The variable frequency winding design ensures the motor's long-term smooth conversion operation between 1HZ-50HZ, energy saving and longer service life. This product stands out for its advanced technology and efficient performance, which can achieve energy-saving and environmentally friendly operation, while ensuring the stability and reliability of the motor for long-term use. Not only that, its design makes the product with a longer life, bringing more value to users. Whether in home applications or industrial fields, this motor can provide you with excellent performance to meet a variety of needs.

1,Power supply: three-phase AC 380V (tolerance + / - 5%), 50HZ (tolerance + / - 1%).

2, kakovost vode:

(1) water temperature is not higher than 20 °C;

(2) vsebnost trdnih nečistoč (masno razmerje) ni večja od 0,01 %;

(3) PH vrednost (pH) 6,5-8,5;

(4) vsebnost vodikovega sulfida ni večja od 1,5 mg/l;

(5) vsebnost kloridnih ionov ni večja od 400 mg/L.

3, the motor is a closed or water-filled wet structure, before use the submersible motor cavity must be full of clean water, to prevent false full, and then tighten the water injection, air release bolts, otherwise not allowed to use

4, the submersible pump must be completely submerged in the water, the diving depth is not greater than 70m, the bottom of the submersible pump from the bottom of the well is not less than 3m.

5, mora biti pretok vode iz vodnjaka sposoben doseči izhod vode potopne črpalke in neprekinjeno delovanje mora biti izhod vode potopne črpalke nadzorovan pri 0,7-1,2-kratnem nazivnem pretoku.

6, vodnjak mora biti raven, potopne črpalke ni mogoče uporabiti ali odložiti, samo navpična uporaba.

7, mora biti potopna črpalka usklajena s kablom v skladu z zahtevami in zunanjo zaščitno napravo pred preobremenitvijo.

8, the pump is strictly prohibited without water no-load test machine.

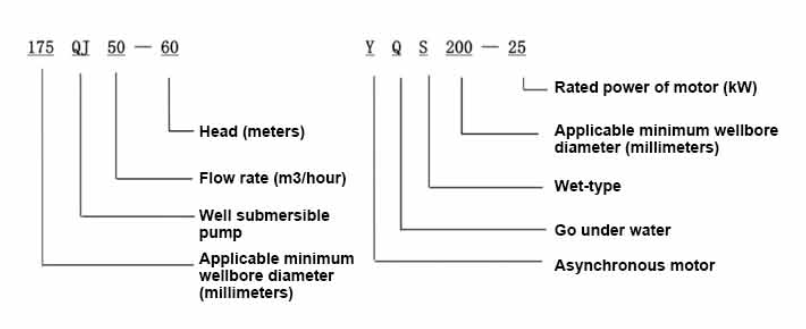

| Model | Pretok (m3/h) | glava (m) |

Hitrost vrtenja (sprememba/točka) |

Črpalka za vodo(%) | Izhod premer (mm) |

Uporabno dobro premer (mm) |

Ocenjeno moč (KW) |

Ocenjeno napetost (V) |

Ocenjeno tok (A) |

Motorna učinkovitost (%) | power factorcosφ | Enota Največja radialna velikost (mm) |

Opomba | |||||||||

| 135QJ5-34 | 5 | 34 | 2850 | 40 | 135nad | 1.5 | 380 | 4.23 | 128 | |||||||||||||

| 135QJ5-51 | 51 | 2.2 | 6.03 | |||||||||||||||||||

| 135QJ5-68 | 68 | 3 | 8.01 | |||||||||||||||||||

| 135QJ5-85 | 85 | 4 | 10.53 | |||||||||||||||||||

| 135QJ5-102 | 102 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ5-119 | 119 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ5-240 | 240 | 11 | 26.28 | |||||||||||||||||||

| 135QJ5-280 | 5 | 280 | 2850 | 40 | 135nad | 13 | 380 | 30.87 | 128 | |||||||||||||

| 135QJ5-320 | 320 | 15 | 35.62 | |||||||||||||||||||

| 135QJ10-24 | 10 | 24 | 2850 | 50 | 135nad | 1.5 | 380 | 4.23 | 128 | |||||||||||||

| 135QJ10-32 | 32 | 2.2 | 6.03 | |||||||||||||||||||

| 135QJ10-48 | 48 | 3 | 8.01 | |||||||||||||||||||

| 135QJ10-56 | 56 | 4 | 10.53 | |||||||||||||||||||

| 135QJ10-72 | 72 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ10-80 | 80 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ10-104 | 104 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ10-120 | 120 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ10-136 | 136 | 9.2 | 22.7 | |||||||||||||||||||

| 135QJ10-180 | 180 | 11 | 26.28 | |||||||||||||||||||

| 135QJ10-210 | 210 | 13 | 30.87 | |||||||||||||||||||

| 135QJ10-240 | 240 | 15 | 35.62 | |||||||||||||||||||

| 135QJ10-300 | 300 | 18.5 | 43.12 | |||||||||||||||||||

| 135QJ15-36 | 15 | 36 | 2850 | 50 | 135nad | 2.2 | 380 | 6.03 | 128 | |||||||||||||

| 135QJ15-39 | 39 | 3 | 8.01 | |||||||||||||||||||

| 135QJ15-46 | 46 | 4 | 10.53 | |||||||||||||||||||

| 135QJ15-52 | 52 | 4 | 10.53 | |||||||||||||||||||

| 135QJ15-59 | 59 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ15-65 | 65 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ15-78 | 78 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ15-91 | 91 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ15-104 | 104 | 9.2 | 22.7 | |||||||||||||||||||

| 135QJ15-120 | 120 | 11 | 26.28 | |||||||||||||||||||

| 135QJ15-142 | 142 | 13 | 30.87 | |||||||||||||||||||

| 135QJ15-162 | 162 | 15 | 35.62 | |||||||||||||||||||

| 135QJ15-200 | 200 | 18.5 | 43.12 | |||||||||||||||||||

| 135QJ20-16 | 20 | 16 | 2850 | 50 | 135above | 2.2 | 380 | 6.03 | 128 | |||||||||||||

| 135QJ20-24 | 24 | 3 | 8.01 | |||||||||||||||||||

| 135QJ20-32 | 32 | 4 | 10.53 | |||||||||||||||||||

| 135QJ20-40 | 40 | 4 | 10.53 | |||||||||||||||||||

| 135QJ20-48 | 48 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ20-56 | 56 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ20-64 | 64 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ20-72 | 72 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ20-80135QJ20-100 | 80 | 9.2 | 22.7 | |||||||||||||||||||

| 100 | 11 | 26.28 | ||||||||||||||||||||

| 135QJ20-120 | 120 | 13 | 30.87 | |||||||||||||||||||

| 135QJ20-136 | 136 | 15 | 35.62 | |||||||||||||||||||

| 135QJ20-168135QJ25-12 | 168 | 18.5 | 43.12 | |||||||||||||||||||

| 25 | 12 | 2850 | 65 | 135nad | 2.2 | 380 | 6.03 | 128 | ||||||||||||||

| 135QJ25-18 | 18 | 3 | 8.01 | |||||||||||||||||||

| 135QJ25-24 | 24 | 4 | 10.53 | |||||||||||||||||||

| 135QJ25-30 | 30 | 4 | 10.53 | |||||||||||||||||||

| 135QJ25-36 | 36 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ25-48 | 48 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ25-60 | 60 | 9.2 | 22.7 | |||||||||||||||||||

| 135QJ25-82 | 82 | 11 | 26.28 | |||||||||||||||||||

| 135QJ25-97 | 97 | 13 | 30.87 | |||||||||||||||||||

| 135QJ25-110 | 110 | 15 | 35.62 | |||||||||||||||||||

| 135QJ25-130 | 130 | 18.5 | 43.12 | |||||||||||||||||||

| 135QJ32-24 | 32 | 24 | 2850 | 80 | 135nad | 4 | 380 | 10.53 | 128 | |||||||||||||

| 135QJ32-30 | 30 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ32-42 | 42 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ32-54 | 54 | 9.2 | 22.7 | |||||||||||||||||||

| 135QJ32-68 | 68 | 11 | 26.28 | |||||||||||||||||||

| 135QJ32-80 | 80 | 13 | 30.87 | |||||||||||||||||||

| 135QJ32-92 | 92 | 15 | 35.62 | |||||||||||||||||||

| 135QJ32-104 | 104 | 18.5 | 43.12 | |||||||||||||||||||

| 135QJ40-46 | 40 | 46 | 2850 | 80 | 135nad | 11 | 380 | 26.28 | 128 | |||||||||||||

| 135QJ40-54 | 54 | 13 | 30.87 | |||||||||||||||||||

| 135QJ40-62 | 62 | 15 | 35.62 | |||||||||||||||||||

| 135QJ40-84 | 84 | 18.5 | 43.12 | |||||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, strogo v skladu z določbami dvigala črpalke, obseg uporabe pretoka, za preprečevanje nizkega pretoka ali visokega dviga črpalne sile, potisni ležaj in drugi deli obrabe, preobremenitev motorja zgorela 6, po črpalki navzdol vodnjak, meritev izolacijske upornosti motorja do tal ne sme biti manjša od 100M, po začetku opazovanja napetosti in toka, preverite izolacijo navitja motorja, ali je v skladu z zahtevami; temperatura na mestu shranjevanja črpalke, če je nižja od ledišča, je treba vodo v votlini motorja posušiti, preprečiti poškodbe vodnega ledu v votlini motorja zaradi nizke temperature.

The pump parts are mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor parts are mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand discharging ring, water inlet section, and lead cable.

Glavne značilnosti izdelka vključujejo:

The main characteristic of the product is that the pump is a water-immersed three-phase asynchronous motor, and the motor cavity is full of water for cooling the motor and lubricating the bearing. The pressure regulating diaphragm at the bottom of the motor is used to adjust the expansion-contraction pressure difference of the water inside the body caused by the change of temperature. At the same time, in order to prevent the sand particles in the well water from entering the motor, two oil seals are installed at the end of the motor shaft, and the sand discharging ring is installed to form a sand control structure. In order to prevent the pump shaft from beating when starting up, the pump shaft and the motor shaft are connected by a coupling, and the thrust bearing is installed at the bottom of the motor. In addition, the motor and the pump bearing are water-lubricated, and the stator winding of the motor uses high-quality submersible motor winding to ensure high insulation performance. The overall design is made of computer CAD, with simple structure and superior technical performance.

(1) Priprava pred namestitvijo:

1. Preverite, ali potopna črpalka ustreza pogojem uporabe in obsegu, navedenim v priročniku.

2. Z uporabo težkega predmeta s premerom, ki je enak največjemu zunanjemu premeru potopne črpalke, izmerite, ali notranji premer vrtine ustreza potopni črpalki, in izmerite, ali globina vrtine ustreza zahtevam za namestitev.

3. Preverite, ali je vrtina čista in ali je voda v vodnjaku motna. Nikoli ne uporabljajte potopne električne črpalke za izpiranje blata in peska črpalke welor, da preprečite prezgodnje poškodbe potopne električne črpalke.

4. Preverite, ali je položaj namestitvene objemke glave valja primeren in ali lahko prenese kakovost celotne enote

5. Preverite, ali so komponente potopne črpalke dokončane in pravilno nameščene v skladu s shemo sestavljanja v priročniku. Odstranite mrežico filtra in zavrtite sklopko, da vidite, ali se vrti prožno

6. Odvijte vodni vijak in napolnite votlino motorja s čisto, nejedko vodo (upoštevajte, da ste jo napolnili), nato privijte vodni vijak. Po 12 urah vbrizgavanja vode izolacijska upornost motorja ne sme biti manjša od 150 M Q, merjena s stresalno mizo 500 V.

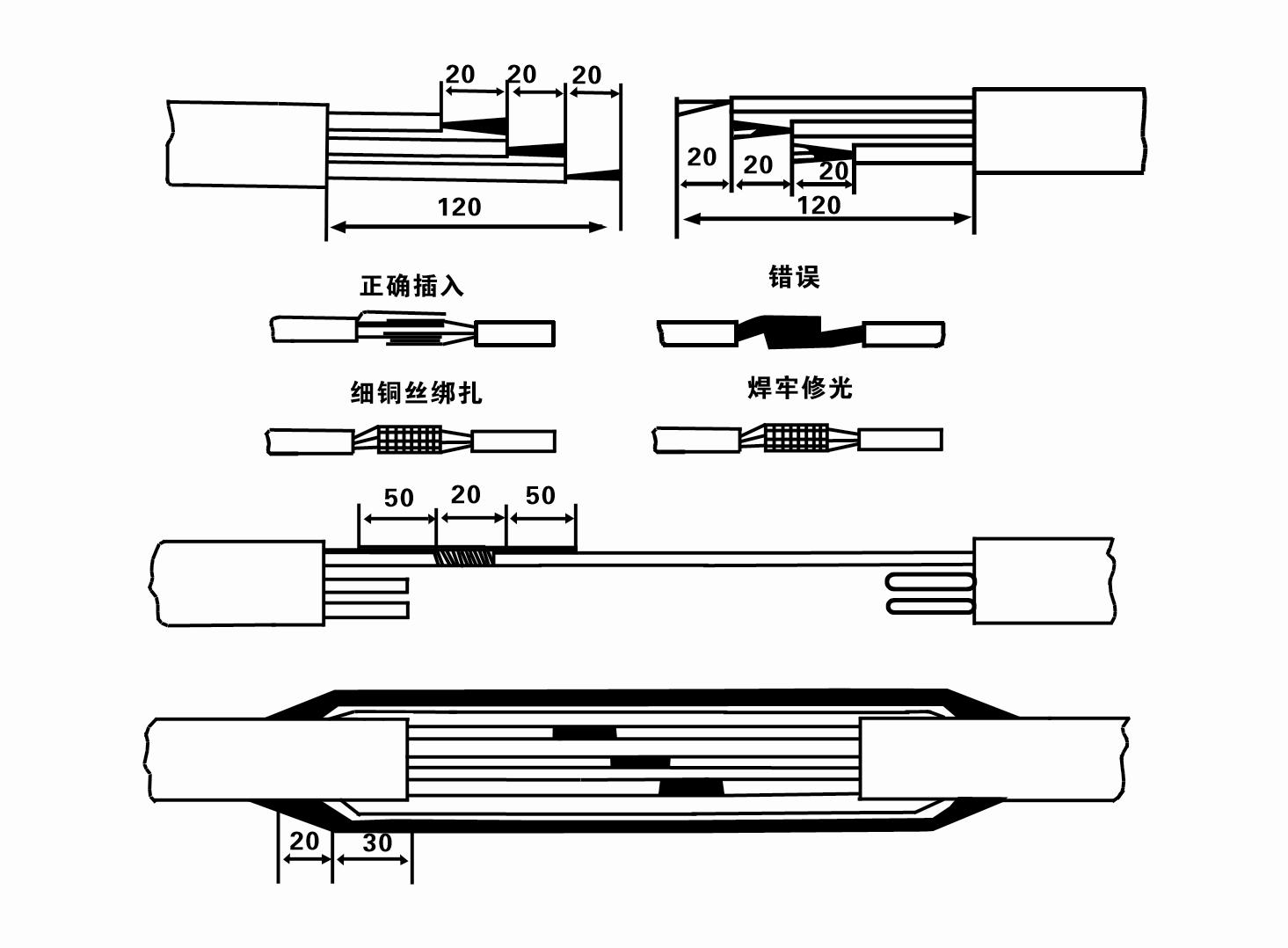

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Priloženi diagram postopka ožičenja kabla je naslednji:

8. Z multimetrom preverite, ali so trifazne žice priključene in ali je upor DC približno uravnotežen.

9. Preverite, ali sta vezje in zmogljivost transformatorja preobremenjena, nato priključite stikalo za zaščito pred preobremenitvijo ali opremo za zagon. Glejte tabelo 2 za določene modele in nato vlijte vedro vode v vodno črpalko iz izhoda vodne črpalke, da namažete gumijaste ležaje v črpalki, nato pa postavite potopno električno črpalko pokonci in mirno. Zaženite (ne več kot ena sekunda) in preverite, ali je smer krmiljenja skladna z znakom za krmiljenje. Če ne, zamenjajte poljubna dva konektorja trifaznega kabla. Nato namestite filter in se pripravite na spust v vodnjak. Če se uporablja v posebnih priložnostih (kot so jarki, jarki, reke, ribniki, ribniki itd.), mora biti električna črpalka zanesljivo ozemljena.

(2) Oprema in orodje za namestitev:

1. En par dvižnih verig za več kot dve toni.

2. Stativ z navpično višino najmanj štiri metre.

3. Dve viseči vrvi (žični vrvi), ki lahko preneseta težo več kot eno tono (lahko preneseta težo celotnega kompleta vodnih črpalk).

4. Namestite dva para sponk (splintov).

5. Ključi, kladiva, izvijači, električna orodja in instrumenti itd.

(3) Namestitev električne črpalke:

1. Namestitveni diagram potopne električne črpalke je prikazan na sliki 2. Posebne namestitvene mere so prikazane v tabeli 3 "Seznam namestitvenih mer potopne električne črpalke".

2. Potopne električne črpalke z višino manj kot 30 metrov je mogoče dvigniti neposredno v vodnjak s pomočjo cevi in žičnih vrvi ali drugih vrvi iz konoplje, ki lahko prenesejo polno težo celotnega stroja, vodovodnih cevi in vode v ceveh.

3. Črpalke z višino nad 30 metrov uporabljajo jeklene cevi, zaporedje namestitve pa je naslednje:

①Uporabite objemko, da vpnete zgornji konec dela vodne črpalke (motor in vodna črpalka sta bila trenutno povezana), jo dvignite z visečo verigo in počasi privežite v vodnjak, dokler ne namestite objemke na glavo vodnjaka in odstranite viseča veriga.

② Uporabite drug par sponk, da vpnete cev, jo dvignite z visečo verigo 15 cm stran od prirobnice in jo počasi spustite. Med prirobnico cevi in prirobnico črpalke Namestite gumijasto podlogo in enakomerno zategnite cev in črpalko z vijaki, maticami in vzmetnimi podložkami.

③ Rahlo privzdignite potopno črpalko, odstranite objemko na zgornjem koncu vodne črpalke, kabel trdno privežite na vodno cev s plastičnim trakom in ga počasi privežite, dokler objemka ni nameščena na ustju vodnjaka.

④Uporabite isto metodo za pritrditev vseh vodovodnih cevi v vodnjak.

⑤Ko je izhodni kabel priključen na krmilno stikalo, je priključen na trifazno napajanje.

(4) Stvari, ki jih morate upoštevati med namestitvijo:

1. Če med postopkom črpanja odkrijete pojav zagozditve, obrnite ali povlecite cev za vodo, da premagate točko zagozdenja. Če različni ukrepi še vedno ne delujejo, vas prosimo, da črpalke ne spustite na silo, da preprečite poškodbe potopne električne črpalke in vodnjaka.

2. Med namestitvijo je treba na prirobnico vsake cevi namestiti gumijasto blazinico in jo enakomerno zategniti.

3. Ko vodno črpalko spustite v vodnjak, jo postavite na sredino cevi vodnjaka, da preprečite, da bi črpalka dlje časa delovala ob steni vodnjaka, zaradi česar bi črpalka vibrirala, motor pa pometal in gorel .

4. Določite globino vodne črpalke do dna vodnjaka glede na razmere tekočega peska in mulja v vodnjaku. Ne zakopajte črpalke v blato. Razdalja od vodne črpalke do dna vodnjaka običajno ni manjša od 3 metrov (glej sliko 2).

5. Globina vstopa vode vodne črpalke ne sme biti manjša od 1-1,5 metra od dinamičnega nivoja vode do vozlišča vstopa vode (glej sliko 2). V nasprotnem primeru se lahko ležaji vodne črpalke zlahka poškodujejo.

6. Dvig vodne črpalke ne sme biti prenizek. V nasprotnem primeru je treba na cevovod za vodo na ustju vrtine namestiti zaporni ventil za nadzor pretoka črpalke pri nazivni točki pretoka, da se prepreči preobremenitev in izgorevanje motorja zaradi velikih pretokov.

7. Ko vodna črpalka deluje, mora biti izhod vode neprekinjen in enakomeren, tok mora biti stabilen (pri nazivnih delovnih pogojih običajno ne več kot 10 % nazivnega toka) in ne sme biti vibracij ali hrupa. Če pride do kakršnih koli nepravilnosti, je treba stroj ustaviti, da ugotovite vzrok in ga odpravite.

8. Pri namestitvi bodite pozorni na nastavitev ozemljitvene žice motorja (glejte sliko 2). Če je cev za vodo jeklena cev, jo speljite od objemke na ustju vodnjaka; če je cev za vodo plastična cev, jo speljite od oznake za ozemljitev električne črpalke.

- 1.After the submersible pump is installed, check the insulation resistance and three-phase conduction from the switch again, check whether the instrument and the connection of the start equipment are wrong, if there is no problem, the trial machine can be started, and after the start, observe whether the indicator readings of the instrument exceed the rated voltage and current specified on the nameplate, observe whether the pump has noise and vibration phenomenon, and put into operation if everything is normal.

- 2. After the first operation of the pump for four hours, the motor should be stopped to test the thermal insulation resistance quickly, and its value should not be less than 0.5 megaohm.

- 3. After the pump is stopped, it should be started after five minutes to prevent the water column in the pipe from being completely reflowed and causing the motor to burn out due to excessive current.

- 4. Our pump is designed to provide efficient, reliable and lasting pumping solutions.After normal operation, in order to prolong the service life of the pump, it is necessary to check the power supply voltage, running current and insulation resistance regularly to ensure that they are normal.

- If the following conditions are found, the machine should be shut down immediately to eliminate the fault:

- - the current exceeds 20% under the rated working conditions;

- - the dynamic water level drops to the inlet section, resulting in intermittent drainage;

- - the submersible pump vibrates violently or emits noisy sounds;

- - the power supply voltage is lower than 340 volts;

- - one phase of a fuse is blown out;

- - the water pipe is damaged;

- - the thermal insulation resistance of the motor to the ground is less than 0.5 megaohm.

- The steps of disassembling the unit include unlocking the cable holder, taking off the pipe part, removing the line protection plate, rotating the drain screw and emptying all the water in the motor chamber, taking out the filter and loosening the screw of the coupling fixed to the motor shaft.Unscrew the bolt connecting the water inlet section and the motor, and separate the pump and the motor (note that the unit should be placed horizontally when separating to prevent the bending of the pump shaft).

- 5. The disassembly sequence of the pump includes: water inlet part, impeller, shunt shell, impeller, check valve body.When removing the impeller, use a special tool to loosen the cone sleeve fixing the impeller.During the disassembly process, avoid bending the pump shaft and damaging various parts.The disassembly process of the motor includes: placing the motor on the platform, and then removing the nuts on the studs, base, shaft head lock nut, thrust plate, key, lower guide rail, bearing seat and bolt from the bottom of the motor, then removing the rotor (be careful not to damage the winding), and finally removing the connecting parts and upper guide bearing seat. Before assembling the unit, it is necessary to clean the rust and dirt of each part, and apply sealant on each mating surface and fastener, and then assemble it in the opposite order of disassembly.After assembly, the coupling should be flexibly rotated, and then the filter should be put on to test the machine. Our pump products are designed to provide superior performance and reliability to meet your pumping needs.

- 6. Submersible pumps operating every year, or less than a year of operation but the submersible time has reached two years, should be taken out of the well according to the 5th dismantled maintenance, replacement of worn parts.

1, izpustite vodo iz votline motorja (zlasti pozimi, da preprečite zmrzovanje motorja) in dobro zavežite kabel.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, dolgotrajna uporaba mora biti pozorna na preprečevanje rje potopnih črpalk.

- Tekač

- Tulec gredi

- Gumijast tulec gredi

- Tesnilni obroč

01 Zajem vode iz globokega vodnjaka

02 Visoka oskrba z vodo

03 gorski vodovod

04 stolpna voda

05 Namakanje v kmetijstvu

06 namakanje vrta

07 zajetje rečne vode

08 gospodinjska voda