The motor winding adopts special water-resistant wire for frequency conversion winding, which has excellent characteristics such as high frequency stamping resistance, pulse peak voltage stamping resistance and high temperature aging resistance. The frequency conversion winding design ensures the long-term stable conversion operation of the motor between 1HZ-50HZ, making the frequency conversion deep well pump more energy saving and longer service life.

The product is supplied by three-phase AC 380V (tolerance ± 5%), 50HZ (tolerance ± 1%). Applicable water quality conditions include water temperature not exceeding 20 °C, solid impurities content (mass ratio) is not greater than 0.01%, PH value (pH) is 6.5-8.5, hydrogen sulfide content is not more than 1.5mg/L, chloride ion content is not more than 400mg/L. The motor adopts closed or water-filled wet structure. Before use, the internal chamber needs to be filled with clean water to prevent virtual filling. The pump needs to be completely immersed in water, the penetration depth shall not exceed 70m, and the distance from the bottom of the well shall not be less than 3m. The water inlet of the well shall meet the water output and continuous operation requirements of the pump, and the output of the pump shall be controlled at 0.7-1.2 times of the rated flow. The pump shall be used vertically, and the pump must be matched with the cable according to the requirements and equipped with external overload protection device. It is strictly prohibited to conduct no-load test of the pump, and it is necessary to avoid operation without water.

| Mionsamhail | Sreabhadh (m3/u) | Ceann (m) |

Rotatingspeed(change/point) | Caidéal Uisce(%) | Asraon trastomhas (mm) |

Infheidhme go maith trastomhas (mm) |

Rátáilte cumhacht (KW) |

Rátáilte voltas(V) |

Rátáilte sruth(A) |

Mótaréifeachtúlacht (%) | power factorcosφ | Aonad Uasmhéid gathach(mm) |

Athmharc | |||||||||

| 150QJ5-100 | 5 | 100 | 2850 | 58 | 40 | 150 | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ5-150 | 5 | 150 | 2850 | 58 | 40 | 150 thuas | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ5-200 | 200 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ5-250 | 250 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ5-300 | 300 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ10-50 | 10 | 50 | 2850 | 63 | 50 | 150os cionn | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ10-66 | 66 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ10-78 | 78 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ10-84 | 84 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ10-91 | 91 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ10-100 | 100 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ10-128 | 128 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ10-150 | 150 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ10-200 | 200 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ10-250 | 250 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ10-300 | 300 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ15-33 | 15 | 33 | 2850 | 63 | 50 | 150os cionn | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ15-42 | 42 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ15-50 | 50 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ15-60 | 60 | 5.5 | 13.74 | 76 | 0.8 | |||||||||||||||||

| 150QJ15-65 | 65 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ15-72 | 72 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ15-81 | 81 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ15-90 | 90 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ15-98 | 98 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ15-106 | 106 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ15-114 | 114 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ15-130 | 130 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ15-146 | 146 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ15-162 | 162 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ15-180 | 180 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 150os cionn | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ20-33 | 33 | 3 | 7.9 | 74.0 | 0.78 | |||||||||||||||||

| 150QJ20-39 | 20 | 39 | 2850 | 64 | 50 | 150os cionn | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ20-52 | 52 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ20-65 | 65 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ20-78 | 78 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ20-91 | 91 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ20-98 | 98 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ20-104 | 104 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ20-111 | 111 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ20-130 | 130 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-143 | 143 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-156 | 156 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-182 | 182 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ25-24 | 25 | 24 | 2850 | 64 | 65 | 150os cionn | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ25-32 | 32 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ25-40 | 40 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ25-48 | 48 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ25-56 | 56 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ25-64 | 64 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ25-72 | 72 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ25-77 | 77 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ25-84 | 84 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ25-96 | 96 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ25-104 | 104 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-110 | 110 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-120 | 120 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-128 | 128 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-136 | 136 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ25-154 | 154 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ32-18 | 32 | 18 | 2850 | 66 | 80 | 150os cionn | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ32-24 | 24 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ32-30 | 30 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ32-36 | 36 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ32-42 | 32 | 42 | 2850 | 66 | 80 | 150os cionn | 7.5 | 380 | 18.5 | 77.0 | 0.8 | 143 | ||||||||||

| 150QJ32-54 | 54 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ32-66 | 66 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ32-72 | 72 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-84 | 84 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-90 | 90 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-96 | 96 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-114 | 114 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ40-16 | 40 | 16 | 2850 | 66 | 80 | 150os cionn | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ40-24 | 24 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ40-30 | 30 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ40-40 | 40 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ40-48 | 48 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ40-56 | 56 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ40-64 | 64 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ40-72 | 72 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ40-80 | 80 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ40-96 | 96 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ50-16 | 50 | 16 | 2850 | 65 | 80 | 150os cionn | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ50-22 | 22 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ50-28 | 28 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ50-34 | 34 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ50-40 | 40 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ50-46 | 46 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ50-52 | 52 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ50-57 | 57 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ50-74 | 74 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ50-80 | 80 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ63-12 | 63 | 12 | 2850 | 60 | 80 | 150os cionn | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ63-18 | 18 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ63-30 | 30 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ63-36 | 36 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ63-42 | 63 | 42 | 2850 | 60 | 80 | 150os cionn | 13 | 380 | 30.87 | 79.0 | 0.81 | 143 | ||||||||||

| 150QJ63-48 | 48 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ63-54 | 54 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ15-220 | 15 | 220 | 2850 | 50 | 150os cionn | 18.5 | 380 | 43.12 | 143 | |||||||||||||

| 150QJ15-260 | 260 | 20 | 49.7 | |||||||||||||||||||

| 150QJ15-300 | 300 | 25 | 56.5 | |||||||||||||||||||

| 150QJ20-210 | 20 | 210 | 2850 | 50 | 150os cionn | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ20-240 | 240 | 25 | 56.5 | |||||||||||||||||||

| 150QJ20-290 | 290 | 30 | 66.6 | |||||||||||||||||||

| 150QJ25-175 | 25 | 175 | 2850 | 65 | 150os cionn | 20 | 49.7 | 143 | ||||||||||||||

| 150QJ25-200 | 200 | 30 | 66.6 | |||||||||||||||||||

| 150QJ25-290 | 290 | 37 | 82.1 | |||||||||||||||||||

| 150QJ32-120 | 32 | 120 | 2850 | 80 | 150os cionn | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ32-132 | 132 | 25 | 56.5 | |||||||||||||||||||

| 150QJ32-156 | 156 | 30 | 66.6 | |||||||||||||||||||

| 150QJ32-190 | 190 | 37 | 82.1 | |||||||||||||||||||

| 150QJ32-240 | 240 | 45 | 96.9 | |||||||||||||||||||

| 150QJ40-110 | 40 | 110 | 2850 | 80 | 150os cionn | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ40-121 | 121 | 25 | 56.5 | |||||||||||||||||||

| 150QJ40-143 | 143 | 30 | 66.6 | |||||||||||||||||||

| 150QJ40-176 | 176 | 37 | 82.1 | |||||||||||||||||||

| 150QJ40-220 | 220 | 45 | 96.9 | |||||||||||||||||||

| 150QJ50-100 | 50 | 100 | 2850 | 80 | 150os cionn | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ50-110 | 110 | 25 | 56.5 | |||||||||||||||||||

| 150QJ50-130 | 130 | 30 | 66.6 | |||||||||||||||||||

| 150QJ50-160 | 160 | 37 | 82.1 | |||||||||||||||||||

| 150QJ50-200 | 200 | 45 | 96.9 | |||||||||||||||||||

This well submersible pump is a pump suitable for clean water. It is strictly prohibited to pump sediment and turbid water in new wells. The voltage level of the pump is 380/50HZ. Other voltage levels of the submersible motor need to be customized. Underground cables must be waterproof and must be equipped with starting equipment, such as distribution box, etc. The starting equipment should have common motor comprehensive protection functions, such as short circuit overload protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. Under abnormal circumstances, the protection device should be tripped in time. In the process of installation and use, the pump must be reliably grounded. It is prohibited to push and pull the switch when the hands and feet are wet. The power must be cut off before installation and maintenance of the pump. The place where the pump is used must set up a clear "anti-electric shock" mark. Before going down the well or installation, the motor must be filled with distilled water or non-corrosive cool water, and the water inlet and outlet screws must be tightened. When testing the pump, water must be injected into the pump chamber to lubricate the rubber bearings. The instant start shall not exceed one second to check whether the direction is correct. It is necessary to pay attention to the safety of the pump when it is erected to prevent it from toppling and hurting people. Strictly in accordance with the provisions of the pump lift and flow range of use, so as not to have a large flow in the low lift pump or a large pull in the high lift, causing extreme wear of thrust bearings and other components, resulting in motor overload burn. After the pump into the well, the measurement of the motor and ground insulation resistance, not less than 100M. After the start, regular observation of voltage and current, and check whether the motor winding insulation meets the requirements; if the pump storage location temperature is below freezing, storage should discharge the water in the motor cavity, to prevent the water in the motor cavity due to low temperature and freeze damage the motor.

Réamhrá gearr ar an struchtúr: tá cuid caidéil comhdhéanta den chuid is mó de seafta caidéil, impeller, bhlaosc atreoraithe, imthacaí rubair, comhlacht comhla seiceála (páirteanna roghnacha) agus comhpháirteanna eile. Tá an chuid mótair comhdhéanta den chuid is mó de bhonn, scannán a rialaíonn brú, imthacaí sá, pláta sá, suíochán treorach níos ísle, stator, rotor, suíochán treorach uachtarach, fáinne gaineamh, alt inlet uisce, cábla agus comhpháirteanna eile.

Áirítear ar phríomhghnéithe an táirge:

1.The motor is a water-filled wet submersible three-phase asynchronous motor, the motor cavity is full of clean water, used to cool the motor and lubricate the bearing, the pressure regulating film at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the water inside the body caused by the change of the temperature rise of the motor.

2.In order to prevent the sand in the well water from entering the motor, the upper end of the motor shaft is equipped with two oil seals, and a sand ring is installed to form a sand prevention structure.

3.In order to prevent the pump shaft from running up when starting, the pump shaft and the motor shaft are connected by a coupling, and an upper thrust bearing is installed at the lower part of the motor.

4.The lubrication of the motor and the pump bearing is water lubrication.

5.The motor stator winding is made of high quality submersible motor winding wire, with high insulation performance.

6.The pump is designed by computer CAD, with simple structure and good technical performance.

(1) Ullmhúchán roimh shuiteáil:

1. Seiceáil an gcomhlíonann an caidéal báite na coinníollacha úsáide agus an raon feidhme a shonraítear sa lámhleabhar.

2. Ag baint úsáide as obiect trom le trastomhas comhionann le trastomhas seachtrach uasta an chaidéil báite, tomhais an féidir le trastomhas inneldiameter an tobair an caidéal báite a fheistiú, agus tomhas an gcomhlíonann doimhneacht an tobair na ceanglais suiteála.

3. Seiceáil an bhfuil tolladh an tobair glan agus an bhfuil uisce an tobair suaite. Ná húsáid caidéal leictreach intumtha riamh chun láib agus gaineamh an chaidéil welor a ní chun damáiste roimh am a sheachaint don chaidéal leictreach intumtha.

4. Seiceáil an bhfuil suíomh an clamp suiteála welhead oiriúnach agus an féidir leis cáilíocht an aonaid iomláin a sheasamh

5. Seiceáil an bhfuil na comhpháirteanna caidéil báite críochnaithe agus suiteáilte i gceart de réir an léaráid tionóil sa lámhleabhar Bain an scáileán scagaire agus rothlaigh an cúpláil féachaint an rothlaíonn sé go solúbtha

6. Díscriú an scriú uisce agus líon an cuas mótair le huisce glan, neamhchreimneach (tabhair faoi deara. Bí cinnte é a chomhdú), ansin déan an scriú uisce níos doichte. Tar éis 12 uair an chloig d'instealladh uisce, níor chóir go mbeadh friotaíocht inslithe an mhótair níos lú ná 150M Q nuair a thomhaistear é le tábla croith 500V.

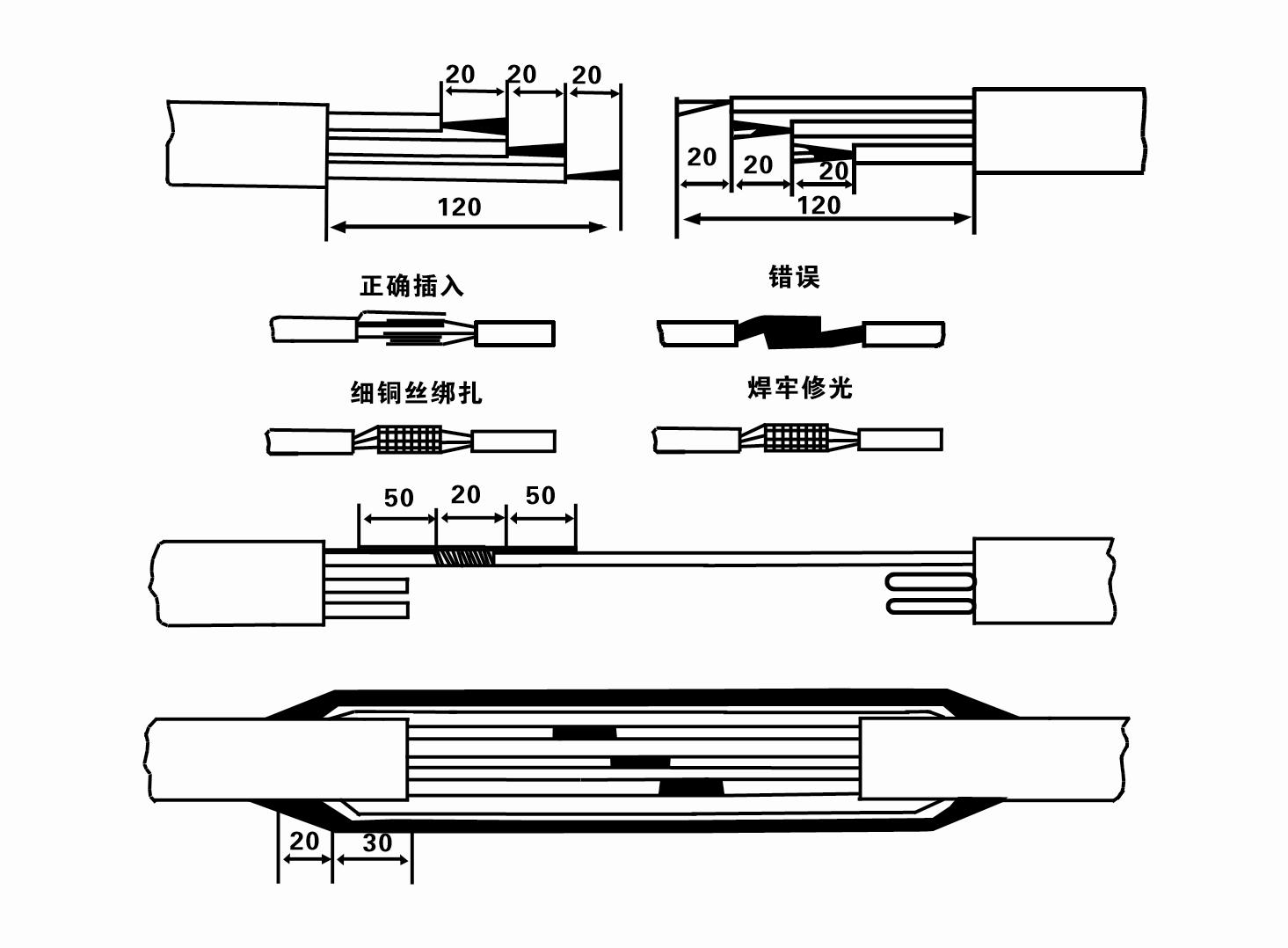

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Is é seo a leanas an léaráid próiseas sreangú cábla ceangailte:

8. Bain úsáid as multimeter chun a sheiceáil an bhfuil na sreanga trí chéim ceangailte agus an bhfuil an fhriotaíocht DC cothromaithe thart.

9. Seiceáil an bhfuil an ciorcad agus an cumas claochladáin ró-ualach, agus ansin an lasc cosanta ró-ualach nó an trealamh tosaigh a nascadh. Féach Tábla 2 le haghaidh samhlacha sonracha, agus ansin Doirt buicéad uisce isteach sa chaidéal uisce ón asraon caidéil uisce chun na imthacaí rubair a lubricadh sa chaidéal, agus ansin cuir an caidéal leictreach intumtha ina seasamh agus go seasta.Start (gan níos mó ná soicind amháin) agus seiceáil an bhfuil an treo stiúrtha comhsheasmhach leis an gcomhartha stiúrtha. Mura bhfuil, babhtáil aon dá chónaisc den chábla trí phas. Ansin shuiteáil an scagaire agus ullmhaigh tú chun dul síos ar an tobar. Má úsáidtear é in ócáidí speisialta (cosúil le díoga, díoga, aibhneacha, locháin, locháin, etc.), ní mór an caidéal leictreach a thalamh go hiontaofa.

(2) Trealamh agus uirlisí suiteála:

1. Péire amháin de slabhraí ardaithe ar feadh níos mó ná dhá tonna.

2. Tripod le airde ingearach nach lú ná ceithre mhéadar.

3. Dhá rópa crochta (rópaí sreang) ar féidir leo meáchan níos mó ná tonna amháin a iompróidh (is féidir meáchan sraith iomlán caidéil uisce a iompróidh).

4. Suiteáil dhá phéire teanntáin (splints).

5. Wrenches, casúir, scriúirí, uirlisí leictreacha agus ionstraimí, etc.

(3) Suiteáil caidéil leictreacha:

1. Taispeántar léaráid suiteála an chaidéil leictreacha intumtha i bhFíor 2. Taispeántar na toisí suiteála sonracha i dTábla 3 "Liosta Toisí Suiteála an Chaidéil Leictreach Intumtha".

2. Is féidir caidéil leictreacha báite le ceann níos lú ná 30 méadar a ardú go díreach isteach sa tobar ag baint úsáide as píobáin agus rópaí sreang nó rópaí cnáib eile ar féidir leo meáchan iomlán an mheaisín iomláin, píopaí uisce, agus uisce sna píopaí a iompar.

3. Úsáideann caidéil le ceann níos mó ná 30 méadar píopaí cruach, agus is é seo a leanas an t-ord suiteála:

① Bain úsáid as clamp chun ceann uachtarach an chaidéil uisce a chlampáil (tá an mótar agus an caidéal uisce ceangailte ag an am seo), ardaigh sé le slabhra crochta, agus ceangail go mall isteach sa tobar é go dtí go gcuirfidh tú an clamp ar cheann an tobair agus bain an slabhra crochta.

② Bain úsáid as péire teanntáin eile chun píopa a chlampáil, é a ardú le slabhra crochta 15 cm ar shiúl ón flange, agus é a ísliú go mall. Idir flange píopa agus flange caidéil Cuir an ceap rubair in áit agus déan an píopa agus an caidéal a dhéanamh níos doichte go cothrom le boltaí, cnónna agus leicneáin earraigh.

③ Ardaigh an caidéal báite beagán, bain an clamp ar thaobh uachtarach an chaidéil uisce, ceangail an cábla go daingean leis an bpíobán uisce le téip plaisteach, agus é a cheangal go mall síos go dtí go gcuirtear an clamp ag ceann an tobair.

④ Bain úsáid as an modh céanna chun na píopaí uisce go léir a cheangal isteach sa tobar.

⑤ Tar éis an cábla luaidhe-amach a bheith ceangailte leis an lasc rialaithe, tá sé ceangailte leis an soláthar cumhachta trí phas.

(4) Rudaí le tabhairt faoi deara le linn na suiteála:

1. Má aimsítear feiniméan jamming le linn an phróisis caidéalaithe, cas nó tarraing an píopa uisce chun an pointe jamming a shárú. Mura n-oibríonn bearta éagsúla fós, le do thoil Ná cuir an caidéal síos chun damáiste a sheachaint don chaidéal leictreach intumtha agus don tobar.

2. Le linn na suiteála, ba chóir eochaircheap rubair a chur ar flange gach píopa agus é a cheangal go cothrom.

3. Nuair a íslítear an caidéal uisce isteach sa tobar, ba chóir é a chur i lár an phíobáin tobair chun an caidéal a chosc ó bheith ag rith i gcoinne bhalla an tobair ar feadh i bhfad, rud a fhágann go mbeidh an caidéal ag creathadh agus an mótar a scuabadh agus a dhó. .

4. Déan doimhneacht an chaidéil uisce go bun an tobair a chinneadh de réir coinníollacha sreafa gaineamh agus siolta an tobair. Ná cuir an caidéal sa láib. De ghnáth ní lú ná 3 mhéadar an fad ón gcaidéal uisce go bun an tobair (féach Fíor 2).

5. Níor cheart go mbeadh doimhneacht iontrála uisce an chaidéil uisce níos lú ná 1-1.5 méadar ón leibhéal uisce dinimiciúil go dtí an nód inlet uisce (féach Fíor 2). Seachas sin, féadfar damáiste a dhéanamh go héasca ar imthacaí an chaidéil uisce.

6. Ní féidir le hardaitheoir an chaidéil uisce a bheith ró-íseal. Seachas sin, is gá comhla geata a shuiteáil ar phíblíne uisce an tobair chun sreabhadh an chaidéil ag an bpointe sreafa rátáilte a rialú chun an mótar a chosc ó ró-ualach agus a dhó mar gheall ar rátaí sreafa móra.

7. Nuair a bhíonn an caidéal uisce ag rith, ba cheart go mbeadh an t-aschur uisce leanúnach agus fiú, ba cheart go mbeadh an sruth cobhsaí (faoi choinníollacha oibre rátáilte, go ginearálta gan níos mó ná 10% den sruth rátáilte), agus níor cheart go mbeadh aon chreathadh nó torann ann. Má tá aon neamhghnáchaíocht ann, ba chóir an meaisín a stopadh chun an chúis a fháil amach agus é a dhíchur.

8. Nuair a shuiteáil tú, tabhair aird ar shocrú na sreinge talún mótair (féach Fíor 2). Nuair is píopa cruach é an píopa uisce, déan é a threorú as clamp an tobair; nuair is píopa plaisteach an píopa uisce, é a threorú ó mharc talún an chaidéil leictreach.

1.submersible pump installation is complete, re-check the insulation resistance and three-phase conduction from the switch, check the instrument and start the equipment connection error, if there is no problem, can start the trial, after the start of the instrument indicating readings whether more than the nameplate stipulated rated voltage and current, observe the pump noise and vibration phenomenon, everything is normal can be put into operation.

2.pump operation for the first four hours, should be shut down quickly test the thermal insulation resistance of the motor, the value should not be less than 0.5 megaohm.

3.pump shutdown, should be started after an interval of five minutes, to prevent the water column in the pipe has not completely reflux caused by excessive motor current and burnout.

4.pump into normal operation, in order to prolong its service life, to check the supply voltage, working current and insulation resistance is normal, if found the following situation, should immediately shut down troubleshooting.

1.in the rated condition, the current is more than20%.

2.dynamic water level to the water inlet section, causing intermittent water.

3.submersible pump severe vibration or noise.

4.supply voltage is lower than 340 volts.

5.fuse burned out a phase.

6.water pipe damage.

7.motor to the thermal insulation resistance is less than 0.5 megaohm. 5. The product is a pump unit with easy disassembly function, with simple steps of disassembly, so that users can easily maintain and clean. The disassembly steps include unraveling the cable rope, taking down the pipeline part and the line protection plate, unloosening the water discharge bolt, excluding all the water in the motor chamber, removing the filter and loosening the coupling fixing screw fixing the motor shaft, unscrewing the bolt connecting the water inlet section and the motor, separating the pump and the motor (note that the unit should be leveled when separating to prevent the bending of the pump shaft), the disassembly sequence of the pump is: water inlet section, impeller, shunt shell, impeller, and cleaning the valve body. When disassembling the impeller, use special tools to loosen the conical sleeve fixing the impeller. In the whole disassembly process, avoid bending the pump shaft and damaging various parts. The disassembly process of the motor is: put the motor on the platform, and remove the nuts, base, shaft head lock nut, thrust plate, key, and lower guide rail from the bottom of the motor in order. Bearing seat, tie rod bolt, and then take out the rotor (be careful not to damage the wiring harness) and finally remove the connecting section and the upper guide bearing seat. Before assembling the unit, the rust and dirt of each part should be cleaned, and the sealant should be coated on each mating surface and fastener, and then the assembly should be carried out in reverse order according to the disassembly (the movement of the motor shaft after assembly is about 1 mm). After the assembly is completed, the coupling should be flexibly rotated, and then the filter should be put on for machine test. This pump unit is not only convenient and easy to use, but also has detailed instructions, which provides users with convenient maintenance experience. 6. Submersible electric pump every operation for one year, or less than one year but the diving time has reached two years, should be put out of the well according to Article 5 for disassembly and maintenance, and replace the worn parts.

1, cuir an t-uisce amach sa chuas mótair (go háirithe sa gheimhreadh chun an mótar a chosc ó reo), agus an cábla a cheangal go maith.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, ba chóir go fadtéarmach aird a thabhairt ar chosc meirge na caidéil báite.

- Impeallóir

- Muinchille seafta

- Muinchille seafta rubair

-

Fáinne séalaithe

01 Iontógáil uisce domhain tobair

02 Soláthar uisce ard-ardú

03 soláthar uisce sléibhe

04 túr uisce

05 Uisciúcháin talmhaíochta

06 uisciúcháin gairdín

07 iontógáil uisce abhann

08 uisce tí