QJ series submersible electric pump is a kind of lifting machine directly connected to the submersible motor and pump to work in the water. This series of pumps are vertical, with small footprint, compact structure, simple installation, easy maintenance and repair. It is widely used in agricultural irrigation, municipal engineering, water conservancy, urban water supply and drainage, as well as industrial and mining enterprises, disaster relief drainage and other fields. The flow range is 5-500m3/h, the head is 4-800m, and the power is 3-315KW. This submersible electric pump can efficiently lift and transport water, providing reliable water supply protection for various fields. Its stable performance and solid structure make it an indispensable machine in various water conservancy projects.

This product is a three-phase AC 380V (tolerance ± 5%), 50HZ (tolerance ± 1%) power supply pump, is designed for water requirements of strict occasions. The product is suitable for water temperature not exceeding 20 °C, solid impurities content (mass ratio) is not greater than 0.01%, PH value (pH) is 6.5-8.5, hydrogen sulfide content is not greater than 1.5mg/L, chloride ion content is not greater than 400mg/L water quality environment. The pump adopts closed or water-filled wet structure motor, the inner cavity must be filled with clean water before use to prevent virtual filling, and then tighten the water injection and pressure relief bolts. The product shall be completely immersed in water, the penetration depth shall not exceed 70m, and the distance from the bottom of the well shall not be less than 3m. The water source required by the pump shall be able to meet its output demand and continuous operation, and the output of the pump shall be controlled at 0.7-1.2 times of the rated flow. The well shall be vertical, and the horizontal or inclined use shall be prohibited, and the cable shall be matched according to the requirements and equipped with external overload protection device. It is strictly prohibited to conduct no water test on the electric pump.

| Eredua | Emaria (m3/h) | Burua (m) |

Biraketa-abiadura (aldaketa/puntua) |

Ur-ponpa (%) | Saltokia diametroa (mm) |

Ondo aplikatzekoa diametroa (mm) |

Baloratua potentzia (KW) |

Baloratua tentsioa (V) |

Baloratua korrontea (A) |

Motor-eraginkortasuna (%) | power factorcosφ | Unitatea Gehienezko tamaina erradiala (mm) |

Oharra | |||||||||

| 150QJ5-100 | 5 | 100 | 2850 | 58 | 40 | 150 | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ5-150 | 5 | 150 | 2850 | 58 | 40 | 150 goian | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ5-200 | 200 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ5-250 | 250 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ5-300 | 300 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ10-50 | 10 | 50 | 2850 | 63 | 50 | 150goian | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ10-66 | 66 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ10-78 | 78 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ10-84 | 84 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ10-91 | 91 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ10-100 | 100 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ10-128 | 128 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ10-150 | 150 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ10-200 | 200 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ10-250 | 250 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ10-300 | 300 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ15-33 | 15 | 33 | 2850 | 63 | 50 | 150goian | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ15-42 | 42 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ15-50 | 50 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ15-60 | 60 | 5.5 | 13.74 | 76 | 0.8 | |||||||||||||||||

| 150QJ15-65 | 65 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ15-72 | 72 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ15-81 | 81 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ15-90 | 90 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ15-98 | 98 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ15-106 | 106 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ15-114 | 114 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ15-130 | 130 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ15-146 | 146 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ15-162 | 162 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ15-180 | 180 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 150goian | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ20-33 | 33 | 3 | 7.9 | 74.0 | 0.78 | |||||||||||||||||

| 150QJ20-39 | 20 | 39 | 2850 | 64 | 50 | 150goian | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ20-52 | 52 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ20-65 | 65 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ20-78 | 78 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ20-91 | 91 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ20-98 | 98 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ20-104 | 104 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ20-111 | 111 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ20-130 | 130 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-143 | 143 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-156 | 156 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-182 | 182 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ25-24 | 25 | 24 | 2850 | 64 | 65 | 150goian | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ25-32 | 32 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ25-40 | 40 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ25-48 | 48 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ25-56 | 56 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ25-64 | 64 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ25-72 | 72 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ25-77 | 77 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ25-84 | 84 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ25-96 | 96 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ25-104 | 104 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-110 | 110 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-120 | 120 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-128 | 128 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-136 | 136 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ25-154 | 154 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ32-18 | 32 | 18 | 2850 | 66 | 80 | 150goian | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ32-24 | 24 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ32-30 | 30 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ32-36 | 36 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ32-42 | 32 | 42 | 2850 | 66 | 80 | 150goian | 7.5 | 380 | 18.5 | 77.0 | 0.8 | 143 | ||||||||||

| 150QJ32-54 | 54 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ32-66 | 66 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ32-72 | 72 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-84 | 84 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-90 | 90 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-96 | 96 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-114 | 114 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ40-16 | 40 | 16 | 2850 | 66 | 80 | 150goian | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ40-24 | 24 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ40-30 | 30 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ40-40 | 40 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ40-48 | 48 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ40-56 | 56 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ40-64 | 64 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ40-72 | 72 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ40-80 | 80 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ40-96 | 96 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ50-16 | 50 | 16 | 2850 | 65 | 80 | 150goian | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ50-22 | 22 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ50-28 | 28 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ50-34 | 34 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ50-40 | 40 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ50-46 | 46 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ50-52 | 52 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ50-57 | 57 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ50-74 | 74 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ50-80 | 80 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ63-12 | 63 | 12 | 2850 | 60 | 80 | 150goian | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ63-18 | 18 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ63-30 | 30 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ63-36 | 36 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ63-42 | 63 | 42 | 2850 | 60 | 80 | 150goian | 13 | 380 | 30.87 | 79.0 | 0.81 | 143 | ||||||||||

| 150QJ63-48 | 48 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ63-54 | 54 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ15-220 | 15 | 220 | 2850 | 50 | 150goian | 18.5 | 380 | 43.12 | 143 | |||||||||||||

| 150QJ15-260 | 260 | 20 | 49.7 | |||||||||||||||||||

| 150QJ15-300 | 300 | 25 | 56.5 | |||||||||||||||||||

| 150QJ20-210 | 20 | 210 | 2850 | 50 | 150goian | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ20-240 | 240 | 25 | 56.5 | |||||||||||||||||||

| 150QJ20-290 | 290 | 30 | 66.6 | |||||||||||||||||||

| 150QJ25-175 | 25 | 175 | 2850 | 65 | 150goian | 20 | 49.7 | 143 | ||||||||||||||

| 150QJ25-200 | 200 | 30 | 66.6 | |||||||||||||||||||

| 150QJ25-290 | 290 | 37 | 82.1 | |||||||||||||||||||

| 150QJ32-120 | 32 | 120 | 2850 | 80 | 150goian | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ32-132 | 132 | 25 | 56.5 | |||||||||||||||||||

| 150QJ32-156 | 156 | 30 | 66.6 | |||||||||||||||||||

| 150QJ32-190 | 190 | 37 | 82.1 | |||||||||||||||||||

| 150QJ32-240 | 240 | 45 | 96.9 | |||||||||||||||||||

| 150QJ40-110 | 40 | 110 | 2850 | 80 | 150goian | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ40-121 | 121 | 25 | 56.5 | |||||||||||||||||||

| 150QJ40-143 | 143 | 30 | 66.6 | |||||||||||||||||||

| 150QJ40-176 | 176 | 37 | 82.1 | |||||||||||||||||||

| 150QJ40-220 | 220 | 45 | 96.9 | |||||||||||||||||||

| 150QJ50-100 | 50 | 100 | 2850 | 80 | 150goian | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ50-110 | 110 | 25 | 56.5 | |||||||||||||||||||

| 150QJ50-130 | 130 | 30 | 66.6 | |||||||||||||||||||

| 150QJ50-160 | 160 | 37 | 82.1 | |||||||||||||||||||

| 150QJ50-200 | 200 | 45 | 96.9 | |||||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade 380/50HZ, the use of other voltage grades of submersible motors need to be customized.The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious sign:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering and steering instructions are the same.When the pump is upright, pay attention to safety, prevent overturning injury.

5, this pump has won wide acclaim for its efficiency and reliability. It is used in strict accordance with the applicable lift and flow range stipulated by the electric pump to avoid excessive wear of thrust bearings and other parts caused by large flow at low lift or excessive pumping force at high lift, resulting in motor overload and burnout. After being put into the well, the insulation resistance to the ground of the electric pump shall be measured and shall not be less than 100MΩ. After starting, the voltage and current shall be observed regularly, and the insulation of the motor winding shall be checked to meet the specified requirements. If the storage temperature is below freezing, the water in the pump shall be dried to avoid damage to the motor due to low temperature freezing in the motor cavity. This electric pump is your reliable choice, which can provide stable and reliable power support for your work.

Structure brief: pump part is mainly composed of pump shaft, impeller, diversion shell, rubber bearing, check valve body (optional parts) and other components.The motor part is mainly composed of base, pressure regulating film, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand ring, water inlet joint, lead cable and other components.

Produktuaren ezaugarri nagusiak honako hauek dira:

- 1.The motor is a water-sealed wet submersible three-phase asynchronous motor.The motor cavity is filled with clean water for cooling the motor and lubricating the bearing.The voltage regulating film at the bottom of the motor is used to regulate the temperature rise caused by the motor.The expansion and contraction pressure difference of the body water caused by the change.

- 2. In order to prevent the sand particles in the well water from entering the motor, two oil seals are installed at the upper end of the motor shaft extension, and a sand ring is installed to form a sand prevention structure.

- 3. In order to prevent the pump shaft from jumping at startup, the pump shaft is connected with the motor shaft through a coupling, and a thrust bearing is installed at the lower part of the motor.

- 4. The lubrication of the motor and pump bearing is water lubrication.

- 5. The motor stator winding is made of high-quality submersible motor winding wire, with excellent insulation performance.

- 6. The pump is designed by computer CAD, with simple structure and excellent technical performance.

(1) Instalazio aurretik prestatzea:

1. Egiaztatu urpeko ponpak eskuliburuan zehaztutako erabilera-baldintzak eta esparruak betetzen dituen ala ez.

2. Urpeko ponparen kanpoko diametroaren gehienezko diametroa duen objektu astun bat erabiliz, neurtu putzuaren barneko diametroa ponpa urperagarrira egoki daitekeen, eta neurtu putzuaren sakonerak instalazio-baldintzak betetzen dituen.

3. Egiaztatu putzua garbi dagoen eta putzuko ura uhera den. Inoiz ez erabili urpeko ponpa elektrikorik welor pump lokatza eta harea ura garbitzeko, ponpa elektriko urperagarriari kalte goiztiarra ekiditeko.

4. Egiaztatu welhead instalazioaren posizioa egokia den eta unitate osoaren kalitatea jasan dezakeen ala ez.

5. Egiaztatu urpeko ponpa osagaiak osatuta dauden eta behar bezala instalatuta dauden eskuliburuko muntaketa-diagramaren arabera. Kendu iragazkia pantaila eta biratu akoplamendua malgutasunez biratzen duen ikusteko.

6. Askatu ur-torlojua eta bete motorraren barrunbea ur garbi eta ez korrosiboarekin (kontuan izan. ziurtatu bete egin duzula), eta estutu ur-torlojua. Ura injektatu 12 ordu igaro ondoren, motorraren isolamendu-erresistentzia ez da 150 M Q baino txikiagoa izan behar 500 V-ko astindu-mahai batekin neurtuta.

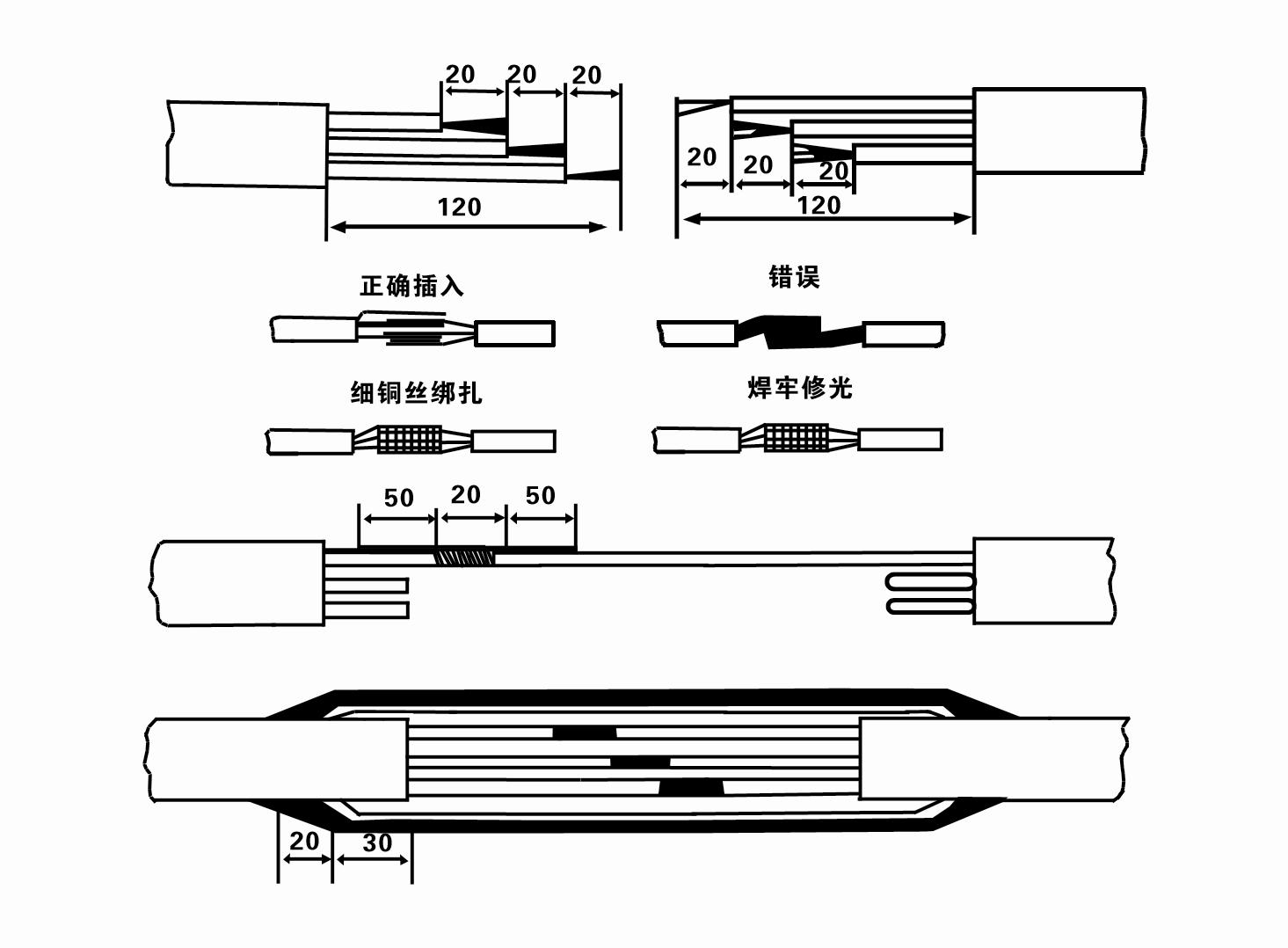

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Erantsitako kablearen kableatu-prozesuaren diagrama hau da:

8. Erabili multimetroa hari trifasikoak konektatuta dauden eta DC erresistentzia gutxi gorabehera orekatuta dagoen egiaztatzeko.

9. Egiaztatu zirkuitua eta transformadorearen ahalmena gainkargatuta dauden ala ez, eta gero konektatu gainkarga babesteko etengailua edo abiarazte-ekipoa. Ikusi 2. taula eredu zehatzetarako, eta, ondoren, isuri ur-ontzi bat ur-ponparen irteeratik ponparen gomazko errodamenduak lubrifikatzeko, eta jarri urpeko ponpa elektrikoa zutik eta egonkor. Hasi (segundo bat baino gehiago). eta egiaztatu direkzio-norabidea koherentea den direkzio-seinalearekin. Hala ez bada, aldatu kable trifasikoko bi konektoreak. Ondoren, instalatu iragazkia eta prestatu putzutik jaisteko. Kasu berezietan erabiltzen bada (adibidez, lubakiak, lubakiak, ibaiak, urmaelak, urmaelak, etab.), ponpa elektrikoa fidagarritasunez lurreratu behar da.

(2) Instalazio ekipoak eta tresnak:

1. Bi tona baino gehiagoko altxatze-kate pare bat.

2. Lau metrotik beherako altuera bertikala duen tripode bat.

3. Tona bat baino gehiagoko pisua jasan dezaketen bi soka zintzilik (alanbrezko sokak) (ur-ponpa multzo oso baten pisua jasan dezakete).

4. Jarri bi besarkada pare (ferulak).

5. Giltzak, mailuak, bihurkinak, erreminta eta tresna elektrikoak, etab.

(3) Ponpa elektrikoaren instalazioa:

1. Urpeko ponpa elektrikoaren instalazio-diagrama 2. Irudian ageri da. Instalazio-neurri espezifikoak 3. Taulan agertzen dira "Sumergigarriko ponpa elektrikoaren instalazio-neurrien zerrenda".

2. 30 metrotik beherako burua duten ponpa elektriko urperagarriak zuzenean putzura igo daitezke, makina osoaren, ur-hodien eta hodietako uraren pisu osoa jasan dezaketen mahukak eta alanbre-sokak edo beste kalamu-soka batzuk erabiliz.

3. 30 metro baino gehiagoko burua duten ponpek altzairuzko hodiak erabiltzen dituzte, eta instalazioaren sekuentzia hau da:

①Erabili besarkada bat ur-ponparen zatiaren goiko muturra estutzeko (motorea eta ur-ponpa konektatuta daude momentu honetan), altxa ezazu zintzilik dagoen kate batekin eta lotu poliki-poliki putzuan. Jarri besarkada putzu-buruan eta kendu zintzilik katea.

② Erabili beste besarkada pare bat hodi bat estutzeko, altxa ezazu zintzilik dagoen kate batekin bridatik 15 cm-ra, eta jaitsi poliki-poliki. Hodiaren bridenaren eta ponparen bridenaren artean. Jarri gomazko kupoia eta estutu hodia eta ponpatu uniformeki torlojuekin, azkoinekin eta malguki-zirrindarekin.

③ Altxatu urpeko ponpa apur bat, kendu ur-ponparen goiko muturrean dagoen besarkada, lotu kablea tinko ur-hodiari plastikozko zinta batekin eta lotu poliki-poliki besarkada putzu-buruan jarri arte.

④Erabili metodo bera ur-hodi guztiak putzuan lotzeko.

⑤ Irteerako kablea kontrol-etengailura konektatu ondoren, elikadura trifasikora konektatzen da.

(4) Instalazioan kontuan izan beharrekoak:

1. Ponpatze-prozesuan blokeo-fenomeno bat aurkitzen bada, bira eman edo tira ur-hodiari traba-puntua gainditzeko. Hainbat neurrik oraindik ez badute funtzionatzen, mesedez, ez behartu ponpa behera urpean dagoen ponpa elektrikoa eta putzua ez kaltetzeko.

2. Instalazioan, gomazko kuskulina bat jarri behar da hodi bakoitzaren bridan eta uniformeki estutu.

3. Ur-ponpa putzuan jaisten denean, putzuaren erdian jarri behar da ponpa putzuaren hormaren kontra denbora luzez ibil ez dadin, ponpa dardara eta motorra miaketa eta erretzea eraginez. .

4. Zehaztu ur-ponparen sakonera putzuaren hondoraino, putzuaren harea eta limo-baldintzen arabera. Ez lurperatu ponpa lokatzetan. Ur-ponpatik putzuaren hondorainoko distantzia, oro har, ez da 3 metro baino gutxiagokoa (ikus 2. irudia).

5. Ur ponparen ura sartzeko sakonera ez da 1-1,5 metro baino txikiagoa izan behar uraren maila dinamikotik uraren sarrerako nodoraino (ikus 2. irudia). Bestela, ur ponparen errodamenduak erraz honda daitezke.

6. Ur-ponparen igoera ezin da baxuegia izan. Bestela, ate-balbula bat instalatu behar da putzu-buruko ur-hodietan ponparen emaria kontrolatzeko emari-puntuan emari handien ondorioz motorra gainkargatu eta erre ez dadin.

7. Ur-ponpa martxan dagoenean, ur-irteera etengabea eta berdina izan behar da, korrontea egonkorra izan behar da (lan-baldintzetan, oro har, korronte nominalaren % 10 baino gehiago), eta ez da bibraziorik edo zaratarik egon behar. Anormaltasunik badago, makina gelditu egin behar da kausa ezagutzeko eta ezabatzeko.

8. Instalatzerakoan, arreta jarri motorra lurreratzeko kablearen ezarpenari (ikus 2. irudia). Ur-hodia altzairuzko hodia denean, eraman ezazu putzu-buruko besarkadatik; ur-hodia plastikozko hodia denean, eraman ezazu ponpa elektrikoaren lurreratze-markatik.

- (1)After the submersible pump is installed, check the insulation resistance and three-phase conduction from the switch again, check whether the instrument and the connection of the start equipment are wrong, if there is no problem, the trial machine can be started, and observe whether the indicator readings of the instrument exceed the rated voltage and current specified on the nameplate after the start, and observe whether the pump has noise and vibration phenomenon, and put into operation if everything is normal.

- (2)After the first operation of the pump for four hours, the motor should be shut down to test the thermal insulation resistance quickly, and its value should not be less than 0.5 megaohm.

- (3)After the pump is shut down, it should be started after five minutes to prevent the water column in the pipe from being completely reflowed and causing excessive motor current and burnout.

- (4)After the pump is put into normal operation, in order to prolong its service life, it is necessary to check whether the supply voltage, working current and insulation resistance are normal regularly. If the following conditions are found, the pump should be shut down immediately to troubleshoot.

1 In the rated condition, the current exceeds 20%.

2 Ur-maila dinamikoa uraren sarrerako sekziora jaisten da, eta tarteka ura eragiten du.

3 Urpeko ponpak bibrazio edo zarata handiak ditu.

4 Hornidura-tentsioa 340 voltio baino txikiagoa da.

5 Fusible bat erreta dago.

6 Ura hornitzeko hodia hondatuta dago.

7 The motor's thermal insulation resistance is lower than 0.5 megaohm.

- (5)Unit disassembly:

1 Untie the cable tie, remove the pipeline part, and remove the wire plate.

2 Torloju ur-torlojua, jarri ura motorraren ganbaran.

3 kendu iragazkia, askatu akoplamenduko torloju finkoa motorraren ardatza finkatzeko.

4 torlojutu uraren sarrerako atala motorrekin lotzen duen torlojua, eta bereizi ponpa motorretik (erreparatu unitateko kuxinari banantzean, ponparen ardatza tolestu ez dadin)

5 ponparen desmuntatze-sekuentzia hau da: (ikusi 1. irudia) uraren sarrerako atala, bulkada, desbideratze-oskola, bultzada...... egiaztapen-balbularen gorputza, bultzatzailea kentzean, erabili tresna bereziak finkoaren mahuka konikoa askatzeko. bultzatzailea lehenik, eta saihestu ponparen ardatza desmuntatzeko prozesuan tolestu eta ubeltzea.

6 motorra desmuntatzeko prozesua hau da: (ikus 1. irudia) jarri motorra plataforman, eta kendu azkoinak, oinarria, ardatzaren burua blokeatzeko azkoina, bultzada-plaka, giltza, beheko gida-eserlekua eta buru bikoitzeko torlojua behetik. motorra aldi berean, eta gero errotorea atera (kontuz hari paketea ez kaltetzeko) eta, azkenik, kendu konexio-atala eta goiko gida-errodamenduaren eserlekua.

7 unitateen muntaketa: muntatu aurretik, piezen herdoila eta zikinkeria garbitu behar dira, eta uztartze-azalera eta finkagailuak zigilatzailez estalita, eta, ondoren, desmuntatzeko ordenaren kontrako ordenan muntatu (motorraren ardatza gora eta behera mugitzen da muntatu ondoren gutxi gorabehera. milimetro), muntatu ondoren, akoplamendua malgua izan behar da eta, ondoren, iragazki pantaila probatzeko makina. Urpeko ponpak putzutik aterako dira desmuntatzeko eta mantentzeko 5. artikuluaren arabera funtzionamendu-urte bat igaro ondoren, edo urtebete baino gutxiago funtzionatzen baina urpekaritza-denbora bi urte igaro ondoren, eta gastatutako piezak ordezkatuko dira.

In order to ensure long-term use of your submersible pump, we strongly recommend that you drain the water in all motor cavities especially in winter to prevent the motor from freezing; at the same time, roll up the cable and tie it well. Store the equipment in a room without corrosive substances and gases, with the temperature below 40 °C. In addition, if you do not use the submersible pump for a long time, be sure to pay attention to rust prevention measures. These simple steps will help you maintain the performance of the equipment and extend its service life.

- Buldagailua

- Ardatz mahuka

- Gomazko ardatzaren mahuka

-

Zigilatzeko eraztuna

01 Putzu sakoneko ura hartzea

02 Goiko ur-hornidura

03 mendiko ur hornidura

04 dorre ura

05 Nekazaritzako ureztatzea

06 lorategiko ureztatzea

07 ibaiko ur-hartunea

08 etxeko ura