QJ series submersible pump is a kind of water lifting equipment directly connected to the submersible motor and pump to work in the water. This series of pumps are vertical, with small use area, compact structure, simple installation, convenient maintenance and repair. It is widely used in agricultural irrigation, municipal engineering, water conservancy engineering, urban water supply and drainage, industrial and mining enterprises water supply and drainage, drought relief and flood relief and so on. The flow range is 5-500m3/h, the head is 4-800m, and the power is 3-315KW. This product has stable and reliable performance, can meet the needs of various different uses of pumps, and is one of the excellent choices in the market.

This product is a three-phase AC 380V electric pump, suitable for various pump applications. The power supply requirements for ± 5% of the three-phase AC 380V voltage, 50HZ frequency fluctuation range of ± 1%. Water quality requirements include water temperature not higher than 20 °C, solid impurities content (mass ratio) is not greater than 0.01%, PH value of 6.5-8.5, hydrogen sulfide content is not greater than 1.5mg/L, chloride ion content is not greater than 400mg/L. The motor adopts a closed or water injection wet structure, before use must be submersible motor inner cavity filled with clean water to prevent empty, while fastening the water injection and pressure relief bolts, otherwise not to use. Submersible pump must be completely immersed in water work, immersion depth shall not exceed 70 meters, the distance from the bottom of the pump to the bottom of the well shall not be less than 3 meters. Well water inflow shall meet the water output and continuous operation requirements of submersible pump, pump output shall be controlled at 0.7-1.2 times the rated flow. The well must be vertical, submersible pump can not be used horizontally or tilted, only vertical use. Submersible pump must be equipped with cables as required, and equipped with external overload protection device. It is strictly prohibited to do no-load test without water.

| Samfura | Yawo (m3/h) | Shugaban (m) |

Rotatingspeed(change/point) | Ruwan Ruwa(%) | Fitowa diamita (mm) |

Aiwatar da kyau diamita (mm) |

An ƙididdigewa power(KW) |

An ƙididdigewa irin ƙarfin lantarki (V) |

An ƙididdigewa halin yanzu (A) |

Ingancin Motoci (%) | power factorcosφ | Naúrar Girman Radial Maximu (mm) |

|||||||||

| 175QJ10-42 | 10 | 42 | 2850 | 53 | 50 | 175a sama | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ10-56 | 56 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-70 | 70 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-84 | 84 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ10-112 | 112 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-126 | 126 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-140 | 140 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ15-42 | 15 | 42 | 2850 | 58 | 50 | 175a sama | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ15-55 | 55 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-65 | 65 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-85 | 85 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ15-112 | 112 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 175a sama | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ20-39 | 39 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ20-52 | 52 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ20-78 | 78 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ20-91 | 91 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-104 | 104 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ20-130 | 130 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-156 | 156 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-182 | 187 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ20-208 | 208 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-247 | 247 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-273 | 273 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-299 | 299 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-325 | 325 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-364 | 364 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-26 | 25 | 26 | 2850 | 66 | 65 | 175a sama | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ25-39 | 39 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ25-65 | 25 | 65 | 2850 | 66 | 65 | 175a sama | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ25-78 | 78 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ25-91 | 91 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ25-104 | 104 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-130 | 130 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-156 | 156 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ25-182 | 182 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-208 | 208 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-221 | 221 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-247 | 247 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-260 | 260 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-299 | 299 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ30-30 | 30 | 30 | 2850 | 67 | 80 | 175a sama | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ30-40 | 40 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-24 | 32 | 24 | 2850 | 67 | 80 | 175a sama | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ32-36 | 36 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-48 | 48 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ32-60 | 60 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ32-72 | 72 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ32-84 | 84 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-96 | 96 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-120 | 120 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ32-144 | 144 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-168 | 168 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-180 | 180 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-192 | 192 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-204 | 204 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-240 | 240 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ35-60 | 35 | 60 | 2850 | 67 | 80 | 175a sama | 10 | 380 | 25.0 | 78.0 | 0.78 | 168 | |||||||||

| 175QJ35-75 | 75 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ35-100 | 100 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ40-24 | 40 | 24 | 2850 | 70 | 80 | 175a sama | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ40-30 | 30 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ40-36 | 36 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ40-48 | 48 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ40-60 | 60 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ40-72 | 72 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-84 | 84 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-96 | 96 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ40-120 | 120 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-132 | 132 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-144 | 144 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-156 | 156 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-168 | 168 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-192 | 192 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-24 | 50 | 24 | 2850 | 72 | 80 | 175a sama | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ50-36 | 36 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ50-48 | 48 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ50-70 | 70 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ50-84 | 84 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ50-96 | 96 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-108 | 108 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-120 | 120 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-132 | 132 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-144 | 144 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-156 | 156 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-22 | 63 | 22 | 2850 | 72 | 80 | 175a sama | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ63-44 | 44 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-55 | 55 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-66 | 66 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ63-77 | 77 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-88 | 88 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-99 | 63 | 99 | 2850 | 72 | 80 | 175a sama | 30 | 380 | 66.6 | 81.5 | 0.84 | 168 | |||||||||

| 175QJ63-110 | 110 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-132 | 132 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-9 | 80 | 9 | 2850 | 73 | 100 | 175a sama | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ80-18 | 18 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ80-27 | 27 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ80-36 | 36 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ80-45 | 45 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ80-54 | 54 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-63 | 63 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-72 | 72 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-81 | 81 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-90 | 90 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-98 | 98 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

1, rijiyar famfo mai ruwa mai tsafta don famfo mai tsafta, hana wanke sabon rijiyar, famfo ruwa da ruwan laka,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have common motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the pump must be reliably grounded in the process of installation and use. Prohibit push and pull switch in the case of wet hands and feet. Must cut off the power supply before installation and maintenance of electric pumps. Must install "electric shock prevention" obvious mark in the place where the pump is used. Before going down the well or installation, the motor cavity must be filled with distilled water or non-corrosive clean cold water, and must tighten the water inlet / outlet bolts.

4, when the pump is tested on the ground, water must be added to the pump cavity to lubricate the rubber bearing. The instantaneous start can not exceed one second, check whether the direction is the same as the direction indicated. When the pump is placed vertically, pay attention to safety to prevent overturning and injury.

5, tsananin bisa ga tanadi na famfo daga, kwarara kewayon amfani, don hana low kwarara ko high daga yin famfo karfi, da tura hali da sauran sassa na lalacewa, da mota obalodi kone.

6, bayan famfo saukar da rijiyar, ma'aunin motar zuwa juriya na ƙasa bai kamata ya zama ƙasa da 100M ba, bayan farawa don lura da ƙarfin lantarki da na yanzu, duba murfin iska na motar, ko daidai da bukatun; famfo ajiya wurin zafin jiki idan kasa da daskarewa batu, ya kamata a bushe da ruwa a cikin kogon mota, hana motor rami ruwa kankara lalacewa lalacewa ta hanyar low zazzabi.

The pump part is mainly composed of pump shaft, impeller, guide housing, rubber bearing, check valve body (optional) and other parts. The motor part is mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand discharging ring, water inlet section, lead cable and other parts.

Babban fasali na samfurin sun haɗa da:

- 1.The motor is a water-immersed wet three-phase asynchronous motor, and the motor cavity is filled with water to cool the motor and lubricate the bearing. The pressure regulating diaphragm at the bottom of the motor is used to adjust the expansion-contraction pressure difference inside and outside the body caused by the change of the motor's temperature rise.

- 2. In order to prevent the sand in the well water from entering the motor, two oil seals are installed on the upper end of the motor shaft extension, and a sand discharging ring is installed to form a sand discharging structure.

- 3. In order to prevent the pump shaft from jumping when starting, the pump shaft and the motor shaft are connected together through a coupling, and a thrust bearing is installed under the motor.

- 4. The motor and pump bearing are lubricated by water.

- 5. The motor stator winding is made of high-quality submersible motor winding wire, with high insulation performance.

- 6. The pump is designed by computer CAD, with simple structure and excellent technical performance.

(1)Shiri kafin shigarwa:

1. Bincika ko famfo mai nutsewa ya dace da yanayin amfani da iyaka da aka ƙayyade a cikin littafin.

2. Yin amfani da maɗaukaki mai nauyi tare da diamita daidai da matsakaicin matsakaicin diamita na waje na famfo, auna ko inneldimeter na rijiyar zai iya dacewa da famfo mai ruwa, kuma auna ko zurfin rijiyar ya dace da bukatun shigarwa.

3. A duba ko rijiyar tana da tsafta da kuma ko ruwan rijiyar turbude ne. Kada a taɓa amfani da famfon lantarki mai nutsewa don wanke laka na welor da ruwan yashi don gujewa lalacewa da wuri ga famfon lantarki mai nisa.

4. Bincika ko matsayin mannen shigarwa na welhead ya dace kuma ko zai iya jure ingancin duka naúrar.

5. Bincika idan kayan aikin famfo na submersible sun cika kuma an shigar dasu yadda ya kamata bisa ga zanen taron da ke cikin littafin

6. Cire dunƙule ruwa kuma cika ramin motar da ruwa mai tsabta mara lalacewa (bayanin kula. Tabbatar da cika shi), sannan ƙara matse ruwan. Bayan sa'o'i 12 na allurar ruwa, juriyar juriya na motar kada ta zama ƙasa da 150M Q lokacin da aka auna tare da tebur girgiza 500V.

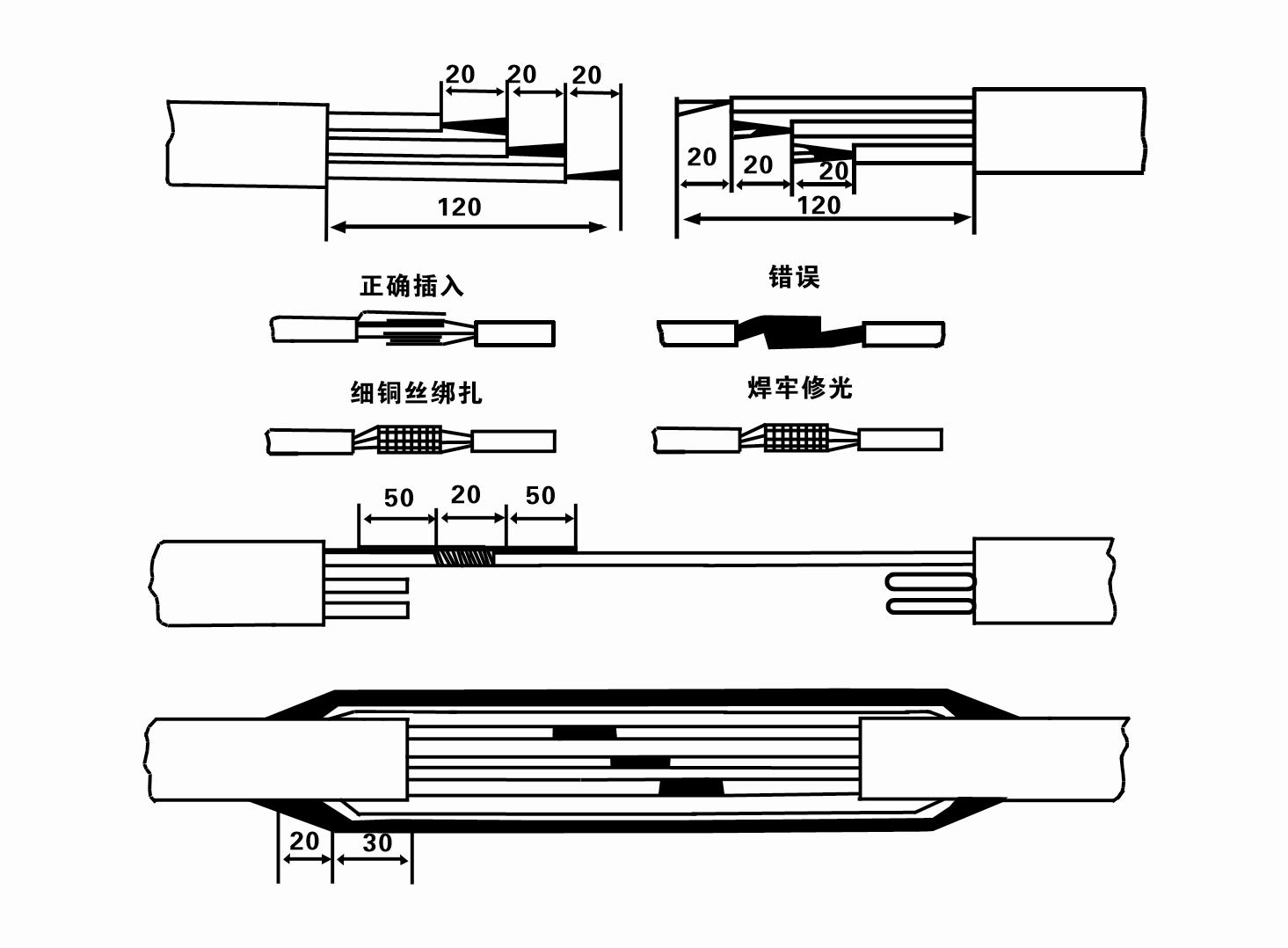

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Jadawalin tsarin aikin wayoyi na USB wanda aka makala shine kamar haka:

8. Yi amfani da multimeter don bincika ko an haɗa wayoyi masu hawa uku kuma ko juriyar DC ta kusan daidaita.

9. Bincika ko ikon kewayawa da na'ura mai canzawa sun yi yawa, sa'an nan kuma haɗa maɓallin kariya daga overload ko kayan farawa. Dubi Table 2 don takamaiman samfura, sa'an nan kuma Zuba guga na ruwa a cikin famfo na ruwa daga tashar famfo na ruwa don sa mai da igiya na roba a cikin famfo, sa'an nan kuma sanya famfo na lantarki da ke karkashin ruwa a tsaye kuma a tsaye. Fara (ba fiye da dakika ɗaya ba) kuma duba ko jagoran tuƙi ya yi daidai da alamar tuƙi. Idan ba haka ba, musanya kowane haɗe-haɗe biyu na kebul na zamani uku. Sannan shigar da tacewa kuma shirya don gangara rijiyar. Idan aka yi amfani da shi a lokuta na musamman (kamar ramuka, ramuka, koguna, tafkuna, tafkuna, da sauransu), famfon lantarki dole ne ya zama ƙasa da dogaro.

(2) Kayan aiki da kayan aiki:

1. Ɗaya daga cikin sarƙoƙi na ɗagawa don fiye da ton biyu.

2. Tafiya mai tsayi a tsaye wanda bai gaza mita hudu ba.

3. Igiyoyin rataye guda biyu ( igiyoyin waya ) waɗanda zasu iya ɗaukar nauyin fiye da ton ɗaya (za su iya ɗaukar nauyin cikakken saitin famfo na ruwa).

4. Shigar da nau'i-nau'i biyu na manne (splints).

5. Wrenches, guduma, screwdrivers, lantarki kayan aiki da kayan aiki, da dai sauransu.

(3) Shigar da famfun lantarki:

1. Shigarwa ta hanyar yin gwajin lantarki mai saukarwa an nuna shi a cikin Hoto na 2. Ana nuna takamaiman girma a cikin Table 3 "Jerin shigarwa girma na famfo mai saukarwa".

2. Za a iya ɗaga famfunan wutar lantarki da ke ƙarƙashin ƙasa da kai ƙasa da mita 30 kai tsaye a cikin rijiyar ta hanyar amfani da tudu da igiyoyin waya ko wasu igiyoyin hemp waɗanda za su iya ɗaukar cikakken nauyin injin gabaɗaya, bututun ruwa, da ruwa a cikin bututu.

3. Pumps tare da shugaban sama da mita 30 suna amfani da bututun ƙarfe, kuma tsarin shigarwa shine kamar haka:

①A yi amfani da matsi don matse ƙarshen ɓangaren fanfo na ruwa (motar da famfon ɗin an haɗa su a wannan lokacin), ɗaga shi da sarƙar rataye, a hankali daure shi a cikin rijiyar har sai a daka matsi a kan rijiyar a cire. sarkar rataye.

② Yi amfani da wani nau'i na manne guda biyu don matsa bututu, ɗaga shi tare da sarƙar rataye 15 cm daga flange, kuma rage shi a hankali. Tsakanin flange na bututu da famfo flange Saka robar kushin a wurin da kuma matsawa bututun da famfo daidai da kusoshi, goro da masu wankin bazara.

③ Ɗaga fam ɗin da ke ƙarƙashin ruwa kaɗan, cire matsi a saman ƙarshen famfon na ruwa, ɗaure kebul ɗin da ƙarfi ga bututun ruwa tare da tef ɗin filastik, sannan a daure ta ƙasa har sai an sanya matsi a bakin rijiyar.

④ Yi amfani da wannan hanyar don ɗaure duk bututun ruwa a cikin rijiyar.

⑤ Bayan an haɗa kebul na gubar da aka haɗa zuwa maɓallin sarrafawa, an haɗa shi da wutar lantarki na matakai uku.

(4) Abubuwan lura yayin shigarwa:

1. Idan an sami wani abin damuwa yayin aikin famfo, juya ko ja bututun ruwa don shawo kan matsewar. Idan har yanzu matakai daban-daban ba su yi aiki ba, don Allah kar a tilasta famfo ƙasa don guje wa lalacewa ga famfon lantarki da ke ƙarƙashin ruwa da rijiyar.

2. A lokacin shigarwa, ya kamata a sanya takalmin roba a gefen kowane bututu kuma a ɗaure shi daidai.

3. Idan aka saukar da famfon ruwa a cikin rijiyar, sai a sanya shi a tsakiyar bututun rijiyar don hana famfo yin gudu da bangon rijiyar na tsawon lokaci, wanda hakan zai sa fam ɗin ya yi rawar jiki, motar kuma ta share ta ƙone. .

4. Ƙayyade zurfin famfo na ruwa zuwa kasan rijiyar bisa ga yanayin yashi da yashi na rijiyar. Kada a binne famfo a cikin laka. Nisa daga famfon ruwa zuwa kasan rijiyar gabaɗaya bai wuce mita 3 ba (duba hoto na 2).

5. Zurfin shigar ruwa na famfo ruwa ya kamata ya zama ƙasa da mita 1-1.5 daga matakin ruwa mai ƙarfi zuwa kullin shigar ruwa (duba Hoto 2). In ba haka ba, famfo famfo na ruwa na iya lalacewa cikin sauƙi.

6. Tashin famfo na ruwa ba zai iya zama ƙasa da ƙasa ba. In ba haka ba, ana buƙatar shigar da bawul ɗin gate a kan bututun ruwa na rijiyar don sarrafa magudanar famfo a wurin da aka ƙididdige shi don hana yin lodin motar da ƙonewa saboda yawan kwararar ruwa.

7. Lokacin da famfo na ruwa ke gudana, fitar da ruwa ya kamata ya kasance mai ci gaba kuma har ma, halin yanzu ya kamata ya kasance mai ƙarfi (a karkashin yanayin aiki mai ƙima, gabaɗaya ba fiye da 10% na halin yanzu ba), kuma kada a yi rawar jiki ko amo. Idan akwai wata matsala, yakamata a dakatar da injin don gano dalilin da kuma kawar da shi.

8. Lokacin shigarwa, kula da saitin waya ta ƙasa (duba hoto 2). Lokacin da bututun ruwa ya kasance bututun ƙarfe, kai shi daga matsewar rijiyar; lokacin da bututun ruwa ya zama bututun filastik, kai shi daga alamar ƙasa na famfon lantarki.

(1)submersible pump installation is complete, re-check the insulation resistance and three-phase conduction from the switch, check the instrument and start the equipment connection error, if there is no problem, can start the trial, after the start of the instrument indicating readings whether more than the nameplate stipulated rated voltage and current, observe the pump noise and vibration phenomenon, everything is normal can be put into operation.

(2)pump operation for the first four hours, should be shut down quickly test the thermal insulation resistance of the motor, the value should not be less than 0.5 megaohm.

(3)pump shutdown, should be started after an interval of five minutes, to prevent the water column in the pipe has not completely reflux caused by excessive motor current and burnout.

(4)pump into normal operation,in order to prolong its service life, to check the supply voltage, working current and insulation resistance is normal, if found the following situation, should immediately shut down troubleshooting.

1 a cikin yanayin da aka ƙididdigewa, halin yanzu ya fi 20%.

Matsayin ruwa mai ƙarfi 2 zuwa sashin shigar ruwa, yana haifar da ruwa mai tsaka-tsaki.

3 submersible famfo mai tsananin girgiza ko amo.

4 wadata ƙarfin lantarki ne kasa da 340 volts.

5 fuse ya ƙone wani lokaci.

6 lalacewar bututun ruwa.

Motar 7 zuwa juriya na rufin zafi bai wuce 0.5 megaohm ba.

(5)This product is a portable water pump, with the characteristics of easy disassembly, the user can disassemble and clean the various components according to the following steps to maintain the normal operation of the pump. First of all to untie the cable tie, remove the pipeline part and take off the line protection plate. Then unscrew the drain bolt, discharge all the water in the motor chamber. Then take off the filter, loosen the fixing screw on the coupling fixed motor shaft. Then unscrew the bolt connecting the water inlet section and the motor, the pump and the motor separation (pay attention to the device leveling when separating, to prevent the bending of the pump shaft). The sequence of disassembly of the pump is: water inlet section, impeller, guide housing, impeller, check valve body. When disassembling the impeller, use special tools to loosen the cone sleeve fixed the impeller. In the whole disassembly process, pay attention to avoid bending the pump shaft and damage various parts. The steps of motor disassembly are: put the motor on the platform, remove the nut, seat, shaft head lock nut, thrust plate, key, lower guide rail from the bottom in order (tie rod bolt), then remove the rotor (pay attention not to damage the wire packet), and finally remove the connecting section and the upper guide bearing seat. Before assembly, the rust and dirt of each part should be cleaned, and sealant should be applied to each mating surface and fastener, and then the assembly should be carried out in the opposite order of disassembly (the movement of the motor shaft after assembly is about 1 mm). After assembly, the coupling should be flexible, and then the filter should be put on for machine test. 6. Submersible electric pump should be taken out of the well for dismantling and maintenance according to Article 5 after operating for one year, or less than one year, but the diving time has reached two years, and the worn parts should be replaced.

1, fitar da ruwa a cikin rami na motar (musamman a lokacin hunturu don hana motar daga daskarewa), kuma daure kebul ɗin da kyau.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, dogon lokacin amfani ya kamata kula da tsatsa rigakafin submersible farashinsa.

- impeller

- Shaft hannun riga

- Rubber shaft hannun riga

-

Zoben rufewa

01 Ruwa mai zurfi mai zurfi

02 Ruwa mai tsayi mai tsayi

03 ruwan tudu

04 Tower ruwa

05 Noma ban ruwa

06 ban ruwa na lambu

07 ruwan kogi

08 ruwan gida