The motor winding adopts special water-resistant wire for frequency conversion winding, which has excellent characteristics such as high frequency stamping resistance, pulse peak voltage stamping resistance and high temperature aging resistance. The frequency conversion winding design ensures the long-term stable conversion operation of the motor between 1HZ-50HZ, making the frequency conversion deep well pump more energy saving and longer service life.

The product is supplied by three-phase AC 380V (tolerance ± 5%), 50HZ (tolerance ± 1%). Applicable water quality conditions include water temperature not exceeding 20 °C, solid impurities content (mass ratio) is not greater than 0.01%, PH value (pH) is 6.5-8.5, hydrogen sulfide content is not more than 1.5mg/L, chloride ion content is not more than 400mg/L. The motor adopts closed or water-filled wet structure. Before use, the internal chamber needs to be filled with clean water to prevent virtual filling. The pump needs to be completely immersed in water, the penetration depth shall not exceed 70m, and the distance from the bottom of the well shall not be less than 3m. The water inlet of the well shall meet the water output and continuous operation requirements of the pump, and the output of the pump shall be controlled at 0.7-1.2 times of the rated flow. The pump shall be used vertically, and the pump must be matched with the cable according to the requirements and equipped with external overload protection device. It is strictly prohibited to conduct no-load test of the pump, and it is necessary to avoid operation without water.

| ሞዴል | ፍሰት (ሜ 3 በሰዓት) | ጭንቅላት (ሜ) |

Rotatingspeed(change/point) | የውሃ ፓምፕ (%) | መውጫ ዲያሜትር (ሚሜ) |

በደንብ ይተገበራል። ዲያሜትር (ሚሜ) |

ደረጃ ተሰጥቶታል። ኃይል (KW) |

ደረጃ ተሰጥቶታል። ቮልቴጅ(V) |

ደረጃ ተሰጥቶታል። ወቅታዊ (ኤ) |

የሞተር ብቃት (%) | power factorcosφ | ክፍል ራዲያል ከፍተኛ መጠን(ሚሜ) |

አስተያየት | |||||||||

| 150QJ5-100 | 5 | 100 | 2850 | 58 | 40 | 150 | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ5-150 | 5 | 150 | 2850 | 58 | 40 | 150 በላይ | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ5-200 | 200 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ5-250 | 250 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ5-300 | 300 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ10-50 | 10 | 50 | 2850 | 63 | 50 | 150በላይ | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ10-66 | 66 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ10-78 | 78 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ10-84 | 84 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ10-91 | 91 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ10-100 | 100 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ10-128 | 128 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ10-150 | 150 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ10-200 | 200 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ10-250 | 250 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ10-300 | 300 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ15-33 | 15 | 33 | 2850 | 63 | 50 | 150በላይ | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ15-42 | 42 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ15-50 | 50 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ15-60 | 60 | 5.5 | 13.74 | 76 | 0.8 | |||||||||||||||||

| 150QJ15-65 | 65 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ15-72 | 72 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ15-81 | 81 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ15-90 | 90 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ15-98 | 98 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ15-106 | 106 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ15-114 | 114 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ15-130 | 130 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ15-146 | 146 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ15-162 | 162 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ15-180 | 180 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 150በላይ | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ20-33 | 33 | 3 | 7.9 | 74.0 | 0.78 | |||||||||||||||||

| 150QJ20-39 | 20 | 39 | 2850 | 64 | 50 | 150በላይ | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ20-52 | 52 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ20-65 | 65 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ20-78 | 78 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ20-91 | 91 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ20-98 | 98 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ20-104 | 104 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ20-111 | 111 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ20-130 | 130 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-143 | 143 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-156 | 156 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-182 | 182 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ25-24 | 25 | 24 | 2850 | 64 | 65 | 150በላይ | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ25-32 | 32 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ25-40 | 40 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ25-48 | 48 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ25-56 | 56 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ25-64 | 64 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ25-72 | 72 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ25-77 | 77 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ25-84 | 84 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ25-96 | 96 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ25-104 | 104 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-110 | 110 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-120 | 120 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-128 | 128 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-136 | 136 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ25-154 | 154 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ32-18 | 32 | 18 | 2850 | 66 | 80 | 150በላይ | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ32-24 | 24 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ32-30 | 30 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ32-36 | 36 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ32-42 | 32 | 42 | 2850 | 66 | 80 | 150በላይ | 7.5 | 380 | 18.5 | 77.0 | 0.8 | 143 | ||||||||||

| 150QJ32-54 | 54 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ32-66 | 66 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ32-72 | 72 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-84 | 84 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-90 | 90 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-96 | 96 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-114 | 114 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ40-16 | 40 | 16 | 2850 | 66 | 80 | 150በላይ | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ40-24 | 24 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ40-30 | 30 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ40-40 | 40 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ40-48 | 48 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ40-56 | 56 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ40-64 | 64 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ40-72 | 72 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ40-80 | 80 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ40-96 | 96 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ50-16 | 50 | 16 | 2850 | 65 | 80 | 150በላይ | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ50-22 | 22 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ50-28 | 28 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ50-34 | 34 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ50-40 | 40 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ50-46 | 46 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ50-52 | 52 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ50-57 | 57 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ50-74 | 74 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ50-80 | 80 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ63-12 | 63 | 12 | 2850 | 60 | 80 | 150በላይ | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ63-18 | 18 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ63-30 | 30 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ63-36 | 36 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ63-42 | 63 | 42 | 2850 | 60 | 80 | 150በላይ | 13 | 380 | 30.87 | 79.0 | 0.81 | 143 | ||||||||||

| 150QJ63-48 | 48 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ63-54 | 54 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ15-220 | 15 | 220 | 2850 | 50 | 150በላይ | 18.5 | 380 | 43.12 | 143 | |||||||||||||

| 150QJ15-260 | 260 | 20 | 49.7 | |||||||||||||||||||

| 150QJ15-300 | 300 | 25 | 56.5 | |||||||||||||||||||

| 150QJ20-210 | 20 | 210 | 2850 | 50 | 150በላይ | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ20-240 | 240 | 25 | 56.5 | |||||||||||||||||||

| 150QJ20-290 | 290 | 30 | 66.6 | |||||||||||||||||||

| 150QJ25-175 | 25 | 175 | 2850 | 65 | 150በላይ | 20 | 49.7 | 143 | ||||||||||||||

| 150QJ25-200 | 200 | 30 | 66.6 | |||||||||||||||||||

| 150QJ25-290 | 290 | 37 | 82.1 | |||||||||||||||||||

| 150QJ32-120 | 32 | 120 | 2850 | 80 | 150በላይ | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ32-132 | 132 | 25 | 56.5 | |||||||||||||||||||

| 150QJ32-156 | 156 | 30 | 66.6 | |||||||||||||||||||

| 150QJ32-190 | 190 | 37 | 82.1 | |||||||||||||||||||

| 150QJ32-240 | 240 | 45 | 96.9 | |||||||||||||||||||

| 150QJ40-110 | 40 | 110 | 2850 | 80 | 150በላይ | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ40-121 | 121 | 25 | 56.5 | |||||||||||||||||||

| 150QJ40-143 | 143 | 30 | 66.6 | |||||||||||||||||||

| 150QJ40-176 | 176 | 37 | 82.1 | |||||||||||||||||||

| 150QJ40-220 | 220 | 45 | 96.9 | |||||||||||||||||||

| 150QJ50-100 | 50 | 100 | 2850 | 80 | 150በላይ | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ50-110 | 110 | 25 | 56.5 | |||||||||||||||||||

| 150QJ50-130 | 130 | 30 | 66.6 | |||||||||||||||||||

| 150QJ50-160 | 160 | 37 | 82.1 | |||||||||||||||||||

| 150QJ50-200 | 200 | 45 | 96.9 | |||||||||||||||||||

This well submersible pump is a pump suitable for clean water. It is strictly prohibited to pump sediment and turbid water in new wells. The voltage level of the pump is 380/50HZ. Other voltage levels of the submersible motor need to be customized. Underground cables must be waterproof and must be equipped with starting equipment, such as distribution box, etc. The starting equipment should have common motor comprehensive protection functions, such as short circuit overload protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. Under abnormal circumstances, the protection device should be tripped in time. In the process of installation and use, the pump must be reliably grounded. It is prohibited to push and pull the switch when the hands and feet are wet. The power must be cut off before installation and maintenance of the pump. The place where the pump is used must set up a clear "anti-electric shock" mark. Before going down the well or installation, the motor must be filled with distilled water or non-corrosive cool water, and the water inlet and outlet screws must be tightened. When testing the pump, water must be injected into the pump chamber to lubricate the rubber bearings. The instant start shall not exceed one second to check whether the direction is correct. It is necessary to pay attention to the safety of the pump when it is erected to prevent it from toppling and hurting people. Strictly in accordance with the provisions of the pump lift and flow range of use, so as not to have a large flow in the low lift pump or a large pull in the high lift, causing extreme wear of thrust bearings and other components, resulting in motor overload burn. After the pump into the well, the measurement of the motor and ground insulation resistance, not less than 100M. After the start, regular observation of voltage and current, and check whether the motor winding insulation meets the requirements; if the pump storage location temperature is below freezing, storage should discharge the water in the motor cavity, to prevent the water in the motor cavity due to low temperature and freeze damage the motor.

የአወቃቀሩ አጭር መግቢያ፡ የፓምፑ ክፍል በዋናነት የፓምፕ ዘንግ፣ impeller፣ diversion ሼል፣ የላስቲክ ተሸካሚ፣ የፍተሻ ቫልቭ አካል (አማራጭ ክፍሎች) እና ሌሎች አካላትን ያቀፈ ነው። የሞተር ክፍል በዋናነት ቤዝ ፣ የግፊት መቆጣጠሪያ ፊልም ፣ የግፊት መሸከም ፣ የግፊት ሰሃን ፣ የታችኛው መመሪያ ተሸካሚ መቀመጫ ፣ ስቶተር ፣ rotor ፣ የላይኛው መመሪያ ተሸካሚ መቀመጫ ፣ የአሸዋ ቀለበት ፣ የውሃ ማስገቢያ ክፍል ፣ ኬብል እና ሌሎች አካላት።

የምርቱ ዋና ባህሪያት የሚከተሉትን ያካትታሉ:

1.The motor is a water-filled wet submersible three-phase asynchronous motor, the motor cavity is full of clean water, used to cool the motor and lubricate the bearing, the pressure regulating film at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the water inside the body caused by the change of the temperature rise of the motor.

2.In order to prevent the sand in the well water from entering the motor, the upper end of the motor shaft is equipped with two oil seals, and a sand ring is installed to form a sand prevention structure.

3.In order to prevent the pump shaft from running up when starting, the pump shaft and the motor shaft are connected by a coupling, and an upper thrust bearing is installed at the lower part of the motor.

4.The lubrication of the motor and the pump bearing is water lubrication.

5.The motor stator winding is made of high quality submersible motor winding wire, with high insulation performance.

6.The pump is designed by computer CAD, with simple structure and good technical performance.

(1) ከመጫኑ በፊት ዝግጅት;

1. የውሃ ውስጥ ፓምፕ በመመሪያው ውስጥ የተገለጹትን የአጠቃቀም ሁኔታዎች እና ወሰን የሚያሟላ መሆኑን ያረጋግጡ።

2. ከከፍተኛው የውጨኛው የፓምፑ ዲያሜትር ጋር እኩል የሆነ ዲያሜትር ያለው የከባድ ኦቢሴክትን በመጠቀም የጉድጓዱ ውስጠ-ህዋው ዲያሜትር የውሃውን ፓምፕ የሚገጥም መሆን አለመሆኑን ይለኩ እና የጉድጓዱ ጥልቀት የመጫኛ መስፈርቶችን የሚያሟላ መሆኑን ይለኩ።

3. የጉድጓድ ጉድጓዱ ንፁህ መሆኑን እና የጉድጓዱ ውሃ የተበጠበጠ መሆኑን ያረጋግጡ። የውሃ ውስጥ የኤሌክትሪክ ፓምፕ ያለጊዜው እንዳይጎዳ የውሃ ፓምፕ ጭቃ እና የአሸዋ ውሃ ለማጠብ የውሃ ውስጥ የኤሌክትሪክ ፓምፕ አይጠቀሙ።

4. የዌልሄድ መጫኛ መቆንጠጫ አቀማመጥ ተስማሚ መሆኑን እና የጠቅላላውን ክፍል ጥራት መቋቋም ይችል እንደሆነ ያረጋግጡ.

5. በመመሪያው ውስጥ ባለው የመገጣጠም ንድፍ መሰረት የውኃ ውስጥ የውኃ ውስጥ ፓምፕ ክፍሎች የተሟሉ እና በትክክል የተጫኑ መሆናቸውን ያረጋግጡ የማጣሪያ ማያ ገጹን ያስወግዱ እና ማያያዣውን በተለዋዋጭነት ይሽከረከራሉ.

6. የውሃውን ጠመዝማዛ ይክፈቱ እና የሞተርን ክፍተት በንጹህ እና በማይበላሽ ውሃ ይሙሉት (ማስታወሻውን መሙላትዎን ያረጋግጡ) ከዚያም የውሃውን መከለያውን ያጥብቁ። ከ 12 ሰአታት የውሃ መርፌ በኋላ, በ 500 ቮ የሚንቀጠቀጥ ጠረጴዛ ሲለካ የሞተር መከላከያ መከላከያ ከ 150M ኪው ያነሰ መሆን የለበትም.

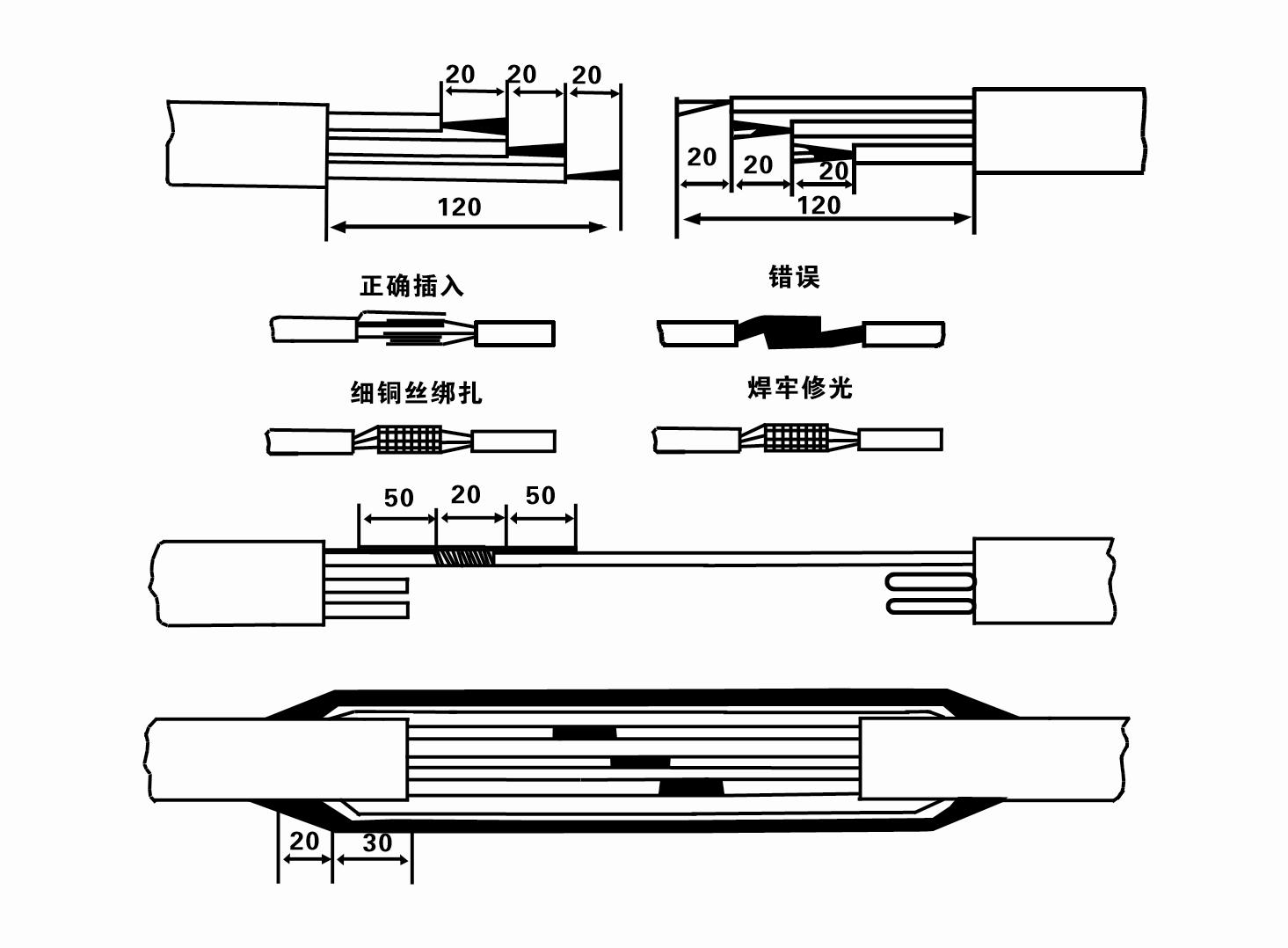

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

የተያያዘው የኬብል ሽቦ ሂደት ንድፍ እንደሚከተለው ነው.

8. ባለ ሶስት ፎቅ ሽቦዎች መገናኘታቸውን እና የዲሲ መከላከያው በግምት ሚዛናዊ መሆኑን ለማረጋገጥ መልቲሜትር ይጠቀሙ።

9. የወረዳው እና ትራንስፎርመር አቅሙ ከመጠን በላይ መጫኑን ያረጋግጡ እና ከዚያ ከመጠን በላይ መከላከያ መቀየሪያን ወይም የመነሻ መሳሪያዎችን ያገናኙ። ለተወሰኑ ሞዴሎች ሠንጠረዥ 2 ን ይመልከቱ እና ከዚያም በፓምፕ ውስጥ ያሉትን የጎማ ማሰሪያዎች ለመቀባት ከውኃ ፓምፑ መውጫ ላይ አንድ የውሃ ባልዲ በውሃ ፓምፕ ውስጥ አፍስሱ እና ከዚያ የውሃ ውስጥ የኤሌክትሪክ ፓምፑን ቀጥ አድርገው ያስቀምጡት. ጀምር (ከአንድ ሰከንድ ያልበለጠ) እና የመሪው አቅጣጫ ከመሪው ምልክት ጋር የሚስማማ መሆኑን ያረጋግጡ። ካልሆነ የሶስት-ደረጃ ገመዱን ሁለት ማገናኛዎች ይቀይሩ.ከዚያ ማጣሪያውን ይጫኑ እና ወደ ጉድጓዱ ለመውረድ ይዘጋጁ. በልዩ ሁኔታዎች (እንደ ጉድጓዶች, ጉድጓዶች, ወንዞች, ኩሬዎች, ኩሬዎች, ወዘተ የመሳሰሉት) ጥቅም ላይ ከዋለ የኤሌክትሪክ ፓምፑ በአስተማማኝ ሁኔታ መቀመጥ አለበት.

(2) የመጫኛ መሳሪያዎች እና መሳሪያዎች;

1. ከሁለት ቶን በላይ የሚሆን አንድ ጥንድ የማንሳት ሰንሰለቶች.

2. ከአራት ሜትር ያላነሰ ቋሚ ቁመት ያለው ትሪፖድ.

3. ከአንድ ቶን በላይ ክብደት ሊሸከሙ የሚችሉ ሁለት የተንጠለጠሉ ገመዶች (የሽቦ ገመዶች) (የተሟላ የውሃ ፓምፖች ክብደት ሊሸከሙ ይችላሉ).

4. ሁለት ጥንድ መቆንጠጫዎች (ስፕሊንቶች) ይጫኑ.

5. ዊንች, መዶሻ, ዊንች, የኤሌክትሪክ መሳሪያዎች እና መሳሪያዎች, ወዘተ.

(3) የኤሌክትሪክ ፓምፕ መጫን;

1. የውሃ ውስጥ የኤሌክትሪክ ፓምፕ የመጫኛ ንድፍ በስእል 2 ውስጥ ይታያል ልዩ የመጫኛ ልኬቶች በሰንጠረዥ 3 "የኤሌክትሪክ ፓምፑ የመጫኛ ልኬቶች ዝርዝር".

2. ከ 30 ሜትር ያነሰ ጭንቅላት ያላቸው የውሃ ውስጥ የኤሌክትሪክ ፓምፖች ሙሉውን ማሽን, የውሃ ቱቦዎች እና በቧንቧው ውስጥ ያለውን ውሃ ሙሉ ክብደት ሊሸከሙ የሚችሉ ቱቦዎችን እና ሽቦዎችን ወይም ሌሎች የሄምፕ ገመዶችን በመጠቀም በቀጥታ ወደ ጉድጓዱ ውስጥ ሊሰቀሉ ይችላሉ.

3. ከ 30 ሜትር በላይ ጭንቅላት ያላቸው ፓምፖች የብረት ቱቦዎችን ይጠቀማሉ, እና የመጫኑ ቅደም ተከተል እንደሚከተለው ነው.

① የውሃውን ፓምፕ ክፍል የላይኛውን ጫፍ ለመዝጋት (ሞተር እና የውሃ ፓምፑ በዚህ ጊዜ ተገናኝተዋል) ፣ በተንጠለጠለ ሰንሰለት ያንሱት እና ቀስ በቀስ ወደ ጉድጓዱ ውስጥ ያስሩ እና ማሰሪያውን በጉድጓዱ ራስ ላይ ያድርጉት እና ያስወግዱት። የተንጠለጠለ ሰንሰለት.

② ቱቦን ለመቆንጠጥ ሌላ ጥንድ ማያያዣዎችን ይጠቀሙ፣ ከተሰቀለው ሰንሰለት በ15 ሴ.ሜ ርቀት ላይ ከፍንጅቱ ይርቁ እና በቀስታ ዝቅ ያድርጉት። በፓይፕ ፍንዳታ እና በፓምፕ flange መካከል የጎማውን ንጣፍ በቦታው ያስቀምጡ እና ቧንቧውን አጥብቀው ይዝጉ እና በብሎኖች ፣ ለውዝ እና የፀደይ ማጠቢያዎች በእኩል መጠን ያሽጉ።

③ የውሃ ውስጥ ፓምፕን በትንሹ በማንሳት የውሃውን ፓምፕ የላይኛው ጫፍ ላይ ያለውን መቆንጠጫ ያስወግዱት, ገመዱን ከውሃ ቱቦው ጋር በፕላስቲክ ቴፕ አጥብቀው ያስሩ እና ቀስ በቀስ ወደ ጉድጓዱ አናት ላይ እስኪቀመጥ ድረስ ወደታች ይዝጉት.

④ ሁሉንም የውሃ ቱቦዎች ወደ ጉድጓዱ ውስጥ ለማሰር ተመሳሳይ ዘዴ ይጠቀሙ.

⑤የእርሳስ መውጫ ገመዱ ከመቆጣጠሪያ ማብሪያ / ማጥፊያ ጋር ከተገናኘ በኋላ ከሶስት-ደረጃ የኃይል አቅርቦት ጋር ይገናኛል.

(4) በሚጫኑበት ጊዜ ልብ ሊባል የሚገባው ነገር

1. በፓምፕ ሂደቱ ውስጥ የመጨናነቅ ክስተት ከተገኘ, የውሃ ቱቦውን በማዞር ወይም በመጎተት የመጨናነቅ ነጥቡን ለማሸነፍ. የተለያዩ እርምጃዎች አሁንም ካልሰሩ እባክዎን ፓምፑን ወደ ታች አያስገድዱት በውሃ ውስጥ በሚፈጠረው የኤሌክትሪክ ፓምፕ እና ጉድጓዱ ላይ ጉዳት እንዳይደርስ ያድርጉ.

2. በሚጫኑበት ጊዜ የጎማ ንጣፍ በእያንዳንዱ የቧንቧ መስመር ጠርዝ ላይ መቀመጥ እና በእኩል መጠን መጨመር አለበት.

3. የውሃ ፓምፑ ወደ ጉድጓዱ ውስጥ ሲወርድ, ፓምፑ ለረጅም ጊዜ ከጉድጓዱ ግድግዳ ላይ እንዳይሮጥ ለመከላከል በጉድጓዱ ቱቦ መሃል ላይ መቀመጥ አለበት, ይህም ፓምፑ እንዲርገበገብ እና ሞተሩ እንዲጠርግ እና እንዲቃጠል ያደርጋል. .

4. በጉድጓዱ ውስጥ በሚፈስሰው የአሸዋ እና የአሸዋ ሁኔታ መሰረት የውሃውን ፓምፕ ወደ ጉድጓዱ ስር ያለውን ጥልቀት ይወስኑ. ፓምፑን በጭቃ ውስጥ አይቀብሩ. ከውኃ ፓምፑ እስከ ጉድጓዱ የታችኛው ክፍል ያለው ርቀት በአጠቃላይ ከ 3 ሜትር ያነሰ አይደለም (ስእል 2 ይመልከቱ).

5. የውሃ ፓምፑ የውሃ መግቢያ ጥልቀት ከተለዋዋጭ የውሃ መጠን ወደ የውሃ መግቢያ መስቀለኛ መንገድ ከ1-1.5 ሜትር ያነሰ መሆን አለበት (ስእል 2 ይመልከቱ). አለበለዚያ, የውሃ ፓምፑ ማቀፊያዎች በቀላሉ ሊበላሹ ይችላሉ.

6. የውሃ ፓምፕ ማንሳት በጣም ዝቅተኛ ሊሆን አይችልም. አለበለዚያ ሞተሩን ከመጠን በላይ መጫን እና በትልቅ ፍሰት መጠን ምክንያት እንዳይቃጠል ለመከላከል የፓምፑን ፍሰት በተገመተው የፍሰት ነጥብ ላይ ለመቆጣጠር በጉድጓድ ውኃ ቱቦ ላይ የበር ቫልቭ መጫን ያስፈልጋል.

7. የውሃ ፓምፑ በሚሰራበት ጊዜ, የውሃው ውጤት ቀጣይ እና አልፎ ተርፎም, አሁኑኑ የተረጋጋ መሆን አለበት (በተገመተው የስራ ሁኔታ, በአጠቃላይ ከ 10% ያልበለጠ ደረጃ የተሰጠው ደረጃ), እና ምንም አይነት ንዝረት ወይም ድምጽ አይኖርም. ምንም አይነት ያልተለመደ ነገር ካለ ምክንያቱን ለማወቅ እና ለማጥፋት ማሽኑ ማቆም አለበት.

8. በሚጫኑበት ጊዜ ለሞተር መሬቱ ሽቦ አቀማመጥ ትኩረት ይስጡ (ስእል 2 ይመልከቱ). የውኃ ቧንቧው የብረት ቱቦ በሚሆንበት ጊዜ ከጉድጓድ መቆንጠጫ ይምሩ; የውሃ ቱቦው የፕላስቲክ ቱቦ ሲሆን, ከኤሌክትሪክ ፓምፑ ከመሬት ምልክት ይምሩ.

1.submersible pump installation is complete, re-check the insulation resistance and three-phase conduction from the switch, check the instrument and start the equipment connection error, if there is no problem, can start the trial, after the start of the instrument indicating readings whether more than the nameplate stipulated rated voltage and current, observe the pump noise and vibration phenomenon, everything is normal can be put into operation.

2.pump operation for the first four hours, should be shut down quickly test the thermal insulation resistance of the motor, the value should not be less than 0.5 megaohm.

3.pump shutdown, should be started after an interval of five minutes, to prevent the water column in the pipe has not completely reflux caused by excessive motor current and burnout.

4.pump into normal operation, in order to prolong its service life, to check the supply voltage, working current and insulation resistance is normal, if found the following situation, should immediately shut down troubleshooting.

1.in the rated condition, the current is more than20%.

2.dynamic water level to the water inlet section, causing intermittent water.

3.submersible pump severe vibration or noise.

4.supply voltage is lower than 340 volts.

5.fuse burned out a phase.

6.water pipe damage.

7.motor to the thermal insulation resistance is less than 0.5 megaohm. 5. The product is a pump unit with easy disassembly function, with simple steps of disassembly, so that users can easily maintain and clean. The disassembly steps include unraveling the cable rope, taking down the pipeline part and the line protection plate, unloosening the water discharge bolt, excluding all the water in the motor chamber, removing the filter and loosening the coupling fixing screw fixing the motor shaft, unscrewing the bolt connecting the water inlet section and the motor, separating the pump and the motor (note that the unit should be leveled when separating to prevent the bending of the pump shaft), the disassembly sequence of the pump is: water inlet section, impeller, shunt shell, impeller, and cleaning the valve body. When disassembling the impeller, use special tools to loosen the conical sleeve fixing the impeller. In the whole disassembly process, avoid bending the pump shaft and damaging various parts. The disassembly process of the motor is: put the motor on the platform, and remove the nuts, base, shaft head lock nut, thrust plate, key, and lower guide rail from the bottom of the motor in order. Bearing seat, tie rod bolt, and then take out the rotor (be careful not to damage the wiring harness) and finally remove the connecting section and the upper guide bearing seat. Before assembling the unit, the rust and dirt of each part should be cleaned, and the sealant should be coated on each mating surface and fastener, and then the assembly should be carried out in reverse order according to the disassembly (the movement of the motor shaft after assembly is about 1 mm). After the assembly is completed, the coupling should be flexibly rotated, and then the filter should be put on for machine test. This pump unit is not only convenient and easy to use, but also has detailed instructions, which provides users with convenient maintenance experience. 6. Submersible electric pump every operation for one year, or less than one year but the diving time has reached two years, should be put out of the well according to Article 5 for disassembly and maintenance, and replace the worn parts.

1, በሞተር ክፍተት ውስጥ ያለውን ውሃ (በተለይ በክረምት ወቅት ሞተሩ እንዳይቀዘቅዝ ለመከላከል) እና ገመዱን በደንብ ያስሩ.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, ለረጅም ጊዜ ጥቅም ላይ የሚውሉ ፓምፖች ዝገትን ለመከላከል ትኩረት መስጠት አለባቸው.

- ኢምፔለር

- ዘንግ እጀታ

- የጎማ ዘንግ እጅጌ

-

የማተም ቀለበት

01 ጥልቅ ጉድጓድ ውሃ መውሰድ

02 ከፍተኛ-መነሳት የውሃ አቅርቦት

03 የተራራ ውሃ አቅርቦት

04 ግንብ ውሃ

05 የግብርና መስኖ

06 የአትክልት መስኖ

07 የወንዝ ውሃ ቅበላ

08 የቤት ውስጥ ውሃ