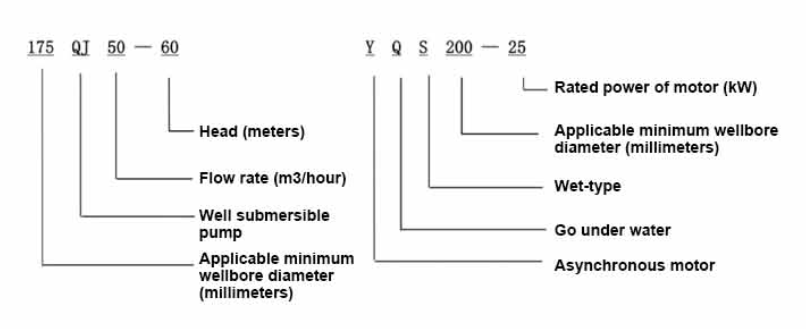

QJ series submersible pump is a kind of water lifting equipment directly connected to the submersible motor and pump to work in the water. This series of pumps are vertical, with small use area, compact structure, simple installation, convenient maintenance and repair. It is widely used in agricultural irrigation, municipal engineering, water conservancy engineering, urban water supply and drainage, industrial and mining enterprises water supply and drainage, drought relief and flood relief and so on. The flow range is 5-500m3/h, the head is 4-800m, and the power is 3-315KW. This product has stable and reliable performance, can meet the needs of various different uses of pumps, and is one of the excellent choices in the market.

This product is a three-phase AC 380V electric pump, suitable for various pump applications. The power supply requirements for ± 5% of the three-phase AC 380V voltage, 50HZ frequency fluctuation range of ± 1%. Water quality requirements include water temperature not higher than 20 °C, solid impurities content (mass ratio) is not greater than 0.01%, PH value of 6.5-8.5, hydrogen sulfide content is not greater than 1.5mg/L, chloride ion content is not greater than 400mg/L. The motor adopts a closed or water injection wet structure, before use must be submersible motor inner cavity filled with clean water to prevent empty, while fastening the water injection and pressure relief bolts, otherwise not to use. Submersible pump must be completely immersed in water work, immersion depth shall not exceed 70 meters, the distance from the bottom of the pump to the bottom of the well shall not be less than 3 meters. Well water inflow shall meet the water output and continuous operation requirements of submersible pump, pump output shall be controlled at 0.7-1.2 times the rated flow. The well must be vertical, submersible pump can not be used horizontally or tilted, only vertical use. Submersible pump must be equipped with cables as required, and equipped with external overload protection device. It is strictly prohibited to do no-load test without water.

| Model | Flow (m3/h) | Caput (m) |

Rotatingspeed(change/point) | Aqua sentinam(%) | Outlet diametri (mm) |

Lorem bene diametri (mm) |

Ratum power(KW) |

Ratum voltage(V) |

Ratum current (A * |

Motorefficiency (%) | power factorcosφ | Unitas Aculeis Maximus amplitudo (mm) |

|||||||||

| 175QJ10-42 | 10 | 42 | 2850 | 53 | 50 | 175supra | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ10-56 | 56 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-70 | 70 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-84 | 84 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ10-112 | 112 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-126 | 126 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-140 | 140 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ15-42 | 15 | 42 | 2850 | 58 | 50 | 175supra | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ15-55 | 55 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-65 | 65 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-85 | 85 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ15-112 | 112 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 175supra | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ20-39 | 39 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ20-52 | 52 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ20-78 | 78 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ20-91 | 91 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-104 | 104 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ20-130 | 130 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-156 | 156 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-182 | 187 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ20-208 | 208 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-247 | 247 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-273 | 273 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-299 | 299 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-325 | 325 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-364 | 364 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-26 | 25 | 26 | 2850 | 66 | 65 | 175supra | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ25-39 | 39 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ25-65 | 25 | 65 | 2850 | 66 | 65 | 175supra | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ25-78 | 78 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ25-91 | 91 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ25-104 | 104 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-130 | 130 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-156 | 156 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ25-182 | 182 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-208 | 208 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-221 | 221 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-247 | 247 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-260 | 260 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-299 | 299 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ30-30 | 30 | 30 | 2850 | 67 | 80 | 175supra | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ30-40 | 40 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-24 | 32 | 24 | 2850 | 67 | 80 | 175supra | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ32-36 | 36 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-48 | 48 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ32-60 | 60 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ32-72 | 72 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ32-84 | 84 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-96 | 96 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-120 | 120 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ32-144 | 144 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-168 | 168 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-180 | 180 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-192 | 192 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-204 | 204 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-240 | 240 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ35-60 | 35 | 60 | 2850 | 67 | 80 | 175supra | 10 | 380 | 25.0 | 78.0 | 0.78 | 168 | |||||||||

| 175QJ35-75 | 75 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ35-100 | 100 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ40-24 | 40 | 24 | 2850 | 70 | 80 | 175supra | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ40-30 | 30 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ40-36 | 36 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ40-48 | 48 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ40-60 | 60 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ40-72 | 72 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-84 | 84 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-96 | 96 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ40-120 | 120 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-132 | 132 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-144 | 144 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-156 | 156 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-168 | 168 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-192 | 192 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-24 | 50 | 24 | 2850 | 72 | 80 | 175supra | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ50-36 | 36 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ50-48 | 48 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ50-70 | 70 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ50-84 | 84 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ50-96 | 96 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-108 | 108 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-120 | 120 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-132 | 132 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-144 | 144 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-156 | 156 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-22 | 63 | 22 | 2850 | 72 | 80 | 175supra | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ63-44 | 44 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-55 | 55 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-66 | 66 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ63-77 | 77 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-88 | 88 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-99 | 63 | 99 | 2850 | 72 | 80 | 175supra | 30 | 380 | 66.6 | 81.5 | 0.84 | 168 | |||||||||

| 175QJ63-110 | 110 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-132 | 132 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-9 | 80 | 9 | 2850 | 73 | 100 | 175supra | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ80-18 | 18 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ80-27 | 27 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ80-36 | 36 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ80-45 | 45 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ80-54 | 54 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-63 | 63 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-72 | 72 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-81 | 81 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-90 | 90 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-98 | 98 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

I, sentinam submersibilem bene sentinam aquam mundam, aquam novam lavare prohibe, sedimen et aquam turbidam flare;

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have common motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the pump must be reliably grounded in the process of installation and use. Prohibit push and pull switch in the case of wet hands and feet. Must cut off the power supply before installation and maintenance of electric pumps. Must install "electric shock prevention" obvious mark in the place where the pump is used. Before going down the well or installation, the motor cavity must be filled with distilled water or non-corrosive clean cold water, and must tighten the water inlet / outlet bolts.

4, when the pump is tested on the ground, water must be added to the pump cavity to lubricate the rubber bearing. The instantaneous start can not exceed one second, check whether the direction is the same as the direction indicated. When the pump is placed vertically, pay attention to safety to prevent overturning and injury.

V, stricte secundum praescripta sentinae tollunt, fluunt usui, ne humilis fluat vel alta vi flare tollat, impulsus sustinens et alias partes indumenti, motor oneris combustus.

VI, post sentinam putei, mensura motoris ad terram resistentia velit non minus quam 100M esse, post initium intentionis et currentis observare, sisto motore sinuoso velit, sive secundum requisita; sentinam repono locationis temperaturae si minus quam punctum congelatur, aqua in cavitate motoria sicca debet, ne aquae motoris cavitas glaciei damnum per frigiditas temperatura exstinguat.

The pump part is mainly composed of pump shaft, impeller, guide housing, rubber bearing, check valve body (optional) and other parts. The motor part is mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand discharging ring, water inlet section, lead cable and other parts.

Pelagus features productum includit:

- 1.The motor is a water-immersed wet three-phase asynchronous motor, and the motor cavity is filled with water to cool the motor and lubricate the bearing. The pressure regulating diaphragm at the bottom of the motor is used to adjust the expansion-contraction pressure difference inside and outside the body caused by the change of the motor's temperature rise.

- 2. In order to prevent the sand in the well water from entering the motor, two oil seals are installed on the upper end of the motor shaft extension, and a sand discharging ring is installed to form a sand discharging structure.

- 3. In order to prevent the pump shaft from jumping when starting, the pump shaft and the motor shaft are connected together through a coupling, and a thrust bearing is installed under the motor.

- 4. The motor and pump bearing are lubricated by water.

- 5. The motor stator winding is made of high-quality submersible motor winding wire, with high insulation performance.

- 6. The pump is designed by computer CAD, with simple structure and excellent technical performance.

(I) Praeparatio ante institutionem:

1. Perspice an sentinam submersibilem usui conditionibus occurrat et ambitum in manuali definitum.

2. Utens obiectu gravi cum diametro aequali maximo diametro exterioris sentinae submersibilis, metire an inneldiametri putoris sentinam submersibilem aptare possit, et metire an puteus profundus ad institutionem requisita occurrat.

3. Reprehendo utrum puteus mundus sit, et si puteus aqua turbidus est. Numquam uti sentinam electricam submersibilem ad lavandum putorem sentinam lutum et aquam arenam ad vitandum praematurum damnum ad sentinam electricam submersibilem.

4. Reprehendo an positio fibulae institutionis welhead sit conveniens et an qualitatem totius unitatis sustinere possit

5. Reprehendo si partes sentinae submersibiles sint perfectae et rite institutae secundum schematis conventus in manu-Removeo velum colum et gyrari queat ad videndum an mollius circumagatur.

6. Aquam cochleae et cavum mobilem reple, non mordax aqua (ex corrosivis (vide ut eam sursum), tum obstringas aqualram. Post 12 horas aquae injectiones, insulatio motoris resistentia non minus quam 150M Q mensurata est cum 500V tabula quatiens.

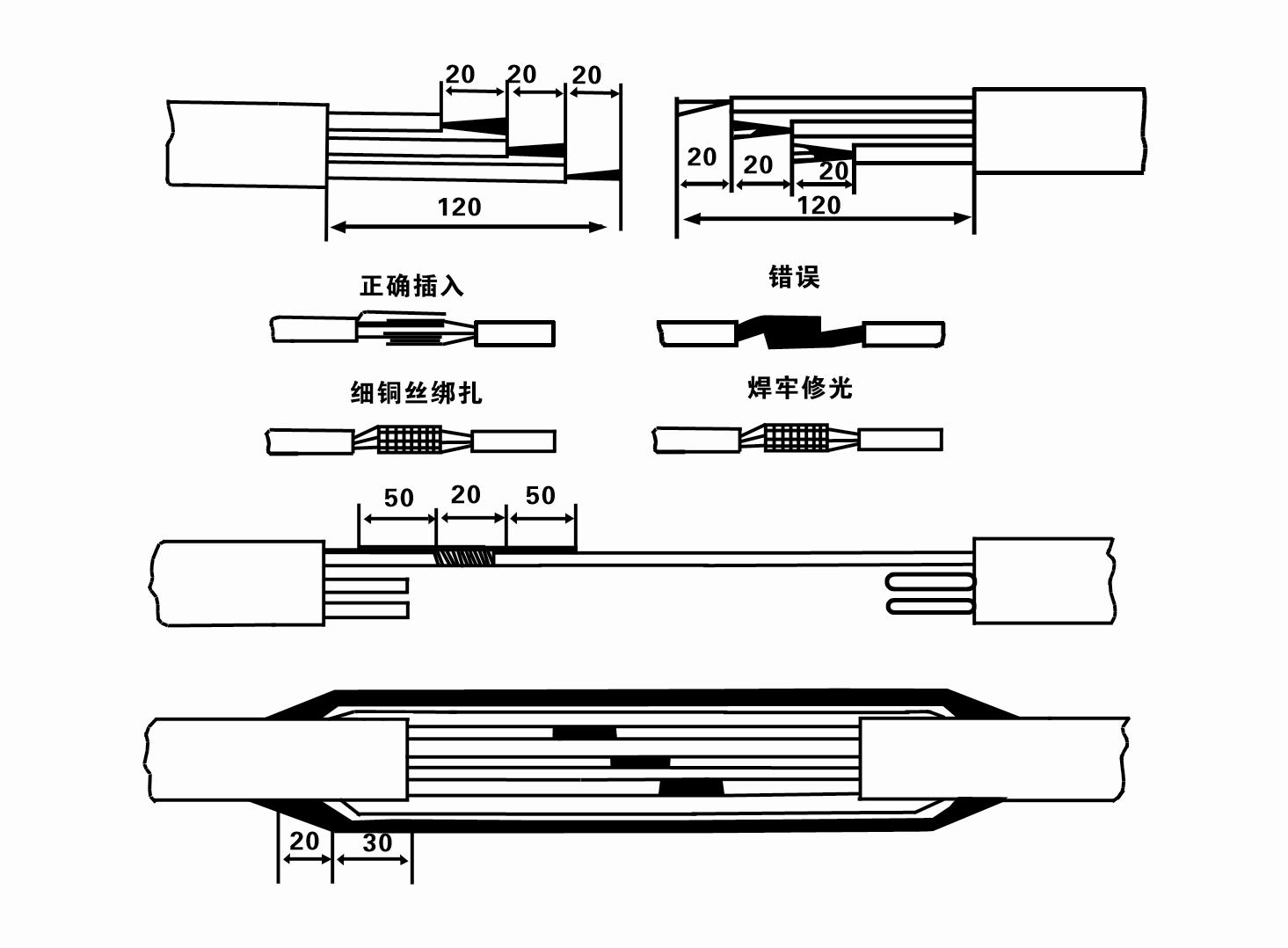

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Adnexa funis processus schematis wiring talis est:

8. Multimetro utere ad reprimendam num tria-phasma fila connexa sint et an resistentia DC proxime libratum sit.

9. Perscriptio num ambitus et transformantis capacitas cumulatur, et tunc coniunge cum onere transitum tutelae vel apparatum incipiens. Vide Tabulam 2 ad exempla specifica, et mitte situlam aquae in sentinam aquae ex aqua sentinae exitum ad praestringendum iuvantis gestus in sentinam, et pone sentinam submersibilem electricam erectam et constantem.Start (non plus quam unum secundum) et vide utrum directio gubernii sit cum signo gubernaculo consonans. Sin minus, aliquos duos connexiones trium-phase cables permuto. Deinde colum inaugurare et ad puteum descendere parant. Si in peculiaribus occasionibus adhibeantur (sicut fossae, fossae, flumina, stagna, stagna, etc.), sentinam electricam certo fundari debent.

(2) Installation instrumentorum et instrumentorum;

1. Unum par catenarum levandi plus duobus talentis.

2. Tripode cum perpendiculo non minus quam quattuor metra.

3. Duo funes suspensi (funes filum) qui pondus plus quam unum ton ferre possunt (pondere aquae soleatus completae).

4. duo paria fibulatorum inaugurare (facile).

5. Clavis, malleis, verticillis, instrumentis electricis et instrumentis, etc.

(III) Electric sentinam institutionem:

1. Tabulae institutionis sentinae submersibilis electrici in Figura ostenditur 2. Specificae institutiones dimensiones in Tabula 3 monstrantur "Index institutionis Dimensiones Submersible Electric Pump".

2. Solatus electrici submersibiles cum capite minore quam 30 metra directe levari possunt in puteum caligarum et funiculos filum vel alias funiculos cannabinos, qui plenum pondus totius machinae, fistulae aquae et aquae in tibiis ferre possunt.

3. Pumps cum capite plusquam 30 metrorum utimur fistulis ferreis, et series institutionis haec est:

① Fibulae utere ad fibulae partem superiorem sentinam aquae (motricis et aquae sentinae hoc tempore coniunctae sunt), eam cum cathena pensili tolle, et lente eam in puteum ligabis, donec Fibulae in putei caput auferas et removeas. catena pendula.

② Alterum par fibularum utere ad fistulam fibulae, eam leva cum cathena pendula 15 cm a LABIUM, et lente deprime. Inter fistulam LABIUM et sentinam flangePut Flexilis caudex in loco, et obstringere tibiam et sentinam aequabiliter cum valvis, nucibus et lavatoribus veris.

③ Sentinam submersibilem leviter tolle, fibulam in superiore fine aquae sentinae tolle, funem ligabis ad fistulam aquae cum taenia plastica firmiter, et lente ligabis eam donec Fibulae ad putei caput ponatur.

Eadem methodo omnes aquae fistulas in puteum alligant.

⑤Post funem plumbeum ad imperium transitum coniungitur, cum copia trium phase iungitur.

(4.) Notae in installation:

1. Si vallum phaenomenon in flantibus processum inveniatur, vertere vel fistulam aquam trahere, ut punctum vallum superetur. Si variae mensurae adhuc non operantur, quaeso Noli sentinam cogere ad vitandum damnum in sentinam electricam et puteum submersibilem.

2. In institutione, codex iuvantis ad cuiusque fistulae LABIUM collocari debet et aequaliter coarctari.

3. Cum aqua sentina in puteum demissa, in media fistula putei poni debet, ne sentinam contra murum putei diu curreret, sentinam pulsum et motorem verrere et comburere. .

4. Determinare profunditatem aquae sentinae ad imum putei iuxta arenam fluentem et condiciones putei limum. Sentinam in luto non sepelias. Distantia aquae sentinae ad fundum putei fere non minus quam 3 metra (vide figura 2).

5. Aquae viscus profunditas aquae sentinae non minus esse debet quam 1-1.5 metra a gradu aquae dynamicae ad nodi aquae diverticulum (vide Figure 2). Alioquin aquae sentinae gestus facile laedantur.

6. Aquae levare sentinam nimis humilis esse non potest. Alioquin valvae portae aquae putei fistulae inaugurari debet ut fluere sentinam fluere apud punctum aestimatum fluere prohibeat ne motor oneretur et exuratur propter magnas rates fluxus.

7. Cum aqua currit sentina, aqua output continuum et par esse debet, currens sit stabilis (sub condiciones operationis aestimatae, plerumque non plus quam 10% currentis aestimatae), nec vibratio nec strepitus esse debet. Si qua deprauatio est, machina cessari debet causam cognoscendi et removendi.

8. Cum inaugurari, attende ad occasum filum fundationis motoris (vide Figure 2). Fistula cum aqua est ferrea tibia, a puteo fibulato duc; cum fistula aquatica fistula plastica est, eam a fundamento sentinae electrici notam duc.

(1)submersible pump installation is complete, re-check the insulation resistance and three-phase conduction from the switch, check the instrument and start the equipment connection error, if there is no problem, can start the trial, after the start of the instrument indicating readings whether more than the nameplate stipulated rated voltage and current, observe the pump noise and vibration phenomenon, everything is normal can be put into operation.

(2)pump operation for the first four hours, should be shut down quickly test the thermal insulation resistance of the motor, the value should not be less than 0.5 megaohm.

(3)pump shutdown, should be started after an interval of five minutes, to prevent the water column in the pipe has not completely reflux caused by excessive motor current and burnout.

(4)pump into normal operation,in order to prolong its service life, to check the supply voltage, working current and insulation resistance is normal, if found the following situation, should immediately shut down troubleshooting.

1 in conditione aestimata, praesens plus quam 20% est.

2 aqua dynamica, planities aquae limbi sectio, aqua intermissa causans.

3 sentinam submersibilem seu tremulum seu sonum gravem.

4 copia intentione infra 340 voltas est.

V pascha fuse exstinctae sunt.

VI fistulae aquarum damnum.

7 motor ad resistentiam scelerisque velitarum minor quam 0.5 megaohm.

(5)This product is a portable water pump, with the characteristics of easy disassembly, the user can disassemble and clean the various components according to the following steps to maintain the normal operation of the pump. First of all to untie the cable tie, remove the pipeline part and take off the line protection plate. Then unscrew the drain bolt, discharge all the water in the motor chamber. Then take off the filter, loosen the fixing screw on the coupling fixed motor shaft. Then unscrew the bolt connecting the water inlet section and the motor, the pump and the motor separation (pay attention to the device leveling when separating, to prevent the bending of the pump shaft). The sequence of disassembly of the pump is: water inlet section, impeller, guide housing, impeller, check valve body. When disassembling the impeller, use special tools to loosen the cone sleeve fixed the impeller. In the whole disassembly process, pay attention to avoid bending the pump shaft and damage various parts. The steps of motor disassembly are: put the motor on the platform, remove the nut, seat, shaft head lock nut, thrust plate, key, lower guide rail from the bottom in order (tie rod bolt), then remove the rotor (pay attention not to damage the wire packet), and finally remove the connecting section and the upper guide bearing seat. Before assembly, the rust and dirt of each part should be cleaned, and sealant should be applied to each mating surface and fastener, and then the assembly should be carried out in the opposite order of disassembly (the movement of the motor shaft after assembly is about 1 mm). After assembly, the coupling should be flexible, and then the filter should be put on for machine test. 6. Submersible electric pump should be taken out of the well for dismantling and maintenance according to Article 5 after operating for one year, or less than one year, but the diving time has reached two years, and the worn parts should be replaced.

I, aquam in cavo motorio extingue (praesertim hieme ne motor a frigore) et funem bene ligaveris.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

III, diu terminus usus observandum ne rubigo soleatus submersible.

- Impeller

- hastile sleeve

- Flexilis scapus sleeve

-

signantes anulum

I Aquam profunda bene attractio

II High-surgere aquarum copia

03 mons aquae copia

04 aqua turris

05 Irrigatio agriculturae

VI hortus irrigationis

07 attractio aquae fluminis

08 aqua domestica