

|||||||||

| 175QJ10-42 | 10 | 42 | 2850 | 53 | 50 | 175pamwamba | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ10-56 | 56 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-70 | 70 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-84 | 84 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ10-112 | 112 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-126 | 126 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-140 | 140 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ15-42 | 15 | 42 | 2850 | 58 | 50 | 175pamwamba | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ15-55 | 55 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-65 | 65 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-85 | 85 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ15-112 | 112 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 175pamwamba | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ20-39 | 39 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ20-52 | 52 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ20-78 | 78 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ20-91 | 91 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-104 | 104 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ20-130 | 130 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-156 | 156 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-182 | 187 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ20-208 | 208 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-247 | 247 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-273 | 273 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-299 | 299 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-325 | 325 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-364 | 364 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-26 | 25 | 26 | 2850 | 66 | 65 | 175pamwamba | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ25-39 | 39 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ25-65 | 25 | 65 | 2850 | 66 | 65 | 175pamwamba | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ25-78 | 78 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ25-91 | 91 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ25-104 | 104 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-130 | 130 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-156 | 156 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ25-182 | 182 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-208 | 208 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-221 | 221 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-247 | 247 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-260 | 260 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-299 | 299 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ30-30 | 30 | 30 | 2850 | 67 | 80 | 175pamwamba | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ30-40 | 40 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-24 | 32 | 24 | 2850 | 67 | 80 | 175pamwamba | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ32-36 | 36 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-48 | 48 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ32-60 | 60 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ32-72 | 72 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ32-84 | 84 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-96 | 96 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-120 | 120 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ32-144 | 144 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-168 | 168 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-180 | 180 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-192 | 192 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-204 | 204 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-240 | 240 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ35-60 | 35 | 60 | 2850 | 67 | 80 | 175pamwamba | 10 | 380 | 25.0 | 78.0 | 0.78 | 168 | |||||||||

| 175QJ35-75 | 75 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ35-100 | 100 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ40-24 | 40 | 24 | 2850 | 70 | 80 | 175pamwamba | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ40-30 | 30 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ40-36 | 36 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ40-48 | 48 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ40-60 | 60 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ40-72 | 72 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-84 | 84 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-96 | 96 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ40-120 | 120 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-132 | 132 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-144 | 144 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-156 | 156 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-168 | 168 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-192 | 192 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-24 | 50 | 24 | 2850 | 72 | 80 | 175pamwamba | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ50-36 | 36 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ50-48 | 48 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ50-70 | 70 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ50-84 | 84 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ50-96 | 96 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-108 | 108 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-120 | 120 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-132 | 132 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-144 | 144 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-156 | 156 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-22 | 63 | 22 | 2850 | 72 | 80 | 175pamwamba | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ63-44 | 44 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-55 | 55 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-66 | 66 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ63-77 | 77 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-88 | 88 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-99 | 63 | 99 | 2850 | 72 | 80 | 175pamwamba | 30 | 380 | 66.6 | 81.5 | 0.84 | 168 | |||||||||

| 175QJ63-110 | 110 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-132 | 132 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-9 | 80 | 9 | 2850 | 73 | 100 | 175pamwamba | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ80-18 | 18 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ80-27 | 27 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ80-36 | 36 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ80-45 | 45 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ80-54 | 54 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-63 | 63 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-72 | 72 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-81 | 81 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-90 | 90 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-98 | 98 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

This well submersible pump is a pump suitable for clean water. Digging new wells and pumping sediment and turbid water are strictly prohibited. The voltage grade of the well pump is 380V/50HZ. Submersible motors with other voltage grades need to be customized. Underground cables must use waterproof cables and must be equipped with starting equipment, such as distribution boxes, etc. The starting equipment should have common comprehensive motor protection functions, such as overload short circuit protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. In abnormal cases, the protection device should be tripped in time. During installation and use, the pump must be reliably grounded. It is prohibited to push and pull the switch when hands and feet are wet. The power supply must be cut off before installation and maintenance of the pump. The place where the pump is used must be set up with obvious "anti-electric shock" marks. Before going down the well or installation, the motor must be injected with distilled water or non-corrosive clear cold water in the inner cavity, and the intake/drain bolts must be tightened. When testing the pump on the ground, water must be injected into the pump chamber to lubricate the rubber bearings. The instant start time should not exceed one second to check whether the direction is correct. The same as the steering instructions. Pay attention to safety when the pump is upright to prevent tilting and injury. Strictly in accordance with the provisions of the pump lift and flow range, to prevent the pump flow at low lift or in high lift pull too large, resulting in extreme wear of thrust bearings and other components, the motor due to overload and burn. After put into the well, the measurement of the motor and the ground insulation resistance value, not less than 100M. After the start, regular observation of voltage and current, and check the motor winding insulation is in line with the requirements of the provisions. If the temperature of the storage site is below the freezing point, the water in the pump chamber should be drained to prevent the water in the motor chamber from freezing and damaging the motor due to low temperature.

Chidule chachidule cha kapangidwe kake: gawo la mpope limapangidwa makamaka ndi shaft ya mpope, chopondera, chipolopolo chosinthira, kunyamula mphira, mawonekedwe a valve (gawo losankha) ndi zigawo zina. Gawo lagalimoto limapangidwa ndi maziko, filimu yowongolera kukakamiza, kukakamiza, mbale yolowera, mpando wowongolera, stator, rotor, mpando wapamwamba wokhala ndi kalozera, mphete yamchenga, gawo lolowera madzi, chingwe ndi zigawo zina.

Zofunika zazikulu za mankhwalawa ndi:

1.The motor is a water-filled wet submersible three-phase asynchronous motor, the motor cavity is full of clean water, used to cool the motor and lubricate the bearing, the pressure regulating film at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the water inside the body caused by the change of the temperature rise of the motor.

2.In order to prevent the sand in the well water from entering the motor, the upper end of the motor shaft is equipped with two oil seals, and a sand ring is installed to form a sand prevention structure.

3.In order to prevent the pump shaft from running up when starting, the pump shaft and the motor shaft are connected by a coupling, and an upper thrust bearing is installed at the lower part of the motor.

4.The lubrication of the motor and the pump bearing is water lubrication.

5.The motor stator winding is made of high quality submersible motor winding wire, with high insulation performance.

6.The pump is designed by computer CAD, with simple structure and good technical performance.

(1) Kukonzekera musanakhazikitse:

1. Yang'anani ngati pampu ya submersible ikugwirizana ndi momwe amagwiritsidwira ntchito komanso kukula kwake komwe kwafotokozedwa m'bukuli.

2. Pogwiritsa ntchito obiect yolemetsa yokhala ndi m'mimba mwake yofanana ndi kukula kwakunja kwa pampu ya submersible, yesani ngati innneldiameter ya chitsimecho ingagwirizane ndi mpope wa submersible, ndikuyesa ngati kuya kwa chitsime kumakwaniritsa zofunikira zoikamo.

3. Yang'anani ngati chitsime chili choyera komanso ngati madzi a m'chitsime ali abwibwi. Musagwiritse ntchito pampu yamagetsi ya submersible kutsuka matope a welor mpope ndi madzi amchenga kuti mupewe kuwonongeka msanga kwa pampu yamagetsi ya submersible.

4. Yang'anani ngati malo achitsulo choyika welhead ndi oyenera komanso ngati angapirire kuchuluka kwa gawo lonse.

5. Yang'anani ngati zigawo za pampu za submersible zatha ndikuyikidwa bwino molingana ndi chithunzi cha msonkhano chomwe chili m'mabuku Chotsani chophimba cha fyuluta ndikuzungulira cholumikizira kuti muwone ngati chimasinthasintha.

6. Chotsani zowononga zamadzi ndikudzaza pabowo lamoto ndi madzi oyera, osawononga (zindikirani. Onetsetsani kuti mwasefa), ndiyeno khwimitsani chopoperapo madzi. Pambuyo pa maola 12 a jakisoni wamadzi, kukana kwa injini sikuyenera kukhala kochepera 150M Q poyesedwa ndi tebulo logwedezeka la 500V.

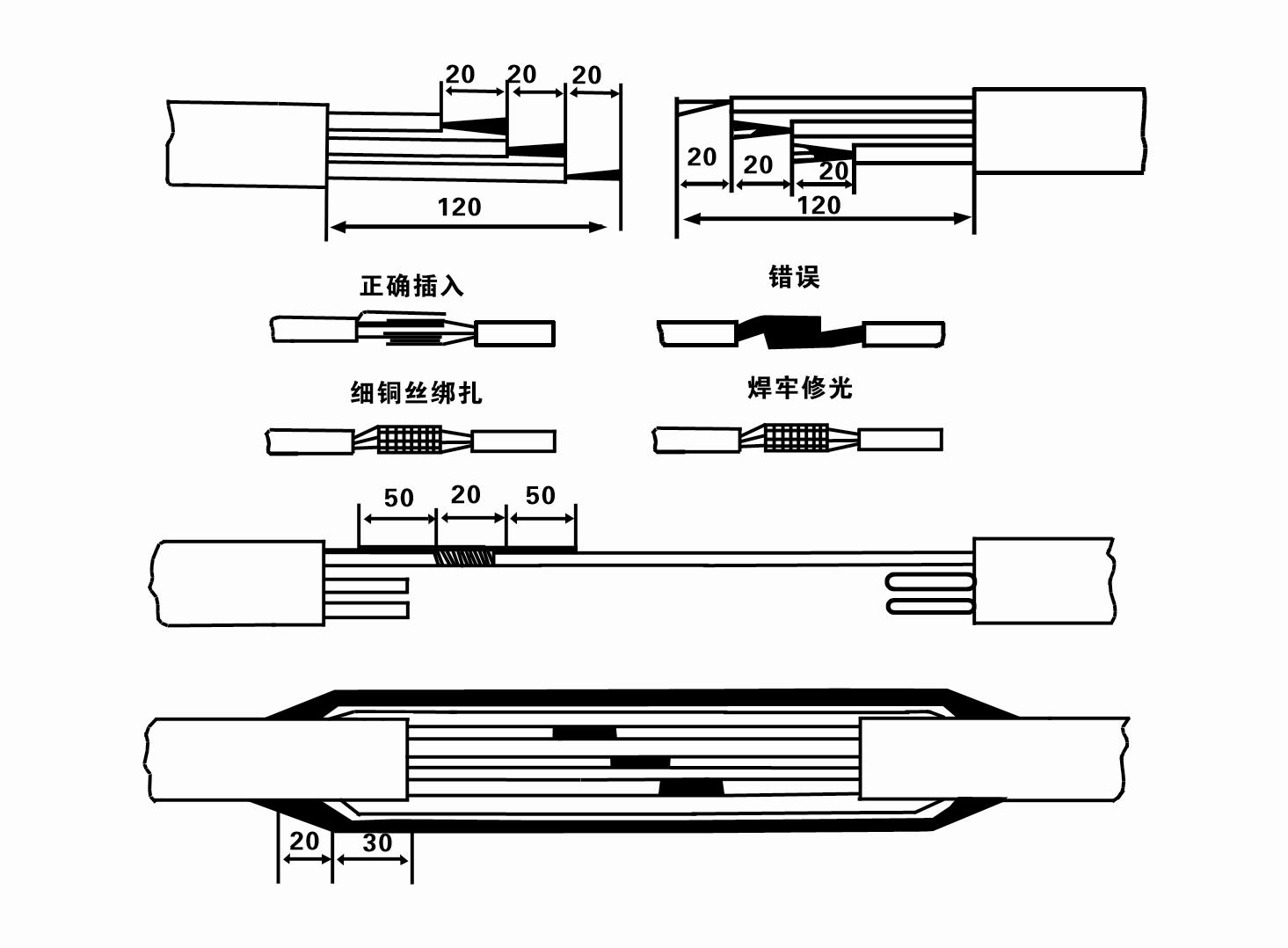

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Chiwonetsero cha njira yolumikizira chingwe chili motere:

8. Gwiritsani ntchito multimeter kuti muwone ngati mawaya a magawo atatu alumikizidwa komanso ngati kukana kwa DC kuli pafupifupi moyenera.

9. Yang'anani ngati mphamvu yozungulira ndi thiransifoma yadzaza kwambiri, ndiyeno gwirizanitsani chotchinga choteteza katundu kapena zida zoyambira. Onani Table 2 kuti mupeze zitsanzo zenizeni, ndiyeno Thirani ndowa yamadzi mu mpope wa madzi kuchokera popopa madzi kuti mutsitsire ma bere a rabara mu mpope, ndiyeno ikani mpope wamagetsi wozama mowongoka ndi wosasunthika. Yambani (osaposa sekondi imodzi) ndikuwona ngati chiwongolerocho chikugwirizana ndi chiwongolero. Ngati sichoncho, sinthanani zolumikizira ziwiri za chingwe cha magawo atatu. Kenako yikani fyuluta ndikukonzekera kutsika pachitsime. Ngati amagwiritsidwa ntchito pazochitika zapadera (monga ngalande, ngalande, mitsinje, maiwe, maiwe, ndi zina zotero), mpope wamagetsi uyenera kukhazikika pansi.

(2) Zida zoyika ndi zida:

1. Peyala imodzi ya unyolo wonyamulira woposa matani awiri.

2. Tripod yokhala ndi utali woyima wosachepera mamita anayi.

3. Zingwe ziwiri zolendewera (zingwe za waya) zomwe zimatha kunyamula kulemera kopitilira tani imodzi (zimatha kunyamula ma pampu athunthu amadzi).

4. Ikani zingwe ziwiri ziwiri (zolumikizira).

5. Wrenches, nyundo, screwdrivers, zida zamagetsi ndi zida, etc.

(3) Kuyika pampu yamagetsi:

1. Chojambula choyikapo cha pampu yamagetsi ya submersible chikuwonetsedwa mu Chithunzi 2. Miyeso yeniyeni yoyika ikuwonetsedwa mu Table 3 "Mndandanda wa Miyeso ya Kuyika kwa Pampu ya Magetsi Oyikirapo".

2. Mapampu amagetsi oyenda pansi pamadzi okhala ndi mutu wosakwana mamita 30 akhoza kukwezedwa molunjika kuchitsime pogwiritsa ntchito mapaipi ndi zingwe za waya kapena zingwe zina za hemp zomwe zimatha kunyamula kulemera kwa makina onse, mapaipi amadzi, ndi madzi mu mapaipi.

3. Mapampu okhala ndi mutu wopitilira 30 metres amagwiritsa ntchito mapaipi achitsulo, ndipo kuyika kwake kuli motere:

①Gwiritsani ntchito chotchinga kuti mutseke kumtunda kwa gawo la mpope wamadzi (motor ndi mpope wamadzi zalumikizidwa pakadali pano), kwezani ndi unyolo wolendewera, ndikumangirira pang'onopang'ono m'chitsime mpakaIkani chingwe pamutu ndikuchotsani. unyolo wopachika.

② Gwiritsani ntchito zingwe zina kuti mutseke chitoliro, ikwezeni ndi unyolo wolendewera wa masentimita 15 kuchokera ku flange, ndikutsitsa pang'onopang'ono. Pakati pa chitoliro cha chitoliro ndi chopopera chopoperaIkani mphira m'malo mwake ndikumangitsani chitoliro ndikupopa mofanana ndi mabawuti, mtedza ndi zochapira masika.

③ Kwezani mpope wa submersible pang'ono, chotsani chotchinga chakumtunda kwa mpope wamadzi, kumangirira chingwe ku chitoliro chamadzi ndi tepi ya pulasitiki, ndikumangirira pang'onopang'ono mpaka Chingwecho chikayikidwa pachitsime.

④Gwiritsani ntchito njira yomweyo kumanga mapaipi onse amadzi pachitsime.

⑤Chingwe chotsogolera chikalumikizidwa ndi chosinthira chowongolera, chimalumikizidwa ndi gawo la magawo atatu.

(4) Zinthu zofunika kuziwona pakuyika:

1. Ngati chodabwitsa cha jamming chikupezeka panthawi yopopera, tembenuzirani kapena kukoka chitoliro cha madzi kuti mugonjetse malo ophimbidwa. Ngati njira zosiyanasiyana sizikugwirabe ntchito, chonde Musakakamize mpope pansi kuti mupewe kuwonongeka kwa pampu yamagetsi yozama komanso chitsime.

2. Pakuyika, mphira wa rabara uyenera kuikidwa pamphepete mwa chitoliro chilichonse ndikumangirira mofanana.

3. Pamene mpope wamadzi watsitsidwa m’chitsime, uyenera kuikidwa pakati pa chitoliro cha chitsimecho kuti mpopeyo usayendetse khoma la chitsime kwa nthawi yaitali, zomwe zimapangitsa kuti pampuyo igwedezeke ndipo injini ikusesa ndi kutentha. .

4. Dziwani kuya kwa mpope wamadzi mpaka pansi pa chitsime molingana ndi mchenga woyenda komanso silt ya pachitsime. Osakwirira mpope m'matope. Mtunda wochokera pa mpope wa madzi kufika pansi pa chitsime nthawi zambiri umakhala wosachepera mamita atatu (onani chithunzi 2).

5. Kuzama kwa madzi pa mpope kuyenera kukhala kosachepera 1-1.5 metres kuchokera pamadzi amphamvu kupita kumalo olowera madzi (onani Chithunzi 2). Kupanda kutero, mayendedwe a pampu amadzi amatha kuwonongeka mosavuta.

6. Kukweza kwa mpope wamadzi sikungakhale kotsika kwambiri. Kupanda kutero, valavu ya pachipata iyenera kuyikidwa papaipi yamadzi yakuchitsime kuti muzitha kuyendetsa pampu pamalo oyendera kuti injini isalemedwe ndikuwotchedwa chifukwa cha kuchuluka kwamadzi.

7. Pamene mpope wamadzi ukuyenda, kutuluka kwa madzi kuyenera kukhala kosalekeza komanso ngakhale, komweko kuyenera kukhala kosasunthika (pansi pa malo ogwirira ntchito, nthawi zambiri osapitirira 10% ya omwe adavotera panopa), ndipo pasakhale kugwedezeka kapena phokoso. Ngati pali vuto lililonse, makinawo ayimitsidwe kuti adziwe chomwe chayambitsa ndikuchichotsa.

8. Mukayika, mvetserani kuyika kwa waya wamoto (onani Chithunzi 2). Pamene chitoliro cha madzi ndi chitoliro chachitsulo, chitsogolereni kuchokera pachitsime chachitsulo; pamene chitoliro cha madzi ndi chitoliro cha pulasitiki, chitsogolereni kuchokera kumalo oyambira pampu yamagetsi.

- 1.After installing the submersible pump, recheck the insulation resistance and three-phase continuity switch, check whether there is any error in the connection between the instrument and the starting equipment.If there is no problem, you can start to test the machine. After starting, observe whether the indication reading of each instrument is correct.If the rated voltage and current specified on the nameplate are exceeded, please observe whether the pump has noise or vibration.If everything is normal, it can be put into operation. After the pump runs for the first time for four hours, the motor thermal insulation resistance should be closed and tested quickly. Its value should not be less than 0.5 megaohm. After the pump stops, it should be restarted after five minutes to prevent the water column in the pipeline from completely reversing, which will cause the motor to burn out due to excessive current.

- 2.After the pump is put into normal operation, in order to prolong its service life, it is necessary to check whether the supply voltage, working current and insulation resistance are normal regularly. If the following conditions are found, the machine should be stopped immediately to troubleshoot.

- 1.Under the rated working condition, the current exceeds 20%.

- 2.The dynamic water level drops to the water inlet section, resulting in intermittent water.

- 3.The submersible pump has severe vibration or noise.

- 4.The supply voltage is lower than 340 volts.

- 5.A fuse is burned out.

- 6.The water pipeline is damaged.

- 7.The motor's insulation resistance to the geothermal state is lower than 0.5 megaohm.

- 3.Unit disassembly:

- - Masulani tayi ya chingwe, chotsani mbali ya mapaipi, ndi kuchotsa mbale ya waya.

- - screw down the water bolt, put out the water in the motor chamber.

- - chotsani fyuluta, masulani chomangira chokhazikika pa cholumikizira kuti mukonze shaft yamoto.

- 4.screw down the bolt connecting the water inlet section with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the opposite order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

1, ikani madzi mumtsempha wamoto (makamaka m'nyengo yozizira kuti injini isaundane), ndikumanga chingwe bwino.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, ntchito yaitali ayenera kulabadira kupewa dzimbiri a mapampu submersible.

- Impeller

- Mtsinje wa shaft

- Chingwe cha rabara

-

mphete yosindikiza

01 Kumwa madzi a pachitsime chakuya

02 Madzi okwera kwambiri

03 madzi a m'mapiri

04 madzi nsanja

05 Kuthirira kwaulimi

06 ulimi wothirira m'munda

07 madzi a mitsinje

08 madzi apakhomo