This product adopts a variable frequency winding design, ensuring the motor's smooth conversion operation between 1HZ and 50HZ for a long time. This innovative design not only saves energy and prolongs service life, but also provides lasting and reliable performance in the work process. Whether in a home or industrial environment, this product will provide users with excellent efficiency and reliability, making it an indispensable tool in the manufacturing and production process.

1, ipese agbara: mẹta-alakoso AC 380V (ifarada +/- 5%), 50HZ (ifarada +/- 1%).

2, Didara omi:

(1) water temperature is not higher than 20 °C;

(2) akoonu aimọ ti o lagbara (ipin ipin) ko tobi ju 0.01%;

(3) PH iye (pH) 6.5-8.5;

(4) akoonu sulfide hydrogen ko tobi ju 1.5mg/L;

(5) akoonu ion kiloraidi ko tobi ju 400mg/L.

3, awọn motor ti wa ni pipade tabi omi-kún tutu be, ṣaaju ki o to lilo awọn submersible motor iho gbọdọ wa ni kún fun o mọ omi, lati se eke ni kikun, ati ki o Mu awọn omi abẹrẹ, air Tu boluti, bibẹkọ ti ko gba ọ laaye lati lo.

4, submersible pump must be completely submerged in the water, the diving depth is not greater than 70m, the bottom of the submersible pump from the bottom of the well is not less than 3m. 5, the well water flow should be able to meet the submersible pump water output and continuous operation, the submersible pump water output should be controlled at 0.7 - 1.2 times the rated flow.

6, kanga yẹ ki o wa ni titọ, fifa omi inu omi ko le ṣee lo tabi da silẹ, lilo inaro nikan.

7, awọn submersible fifa gbọdọ wa ni ibamu pẹlu okun ni ibamu si awọn ibeere, ati awọn ita apọju Idaabobo ẹrọ.

8, fifa naa jẹ idinamọ muna laisi omi ko si ẹrọ idanwo fifuye

| Awoṣe | Sisan (m3/h) | Ori (m) |

Iyara yiyipo (ayipada/ojuami) |

Omi (%) | Ijabọ opin (mm) |

Wulo daradara opin (mm) |

Ti won won power(KW) |

Ti won won foliteji(V) |

Ti won won lọwọlọwọ (A) |

Iṣiṣẹ mọto (%) | power factorcosφ | Ẹyọ Iwọn Radial ti o pọju (mm) |

Akiyesi | |||||||||

| 300QJ200-40 | 200 | 40 | 2900 | 76 | 150 | 300loke | 37 | 380 | 77.8 | 85.0 | 0.85 | 281 | ||||||||||

| 300QJ200-60 | 60 | 55 | 115 | 85.5 | 0.85 | |||||||||||||||||

| 300QJ200-80 | 80 | 75 | 154.1 | 86.0 | 0.86 | |||||||||||||||||

| 300QJ200-100 | 100 | 90 | 183.8 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ200-120 | 120 | 100 | 204.3 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ200-140 | 140 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

| 300QJ200-160 | 160 | 140 | 277.8 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-180 | 180 | 160 | 317.5 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-200 | 200 | 185 | 367.2 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-240 | 240 | 220 | 436.6 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ320-30 | 320 | 30 | 2900 | 77 | 200 | 300loke | 45 | 380 | 94.6 | 85.0 | 0.85 | 281 | ||||||||||

| 300QJ320-60 | 60 | 90 | 183.8 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ320-90 | 90 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

| 300QJ320-120 | 120 | 160 | 317.5 | 88.0 | 0.87 | |||||||||||||||||

This well submersible pump is a pump suitable for clean water. It is strictly prohibited to dig new wells and pump dirty water containing sediment. The voltage grade of the pump is 380/50HZ, and other submersible motors with different voltage grades need to be customized. Underground cables must be waterproof cables and must be equipped with starting equipment, such as distribution boxes, etc. The starting equipment should have common comprehensive motor protection functions, such as short circuit overload protection, dephase protection, undervoltage protection, grounding protection and idling protection, etc., in order to prevent timely tripping when abnormal conditions occur. During the installation and use process, the pump must have reliable grounding. It is strictly prohibited to push and pull the switch when your hands and feet are wet. The power supply must be cut off before installation and maintenance of the pump. An obvious sign "anti-electric shock" must be set up where the pump is used. Before going down the well or installation, the motor must be filled with distilled water or non-corrosive clean cold water, and the water inlet and outlet bolts must be tightened. When testing the pump on the ground, water must be filled into the pump chamber to lubricate the rubber bearings. The instant start time shall not exceed one second to check whether the steering is correct. Pay attention to safety when the pump is upright to prevent toppling and injury. Strictly in accordance with the provisions of the pump lift and flow range, to prevent the pump with a large flow at low lift or produce a large pull at high lift, resulting in extreme wear of thrust bearings and other parts, the motor overload and burn. After the pump into the well, the measurement of the motor to the ground insulation resistance should not be less than 100MΩ. After starting, regularly observe the voltage and current, and check whether the motor winding insulation meets the requirements; if the pump storage temperature below freezing point, should be drained to prevent the water in the motor cavity from freezing and cause the motor damage due to low temperature.

The pump part is mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor part is mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand ring, water inlet section, lead cable and other components.

Awọn ẹya akọkọ ti ọja naa pẹlu:

- 1.The motor is a water-filled wet submersible three-phase asynchronous motor. The motor cavity is filled with clean water, used to cool the motor and lubricate the bearing. The pressure regulating diaphragm at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the water in the body caused by the temperature rise of the motor.

- 2. In order to prevent the sand particles from entering the motor, two sand seals are installed at the upper end of the motor shaft extension, and a sand control structure is formed by installing the sand ring.

- 3. In order to prevent the pump shaft from jumping when starting, the pump shaft is connected with the motor shaft through a coupling, and the thrust bearing is installed at the bottom of the motor.

- 4. The lubrication method of the motor and the pump bearing is water lubrication.

- 5. The stator winding of the motor adopts high quality submersible motor winding wire with high insulation performance.

- 6. The pump is designed by computer CAD, with simple structure and excellent technical performance.

(1) Igbaradi ṣaaju fifi sori:

1. Ṣayẹwo boya fifa omi inu omi ba pade awọn ipo lilo ati iwọn ti a pato ninu itọnisọna.

2. Lilo obiect ti o wuwo pẹlu iwọn ila opin ti o dọgba si iwọn ila opin ti ita ti o pọju ti fifa fifa, wiwọn boya inneldiameter ti wellbore le ni ibamu si fifa omi ti o wa ni isalẹ, ki o si wiwọn boya ijinle kanga ni ibamu pẹlu awọn ibeere fifi sori ẹrọ.

3. Ṣayẹwo boya ibi kanga jẹ mimọ ati boya omi kanga jẹ turbid. Maṣe lo fifa ina submersible lati fọ ẹrẹ fifa welor ati omi iyanrin lati yago fun ibajẹ ti tọjọ si fifa ina submersible.

4. Ṣayẹwo boya awọn ipo ti awọn welhead fifi sori dimole jẹ dara ati boya o le withstand awọn qualty ti gbogbo kuro

5. Ṣayẹwo boya awọn paati fifa submersible ti pari ati fi sori ẹrọ daradara ni ibamu si apẹrẹ apejọ ti o wa ninu iwe afọwọkọ Yọ iboju àlẹmọ naa ki o si yi asopọ pọ lati rii boya o n yi ni irọrun

6. Unscrew omi dabaru ati ki o fillthe motor iho pẹlu mọ, ti kii ipata omi (akọsilẹ. jẹ daju lati Fil o soke), ki o si Mu awọn waterscrew. Lẹhin awọn wakati 12 ti abẹrẹ omi, idabobo idabobo ti motor ko yẹ ki o kere ju 150M Q nigbati wọn wọn pẹlu tabili gbigbọn 500V.

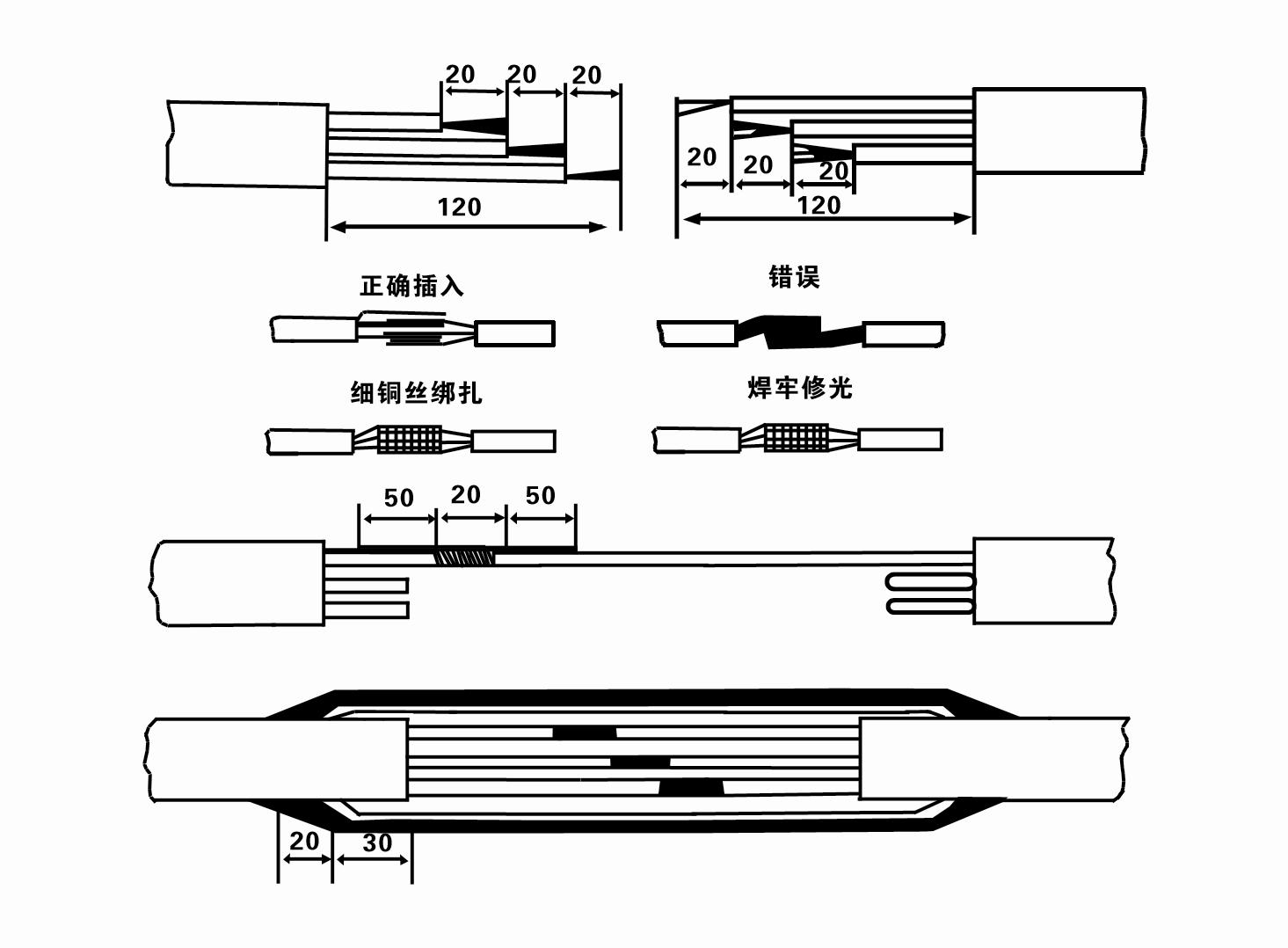

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Aworan ilana onirin okun ti a so mọ jẹ bi atẹle:

8. Lo multimeter kan lati ṣayẹwo boya awọn onirin mẹta-alakoso ti wa ni ti sopọ ati boya awọn DC resistance jẹ to iwontunwonsi.

9. Ṣayẹwo boya awọn Circuit ati transformer agbara ti wa ni apọju, ati ki o si so apọju Idaabobo yipada tabi ti o bere ẹrọ. Wo Tabili 2 fun awọn awoṣe kan pato, ati lẹhinna Tú garawa omi kan sinu fifa omi lati inu iṣan omi lati lubricate awọn bearings roba ninu fifa soke, ati lẹhinna gbe fifa ina mọnamọna submersible ni titọ ati iduroṣinṣin.Bẹrẹ (ko si ju iṣẹju kan lọ) ati ki o ṣayẹwo boya itọsọna idari ni ibamu pẹlu ami idari. Ti kii ba ṣe bẹ, paarọ eyikeyi awọn asopọ meji ti okun oni-mẹta. Lẹhinna fi àlẹmọ sori ẹrọ ki o mura lati lọ si isalẹ kanga naa. Ti a ba lo ni awọn iṣẹlẹ pataki (gẹgẹbi awọn koto, awọn koto, awọn odo, awọn adagun omi, awọn adagun omi, ati bẹbẹ lọ), fifa ina mọnamọna gbọdọ wa ni ilẹ ni igbẹkẹle.

(2) Awọn ohun elo fifi sori ẹrọ ati awọn irinṣẹ:

1. Ọkan bata ti awọn ẹwọn gbigbe fun diẹ ẹ sii ju awọn toonu meji lọ.

2. A mẹta pẹlu kan inaro iga ti ko kere ju mẹrin mita.

3. Awọn okun adiye meji (awọn okun waya) ti o le jẹ iwuwo diẹ ẹ sii ju ọkan lọ (le jẹ iwuwo ti pipe pipe ti awọn fifa omi).

4. Fi sori ẹrọ meji orisii clamps (splints).

5. Wrenches, òòlù, screwdrivers, itanna irinṣẹ ati ohun elo, ati be be lo.

(3) Fifi sori ẹrọ fifa ẹrọ itanna:

1. Aworan fifi sori ẹrọ ti fifa ina mọnamọna submersible ti wa ni afihan ni Nọmba 2. Awọn iwọn fifi sori ẹrọ pato ni a fihan ni Table 3 "Akojọ ti Awọn Iwọn fifi sori ẹrọ ti Imudanu Imọlẹ Imọlẹ".

2. Awọn ifasoke ina mọnamọna ti o wa ni isalẹ pẹlu ori ti o kere ju 30 mita ni a le gbe soke taara sinu kanga nipa lilo awọn okun ati awọn okun waya tabi awọn okun hemp miiran ti o le ni kikun iwuwo ti gbogbo ẹrọ, awọn ọpa omi, ati omi ninu awọn paipu.

3. Awọn ifasoke pẹlu ori ti o ju 30 mita lo awọn paipu irin, ati ilana fifi sori ẹrọ jẹ bi atẹle:

① Lo dimole kan lati di opin oke ti apakan fifa omi (moto ati fifa omi ti wa ni asopọ ni akoko yii), gbe e pẹlu ẹwọn ikele, ki o si sorara di e sinu kanga naa titi ti o fi fi dimole si ori kanga ki o si yọkuro ikele pq.

② Lo awọn clamps meji miiran lati di paipu kan, gbe e pẹlu ẹwọn ikele 15 cm kuro ni flange, ki o si lọ silẹ laiyara. Laarin pipe flange ati fifa flangeFi awọn roba pad ni ibi ati Mu paipu ati fifa boṣeyẹ pẹlu boluti, eso ati orisun omi washers.

③ Gbe fifa omi ti o wa ni isalẹ diẹ diẹ, yọ idimu ti o wa ni opin oke ti fifa omi, di okun naa ṣinṣin si paipu omi pẹlu teepu ike kan, ki o si so o lọra titi di igba ti a fi dimu si ibi kanga.

④ Lo ọna kanna lati di gbogbo awọn paipu omi sinu kanga.

⑤ Lẹhin ti okun-jade ti a ti sopọ si iyipada iṣakoso, o ti sopọ si ipese agbara mẹta-alakoso.

(4) Awọn nkan lati ṣe akiyesi lakoko fifi sori ẹrọ:

1. Ti o ba ti a jamming lasan ti wa ni ri nigba ti fifa ilana, tan tabi fa omi paipu lati bori awọn jamming ojuami. Ti ọpọlọpọ awọn igbese ko ba ṣiṣẹ, jọwọ maṣe fi agbara mu fifa soke lati yago fun ibajẹ si fifa ina submersible ati kanga.

2. Lakoko fifi sori ẹrọ, paadi rọba yẹ ki o gbe ni flange ti paipu kọọkan ati ki o ni wiwọ paapaa.

3. Nigbati fifa omi ba ti wa ni isalẹ sinu kanga, o yẹ ki o gbe si arin paipu kanga naa lati ṣe idiwọ fifa soke lati ṣiṣẹ lodi si odi kanga fun igba pipẹ, ti o mu ki fifa soke lati gbọn ati pe ọkọ ayọkẹlẹ lati gba ati sisun. .

4. Ṣe ipinnu ijinle ti fifa omi si isalẹ ti kanga gẹgẹbi iyanrin ti nṣan ati awọn ipo silt ti kanga. Ma ṣe sin fifa soke sinu ẹrẹ. Ijinna lati fifa omi si isalẹ ti kanga ni gbogbogbo ko kere ju awọn mita 3 (wo Nọmba 2).

5. Ijinle titẹsi omi ti fifa omi yẹ ki o jẹ ko kere ju awọn mita 1-1.5 lati ipele omi ti o ni agbara si oju omi ti nwọle (wo Nọmba 2). Bibẹẹkọ, awọn bearings fifa omi le ni irọrun bajẹ.

6. Gbigbe ti fifa omi ko le jẹ kekere ju. Bibẹẹkọ, àtọwọdá ẹnu-ọna nilo lati fi sori ẹrọ lori opo gigun ti omi kanga lati ṣakoso ṣiṣan fifa ni aaye ṣiṣan ti o ni iwọn lati ṣe idiwọ mọto lati ni apọju ati sisun nitori awọn iwọn sisan nla.

7. Nigbati fifa omi ba n ṣiṣẹ, ṣiṣan omi yẹ ki o wa ni ilọsiwaju ati paapaa, lọwọlọwọ yẹ ki o wa ni iduroṣinṣin (labẹ awọn ipo iṣẹ ti a ṣe ayẹwo, ni gbogbo igba ko ju 10% ti iṣiro lọwọlọwọ), ati pe ko yẹ ki o jẹ gbigbọn tabi ariwo. Ti aiṣedeede eyikeyi ba wa, ẹrọ naa yẹ ki o da duro lati wa idi ti o fa ati imukuro rẹ.

8. Nigbati fifi sori, san ifojusi si awọn eto ti awọn motor grounding waya (wo Figure 2). Nigbati paipu omi jẹ paipu irin, darí rẹ lati dimole kanga; nigbati paipu omi jẹ paipu ike kan, darí rẹ lati aami ilẹ ti fifa ina.

- 1.After the submersible pump is installed, check the insulation resistance and three-phase conduction from the switch again, check whether the instrument and the connection of the start equipment are wrong, if there is no problem, the trial machine can be started, and observe whether the indicator readings of the instrument exceed the rated voltage and current specified on the nameplate after the start, and observe whether the pump has noise and vibration phenomenon. If everything is normal, it can be put into operation.

- 2. After the first operation of the pump for four hours, the motor should be shut down to test the thermal insulation resistance quickly, and its value should not be less than 0.5 megaohm.

- 3. After the pump is shut down, it should be started after five minutes to prevent the water column in the pipe from being completely reflowed and causing excessive motor current and burnout.

- 4.After the pump is running normally, in order to prolong its service life, it is necessary to check the power supply voltage, running current and insulation resistance regularly to see if they are normal.If the following conditions are found, the equipment should be shut down immediately to troubleshoot.

- (1)Under the rated working conditions, the current exceeds 20% of the rated value.

- (2)The dynamic water level drops to the inlet part, resulting in intermittent water discharge.

- (3)The submersible pump vibrates violently or emits noisy noise.

- (4)The power supply voltage is lower than 340 volts.

- (5)A fuse is burned out.

- (6)The water pipe is damaged.

- (7)The thermal insulation resistance of the motor to the ground is less than 0.5 megaohm.

- These inspections will help to ensure the normal operation of the pump, improve its reliability and stability, so as to ensure its durability and service life.

- 5.unit disassembly:

- - untie cable rope, remove the pipeline part, remove the wire plate.

- - dabaru boluti omi, fi omi sinu iyẹwu motor.

- - remove the filter, loose the fixed screw on the coupling fixed motor shaft.

- - screw down the bolt connected with the motor at the inlet junction, separate the pump and the motor (pay attention to the unit cushion when separating, prevent the bending of the pump shaft)

- - pump disassembly sequence is: (see figure 1) inlet junction, impeller, guide housing, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, avoid bending the pump shaft and each part in the disassembly process.

- - motor disassembly process is: (see figure 1) place the motor on the platform, remove the nut, base, shaft head lock nut, thrust plate, key, lower guide bearing seat, double head bolt from the bottom of the motor in turn, then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- - unit assembly: Before assembly, the rust and dirt of the parts should be cleaned, and the mating surfaces and fasteners should be coated with sealant. Then they should be assembled in the reverse order of disassembly (the up and down momentum of the motor shaft is about 1 mm after assembly). After assembly, the coupling should be flexible, and then the filter screen test machine.

- 6.The submersible pump should be dismantled and repaired according to Article 5 for each operation year, or less than one year, but the submersible time has reached two years, and the worn parts should be replaced.

1, gbe omi jade ninu iho moto (paapaa ni igba otutu lati ṣe idiwọ mọto lati didi), ki o di okun naa daradara.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, gun-igba lilo yẹ ki o san ifojusi si ipata idena ti submersible bẹtiroli.

- Impeller

- Ọwọ ọpa

- Roba ọpa apo

-

Iwọn edidi

01 Gbigbe omi kanga ti o jinlẹ

02 Giga-jinde omi ipese

03 oke omi ipese

04 omi ẹṣọ

05 Ogbin irigeson

06 irigeson ọgba

07 odo omi gbigbemi

08 omi inu ile