Designed for underground hot water mining below 100°C, this product has the characteristics of high temperature resistance, corrosion resistance and aging resistance. Whether in underground mining or other hot water environment applications, it can effectively resist the challenges of harsh environment. Its excellent performance and stable quality make it an ideal choice in the mining field.

1, catu daya: tilu-fase AC 380V (kasabaran + / - 5%), 50HZ (kasabaran + / - 1%).

2, kualitas cai:

(1) water temperature is not higher than 20 °C;

(2) eusi najis padet (rasio massa) teu leuwih gede ti 0,01%;

(3) Nilai PH (pH) 6,5-8,5;

(4) eusi hidrogén sulfida teu leuwih gede ti 1.5mg/L;

(5) eusi ion klorida teu leuwih gede ti 400mg/L.

3, motor ditutup atawa struktur baseuh cai-kaeusi, saméméh pamakéan rongga motor submersible kudu pinuh ku cai bersih, pikeun nyegah palsu pinuh, lajeng tighten suntik cai, bolts release hawa, disebutkeun teu diwenangkeun ngagunakeun.

4, pompa submersible kudu sagemblengna submerged dina caina, jero diving teu leuwih gede ti 70m, handap pompa submersible ti handap sumur teu kurang ti 3m.

5, aliran cai sumur kudu bisa minuhan kaluaran cai pompa submersible sarta operasi kontinyu, kaluaran cai pompa submersible kudu dikawasa dina 0.7 - 1.2 kali aliran dipeunteun.

6, sumur kudu lempeng, pompa submersible teu bisa dipaké atawa dumped, ngan pamakéan nangtung.

7, pompa submersible kudu loyog jeung kabel nurutkeun sarat, jeung alat panyalindungan overload éksternal. 8, pompa nu mastikeun dilarang tanpa cai no-beban mesin test

| Modél | Aliran (m3/h) | Sirah (m) |

Laju puteran (robah / titik) |

Pompa cai(%) | Outlet diameter (mm) |

Lumaku ogé diaméterna (mm) |

Dipeunteun kakuatan (KW) |

Dipeunteun tegangan (V) |

Dipeunteun ayeuna (A) |

Efisiensi motor (%) | power factorcosφ | Unit Ukuran Radial Maximum (mm) |

Nyarios | |||||||||

| 150QJ5-100 | 5 | 100 | 2850 | 58 | 40 | 150 | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ5-150 | 5 | 150 | 2850 | 58 | 40 | 150 di luhur | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ5-200 | 200 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ5-250 | 250 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ5-300 | 300 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ10-50 | 10 | 50 | 2850 | 63 | 50 | 150di luhur | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ10-66 | 66 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ10-78 | 78 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ10-84 | 84 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ10-91 | 91 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ10-100 | 100 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ10-128 | 128 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ10-150 | 150 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ10-200 | 200 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ10-250 | 250 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ10-300 | 300 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ15-33 | 15 | 33 | 2850 | 63 | 50 | 150di luhur | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ15-42 | 42 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ15-50 | 50 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ15-60 | 60 | 5.5 | 13.74 | 76 | 0.8 | |||||||||||||||||

| 150QJ15-65 | 65 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ15-72 | 72 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ15-81 | 81 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ15-90 | 90 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ15-98 | 98 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ15-106 | 106 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ15-114 | 114 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ15-130 | 130 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ15-146 | 146 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ15-162 | 162 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ15-180 | 180 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 150di luhur | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ20-33 | 33 | 3 | 7.9 | 74.0 | 0.78 | |||||||||||||||||

| 150QJ20-39 | 20 | 39 | 2850 | 64 | 50 | 150di luhur | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ20-52 | 52 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ20-65 | 65 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ20-78 | 78 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ20-91 | 91 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ20-98 | 98 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ20-104 | 104 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ20-111 | 111 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ20-130 | 130 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-143 | 143 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-156 | 156 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ20-182 | 182 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ25-24 | 25 | 24 | 2850 | 64 | 65 | 150di luhur | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ25-32 | 32 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ25-40 | 40 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ25-48 | 48 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ25-56 | 56 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ25-64 | 64 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ25-72 | 72 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ25-77 | 77 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ25-84 | 84 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ25-96 | 96 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ25-104 | 104 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-110 | 110 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-120 | 120 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-128 | 128 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ25-136 | 136 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ25-154 | 154 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ32-18 | 32 | 18 | 2850 | 66 | 80 | 150di luhur | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ32-24 | 24 | 4 | 10.25 | 75.0 | 0.79 | |||||||||||||||||

| 150QJ32-30 | 30 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ32-36 | 36 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ32-42 | 32 | 42 | 2850 | 66 | 80 | 150di luhur | 7.5 | 380 | 18.5 | 77.0 | 0.8 | 143 | ||||||||||

| 150QJ32-54 | 54 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ32-66 | 66 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ32-72 | 72 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-84 | 84 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-90 | 90 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-96 | 96 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ32-114 | 114 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ40-16 | 40 | 16 | 2850 | 66 | 80 | 150di luhur | 3 | 380 | 7.9 | 74.0 | 0.78 | 143 | ||||||||||

| 150QJ40-24 | 24 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ40-30 | 30 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ40-40 | 40 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ40-48 | 48 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ40-56 | 56 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ40-64 | 64 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ40-72 | 72 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ40-80 | 80 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ40-96 | 96 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ50-16 | 50 | 16 | 2850 | 65 | 80 | 150di luhur | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ50-22 | 22 | 5.5 | 13.74 | 76.0 | 0.8 | |||||||||||||||||

| 150QJ50-28 | 28 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ50-34 | 34 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ50-40 | 40 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ50-46 | 46 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ50-52 | 52 | 13 | 30.87 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ50-57 | 57 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ50-74 | 74 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ50-80 | 80 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ63-12 | 63 | 12 | 2850 | 60 | 80 | 150di luhur | 4 | 380 | 10.25 | 75.0 | 0.79 | 143 | ||||||||||

| 150QJ63-18 | 18 | 7.5 | 18.5 | 77.0 | 0.8 | |||||||||||||||||

| 150QJ63-30 | 30 | 9.2 | 22.12 | 78.0 | 0.81 | |||||||||||||||||

| 150QJ63-36 | 36 | 11 | 26.28 | 78.5 | 0.81 | |||||||||||||||||

| 150QJ63-42 | 63 | 42 | 2850 | 60 | 80 | 150di luhur | 13 | 380 | 30.87 | 79.0 | 0.81 | 143 | ||||||||||

| 150QJ63-48 | 48 | 15 | 35.62 | 79.0 | 0.81 | |||||||||||||||||

| 150QJ63-54 | 54 | 18.5 | 43.12 | 79.5 | 0.82 | |||||||||||||||||

| 150QJ15-220 | 15 | 220 | 2850 | 50 | 150di luhur | 18.5 | 380 | 43.12 | 143 | |||||||||||||

| 150QJ15-260 | 260 | 20 | 49.7 | |||||||||||||||||||

| 150QJ15-300 | 300 | 25 | 56.5 | |||||||||||||||||||

| 150QJ20-210 | 20 | 210 | 2850 | 50 | 150di luhur | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ20-240 | 240 | 25 | 56.5 | |||||||||||||||||||

| 150QJ20-290 | 290 | 30 | 66.6 | |||||||||||||||||||

| 150QJ25-175 | 25 | 175 | 2850 | 65 | 150di luhur | 20 | 49.7 | 143 | ||||||||||||||

| 150QJ25-200 | 200 | 30 | 66.6 | |||||||||||||||||||

| 150QJ25-290 | 290 | 37 | 82.1 | |||||||||||||||||||

| 150QJ32-120 | 32 | 120 | 2850 | 80 | 150di luhur | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ32-132 | 132 | 25 | 56.5 | |||||||||||||||||||

| 150QJ32-156 | 156 | 30 | 66.6 | |||||||||||||||||||

| 150QJ32-190 | 190 | 37 | 82.1 | |||||||||||||||||||

| 150QJ32-240 | 240 | 45 | 96.9 | |||||||||||||||||||

| 150QJ40-110 | 40 | 110 | 2850 | 80 | 150di luhur | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ40-121 | 121 | 25 | 56.5 | |||||||||||||||||||

| 150QJ40-143 | 143 | 30 | 66.6 | |||||||||||||||||||

| 150QJ40-176 | 176 | 37 | 82.1 | |||||||||||||||||||

| 150QJ40-220 | 220 | 45 | 96.9 | |||||||||||||||||||

| 150QJ50-100 | 50 | 100 | 2850 | 80 | 150di luhur | 20 | 380 | 49.7 | 143 | |||||||||||||

| 150QJ50-110 | 110 | 25 | 56.5 | |||||||||||||||||||

| 150QJ50-130 | 130 | 30 | 66.6 | |||||||||||||||||||

| 150QJ50-160 | 160 | 37 | 82.1 | |||||||||||||||||||

| 150QJ50-200 | 200 | 45 | 96.9 | |||||||||||||||||||

The well submersible pump is a kind of pump suitable for clean water. It is strictly prohibited to dig new wells and extract sediment and turbid water. The voltage grade of the pump is 380/50HZ, and other submersible motors with different voltage grades need to be customized. Underground cables must be waterproof and must be equipped with starting equipment, such as distribution box, etc. The starting equipment should have conventional comprehensive motor protection functions, such as short circuit overload protection, phase loss protection, undervoltage protection, grounding protection and no-load protection. In abnormal cases, the protection device should be tripped in time. During installation and use, it is necessary to ensure that the pump is reliably grounded. It is forbidden to push and pull the switch when hands and feet are wet. The power supply must be cut off before installation and maintenance of the pump. In the place where the pump is used, an obvious "anti-electric shock" sign must be set up. Before going down the well or installing the motor, the internal chamber must be filled with distilled water or non-corrosive clean cold water. The water adding/discharge bolt must be tightened. When testing the pump on the ground, water must be poured into the pump chamber to lubricate the rubber bearings. The instant start should not exceed one second to check whether the direction is correct, the same as the steering indication. Pay attention to safety when the pump is upright to prevent overturning and injury. Strictly in accordance with the provisions of the pump lift and flow range of use, to prevent the pump in low lift has a large flow or in high lift has a large pull, resulting in extreme wear of thrust bearings and other components, resulting in motor overload burnout. After the pump into the well, the insulation resistance of the motor and the ground shall be measured, which shall not be less than 100MΩ. After the start, observe the voltage and current regularly, and check whether the motor winding insulation meets the requirements; if the temperature of the pump storage location is below the freezing point, the water in the motor cavity shall be discharged to prevent freezing damage to the motor.

bubuka ringkes struktur: bagian pompa utamana diwangun ku aci pompa, impeller, cangkang diversion, bearing karét, pariksa awak klep (bagian pilihan) sareng komponenana lianna. Bagian Motor utamana diwangun ku basa, tekanan régulasi pilem, dorong bearing, piring dorong, handap pituduh bearing korsi, stator, rotor, pituduh luhur bearing korsi, ring keusik, bagian inlet cai, kabel sareng komponenana lianna.

Fitur utama produk di antarana:

1, motor nyaéta motor asynchronous tilu-fase baseuh cai-kaeusi cai, rongga motor pinuh ku cai bersih, dipaké pikeun niiskeun motor jeung lubricate bearing nu, tekanan régulasi pilem di handapeun motor dipaké pikeun nyaluyukeun. bédana ékspansi jeung kontraksi tekanan cai di jero awak disababkeun ku parobahan naékna suhu motor.

2, Dina raraga nyegah keusik dina cai sumur ti ngasupkeun motor, tungtung luhur aci motor dilengkepan dua segel minyak, sarta cingcin keusik dipasang pikeun ngabentuk struktur pencegahan keusik.

3, Dina raraga nyegah aci pompa ti ngajalankeun up nalika dimimitian, aci pompa jeung aci motor disambungkeun ku gandeng a, sarta hiji bearing dorong luhur dipasang di bagian handap motor.

4, The lubrication tina motor jeung bearing pompa nyaéta lubrication cai.

5, The motor stator pungkal dijieunna tina kualitas luhur submersible motor pungkal kawat, kalawan kinerja insulasi tinggi.

6, pompa dirancang ku komputer CAD, kalawan struktur basajan tur kinerja teknis alus.

(1) Persiapan saméméh instalasi:

1. Pariksa naha pompa submersible meets kaayaan pamakéan sarta wengkuan spésifed dina manual.

2. Ngagunakeun obiect beurat kalawan diaméter sarua jeung diaméter luar maksimum pompa submersible, ngukur naha inneldiameter of wellbore nu bisa nyocogkeun ka pompa submersible, sarta ngukur naha jero sumur meets sarat instalasi.

3. Pariksa naha liang sumur beresih jeung cai sumur keruh. Pernah ngagunakeun pompa listrik submersible pikeun ngumbah leutak pompa welor jeung cai keusik pikeun nyegah karuksakan prématur kana pompa listrik submersible.

4. Pariksa naha posisi clamp pamasangan welhead cocog sareng naha éta tiasa tahan kualitas sadaya unit.

5. Pariksa lamun komponén pompa submersible geus réngsé sarta dipasang leres nurutkeun diagram assembly dina manualLeupaskeun layar filter sarta muterkeun gandeng pikeun nempo lamun rotates flexibly

6. Unscrew nu screw cai jeung fillthe rohangan motor jeung bersih, cai non corrosive (catetan. Pastikeun pikeun fil eta nepi), teras tighten waterscrew nu. Saatos 12 jam suntikan cai, résistansi insulasi motor henteu kedah kirang ti 150M Q nalika diukur nganggo méja oyag 500V.

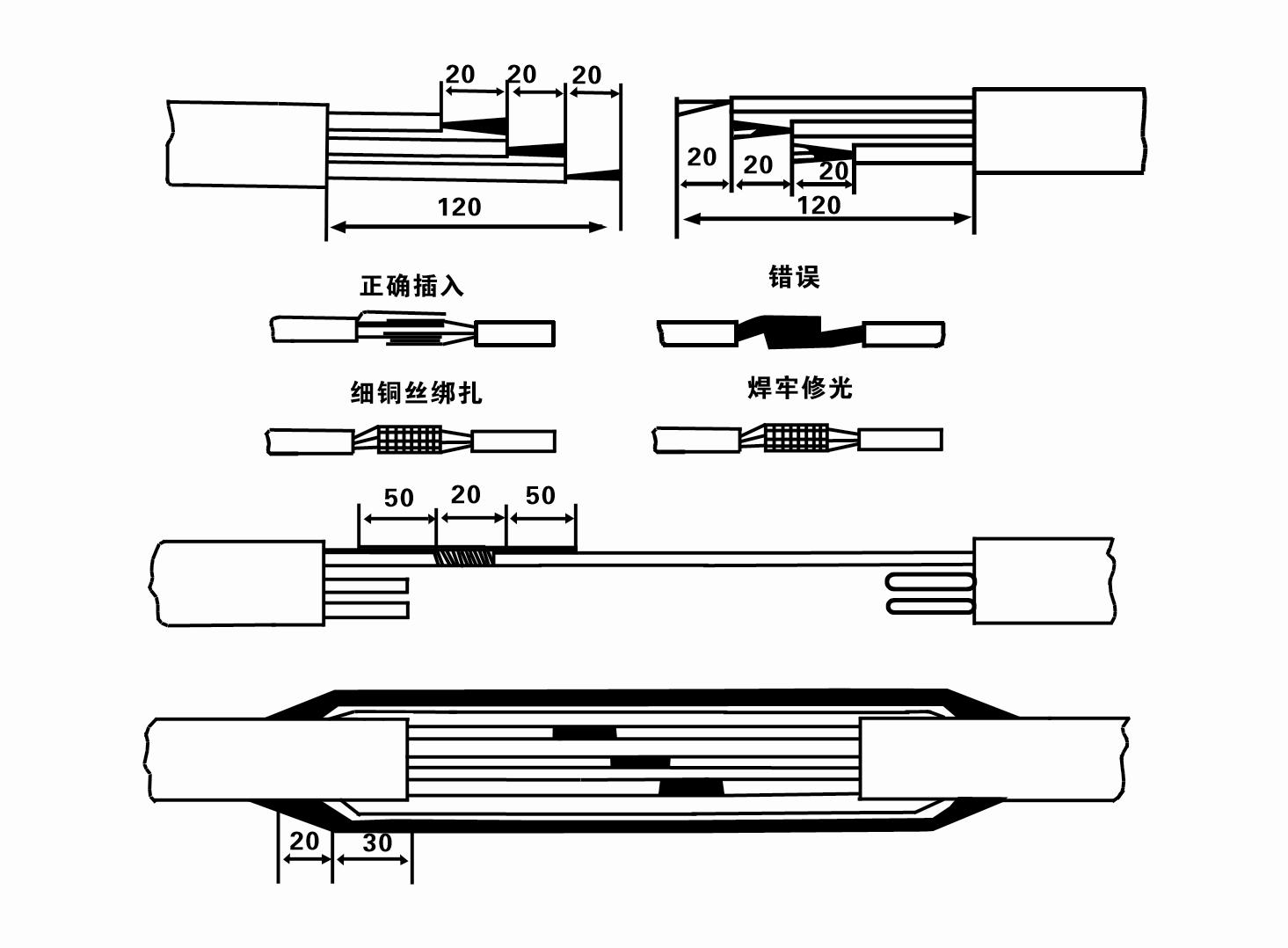

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Diagram prosés wiring kabel napel nyaéta kieu:

8. Paké multimeter pikeun pariksa naha kawat tilu-fase disambungkeun tur naha lalawanan DC kira saimbang.

9. Pariksa naha sirkuit jeung trafo kapasitas overloaded, lajeng sambungkeun switch panyalindungan overload atawa alat dimimitian. Tempo Table 2 pikeun model husus, lajengTuang ember cai kana pompa cai ti outlet pompa cai mun lubricate bantalan karét dina pompa, lajeng nempatkeun pompa listrik submersible orientasi tegak tur steady.Start (teu leuwih ti hiji detik) jeung pariksa naha arah steering konsisten jeung tanda steering. Lamun henteu, swap wae dua panyambungna tina kabel tilu-fase. Lajeng install filter sarta nyiapkeun turun sumur. Upami dianggo dina kaayaan anu khusus (sapertos parit, parit, walungan, balong, balong, jsb.), pompa listrik kedah didasarkeun sacara dipercaya.

(2) Alat sareng alat pamasangan:

1. Hiji pasangan ngangkat ranté pikeun leuwih ti dua ton.

2. A tripod kalayan jangkungna nangtung teu kurang ti opat méter.

3. Dua tali gantung (tali kawat) nu bisa nanggung beurat leuwih ti hiji ton (bisa nanggung beurat hiji set lengkep pompa cai).

4. Pasang dua pasang jepitan (splints).

5. Wrenches, palu, obeng, pakakas listrik jeung instrumen, jsb.

(3) pamasangan pompa listrik:

1. Diagram instalasi tina pompa listrik submersible ditémbongkeun dina Gambar 2. Dimensi instalasi husus ditémbongkeun dina Table 3 "Daptar Dimensi Instalasi Pompa Electric Submersible".

2. Pompa listrik submersible kalawan sirah kirang ti 30 méter bisa hoisted langsung kana sumur ngagunakeun hoses jeung tali kawat atawa tali hemp lianna nu bisa nanggung beurat pinuh ku sakabéh mesin, pipa cai, jeung cai dina pipa.

3. Pompa kalayan sirah leuwih ti 30 méter ngagunakeun pipa baja, sarta runtuyan instalasi nyaéta kieu:

①Pake jepitan pikeun ngajepit tungtung luhur bagian pompa cai (motor sareng pompa cai parantos nyambungkeun waktos ayeuna), angkat nganggo ranté gantung, teras dasikeun lalaunan kana sumur dugi ka Pasang jepitan dina sirah sumur teras cabut ranté gantung.

② Paké sapasang clamps séjén pikeun clamp pipa, angkat eta kalawan ranté gantung 15 cm jauh ti flange, sarta nurunkeun eta lalaunan. Antara flange pipe jeung flange pompa Pasang pad karét di tempat sarta tighten pipa na pompa merata kalawan bolts, kacangan sarta spring washers.

③ Angkat pompa beuleum saeutik, cabut jepitan dina tungtung luhur pompa cai, dasi kabelna pageuh kana pipa cai nganggo pita plastik, teras talitikeun lalaunan dugi ka jepitan disimpen dina sumur.

④Paké cara nu sarua pikeun ngabeungkeut sakabéh pipa cai kana sumur.

⑤Saatos kabel timbal-kaluar disambungkeun ka saklar kontrol, éta disambungkeun ka catu daya tilu-fase.

(4) Hal-hal anu kedah diperhatoskeun nalika instalasi:

1. Lamun fenomena jamming kapanggih salila prosés ngompa, balikkeun atawa tarik pipa cai pikeun nungkulan titik jamming. Lamun sagala rupa ukuran masih teu hasil, mangga Ulah maksakeun pompa ka handap pikeun nyegah karuksakan kana pompa listrik submersible jeung sumur.

2. Salila instalasi, a Pad karét kudu ditempatkeun di flange unggal pipa na tightened merata.

3. Nalika pompa cai diturunkeun kana sumur, éta kudu ditempatkeun di tengah-tengah pipa sumur pikeun nyegah pompa tina ngajalankeun kana témbok sumur pikeun lila, ngabalukarkeun pompa ngageter jeung motor keur nyapu jeung kaduruk. .

4. Nangtukeun jero pompa cai ka handapeun sumur dumasar kana keusik anu ngalir sareng kaayaan leutak sumur. Ulah ngubur pompa dina leutak. Jarak ti pompa cai ka handapeun sumur umumna teu kurang ti 3 méter (tingali Gambar 2).

5. Jero asupna cai tina pompa cai kedah teu kurang ti 1-1,5 méter ti tingkat cai dinamis ka titik inlet cai (tingali Gambar 2). Upami teu kitu, bantalan pompa cai tiasa gampang ruksak.

6. The lift tina pompa cai teu tiasa teuing low. Upami teu kitu, klep gerbang kedah dipasang dina pipa cai sumur pikeun ngontrol aliran pompa dina titik aliran anu dipeunteun pikeun nyegah motor kabeungharan sareng kaduruk kusabab laju aliran anu ageung.

7. Nalika pompa cai dijalankeun, kaluaran cai kedah kontinyu sareng malah, arus kedah stabil (dina kaayaan kerja anu dipeunteun, umumna henteu langkung ti 10% tina arus anu dipeunteun), sareng teu kedah aya geter atanapi bising. Upami aya abnormalitas, mesin kedah dieureunkeun pikeun milari panyababna sareng ngaleungitkeunana.

8. Nalika masang, nengetan setelan tina kawat grounding motor (tingali Gambar 2). Nalika pipa cai nyaéta pipa baja, ngarah tina clamp wellhead; lamun pipa cai téh pipa plastik, ngarah tina tanda grounding tina pompa listrik.

- 1.After pompa submersible dipasang, pariksa résistansi insulasi sarta konduksi tilu-fase ti saklar deui, pariksa naha alat jeung sambungan tina alat ngamimitian anu salah, upami teu aya masalah, mesin percobaan bisa dimimitian, sarta niténan naha bacaan indikator alat ngaleuwihan tegangan dipeunteun sarta ayeuna dieusian dina nameplate sanggeus mimiti, sarta nitenan naha pompa ngabogaan fenomena noise jeung Geter, sarta nempatkeun kana operasi lamun sagalana geus normal.

- 2.After operasi mimiti pompa pikeun opat jam, motor kudu Cicing turun pikeun nguji lalawanan insulasi termal gancang, sarta nilaina teu kudu kirang ti 0,5 megaohm.

- 3.After pompa nu geus Cicing turun, éta kudu dimimitian sanggeus lima menit pikeun nyegah kolom cai dina pipe ti keur sagemblengna reflowed sarta ngabalukarkeun arus motor kaleuleuwihan sarta burnout.

- 4.After pompa ieu nempatkeun kana operasi normal, guna manjangkeun umur layanan na, perlu mariksa naha tegangan suplai, arus gawé sarta lalawanan insulasi anu normal rutin. Upami kaayaan di handap ieu kapanggih, pompa kedah dipareuman langsung pikeun ngabéréskeun masalah.

- - Dina kaayaan dipeunteun, ayeuna ngaleuwihan 20%.

- - Tingkat cai dinamis turun ka bagian inlet cai, ngabalukarkeun cai intermittent.

- - Pompa submersible gaduh geter parah atanapi bising.

- - Tegangan suplai leuwih handap 340 volt.

- - A sekering dibeuleum kaluar.

- - Pipa suplai cai ruksak.

- - Résistansi insulasi termal motor langkung handap tina 0,5 megaohm.

- 5. Unit disassembly:

- - Buka dasi kabel, cabut bagian pipa, jeung cabut plat kawat.

- - screw handap baud cai, nempatkeun cai dina chamber motor.

- - nyabut filter nu, leupas screw tetep dina gandeng pikeun ngalereskeun aci motor.

- - screw handap baud nyambungkeun bagian inlet cai jeung motor, sarta misahkeun pompa ti motor (perhatikeun cushion Unit nalika misahkeun, pikeun nyegah bending tina aci pompa)

- - runtuyan disassembly tina pompa nyaéta: (tingali gambar 1) bagian inlet cai, impeller, cangkang diversion, impeller...... pariksa awak klep, nalika nyoplokkeun impeller, ngagunakeun parabot husus pikeun loosen leungeun baju kerucut tina tetep. impeller munggaran, sarta ulah bending na bruising aci pompa dina prosés disassembly.

- - prosés disassembly motor nyaéta: (tingali gambar 1) nempatkeun motor dina platform, sarta cabut kacangan, basa, aci sirah ngonci nut, dorong plat, konci, handap pituduh bearing korsi jeung baud sirah ganda ti handap. motor dina gilirannana, lajeng nyandak kaluar rotor nu (perhatikeun teu ngaruksak pakét kawat) sarta tungtungna nyabut bagian nyambungkeun jeung pituduh luhur bearing korsi.

- - Unit assembly: saméméh assembly, karat jeung kokotor tina bagian kudu cleaned, sarta permukaan jalangan jeung fasteners coated kalawan sealant, lajeng dirakit dina urutan sabalikna ti disassembly (aci motor ngalir luhur jeung ka handap sanggeus assembly salila kira hiji. millimeter), sanggeus assembly, gandeng kudu fléksibel, lajeng mesin test layar filter. Pompa submersible kedah dicandak kaluar tina sumur pikeun ngabongkar sareng pangropéa nurutkeun Pasal 5 saatos sataun operasi, atanapi kirang ti sataun operasi tapi dua taun waktos nyilem, sareng bagian-bagian anu tos digentos kedah diganti.

Welcome to use our submersible pump products!Our products are exquisitely designed and convenient to use, widely used in family, agriculture, and industrial fields.In order to ensure the lasting and stable performance of your products, we suggest paying special attention to drainage in winter to prevent motor icing, and rolling and tying the cable tightly.When storing, please choose an environment without corrosive substances and harmful gases, and keep the temperature below 40 °C.If you do not use it for a long time, please pay attention to rust prevention to protect the quality of the submersible pump.Wish you a smooth and unimpeded use experience, thank you for choosing our products!

- Impeller

- leungeun baju aci

- leungeun baju karét aci

-

Cingcin segel

01 Asupan cai sumur jero

02 Pasokan cai luhur

03 suplai cai gunung

04 cai munara

05 irigasi tatanén

06 irigasi kebon

07 asupan cai walungan

08 cai domestik