Hot water motor using 50W400 high grade cold rolled silicon steel, stamping by high speed punch, make its stator iron loss is low, less heating advantages, the motor winding using high temperature, anti-aging hot water motor special winding water line, using 3CR13 stainless steel impeller shaft, high temperature sleeve and other high quality accessories, so that it can run at high temperature for a long time, and can be used with a frequency converter, so that it can automatically adjust according to the size of the water consumption.

This product is a three-phase AC 380V power supply (tolerance ± 5%), 50HZ frequency (tolerance ± 1%) pump, suitable for pumping water temperature not higher than 20 °C water. Specific requirements include: solid impurities content is not greater than 0.01%; PH value between 6.5-8.5; hydrogen sulfide content is not more than 1.5mg/L; chloride ion content is not more than 400mg/L. The pump adopts closed or water sealed structure, before use must be filled with water, tighten the water and air exhaust bolts, otherwise not to use. The pump must be completely immersed in water, immersion depth shall not exceed 70m, and the distance from the bottom of the well shall not be less than 3m. The water flow in the well shall meet the requirements of the pump output and continuous operation, the pump output shall be controlled at 0.7-1.2 times the rated flow. The well shall be vertical, the pump can not be used horizontally or tilted, only vertical use. The pump must be equipped with cables and external overload protection device according to the requirements. It is strictly prohibited to test the pump without water and no load.

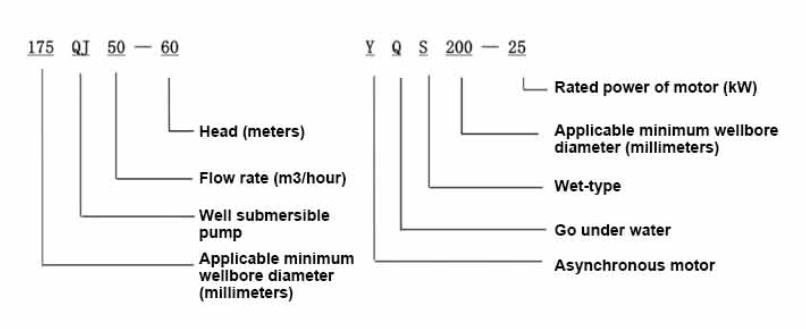

| Model | Aliran (m3/jam) | sirah (m) |

Kacepetan puteran (ganti/titik) |

Pompa banyu (%) | Outlet diameteripun (mm) |

Ditrapake kanthi apik diameteripun (mm) |

Dirating power(KW) |

Dirating tegangan (V) |

Dirating saiki (A) |

Efisiensi motor (%) | power factorcosφ | Unit Ukuran maksimal Radial (mm) |

Tetembungane | |||||||||

| 200QJ20-40 | 20 | 40 | 2850 | 66 | 50 | 200ndhuwur | 4 | 380 | 10.1 | 76.0 | 0.79 | 184 | ||||||||||

| 200QJ20-54 | 54 | 5.5 | 13.6 | 77.0 | 0.8 | |||||||||||||||||

| 200QJ20-81 | 81 | 7.5 | 18.0 | 78.0 | 0.81 | |||||||||||||||||

| 200QJ20-93 | 93 | 9.2 | 21.7 | 78.5 | 0.82 | |||||||||||||||||

| 200QJ20-108 | 108 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ20-121 | 121 | 13 | 29.8 | 80.0 | 0.83 | |||||||||||||||||

| 200QJ20-148 | 148 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 200QJ20-175 | 175 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ20-202 | 202 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ20-243 | 243 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ20-270 | 270 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ20-360 | 360 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ20-442 | 442 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ25-28 | 25 | 28 | 2850 | 68 | 65 | 200ndhuwur | 4 | 380 | 10.1 | 76.0 | 0.79 | 184 | ||||||||||

| 200QJ25-42 | 42 | 5.5 | 13.6 | 77.0 | 0.8 | |||||||||||||||||

| 200QJ25-56 | 56 | 7.5 | 18.0 | 78.0 | 0.81 | |||||||||||||||||

| 200QJ25-70 | 70 | 9.2 | 21.7 | 78.5 | 0.82 | |||||||||||||||||

| 200QJ25-98 | 98 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ25-112 | 25 | 112 | 2850 | 68 | 65 | 200ndhuwur | 13 | 380 | 29.8 | 80.0 | 0.83 | 184 | ||||||||||

| 200QJ25-126 | 126 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 200QJ25-154 | 154 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ25-182 | 182 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ25-210 | 210 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ25-252 | 252 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ25-308 | 308 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ25-378 | 378 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ32-26 | 32 | 26 | 2850 | 70 | 80 | 200ndhuwur | 4 | 380 | 10.1 | 76.0 | 0.79 | 184 | ||||||||||

| 200QJ32-39 | 39 | 5.5 | 13.6 | 77.0 | 0.8 | |||||||||||||||||

| 200QJ32-52 | 52 | 7.5 | 18.0 | 78.0 | 0.81 | |||||||||||||||||

| 200QJ32-65 | 65 | 9.2 | 21.7 | 78.5 | 0.82 | |||||||||||||||||

| 200QJ32-78 | 78 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ32-91 | 91 | 13 | 29.8 | 80.0 | 0.83 | |||||||||||||||||

| 200QJ32-104 | 104 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 200QJ32-130 | 130 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ32-143 | 143 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ32-169 | 169 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ32-195 | 195 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ32-247 | 247 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ32-299 | 299 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ40-26 | 40 | 26 | 2850 | 72 | 80 | 200ndhuwur | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 184 | ||||||||||

| 200QJ40-39 | 39 | 7.5 | 18.0 | 78.0 | 0.81 | |||||||||||||||||

| 200QJ40-52 | 52 | 9.2 | 21.7 | 78.5 | 0.82 | |||||||||||||||||

| 200QJ40-65 | 65 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ40-78 | 78 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 200QJ40-104 | 104 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ40-117 | 117 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ40-143 | 143 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ40-169 | 169 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ40-208 | 208 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ40-247 | 247 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ50-26 | 50 | 26 | 2850 | 74 | 80 | 200ndhuwur | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 184 | ||||||||||

| 200QJ50-39 | 39 | 9.2 | 21.7 | 78.5 | 0.82 | |||||||||||||||||

| 200QJ50-52 | 52 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ50-65 | 65 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 200QJ50-78 | 78 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ50-91 | 91 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ50-104 | 104 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ50-130 | 130 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ50-156 | 156 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ50-208 | 208 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ63-24 | 63 | 24 | 2850 | 74 | 80 | 200ndhuwur | 7.5 | 380 | 18.0 | 78.0 | 0.81 | 184 | ||||||||||

| 200QJ63-36 | 36 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ63-60 | 60 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ63-72 | 72 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ63-84 | 84 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ63-96 | 96 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ63-120 | 120 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ63-144 | 144 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ80-22 | 80 | 22 | 2850 | 75 | 100 | 200ndhuwur | 7.5 | 380 | 18.0 | 78.0 | 0.81 | 184 | ||||||||||

| 200QJ80-33 | 33 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ80-44 | 44 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 200QJ80-55 | 55 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ80-66 | 66 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ80-88 | 88 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ80-99 | 99 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ80-121 | 121 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ100-18 | 100 | 18 | 2850 | 75 | 100 | 200ndhuwur | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 184 | ||||||||||

| 200QJ100-27 | 27 | 13 | 29.8 | 80.0 | 0.83 | |||||||||||||||||

| 200QJ100-36 | 36 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ100-45 | 45 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ100-54 | 54 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ100-63 | 63 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ100-72 | 100 | 72 | 2850 | 75 | 100 | 200ndhuwur | 37 | 380 | 79.7 | 84.0 | 0.84 | 184 | ||||||||||

| 200QJ100-90 | 90 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, strictly miturut pranata angkat pump, sawetara aliran nggunakake, kanggo nyegah aliran kurang utawa angkat dhuwur pumping pasukan, bantalan tikaman lan bagean liyane saka nyandhang, kakehan motor burned

6, after the pump down the well, the measurement of the motor to the ground insulation resistance should not be less than 100M, after the start to observe the voltage and current, check the motor winding insulation, whether in line with the requirements; pump storage location temperature if less than freezing point, should be dry the motor cavity water, prevent the motor cavity water ice damage caused by low temperature.

introduksi Brief saka struktur: bagean pump utamané dumadi saka poros pump, impeller, cangkang pangalihan, bantalan karet, mriksa awak tutup (bagian opsional) lan komponen liyane. Motor part utamané dumadi saka basa, meksa ngatur film, tikaman prewangan, tikaman piring, ngisor guide prewangan jog, stator, rotor, guide ndhuwur prewangan jog, wedhi ring, bagean welingan banyu, kabel lan komponen liyane.

Fitur utama produk kalebu:

1, Motor minangka motor asynchronous telung fase udan sing diisi banyu, rongga motor kebak banyu resik, digunakake kanggo kelangan motor lan pelumas bantalan, film pangaturan tekanan ing ngisor motor digunakake kanggo nyetel prabédan tekanan ekspansi lan kontraksi banyu ing njero awak disebabake owah-owahan suhu motor.

2, Kanggo nyegah wedhi ing banyu sumur mlebu motor, ujung ndhuwur poros motor dilengkapi rong segel minyak, lan cincin pasir dipasang kanggo mbentuk struktur pencegahan pasir.

3, Supaya batang pompa ora mlaku nalika diwiwiti, poros pompa lan poros motor disambungake kanthi kopling, lan bantalan dorong ndhuwur dipasang ing sisih ngisor motor.

4, Pelumasan motor lan bantalan pompa yaiku pelumasan banyu.

5, Motor stator nduwurke tumpukan digawe saka kualitas dhuwur submersible motor nduwurke tumpukan kabel, karo kinerja jampel dhuwur.

6, pump dirancang dening komputer CAD, karo struktur prasaja lan kinerja technical apik.

(1) Preparation sadurunge instalasi:

1. Priksa manawa pompa submersible cocog karo kahanan panggunaan lan ruang lingkup sing ditemtokake ing manual.

2. Nggunakake obiect abot karo diameteripun witjaksono menyang diameteripun njaba maksimum pump submersible, ngukur apa inneldiameter saka wellbore bisa pas pump submersible, lan ngukur apa ambane sumur meets syarat instalasi.

3. Priksa manawa sumur sumur resik lan banyu sumur keruh. Aja nggunakake pompa listrik submersible kanggo ngumbah lendhut pompa welor lan banyu pasir supaya ora rusak sadurunge pompa listrik submersible.

4. Priksa manawa posisi clamp instalasi welhead cocok lan apa bisa tahan kualitas kabeh unit

5. Priksa manawa komponen pompa submersible wis lengkap lan dipasang kanthi bener miturut diagram perakitan ing manual Copot layar panyaring lan puterake kopling kanggo ndeleng apa rotasi kanthi fleksibel

6. Copot sekrup banyu lan isi rongga motor kanthi banyu sing resik lan ora korosif (cathetan, manawa kanggo ngisi), banjur kencengake sekrup banyu. Sawise 12 jam injeksi banyu, ing resistance jampel saka motor ngirim ora kurang saka 150M Q nalika diukur karo 500V goyang meja.

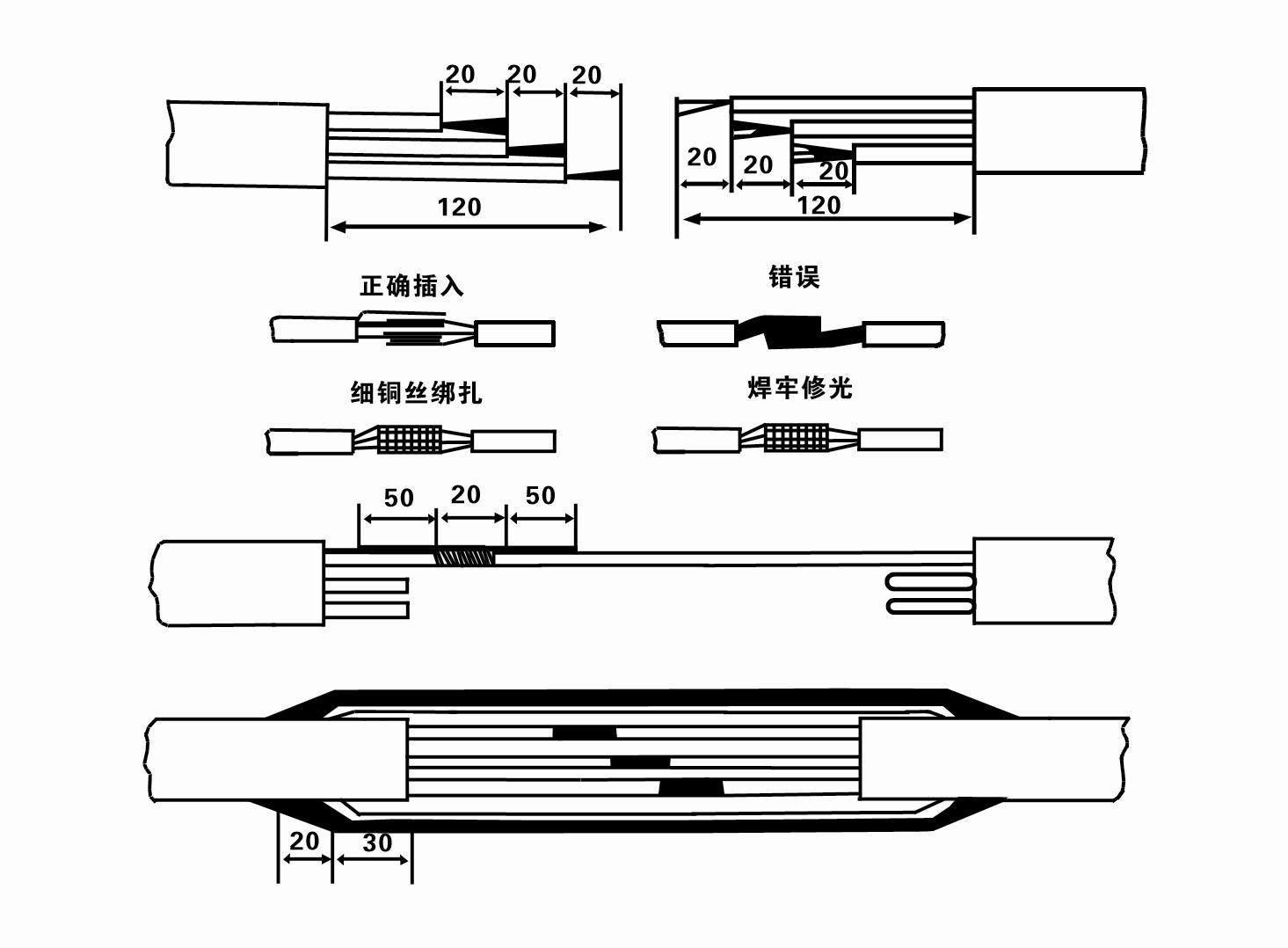

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Diagram proses pengkabelan kabel minangka nderek:

8. Gunakake multimeter kanggo mriksa apa kabel telung phase disambungake lan apa resistance DC kira-kira imbang.

9. Priksa manawa sirkuit lan trafo kapasitas overloaded, lan banjur nyambungake ngalih pangayoman kakehan utawa miwiti peralatan. Waca Tabel 2 kanggo model tartamtu, banjurPour ember banyu menyang kumpa banyu saka stopkontak pump banyu kanggo lubricate bantalan karet ing kumpa, lan banjur sijine pump listrik submersible mujur lan ajeg.Mulai (ora luwih saka siji detik) lan priksa manawa arah setir cocog karo tandha setir. Yen ora, ganti loro konektor kabel telung fase. Banjur pasang filter lan siyap mudhun sumur. Yen digunakake ing acara khusus (kayata selokan, selokan, kali, blumbang, blumbang, lan sapiturute), pompa listrik kudu dilebokake kanthi andal.

(2) Peralatan lan piranti instalasi:

1. Siji pasang rentengan ngangkat luwih saka rong ton.

2. Tripod kanthi dhuwur vertikal ora kurang saka patang meter.

3. Rong tali gantung (tali kawat) sing bisa nanggung bobot luwih saka siji ton (bisa nanggung bobot saka set lengkap pompa banyu).

4. Pasang rong pasang clamps (splints).

5. Kunci pas, palu, obeng, piranti lan piranti listrik, lsp.

(3) Instalasi pompa listrik:

1. Diagram instalasi pompa listrik submersible ditampilake ing Gambar 2. Dimensi instalasi spesifik ditampilake ing Tabel 3 "Dhaptar Dimensi Instalasi Pompa Listrik Submersible".

2. Pompa listrik submersible kanthi sirah kurang saka 30 meter bisa diangkat langsung menyang sumur nggunakake selang lan tali kawat utawa tali rami liyane sing bisa nanggung bobot kabeh mesin, pipa banyu, lan banyu ing pipa.

3. Pumps kanthi sirah luwih saka 30 meter nggunakake pipa baja, lan urutan instalasi kaya ing ngisor iki:

①Gunakake penjepit kanggo ngapit ujung ndhuwur bagean pompa banyu (motor lan pompa banyu wis disambungake ing wektu iki), angkat nganggo rantai gantung, lan alon-alon dasi menyang sumur nganti pasang clamp ing sirah sumur lan copot ranté gantung.

② Gunakake sepasang klem liyane kanggo njepit pipa, angkat nganggo rante gantung 15 cm adoh saka flange, banjur mudhunake alon-alon. Antarane flange pipe lan flange pumpLebokake pad karet ing panggonan lan kenceng pipa lan pompa roto-roto nganggo bolts, perkakas lan spring washers.

③ Angkat pompa submersible rada, copot clamp ing mburi ndhuwur pump banyu, dasi kabel kuwat menyang pipa banyu karo plastik tape, lan alon dasi mudhun nganti Clamp diselehake ing wellhead.

④Gunakake cara sing padha kanggo naleni kabeh pipa banyu menyang sumur.

⑤Sawise kabel timbal-metu disambungake menyang saklar kontrol, disambungake menyang sumber daya telung fase.

(4) Bab sing kudu digatekake sajrone instalasi:

1. Yen ana fenomena jamming nalika proses pumping, nguripake utawa narik pipa banyu kanggo ngatasi titik jamming. Yen macem-macem langkah isih ora bisa, please Aja meksa kumpa mudhun kanggo ngindhari karusakan ing pompa listrik submersible lan sumur.

2. Sajrone instalasi, pad karet kudu diselehake ing flange saben pipa lan tightened roto-roto.

3. Nalika pompa banyu diturunake menyang sumur, kudu diselehake ing tengah pipa sumur supaya pompa ora mlaku ing tembok sumur nganti suwe, nyebabake pompa kedher lan motor nyapu lan diobong. .

4. Nemtokake ambane pompa banyu ing ngisor sumur miturut kondisi pasir lan lempung sing mili. Aja ngubur pompa ing lendhut. Jarak saka pompa banyu menyang dhasar sumur umume ora kurang saka 3 meter (pirsani Gambar 2).

5. Ambane entri banyu saka pompa banyu kudu ora kurang saka 1-1,5 meter saka tingkat banyu dinamis menyang simpul inlet banyu (pirsani Gambar 2). Yen ora, bantalan pompa banyu bisa gampang rusak.

6. Angkat pompa banyu ora bisa sithik banget. Yen ora, katup gapura kudu dipasang ing pipa banyu sumur kanggo ngontrol aliran pompa ing titik aliran sing dirating kanggo nyegah motor kakehan lan kobong amarga tingkat aliran gedhe.

7. Nalika pompa banyu mlaku, output banyu kudu terus-terusan lan malah, arus kudu stabil (ing kondisi kerja sing dirating, umume ora luwih saka 10% saka arus sing dirating), lan ora ana getaran utawa gangguan. Yen ana kelainan, mesin kudu mandheg kanggo ngerteni sababe lan ngilangi.

8. Nalika nginstal, mbayar manungsa waé menyang setelan saka kabel grounding motor (ndeleng Figure 2). Nalika pipa banyu minangka pipa baja, mimpin saka clamp wellhead; nalika pipa banyu minangka pipa plastik, mimpin saka tandha grounding pompa listrik.

According to the product description, our submersible pump after installation needs careful inspection and testing to ensure its normal operation and prolong the service life. After installation, it is necessary to recheck the insulation resistance and three-phase continuity to ensure that the instrument and the start-up equipment are connected correctly. Before starting the test machine, observe whether the indication readings of the instruments are correct, check whether the rated voltage and current specified on the nameplate are exceeded, and observe whether there is noise or vibration in the pump. If everything is normal, it can be put into operation. After the pump runs for the first four hours, the motor thermal insulation resistance should be closed and quickly tested, and its value should not be less than 0.5 megaohms. After stopping the pump, it needs to be restarted at an interval of five minutes to prevent the water column in the pipeline from returning to cause the motor to burn out due to excessive current. After normal operation, it is necessary to check whether the supply voltage, working current and insulation resistance are normal regularly. Once abnormal conditions are found, such as the current exceeds 20% of the rated working conditions, the water level drops causing intermittent drainage, the submersible pump vibrates or makes loud noise, the supply voltage is lower than 340 volts, one phase in the fuse is burned out, the water pipe is damaged or the motor's thermal insulation resistance to the earth is less than 0.5 megaohms, the machine should be stopped immediately to eliminate the fault. When disassembling the unit, it is necessary to operate in accordance with the specified sequence to avoid damaging various components. Once a year or less than one year of use but has been immersed for two years, it must be disassembled and inspected in accordance with the provisions, and the worn parts must be replaced to ensure the normal operation and service life of the submersible electric pump.

1, sijine metu banyu ing growong motor (utamané ing mangsa kanggo nyegah motor saka pembekuan), lan dasi kabel uga.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, nggunakake long-term kudu mbayar manungsa waé kanggo Nyegah teyeng saka pumps submersible.

- Impeller

- Lengan poros

- Lengan poros karet

-

Ring segel

01 Intake banyu sumur jero

02 Sumber banyu dhuwur

03 banyu gunung

04 banyu menara

05 Irigasi Pertanian

06 irigasi kebon

07 intake banyu kali

08 banyu omah