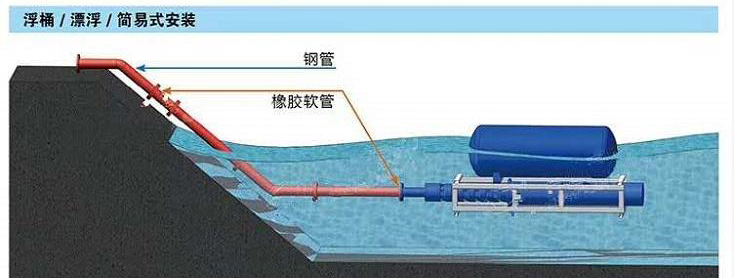

Iphampu ethambile yohlobo lwepompo eyenziwe yaba yiphampu engaphansi kwamanzi evundlile, idivayisi ye-buoy, idivayisi yokulungisa, idivayisi yokuthekelisa kanye nokunye ukuhlanganiswa okuhlanganisiwe, ukusetshenziswa kwamanzi kukonke. Izinzuzo: ukufakwa kwayo kulula futhi kuyashesha, kulula ukuyimpompa, kulula ukuyishintsha kanye nokugcinwa kwepompo.Ifanele imifula, amanzi esitsha samanzi amachibi, amaphrojekthi wobunjiniyela bamanzi aphuthumayo kudingeka aphendule ngokushesha.Uma kuqhathaniswa nobunjiniyela bomphakathi bendabuko, izindleko ze ubunjiniyela bomphakathi bulondoloziwe, izindleko eziphelele ziphansi, futhi ukwenzeka kunamandla.

Iphampu ye-buoy ingakwazi ukulungisa indawo yayo ngokuya ngokushintsha kwezinga lamanzi, engahlala igcina iphampu engaphansi kwamanzi isendaweni efanayo ngaphansi kwamanzi.

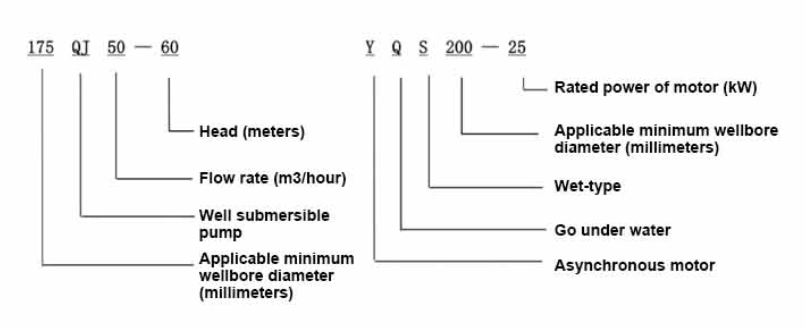

We are pleased to introduce our product, a three-phase AC 380V power supply (tolerance ± 5%), 50HZ (tolerance ± 1%) submersible pump. The product requires water quality meets the following conditions: water temperature is not higher than 20 °C; solid impurities content (mass ratio) is not greater than 0.01%; PH value (pH) is 6.5-8.5; hydrogen sulfide content is not more than 1.5mg/L; chloride ion content is not greater than 400mg/L. The motor adopts a closed or water immersion wet structure. Before use, the inner cavity of the submersible motor needs to be filled with clean water to prevent mistakes. And the water injection and exhaust bolts need to be tightened, otherwise it can not be used. The submersible pump must be completely immersed in water to work, the immersion depth shall not exceed 70 meters, and the distance between the bottom of the submersible pump and the bottom of the well shall not be less than 3 meters. The well water flow should be able to meet the water output and continuous operation of the submersible pump, and the water output of the submersible pump shall be controlled at 0.7-1.2 times of the rated flow. The well must be vertical, and the submersible pump can not be used horizontally or inclined, but only vertically. The submersible pump must match the cable according to the requirements and be equipped with external overload protection device. The pump is strictly prohibited from no-load test without water. This product is suitable for a variety of demanding pump working environment, guaranteeing efficient and stable operation, which is your ideal choice.

Wonke amamodeli angenziwa ngezifiso, sicela usithinte ukuze uthole imininingwane.

1, iphampu engaphansi kwamanzi empompa amanzi ahlanzekile, ivimbela umthombo omusha, ukupompa inzika namanzi anodaka,

2, Ibanga lika-380/50HZ lephampu yamanzi yomthombo, ukusetshenziswa kwamanye amamaki kagesi wamamotho angaphansi kwamanzi kudinga ukwenziwa ngezifiso. Ikhebula elingaphansi komhlaba kufanele lisebenzise ikhebula elingangeni manzi, kufanele libe nemishini yokuqalisa, njengebhokisi lokusabalalisa, isiqalo esingakalungi kufanele sibe nomsebenzi ovame ukusetshenziswa wokuvikela ophelele wemoto, njengokuvikela ukugcwala kwesifunda esifushane, ukuvikelwa kwesigaba, ukuvikela ugesi, ukuvikela phansi, ukuvikela idling. , uma kunezimo ezingavamile, idivayisi yokuvikela kufanele ibe uhambo olufika ngesikhathi.

3, ukufakwa kanye nokusetshenziswa kwepompo kufanele kusekelwe ngokuthembekile, kuvimbela ukusunduza nokudonsa inkinobho lapho izandla nezinyawo zimanzi, kumele kunqamule ukunikezwa kwamandla ngaphambi kokufakwa nokugcinwa kwepompo, indawo yokusebenzisa iphampu ukuze usethe " ukuvimbela ukushaqeka kukagesi" izimpawu ezisobala:

4, phansi emthonjeni noma ngaphambi kokufakwa, i-motor cavity kufanele igcwaliswe ngamanzi acwengekile noma amanzi abandayo ahlanzekile ahlanzekile angagqwali, qinisa umshudo wamanzi, iphampu ekuhlolweni komhlabathi, kufanele ibe yirabha yokugcoba amanzi egunjini lepompo. ama-bearings, ukuqala ngokushesha kungabi ngaphezu kwesekhondi, bheka ukuthi isiteringi siyefana yini nomyalelo wokuqondisa. Lapho iphampu iqondile, qaphela ukuphepha, vimbela ukulimala okugumbuqela.

5, ngokuqinile ngokwezinhlinzeko zokuphakanyiswa kwepompo, ububanzi bokugeleza bokusetshenziswa, ukuvimbela ukugeleza okuphansi noma amandla okumpompa aphakeme kakhulu, i-thrust bear nezinye izingxenye zokugqokwa, ukugcwala kwemoto kushisiwe.

6, ngemva futha phansi emthonjeni, ukukalwa motor kuya emhlabathini ukwahlukanisa ukumelana akufanele kube ngaphansi kuka-100M, ngemva kokuqala bagcine voltage kanye zamanje, hlola motor emazombezombe ukwahlukanisa, kungakhathaliseki ngokuvumelana nezidingo; futha isitoreji izinga lokushisa uma ngaphansi iphuzu umnkantsha, kufanele ome amanzi emgodini motor, ukuvimbela motor cavity amanzi ice umonakalo obangelwa lokushisa aphansi.

Isethulo esifushane sesakhiwo: ingxenye yepompo yakhiwe ikakhulukazi i-pump shaft, i-impeller, igobolondo lokuphambukisa, i-rubber bear, hlola umzimba we-valve (izingxenye ozikhethela) nezinye izingxenye. , isihlalo esiphethe umhlahlandlela ophansi, i-stator, i-rotor, isihlalo esiphezulu somhlahlandlela, indandatho yesihlabathi, ingxenye yokungena kwamanzi, ikhebula nezinye izingxenye.

Izici eziyinhloko zomkhiqizo zihlanganisa:

I-1, I-motor iyi-motor egcwele amanzi emanzi e-submersible enezigaba ezintathu ze-asynchronous motor, i-motor cavity igcwele amanzi ahlanzekile, esetshenziselwa ukupholisa i-motor kanye nokugcoba i-bearing, ifilimu elawula ukucindezela phansi kwe-motor isetshenziselwa ukulungisa. ukunwetshwa kanye nomehluko wengcindezi yokufinyela kwamanzi ngaphakathi emzimbeni okubangelwa ukushintsha kokukhuphuka kwezinga lokushisa kwemoto.

I-2, Ukuze uvimbele isihlabathi esisemanzini omthombo ukuthi singangeni emotweni, indawo engaphezulu ye-motor shaft ifakwe izimpawu ezimbili zamafutha, futhi indandatho yesihlabathi ifakwe ukwakha isakhiwo sokuvimbela isihlabathi.

I-3, Ukuze uvimbele i-pump shaft ukuthi ingaqhubeki lapho iqala, i-pump shaft kanye ne-motor shaft ixhunywe ngokuhlanganisa, futhi i-top thrust bear ifakwe engxenyeni engezansi ye-motor.

4, Ukugcotshwa kwenjini kanye nephampu ephethe ukugcotshwa kwamanzi.

I-5, i-motor stator winding yenziwe ngocingo olusezingeni eliphezulu lwe-submersible motor winding, olusebenza kahle kakhulu.

6, Iphampu iklanywe yi-CAD yekhompyutha, enesakhiwo esilula nokusebenza okuhle kobuchwepheshe.

(1) Ukulungiselela ngaphambi kokufakwa:

1. Hlola ukuthi ingabe iphampu engaphansi kwamanzi iyahlangabezana yini nezimo zokusetshenziswa kanye nobubanzi obushiwo kubhukwana.

2. Usebenzisa i-obiect esindayo enobubanzi obulingana nobukhulu bedayamitha yangaphandle yephampu engaphansi kwamanzi, linganisa ukuthi i-inneldiameter yomthombo ingalingana nephampu engaphansi kwamanzi, futhi ulinganise ukuthi ukujula komthombo kuyahlangabezana yini nezidingo zokufakwa.

3. Hlola ukuthi umthombo uhlanzekile yini nokuthi amanzi omthombo anodaka. Ungalokothi usebenzise iphampu kagesi engaphansi kwamanzi ukugeza udaka lwepompo le-welor namanzi esihlabathi ukuze ugweme ukulimala ngaphambi kwesikhathi kwepompo kagesi engaphansi kwamanzi.

4. Hlola ukuthi indawo ye-welhead yokufaka i-welhead ifanelekile yini nokuthi ingakwazi yini ukumelana nekhwalithi yayo yonke iyunithi.

5. Hlola ukuthi izingxenye zepompo ezingaphansi kwamanzi ziphelele yini futhi zifakwe ngendlela efanele ngokomdwebo womhlangano osebhukwini Susa isikrini sokuhlunga bese uzungezisa ukuhlanganisa ukuze ubone ukuthi siyazungeza yini

6. Khipha isikulufu samanzi bese ugcwalisa imbobo yesithuthuthu ngamanzi ahlanzekile, angagqwali (qaphela. qiniseka ukuthi uyasigcwalisa), bese uqinisa isikrufu samanzi. Ngemuva kwamahora ayi-12 omjovo wamanzi, ukumelana nokufakwa kwenjini akufanele kube ngaphansi kuka-150M Q uma kulinganiswa netafula lokunyakazisa elingu-500V.

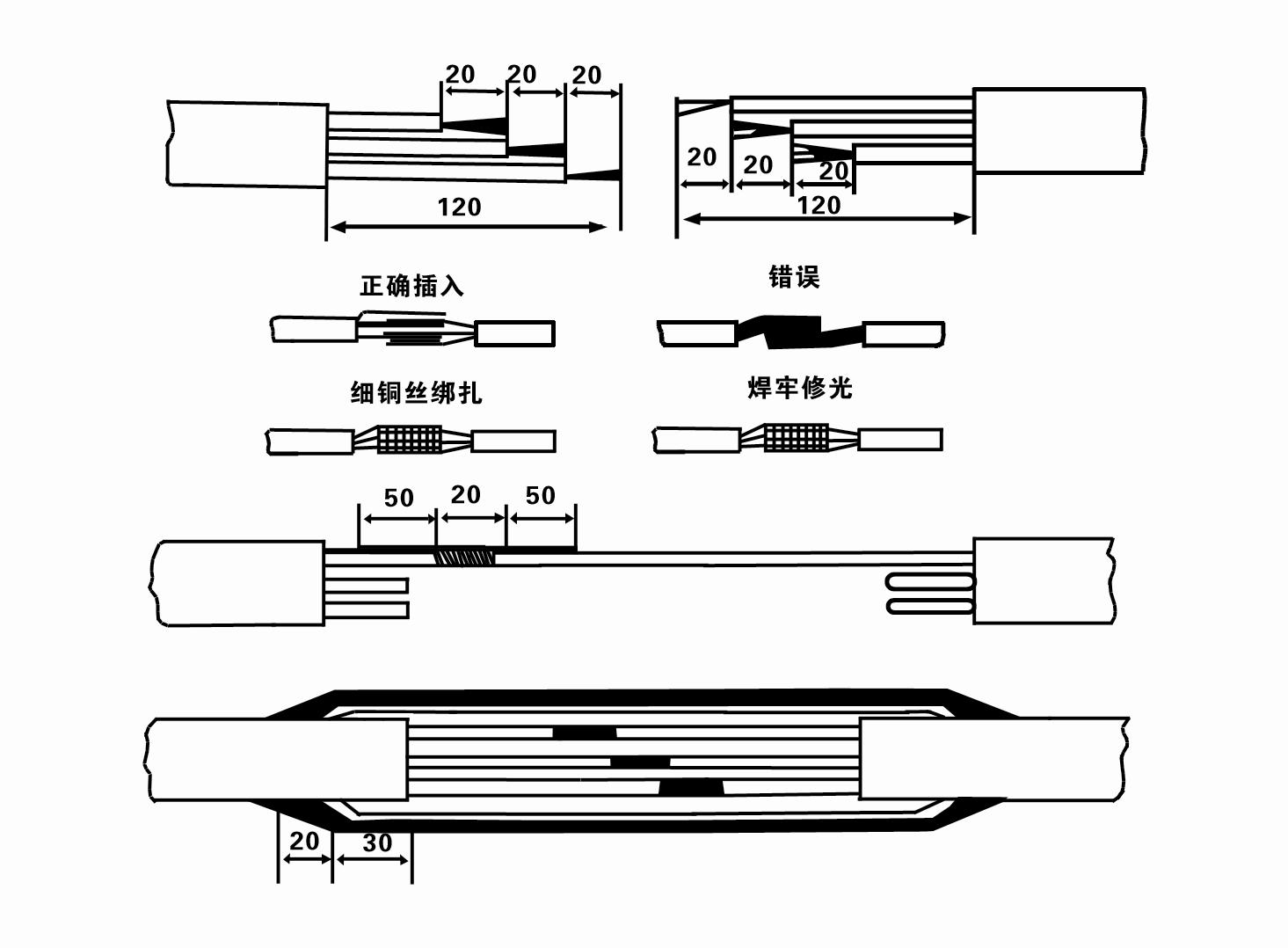

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Umdwebo wenqubo yokufaka izintambo zekhebula umi kanje:

8. Sebenzisa i-multimeter ukuze uhlole ukuthi izintambo zezigaba ezintathu zixhumekile yini nokuthi ukumelana ne-DC cishe kulinganiselwe.

9. Hlola ukuthi umthamo wesekethe kanye ne-transformer ugcwele ngokweqile, bese uxhuma iswishi yokuvikela ukulayisha ngokweqile noma okokusebenza kokuqala. Bheka Ithebula 2 ukuze uthole amamodeli athile, bese uThela ibhakede lamanzi empompini yamanzi usuka endaweni yepompo yamanzi ukuze ugcobe amabheringi erabha epompo, bese ubeka iphampu kagesi engaphansi kwamanzi iqonde futhi inganyakazi.Qala (ingabi ngaphezu komzuzwana owodwa) futhi uhlole ukuthi isiqondiso sokuqondisa siyahambisana yini nophawu lokuqondisa. Uma kungenjalo, shintsha noma yiziphi izixhumi ezimbili zekhebula lezigaba ezintathu.Bese ufaka isihlungi bese ulungiselela ukwehla ngomthombo. Uma isetshenziswa ngezikhathi ezikhethekile (njengemisele, imisele, imifula, amachibi, amachibi, njll.), iphampu kagesi kufanele ibekwe phansi ngendlela enokwethenjelwa.

(2)Imishini yokufaka namathuluzi:

1. Ipheya elilodwa lamaketango okuphakamisa amathani angaphezu kwamabili.

2. I-tripod enobude obuqondile obungekho ngaphansi kwamamitha amane.

3. Izintambo ezimbili ezilengayo (izintambo zocingo) ezingathwala isisindo esingaphezu kwethani elilodwa (zingathwala isisindo sesethi ephelele yamaphampu amanzi).

4. Faka amapheya amabili ezinsimbi (ama-splint).

5. Izikele, izando, izikulufu, amathuluzi kagesi nezinsimbi, njll.

(3)Ukufakwa kwephampu kagesi:

1. Umdwebo wokufakwa kwephampu kagesi engaphansi kwamanzi uboniswa kuMfanekiso 2. Ubukhulu obuthile bokufaka buboniswa kuThebula lesi-3 "Uhlu Lobukhulu Bokufakwa Kwephampu Kagesi Engaphansi".

2. Amaphampu kagesi angaphansi kwamanzi anekhanda elingaphansi kwamamitha angu-30 angaphakanyiselwa ngqo emthonjeni kusetshenziswa amapayipi nezintambo zocingo noma ezinye izintambo ze-hemp ezingathwala isisindo esigcwele sawo wonke umshini, amapayipi amanzi, namanzi emapayipini.

3. Amaphampu anekhanda elingaphezu kwamamitha angu-30 asebenzisa amapayipi ensimbi, futhi ukulandelana kokufakwayo kungokulandelayo:

①Sebenzisa i-clamp ukuze ubambe ingxenye engenhla yengxenye yepompo yamanzi (injini nepompo yamanzi kuxhunyiwe ngalesi sikhathi), yiphakamise ngeketango elilengayo, bese uyibopha kancane kancane emthonjeni uze ufake i-clamp ekhanda lomthombo bese ukhipha iketango elilengayo.

②Sebenzisa amanye ama-clamp ukuze ubambe ipayipi, uliphakamise ngeketango elilengayo eliqhele ngamasentimitha angu-15 ukusuka ku-flange, bese ulehlisa kancane. Phakathi kwe-flange yepayipi ne-pump flangeFaka iphedi yenjoloba endaweni bese uqinisa ipayipi bese umpompa ngokulinganayo ngamabhawodi, amantongomane namawasha asentwasahlobo.

③Phakamisa iphampu engaphansi kwamanzi kancane, susa isibambisi engxenyeni engenhla yepompo yamanzi, bopha intambo ngokuqinile epayipini lamanzi ngetheyiphu yepulasitiki, bese uyibopha kancane kuze kube yilapho Ibamba libekwe emthonjeni.

④Sebenzisa indlela efanayo ukubopha wonke amapayipi amanzi emthonjeni.

⑤Ngemva kokuthi ikhebuli ephumayo ixhunywe kusiwishi sokulawula, ixhunywa ekunikezeni amandla kwezigaba ezintathu.

(4) Izinto okufanele uziqaphele ngesikhathi sokufakwa:

1. Uma i-jamming itholakala phakathi nenqubo yokumpompa, vula noma udonse ipayipi lamanzi ukuze unqobe indawo yokuma. Uma izinyathelo ezihlukahlukene zingasebenzi, sicelaUngaphoqeleli iphampu phansi ukuze ugweme ukulimala kwepompo kagesi engaphansi kwamanzi kanye nomthombo.

2. Ngesikhathi sokufakwa, i-rubber pad kufanele ibekwe ku-flange yepayipi ngayinye futhi iqiniswe ngokulinganayo.

3. Lapho iphampu yamanzi yehliselwa emthonjeni, kufanele ibekwe phakathi nepayipi lomthombo ukuze ivimbele ukuthi iphampu ingagijimi odongeni lomthombo isikhathi eside, okubangela ukuba iphampu inyakaze futhi injini ishanele futhi ishise. .

4. Thola ukujula kwepompo yamanzi ukuya phansi komthombo ngokwesihlabathi esigelezayo kanye nezimo zodaka lomthombo. Ungangcwabi iphampu odakeni. Ibanga ukusuka empompini ukuya phansi komthombo ngokuvamile alikho ngaphansi kwamamitha amathathu (bheka uMdwebo 2).

5. Ukujula kokungena kwamanzi kwephampu yamanzi kufanele kungabi ngaphansi kwamamitha angu-1-1.5 ukusuka ezingeni lamanzi aguquguqukayo kuya endaweni yokungena kwamanzi (bheka uMdwebo 2). Uma kungenjalo, ama-bearings epompo yamanzi angase alimale kalula.

6. Ukuphakanyiswa kwepompo yamanzi angeke kube phansi kakhulu. Uma kungenjalo, i-valve yesango idinga ukufakwa epayipini lamanzi elisemthonjeni ukuze kulawulwe ukugeleza kwepompo endaweni elinganiselwe yokugeleza ukuze kuvinjwe injini ukuthi ingagcwali kakhulu futhi ishiswe ngenxa yamazinga amakhulu okugeleza.

7. Lapho ipompo yamanzi isebenza, ukuphuma kwamanzi kufanele kuqhubeke futhi ngisho, okwamanje kufanele kuzinzile (ngaphansi kwezimo zokusebenza ezilinganiselwe, ngokuvamile kungabi ngaphezu kuka-10% wamanje olinganiselwe), futhi akufanele kube nokudlidliza noma umsindo. Uma kukhona okungahambi kahle, umshini kufanele umiswe ukuze kutholwe imbangela futhi kuqedwe.

8. Lapho ufaka, naka ukumiswa kocingo lwe-motor grounding wire (bheka Umfanekiso 2). Uma ipayipi lamanzi liyipayipi lensimbi, lihole kusukela ku-wellhead clamp; lapho ipayipi lamanzi liyipayipi lepulasitiki, lihole ukusuka endaweni yokubeka phansi yepompo kagesi.

- Ukufakwa kwepompo engaphansi kwe-1 kuqediwe, hlola kabusha ukumelana nokufakwa kwe-insulation kanye nokuqhutshwa kwesigaba sesithathu kusuka ku-switch, hlola ithuluzi bese uqala iphutha lokuxhumeka kwemishini, uma kungekho nkinga, ungaqala ukugijima kwesilingo, ngemuva kokuqala kwethuluzi. okubonisa ukufundwa ukuthi kungaphezu kwe-nameplate eshiwo ukulinganisa kwe-voltage kanye neyamanje, bheka umsindo wepompo kanye nokwenzeka kokudlidliza, konke kujwayelekile kungafakwa ekusebenzeni.

- 2 ukusebenza kwephampu amahora amane okuqala, kufanele ivalwe ngokushesha ukuhlola ukumelana nokushisa okushisayo kwemoto, inani akufanele libe ngaphansi kuka-0.5 megaohm.

- 3 ukuvalwa kwephampu, kufanele kube isikhawu imizuzu emihlanu ngemva kokuqala, vimbela ikholomu yamanzi epayipini ukuthi ingabi ne-reflux ngokuphelele futhi ibangele ukuthi i-motor current inkulu kakhulu futhi iyavutha.

- I-4 impompa ekusebenzeni okujwayelekile, ukuze kunwetshwe impilo yayo yesevisi, ukuhlola amandla kagesi, ukusebenza kwamanje kanye nokumelana nokufakwa kujwayelekile, uma kutholakala isimo esilandelayo, kufanele kucishwe ngokushesha ukuxazulula inkinga.

- - esimweni esilinganiselwe, okwamanje kungaphezu kuka-20%.

- - Izinga lamanzi aguquguqukayo esigabeni sokungena kwamanzi, okubangela amanzi ngezikhathi ezithile.

- - iphampu engaphansi kwamanzi ukudlidliza noma umsindo oqinile.

- - I-voltage yokuhlinzeka ingaphansi kuka-340 volts.

- - i-fuse yashisa isigaba.

- - ukulimala kwepayipi lamanzi.

- - Injini yokumelana nokushisa okushisayo ingaphansi kuka-0.5 megaohm.

- 5 lo mkhiqizo unezici zokuhlakazeka okulula, ungahlukaniswa ngezinyathelo ezilula.

- Izinyathelo zokuqaqa zihlanganisa: 1 qaqa intambo yekhebula, khipha izingxenye zepayipi kanye nepuleti lokuvikela umugqa. 2 screw isikulufu sokukhipha amanzi bese ukhipha wonke amanzi egumbini lemoto. 3 khipha isihlungi bese ukhulula isikulufu sokulungisa esixhunywe ku-motor shaft. 4 jikijela phansi ibhawodi elixhuma ingxenye yokungena kwamanzi kanye nenjini, bese uhlukanisa iphampu nenjini (naka ukuze ugcine iyunithi ivundlile ukuze uvimbele ukugoba kwe-shaft yepompo lapho uhlukaniswa). 5 ukulandelana kokuqaqa iphampu yilena: (bheka Umfanekiso 1) ingxenye yokungena kwamanzi, i-impeller, igobolondo le-shunt, i-impeller, i-valve yokuhlola umzimba.

- Uma ususa i-impeller, sebenzisa ithuluzi elikhethekile lokukhulula umkhono we-conical ukulungisa i-impeller. Enqubweni yokuqaqa, gwema ukugoba i-pump shaft futhi ulimaze izingxenye ezihlukahlukene.

- 6 inqubo yokuhlakaza i-motor yile: (bheka Umfanekiso 1) beka injini endaweni yesikhulumi, bese ususa amantongomane kumabhawodi (amabhawodi okudonsa), isisekelo, i-shaft head lock nut, i-thrust plate, ukhiye, isitimela esingaphansi, yonakaliswe kancane) bese ekugcineni isuse ingxenye exhumayo kanye nesihlalo esinesihlalo sikaloliwe somhlahlandlela.

- Ukuhlanganiswa kweyunithi engu-7: ngaphambi kokuhlanganiswa, ukugqwala nokungcola kwengxenye ngayinye kufanele kuhlanzwe, futhi uphawu kufanele lufakwe endaweni ngayinye yokukhwelana kanye ne-fastener, bese umhlangano kufanele wenziwe ngokulandelana kwe-disassembly (ukunyakaza kwe-motor. umphini ngemva kokuhlanganiswa cishe imilimitha eyodwa), ngemva kokuba umhlangano usuphothuliwe, ukuhlanganisa kufanele kujikeleze ngokuguquguqukayo, bese kufakwa isihlungi ukuze sihlolwe.6. Amaphampu angaphansi kwamanzi azokhishwa emthonjeni ukuze ahlakazwe futhi agcinwe ngokweSigaba 5 ngemva konyaka esebenza, noma ngaphansi konyaka esebenza kodwa iminyaka emibili yesikhathi sokutshuza, futhi izingxenye ezigugile zizoshintshwa.

1, khipha amanzi ku-motor cavity (ikakhulukazi ebusika ukuvimbela injini ukuba ingaqhwa), futhi ubophe ikhebula kahle.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, ukusetshenziswa isikhathi eside kufanele sinake ukuvimbela nokugqwala amaphampu submersible.

- Impeller

- Umkhono we-shaft

- Umkhono we-rubber shaft

-

Indandatho yokuvala

01 Ukuphuza amanzi omthombo ojulile

02 Ukuhlinzekwa kwamanzi asezingeni eliphezulu

03 amanzi asezintabeni

04 amanzi ombhoshongo

05 Ukuchelela kwezolimo

06 ukuchelela engadini

07 amanzi omfula

08 amanzi asekhaya