QJ series submersible pump is a kind of water lifting machine directly connected to the submersible motor and pump to work in the water. This series of pumps is vertical, small use area, compact structure, easy installation, easy maintenance and repair. Widely used in agricultural irrigation, municipal engineering, water conservancy engineering, urban water supply and drainage and industrial and mining enterprises, drought relief and flood drainage and other fields. Flow range of 5-500m3/h, lift of 4-800m, power 3-315KW. The QJ series submersible pump has stable and reliable performance, suitable for various needs of pump applications.

1, catu daya: tilu-fase AC 380V (kasabaran + / - 5%), 50HZ (kasabaran + / - 1%).

2, kualitas cai:

(1) water temperature is not higher than 20 °C;

(2) eusi najis padet (rasio massa) teu leuwih gede ti 0,01%;

(3) Nilai PH (pH) 6,5-8,5;

(4) eusi hidrogén sulfida teu leuwih gede ti 1.5mg/L;

(5) eusi ion klorida teu leuwih gede ti 400mg/L.

3, the motor is closed or water-filled wet structure, before use the submersible motor cavity must be full of clean water, to prevent false full, and then tighten the water injection, air release bolts, otherwise not allowed to use.

4, pompa submersible kudu sagemblengna submerged dina caina, jero diving teu leuwih gede ti 70m, handap pompa submersible ti handap sumur teu kurang ti 3m.

5, aliran cai sumur kudu bisa minuhan kaluaran cai pompa submersible sarta operasi kontinyu, kaluaran cai pompa submersible kudu dikawasa dina 0.7 - 1.2 kali aliran dipeunteun.

6, sumur kudu lempeng, pompa submersible teu bisa dipaké atawa dumped, ngan pamakéan nangtung.

7, pompa submersible kudu loyog jeung kabel nurutkeun sarat, jeung alat panyalindungan overload éksternal.

8, the pump is strictly prohibited without water no-load test machine.

| Modél | Aliran (m3/h) | Sirah (m) |

Laju puteran (robah / titik) |

Pompa cai(%) | Outlet diameter (mm) |

Lumaku ogé diaméterna (mm) |

Dipeunteun power(KW) |

Dipeunteun tegangan (V) |

Dipeunteun ayeuna (A) |

Efisiensi motor (%) | power factorcosφ | Unit Ukuran Radial Maximum (mm) |

Nyarios | |||||||||

| 200QJ20-40 | 20 | 40 | 2850 | 66 | 50 | 200di luhur | 4 | 380 | 10.1 | 76.0 | 0.79 | 184 | ||||||||||

| 200QJ20-54 | 54 | 5.5 | 13.6 | 77.0 | 0.8 | |||||||||||||||||

| 200QJ20-81 | 81 | 7.5 | 18.0 | 78.0 | 0.81 | |||||||||||||||||

| 200QJ20-93 | 93 | 9.2 | 21.7 | 78.5 | 0.82 | |||||||||||||||||

| 200QJ20-108 | 108 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ20-121 | 121 | 13 | 29.8 | 80.0 | 0.83 | |||||||||||||||||

| 200QJ20-148 | 148 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 200QJ20-175 | 175 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ20-202 | 202 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ20-243 | 243 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ20-270 | 270 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ20-360 | 360 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ20-442 | 442 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ25-28 | 25 | 28 | 2850 | 68 | 65 | 200di luhur | 4 | 380 | 10.1 | 76.0 | 0.79 | 184 | ||||||||||

| 200QJ25-42 | 42 | 5.5 | 13.6 | 77.0 | 0.8 | |||||||||||||||||

| 200QJ25-56 | 56 | 7.5 | 18.0 | 78.0 | 0.81 | |||||||||||||||||

| 200QJ25-70 | 70 | 9.2 | 21.7 | 78.5 | 0.82 | |||||||||||||||||

| 200QJ25-98 | 98 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ25-112 | 25 | 112 | 2850 | 68 | 65 | 200di luhur | 13 | 380 | 29.8 | 80.0 | 0.83 | 184 | ||||||||||

| 200QJ25-126 | 126 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 200QJ25-154 | 154 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ25-182 | 182 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ25-210 | 210 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ25-252 | 252 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ25-308 | 308 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ25-378 | 378 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ32-26 | 32 | 26 | 2850 | 70 | 80 | 200di luhur | 4 | 380 | 10.1 | 76.0 | 0.79 | 184 | ||||||||||

| 200QJ32-39 | 39 | 5.5 | 13.6 | 77.0 | 0.8 | |||||||||||||||||

| 200QJ32-52 | 52 | 7.5 | 18.0 | 78.0 | 0.81 | |||||||||||||||||

| 200QJ32-65 | 65 | 9.2 | 21.7 | 78.5 | 0.82 | |||||||||||||||||

| 200QJ32-78 | 78 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ32-91 | 91 | 13 | 29.8 | 80.0 | 0.83 | |||||||||||||||||

| 200QJ32-104 | 104 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 200QJ32-130 | 130 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ32-143 | 143 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ32-169 | 169 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ32-195 | 195 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ32-247 | 247 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ32-299 | 299 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ40-26 | 40 | 26 | 2850 | 72 | 80 | 200di luhur | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 184 | ||||||||||

| 200QJ40-39 | 39 | 7.5 | 18.0 | 78.0 | 0.81 | |||||||||||||||||

| 200QJ40-52 | 52 | 9.2 | 21.7 | 78.5 | 0.82 | |||||||||||||||||

| 200QJ40-65 | 65 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ40-78 | 78 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 200QJ40-104 | 104 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ40-117 | 117 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ40-143 | 143 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ40-169 | 169 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ40-208 | 208 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ40-247 | 247 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ50-26 | 50 | 26 | 2850 | 74 | 80 | 200di luhur | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 184 | ||||||||||

| 200QJ50-39 | 39 | 9.2 | 21.7 | 78.5 | 0.82 | |||||||||||||||||

| 200QJ50-52 | 52 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ50-65 | 65 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 200QJ50-78 | 78 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ50-91 | 91 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ50-104 | 104 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ50-130 | 130 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ50-156 | 156 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ50-208 | 208 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ63-24 | 63 | 24 | 2850 | 74 | 80 | 200di luhur | 7.5 | 380 | 18.0 | 78.0 | 0.81 | 184 | ||||||||||

| 200QJ63-36 | 36 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ63-60 | 60 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ63-72 | 72 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ63-84 | 84 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ63-96 | 96 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ63-120 | 120 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ63-144 | 144 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ80-22 | 80 | 22 | 2850 | 75 | 100 | 200di luhur | 7.5 | 380 | 18.0 | 78.0 | 0.81 | 184 | ||||||||||

| 200QJ80-33 | 33 | 11 | 25.8 | 79.0 | 0.82 | |||||||||||||||||

| 200QJ80-44 | 44 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 200QJ80-55 | 55 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ80-66 | 66 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ80-88 | 88 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ80-99 | 99 | 37 | 79.7 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ80-121 | 121 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

| 200QJ100-18 | 100 | 18 | 2850 | 75 | 100 | 200di luhur | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 184 | ||||||||||

| 200QJ100-27 | 27 | 13 | 29.8 | 80.0 | 0.83 | |||||||||||||||||

| 200QJ100-36 | 36 | 18.5 | 41.6 | 81.5 | 0.83 | |||||||||||||||||

| 200QJ100-45 | 45 | 22 | 48.2 | 82.5 | 0.84 | |||||||||||||||||

| 200QJ100-54 | 54 | 25 | 54.5 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ100-63 | 63 | 30 | 65.4 | 83.0 | 0.84 | |||||||||||||||||

| 200QJ100-72 | 100 | 72 | 2850 | 75 | 100 | 200di luhur | 37 | 380 | 79.7 | 84.0 | 0.84 | 184 | ||||||||||

| 200QJ100-90 | 90 | 45 | 96.9 | 84.0 | 0.84 | |||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, mastikeun nurutkeun dibekelan tina angkat pompa, rentang aliran pamakéan, pikeun nyegah aliran low atawa gaya ngompa angkat tinggi, dorong bearing jeung bagian séjén maké, nu overload motor dibeuleum 6, sanggeus pompa handap sumur, pangukuran motor ka résistansi insulasi taneuh teu kudu kirang ti 100M, sanggeus mimiti niténan tegangan jeung arus, pariksa insulasi motor pungkal, naha luyu jeung sarat; pompa suhu lokasi gudang lamun kirang ti titik beku, kudu garing cai Rongga motor, nyegah karuksakan és cai Rongga motor disababkeun ku hawa low.

Structure brief: pump part is mainly composed of pump shaft, impeller, diversion shell, rubber bearing, check valve body (optional parts) and other components.The motor part is mainly composed of base, pressure regulating film, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand ring, water inlet section, cable and other components.

Fitur utama produk di antarana:

1, motor nyaéta motor asynchronous tilu-fase baseuh cai-kaeusi cai, rongga motor pinuh ku cai bersih, dipaké pikeun niiskeun motor jeung lubricate bearing nu, tekanan régulasi pilem di handapeun motor dipaké pikeun nyaluyukeun. bédana ékspansi jeung kontraksi tekanan cai di jero awak disababkeun ku parobahan naékna suhu motor.

2, Dina raraga nyegah keusik dina cai sumur ti ngasupkeun motor, tungtung luhur aci motor dilengkepan dua segel minyak, sarta cingcin keusik dipasang pikeun ngabentuk struktur pencegahan keusik.

3, Dina raraga nyegah aci pompa ti ngajalankeun up nalika dimimitian, aci pompa jeung aci motor disambungkeun ku gandeng a, sarta hiji bearing dorong luhur dipasang di bagian handap motor.

4, The lubrication tina motor jeung bearing pompa nyaéta lubrication cai.

5, The motor stator pungkal dijieunna tina kualitas luhur submersible motor pungkal kawat, kalawan kinerja insulasi tinggi.

6, pompa dirancang ku komputer CAD, kalawan struktur basajan tur kinerja teknis alus.

(1) Persiapan saméméh instalasi:

1. Pariksa naha pompa submersible meets kaayaan pamakéan sarta wengkuan spésifed dina manual.

2. Ngagunakeun obiect beurat kalawan diaméter sarua jeung diaméter luar maksimum pompa submersible, ngukur naha inneldiameter of wellbore nu bisa nyocogkeun ka pompa submersible, sarta ngukur naha jero sumur meets sarat instalasi.

3. Pariksa naha liang sumur beresih jeung cai sumur keruh. Pernah ngagunakeun pompa listrik submersible pikeun ngumbah leutak pompa welor jeung cai keusik pikeun nyegah karuksakan prématur kana pompa listrik submersible.

4. Pariksa naha posisi clamp pamasangan welhead cocog sareng naha éta tiasa tahan kualitas sadaya unit.

5. Pariksa lamun komponén pompa submersible geus réngsé sarta dipasang leres nurutkeun diagram assembly dina manualLeupaskeun layar filter sarta muterkeun gandeng pikeun nempo lamun rotates flexibly

6. Unscrew nu screw cai jeung fillthe rohangan motor jeung bersih, cai non corrosive (catetan. Pastikeun pikeun fil eta nepi), teras tighten waterscrew nu. Saatos 12 jam suntikan cai, résistansi insulasi motor henteu kedah kirang ti 150M Q nalika diukur nganggo méja oyag 500V.

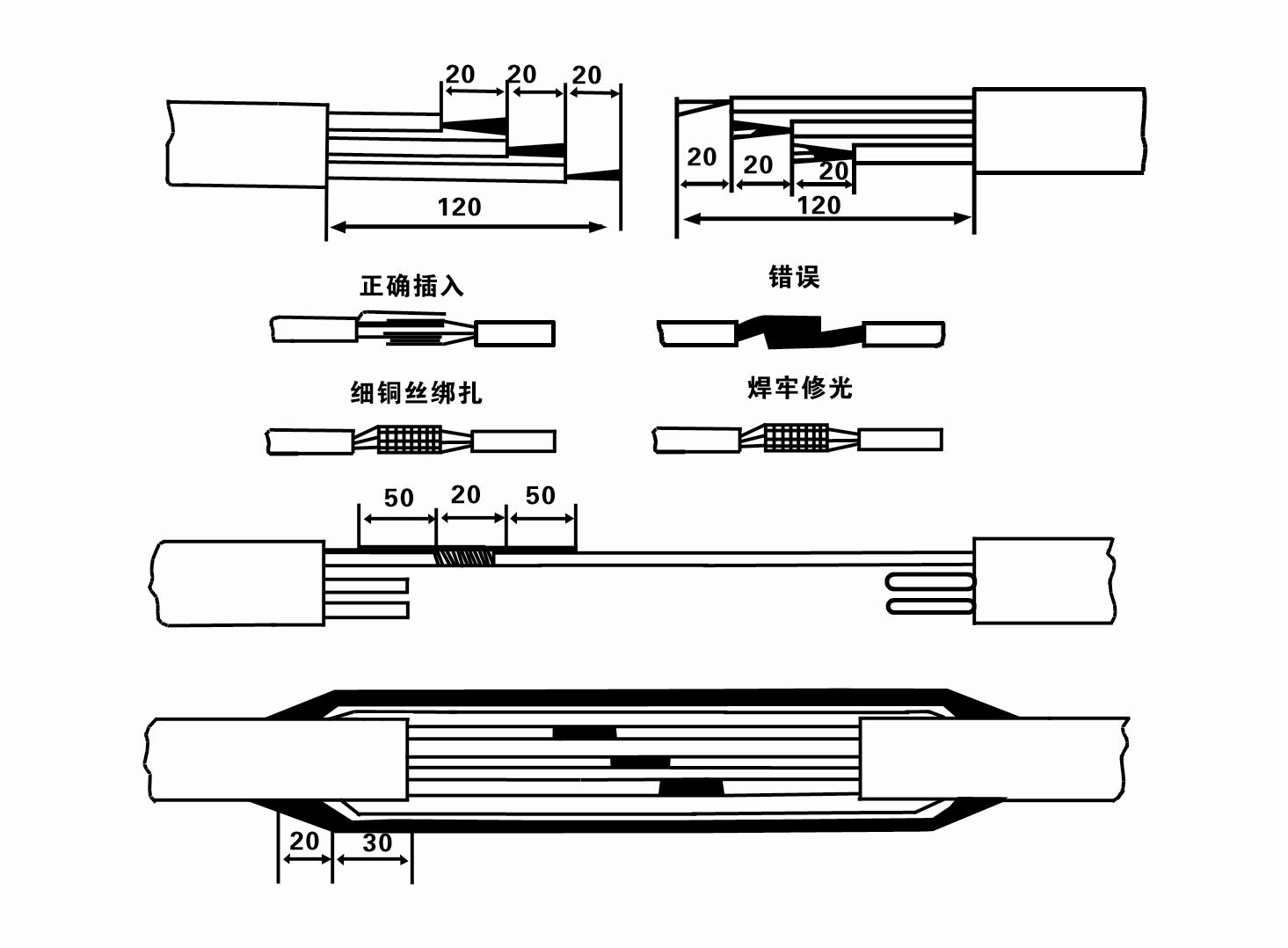

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Diagram prosés wiring kabel napel nyaéta kieu:

8. Paké multimeter pikeun pariksa naha kawat tilu-fase disambungkeun tur naha lalawanan DC kira saimbang.

9. Pariksa naha sirkuit jeung trafo kapasitas overloaded, lajeng sambungkeun switch panyalindungan overload atawa alat dimimitian. Tempo Table 2 pikeun model husus, lajengTuang ember cai kana pompa cai ti outlet pompa cai mun lubricate bantalan karét dina pompa, lajeng nempatkeun pompa listrik submersible orientasi tegak tur steady.Start (teu leuwih ti hiji detik) jeung pariksa naha arah steering konsisten jeung tanda steering. Lamun henteu, swap wae dua panyambungna tina kabel tilu-fase. Lajeng install filter sarta nyiapkeun turun sumur. Upami dianggo dina kaayaan anu khusus (sapertos parit, parit, walungan, balong, balong, jsb.), pompa listrik kedah didasarkeun sacara dipercaya.

(2) Alat sareng alat pamasangan:

1. Hiji pasangan ngangkat ranté pikeun leuwih ti dua ton.

2. A tripod kalayan jangkungna nangtung teu kurang ti opat méter.

3. Dua tali gantung (tali kawat) nu bisa nanggung beurat leuwih ti hiji ton (bisa nanggung beurat hiji set lengkep pompa cai).

4. Pasang dua pasang jepitan (splints).

5. Wrenches, palu, obeng, pakakas listrik jeung instrumen, jsb.

(3) pamasangan pompa listrik:

1. Diagram instalasi tina pompa listrik submersible ditémbongkeun dina Gambar 2. Dimensi instalasi husus ditémbongkeun dina Table 3 "Daptar Dimensi Instalasi Pompa Electric Submersible".

2. Pompa listrik submersible kalawan sirah kirang ti 30 méter bisa hoisted langsung kana sumur ngagunakeun hoses jeung tali kawat atawa tali hemp lianna nu bisa nanggung beurat pinuh ku sakabéh mesin, pipa cai, jeung cai dina pipa.

3. Pompa kalayan sirah leuwih ti 30 méter ngagunakeun pipa baja, sarta runtuyan instalasi nyaéta kieu:

①Pake jepitan pikeun ngajepit tungtung luhur bagian pompa cai (motor sareng pompa cai parantos nyambungkeun waktos ayeuna), angkat nganggo ranté gantung, teras dasikeun lalaunan kana sumur dugi ka Pasang jepitan dina sirah sumur teras cabut ranté gantung.

② Paké sapasang clamps séjén pikeun clamp pipa, angkat eta kalawan ranté gantung 15 cm jauh ti flange, sarta nurunkeun eta lalaunan. Antara flange pipe jeung flange pompa Pasang pad karét di tempat sarta tighten pipa na pompa merata kalawan bolts, kacangan sarta spring washers.

③ Angkat pompa beuleum saeutik, cabut jepitan dina tungtung luhur pompa cai, dasi kabelna pageuh kana pipa cai nganggo pita plastik, teras talitikeun lalaunan dugi ka jepitan disimpen dina sumur.

④Paké cara nu sarua pikeun ngabeungkeut sakabéh pipa cai kana sumur.

⑤Saatos kabel timbal-kaluar disambungkeun ka saklar kontrol, éta disambungkeun ka catu daya tilu-fase.

(4) Hal-hal anu kedah diperhatoskeun nalika instalasi:

1. Lamun fenomena jamming kapanggih salila prosés ngompa, balikkeun atawa tarik pipa cai pikeun nungkulan titik jamming. Lamun sagala rupa ukuran masih teu hasil, mangga Ulah maksakeun pompa ka handap pikeun nyegah karuksakan kana pompa listrik submersible jeung sumur.

2. Salila instalasi, a Pad karét kudu ditempatkeun di flange unggal pipa na tightened merata.

3. Nalika pompa cai diturunkeun kana sumur, éta kudu ditempatkeun di tengah-tengah pipa sumur pikeun nyegah pompa tina ngajalankeun kana témbok sumur pikeun lila, ngabalukarkeun pompa ngageter jeung motor keur nyapu jeung kaduruk. .

4. Nangtukeun jero pompa cai ka handapeun sumur dumasar kana keusik anu ngalir sareng kaayaan leutak sumur. Ulah ngubur pompa dina leutak. Jarak ti pompa cai ka handapeun sumur umumna teu kurang ti 3 méter (tingali Gambar 2).

5. Jero asupna cai tina pompa cai kedah teu kurang ti 1-1,5 méter ti tingkat cai dinamis ka titik inlet cai (tingali Gambar 2). Upami teu kitu, bantalan pompa cai tiasa gampang ruksak.

6. The lift tina pompa cai teu tiasa teuing low. Upami teu kitu, klep gerbang kedah dipasang dina pipa cai sumur pikeun ngontrol aliran pompa dina titik aliran anu dipeunteun pikeun nyegah motor kabeungharan sareng kaduruk kusabab laju aliran anu ageung.

7. Nalika pompa cai dijalankeun, kaluaran cai kedah kontinyu sareng malah, arus kedah stabil (dina kaayaan kerja anu dipeunteun, umumna henteu langkung ti 10% tina arus anu dipeunteun), sareng teu kedah aya geter atanapi bising. Upami aya abnormalitas, mesin kedah dieureunkeun pikeun milari panyababna sareng ngaleungitkeunana.

8. Nalika masang, nengetan setelan tina kawat grounding motor (tingali Gambar 2). Nalika pipa cai nyaéta pipa baja, ngarah tina clamp wellhead; lamun pipa cai téh pipa plastik, ngarah tina tanda grounding tina pompa listrik.

- (1)After the submersible pump is installed, check the insulation resistance and three-phase conduction from the switch again, check whether the instrument and the connection of the start equipment are wrong, if there is no problem, the trial machine can be started, and observe whether the indicator readings of the instrument exceed the rated voltage and current specified on the nameplate after the start, and observe whether the pump has noise and vibration phenomenon. If everything is normal, it can be put into operation.

- (2) After the first operation of the pump for four hours, the motor should be shut down to test the thermal insulation resistance quickly, and its value should not be less than 0.5 megaohm.

- (3) After the pump is shut down, it should be started after five minutes to prevent the water column in the pipe from being completely reflowed and causing the motor to burn out due to excessive current.

- (4)After the pump is put into normal operation, in order to prolong its service life, it is necessary to check regularly whether the supply voltage, running current and insulation resistance are normal.If the following conditions are found, the pump should be shut down immediately to eliminate the fault:

- 1 under the rated working conditions, the current exceeds 20%;

- 2 the dynamic water level drops to the water inlet part, resulting in intermittent drainage;

- 3 the submersible pump vibrates seriously or emits huge noise;

- 4 the supply voltage is lower than 340 volts;

- 5 a fuse is blown out;

- 6 the water pipe is damaged;

- 7 the thermal insulation resistance between the motor and the ground is less than 0.5 megaohm. The discovery of these problems need to be handled in time to ensure the normal operation of the pump, improve its reliability, so as to ensure the stable operation of the equipment for a long time.

(5)unit disassembly:

1 untie the cable tie, remove the pipeline part, remove the wire plate.

2 screw handap baud cai, nempatkeun cai dina chamber motor.

3 remove the filter, loose the fixing screw on the coupling to fix the motor shaft.

4 screw down the bolt connecting the water inlet section with the motor, separate the pump and the motor (pay attention to the unit cushion when separating, prevent the bending of the pump shaft)

5 pump disassembly sequence is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, avoid bending the pump shaft and each part in the disassembly process.

6 motor disassembly process is: (see figure 1) place the motor on the platform, and remove the nut, base, shaft head lock nut, thrust plate, key, lower guide bearing seat, double head bolt from the bottom of the motor in turn. Then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and the upper guide bearing seat.

7 unit assembly: Before assembly, the rust and dirt of the parts should be cleaned, and the mating surfaces and fasteners should be coated with sealant. Then they should be assembled in the reverse order of disassembly (the up and down momentum of the motor shaft is about 1 mm after assembly). After assembly, the coupling should be flexible, and then the filter screen test machine.

- The submersible pump should be dismantled and repaired according to Article 5 for each operation year, or less than one year, but the submersible time has reached two years, and the worn parts should be replaced.

1, nempatkeun kaluar cai dina rohangan motor (utamana dina usum tiis pikeun nyegah motor ti katirisan), sarta dasi kabel ogé.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, pamakéan jangka panjang kedah nengetan pencegahan karat tina pompa submersible.

- Impeller

- leungeun baju aci

- leungeun baju karét aci

-

Cingcin segel

01 Asupan cai sumur jero

02 Pasokan cai luhur

03 suplai cai gunung

04 cai munara

05 irigasi tatanén

06 irigasi kebon

07 asupan cai walungan

08 cai domestik