QJP series fountain pump is a special pump for fountain developed by our factory.The pump motor core is made of high quality cold rolled silicon steel, which makes the pump more efficient, good magnetic conductivity, and frequent start will not fever.Both ends of the motor rotor use water as lubricant alloy copper sleeve.Stainless steel sleeve instead of ball bearings, to avoid the problem of easy rust ball bearings and lack of oil wear and tear the motor.The most suitable for music fountain use, all models can be used.

This product is a three-phase AC 380V (tolerance + / - 5%), 50HZ (tolerance + / - 1%) power supply system. Applicable water quality conditions include water temperature not exceeding 20 °C, solid impurities content (mass ratio) is not greater than 0.01%, PH value (pH) is 6.5-8.5, hydrogen sulfide content is not greater than 1.5mg/L, chloride ion content is not greater than 400mg/L. The motor is a closed or water-filled wet structure. Before use, it must be filled with clean water to prevent false filling, and then tighten the water injection and exhaust bolts, otherwise it is not allowed to use. The submersible pump must be completely immersed in water, and the penetration depth shall not exceed 70m. The distance between the submersible pump base and the bottom of the well shall not be less than 3m. The well flow shall be able to meet the water output and continuous operation of the submersible pump. The water output of the submersible pump shall be controlled at 0.7-1.2 times of the rated flow. The well shall be vertical, and the submersible pump can not be used horizontally or upside down, but only vertically. The submersible pump shall be equipped with cables and external overload protection devices as required. The pump is strictly prohibited from no-load test without water.

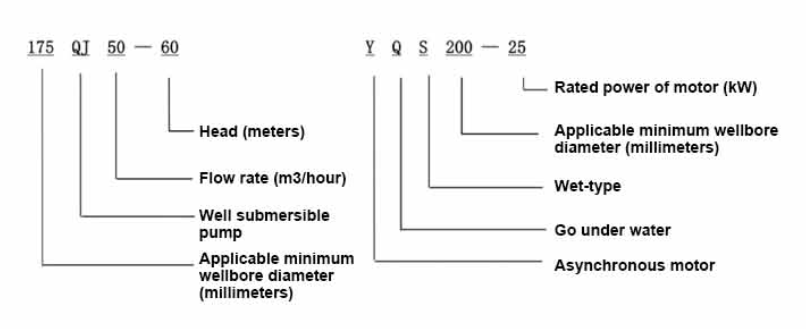

| Mudell | Fluss (m3/h) | Kap (m) |

Rotatingspeed (bidla/punt) |

Pompa tal-ilma (%) | Żbokk dijametru (mm) |

Applikabbli sew dijametru (mm) |

Rated power(KW) |

Rated vultaġġ (V) |

Rated kurrenti (A) |

Effiċjenza tal-mutur (%) | power factorcosφ | Unità Daqs massimu radjali (mm) |

|||||||||

| 175QJ10-42 | 10 | 42 | 2850 | 53 | 50 | 175hawn fuq | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ10-56 | 56 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-70 | 70 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-84 | 84 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ10-112 | 112 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-126 | 126 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-140 | 140 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ15-42 | 15 | 42 | 2850 | 58 | 50 | 175hawn fuq | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ15-55 | 55 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-65 | 65 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-85 | 85 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ15-112 | 112 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 175hawn fuq | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ20-39 | 39 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ20-52 | 52 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ20-78 | 78 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ20-91 | 91 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-104 | 104 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ20-130 | 130 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-156 | 156 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-182 | 187 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ20-208 | 208 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-247 | 247 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-273 | 273 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-299 | 299 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-325 | 325 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-364 | 364 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-26 | 25 | 26 | 2850 | 66 | 65 | 175hawn fuq | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ25-39 | 39 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ25-65 | 25 | 65 | 2850 | 66 | 65 | 175hawn fuq | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ25-78 | 78 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ25-91 | 91 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ25-104 | 104 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-130 | 130 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-156 | 156 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ25-182 | 182 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-208 | 208 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-221 | 221 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-247 | 247 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-260 | 260 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-299 | 299 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ30-30 | 30 | 30 | 2850 | 67 | 80 | 175hawn fuq | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ30-40 | 40 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-24 | 32 | 24 | 2850 | 67 | 80 | 175hawn fuq | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ32-36 | 36 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-48 | 48 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ32-60 | 60 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ32-72 | 72 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ32-84 | 84 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-96 | 96 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-120 | 120 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ32-144 | 144 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-168 | 168 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-180 | 180 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-192 | 192 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-204 | 204 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-240 | 240 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ35-60 | 35 | 60 | 2850 | 67 | 80 | 175hawn fuq | 10 | 380 | 25.0 | 78.0 | 0.78 | 168 | |||||||||

| 175QJ35-75 | 75 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ35-100 | 100 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ40-24 | 40 | 24 | 2850 | 70 | 80 | 175hawn fuq | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ40-30 | 30 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ40-36 | 36 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ40-48 | 48 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ40-60 | 60 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ40-72 | 72 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-84 | 84 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-96 | 96 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ40-120 | 120 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-132 | 132 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-144 | 144 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-156 | 156 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-168 | 168 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-192 | 192 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-24 | 50 | 24 | 2850 | 72 | 80 | 175hawn fuq | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ50-36 | 36 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ50-48 | 48 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ50-70 | 70 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ50-84 | 84 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ50-96 | 96 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-108 | 108 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-120 | 120 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-132 | 132 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-144 | 144 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-156 | 156 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-22 | 63 | 22 | 2850 | 72 | 80 | 175hawn fuq | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ63-44 | 44 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-55 | 55 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-66 | 66 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ63-77 | 77 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-88 | 88 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-99 | 63 | 99 | 2850 | 72 | 80 | 175hawn fuq | 30 | 380 | 66.6 | 81.5 | 0.84 | 168 | |||||||||

| 175QJ63-110 | 110 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-132 | 132 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-9 | 80 | 9 | 2850 | 73 | 100 | 175hawn fuq | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ80-18 | 18 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ80-27 | 27 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ80-36 | 36 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ80-45 | 45 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ80-54 | 54 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-63 | 63 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-72 | 72 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-81 | 81 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-90 | 90 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-98 | 98 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, strettament skond id-dispożizzjonijiet tal-lift tal-pompa, firxa tal-fluss ta 'użu, biex jipprevjenu fluss baxx jew forza ta' ippumpjar ta 'lift għoli, il-bearing ta' l-ispinta u partijiet oħra ta 'l-ilbies, it-tagħbija żejda tal-mutur maħruqa

6, after the pump down the well, the measurement of the motor to the ground insulation resistance should not be less than 100M, after the start to observe the voltage and current, check the motor winding insulation, whether in line with the requirements; pump storage location temperature if less than freezing point, should be dry the motor cavity water, prevent the motor cavity water ice damage caused by low temperature.

The pump part is mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor part mainly includes base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand ring, water inlet section, lead cable and other components. The main features of the product include: the motor is a water immersed wet three-phase asynchronous motor, the motor cavity is full of water, used to cool the motor and lubricate the bearing; the pressure regulating film at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the internal water caused by the change of temperature; in order to prevent the sand particles in the well water from entering the motor, two oil seals are installed on the upper end of the motor shaft extension, and a sand control structure is formed by installing the sand ring; in order to prevent the pump shaft from jumping at startup, the pump shaft is connected with the motor shaft through a coupling, and the thrust bearing is installed under the motor; the lubrication of the motor and the pump bearing is water lubrication; the stator winding of the motor is made of high quality submersible motor winding, with high insulation performance; the pump is designed by computer CAD, with simple structure and excellent technical performance.

(1) Tħejjija qabel l-installazzjoni:

1. Iċċekkja jekk il-pompa sommerġibbli tissodisfax il-kundizzjonijiet tal-użu u l-ambitu speċifikati fil-manwal.

2. billi tuża object tqil b'dijametru ugwali għad-dijametru massimu ta 'barra tal-pompa sommerġibbli, kejjel jekk il-inneldiameter tal-wellbore jistax joqgħod mal-pompa sommerġibbli, u kejjel jekk il-fond tal-bir jissodisfax ir-rekwiżiti tal-installazzjoni.

3. Iċċekkja jekk il-bore huwiex nadif u jekk l-ilma tal-bir huwiex imdardra. Qatt tuża pompa elettrika sommerġibbli biex taħsel it-tajn tal-pompa welor u l-ilma tar-ramel biex tevita ħsara prematura lill-pompa elettrika sommerġibbli.

4. Iċċekkja jekk il-pożizzjoni tal-morsa tal-installazzjoni tal-welhead hijiex adattata u jekk tistax tiflaħ il-kwalità tal-unità kollha

5. Iċċekkja jekk il-komponenti tal-pompa sommerġibbli humiex kompluti u installati kif suppost skont id-dijagramma tal-assemblaġġ fil-manwal Neħħi l-iskrin tal-filtru u dawwar l-akkoppjar biex tara jekk idurx b'mod flessibbli

6. Ħoll il-kamin tal-ilma u fillthe kavità tal-mutur b'ilma nadif, mhux korrużiv (nota. kun żgur li fil it up), imbagħad issikka l-kamin tal-ilma. Wara 12-il siegħa ta 'injezzjoni ta' l-ilma, ir-reżistenza ta 'insulazzjoni tal-mutur m'għandhiex tkun inqas minn 150M Q meta titkejjel b'tabella li tħawwad 500V.

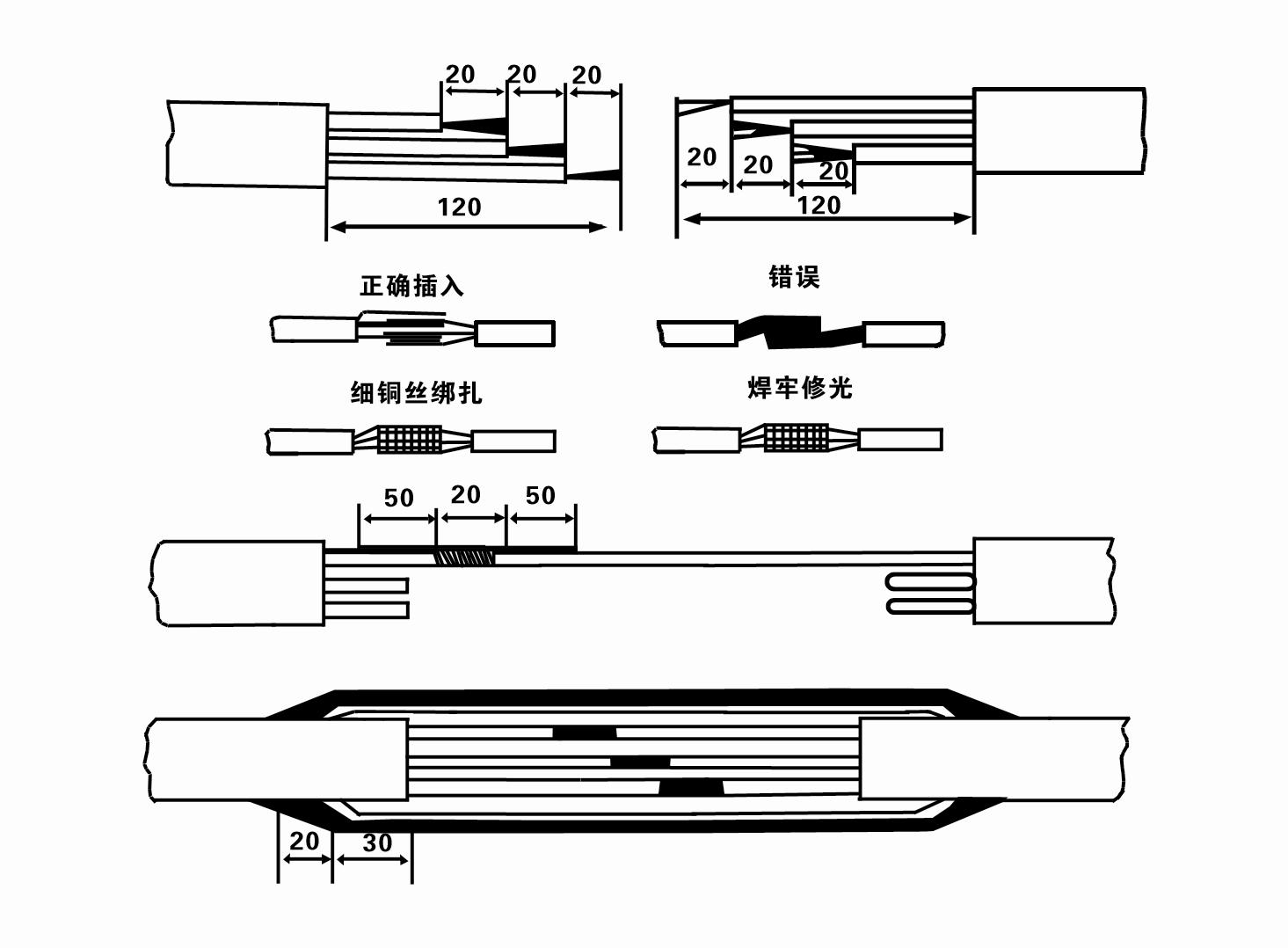

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Id-dijagramma tal-proċess tal-wiring tal-kejbil mehmuża hija kif ġej:

8. Uża multimeter biex tivverifika jekk il-wajers bi tliet fażijiet humiex konnessi u jekk ir-reżistenza DC hijiex bejn wieħed u ieħor bilanċjata.

9. Iċċekkja jekk iċ-ċirkwit u l-kapaċità tat-transformer humiex mgħobbija żżejjed, u mbagħad qabbad is-swiċċ tal-protezzjoni ta 'tagħbija żejda jew it-tagħmir tal-bidu. Ara Tabella 2 għal mudelli speċifiċi, and thenPour barmil ilma fil-pompa tal-ilma mill-iżbokk tal-pompa tal-ilma biex tillubrikha l-berings tal-gomma fil-pompa, u mbagħad poġġi l-pompa elettrika sommerġibbli wieqfa u stabbli.Ibda (mhux aktar minn sekonda) u iċċekkja jekk id-direzzjoni ta 'l-istering hijiex konsistenti mas-sinjal ta' l-istering. Jekk le, tbiddel kwalunkwe żewġ konnetturi tal-kejbil bi tliet fażijiet. Imbagħad installa l-filtru u pprepara biex tinżel fil-bir. Jekk tintuża f'okkażjonijiet speċjali (bħal fosos, fosos, xmajjar, għadajjar, għadajjar, eċċ.), Il-pompa elettrika għandha tkun ertjata b'mod affidabbli.

(2) Tagħmir u għodda ta' installazzjoni:

1. Par wieħed ta 'ktajjen ta' rfigħ għal aktar minn żewġ tunnellati.

2. Tripod b'għoli vertikali ta' mhux inqas minn erba' metri.

3. Żewġ ħbula mdendlin (ħbula tal-wajer) li jistgħu jġorru piż ta 'aktar minn tunnellata (jistgħu iġorru l-piż ta' sett komplut ta 'pompi tal-ilma).

4. Installa żewġ pari ta 'klampi (splints).

5. Wrenches, imrietel, tornaviti, għodod u strumenti elettriċi, eċċ.

(3) Installazzjoni ta 'pompa elettrika:

1. Id-dijagramma tal-installazzjoni tal-pompa elettrika sommerġibbli hija murija fil-Figura 2. Id-dimensjonijiet tal-installazzjoni speċifiċi huma murija fit-Tabella 3 "Lista tad-Dimensjonijiet tal-Installazzjoni tal-Pompa Elettrika Sommerġibbli".

2. Pompi elettriċi sommerġibbli b'ras ta 'inqas minn 30 metru jistgħu jittellgħu direttament fil-bir bl-użu ta' pajpijiet u ħbula tal-wajer jew ħbula oħra tal-qanneb li jistgħu jġorru l-piż sħiħ tal-magna kollha, pajpijiet tal-ilma, u ilma fil-pajpijiet.

3. Pompi b'ras ta 'aktar minn 30 metru jużaw pajpijiet ta' l-azzar, u s-sekwenza ta 'installazzjoni hija kif ġej:

①Uża morsa biex tikklampja t-tarf ta 'fuq tal-parti tal-pompa ta' l-ilma (il-mutur u l-pompa ta 'l-ilma ġew imqabbda f'dan il-ħin), erfaha b'katina mdendla, u orbotha bil-mod fil-bir sakemm Poġġi l-morsa fuq ir-ras u neħħi l- katina mdendlin.

② Uża par klampi ieħor biex tikklampja pajp, erfah b'katina mdendla 15 ċm 'il bogħod mill-flanġ, u niżżlu bil-mod. Bejn il-flanġ tal-pajp u l-flanġ tal-pompa Poġġi l-kuxxinett tal-gomma f'postu u issikka l-pajp u l-pompa b'mod uniformi b'boltijiet, ġewż u woxers tar-rebbiegħa.

③ Neħħi ftit il-pompa sommerġibbli, neħħi l-morsa fuq it-tarf ta 'fuq tal-pompa ta' l-ilma, torbot il-kejbil sew mal-pajp ta 'l-ilma b'tejp tal-plastik, u orbotha bil-mod sakemm Il-morsa titqiegħed fil-bir.

④Uża l-istess metodu biex torbot il-pajpijiet tal-ilma kollha fil-bir.

⑤Wara li l-kejbil tal-ħruġ ikun imqabbad mal-iswiċċ tal-kontroll, huwa konness mal-provvista tal-enerġija bi tliet fażijiet.

(4) Affarijiet li għandek tinnota waqt l-installazzjoni:

1. Jekk jinstab fenomenu ta 'iġġammjar waqt il-proċess ta' l-ippumpjar, dawwar jew iġbed il-pajp ta 'l-ilma biex tegħleb il-punt ta' iġġamjar. Jekk il-miżuri varji għadhom ma jaħdmux, jekk jogħġbokMa jġiegħelx il-pompa 'l isfel biex tevita ħsara lill-pompa elettrika sommerġibbli u l-bir.

2. Waqt l-installazzjoni, kuxxinett tal-gomma għandu jitqiegħed fil-ħanek ta 'kull pajp u ssikkat indaqs.

3. Meta l-pompa tal-ilma titbaxxa fil-bir, għandha titqiegħed fin-nofs tal-pajp tal-bir biex tevita li l-pompa taħdem kontra l-ħajt tal-bir għal żmien twil, u tikkawża li l-pompa tivvibra u l-mutur jiknes u jinħaraq .

4. Iddetermina l-fond tal-pompa ta 'l-ilma sal-qiegħ tal-bir skond il-kundizzjonijiet ta' ramel u ħama li jirriżultaw tal-bir. Tidfenx il-pompa fit-tajn. Id-distanza mill-pompa tal-ilma sal-qiegħ tal-bir hija ġeneralment mhux inqas minn 3 metri (ara Figura 2).

5. Il-fond tad-dħul ta 'l-ilma tal-pompa ta' l-ilma m'għandux ikun inqas minn 1-1.5 metri mil-livell dinamiku ta 'l-ilma għan-nodu tad-dħul ta' l-ilma (ara l-Figura 2). Inkella, il-bearings tal-pompa tal-ilma jistgħu jiġu mħassra faċilment.

6. Il-lift tal-pompa tal-ilma ma jistax ikun baxx wisq. Inkella, valv gate jeħtieġ li jiġi installat fuq il-pipeline ta 'l-ilma tar-ras biex jikkontrolla l-fluss tal-pompa fil-punt tal-fluss nominali biex jipprevjeni li l-mutur jiġi mgħobbi żżejjed u jinħaraq minħabba rati ta' fluss kbar.

7. Meta l-pompa ta 'l-ilma tkun qed taħdem, l-output ta' l-ilma għandu jkun kontinwu u saħansitra, il-kurrent għandu jkun stabbli (taħt kundizzjonijiet tax-xogħol ratati, ġeneralment mhux aktar minn 10% tal-kurrent nominali), u m'għandux ikun hemm vibrazzjoni jew storbju. Jekk ikun hemm xi anormalità, il-magna għandha titwaqqaf biex issir taf il-kawża u teliminaha.

8. Meta tinstalla, oqgħod attent għall-issettjar tal-wajer tal-ert tal-mutur (ara l-Figura 2). Meta l-pajp ta 'l-ilma jkun pajp ta' l-azzar, wassalha mill-morsa tal-ħofor; meta l-pajp ta 'l-ilma huwa pajp tal-plastik, wassalha mill-marka ta' l-ert tal-pompa elettrika.

- 1.After installing the submersible pump, recheck the insulation resistance and the three-phase continuity at the switch, and check whether there are errors in the connection of the instrument and the starting equipment.If there are no problems, you can start to test the machine. After starting, observe whether the indication readings of each instrument are correct. If the rated voltage and current specified on the nameplate are exceeded, observe whether the pump emits any noise or vibration. If everything is normal, it can be put into operation.

- 2. After the pump runs for the first four hours, the thermal insulation resistance of the motor should be closed and tested quickly.Its value should not be less than 0.5 megaohm.After the pump stops, it should be restarted after an interval of five minutes to prevent the water column in the pipeline from completely reversing and burning the motor due to excessive current.

- 3. After the pump is put into normal operation, in order to prolong its service life, it is necessary to check regularly whether the supply voltage, working current and insulation resistance are normal. If the following conditions are found, the machine should be stopped immediately to troubleshoot.

- 1 Fil-kundizzjoni tax-xogħol ratata, il-kurrent jaqbeż l-20%.

- 2 Il-livell tal-ilma dinamiku jinżel fis-sezzjoni tad-daħla tal-ilma, u jikkawża ilma intermittenti.

- 3 Il-pompa sommerġibbli għandha vibrazzjoni jew storbju severi.

- 4 Il-vultaġġ tal-provvista huwa inqas minn 340 volt.

- 5 Fjus jinħaraq.

- 6 Il-pajp tal-provvista tal-ilma huwa bil-ħsara.

- 7 Ir-reżistenza tal-insulazzjoni tal-mutur għall-istat ġeotermali hija inqas minn 0.5 megaohm.

- Unit disassembly:

- 1.untie cable rope, remove the pipeline part, remove the wire plate.

- 2.screw down the water bolt, put the water in the motor chamber.

- 3.remove the filter, loose the fixed screw on the coupling to fix the motor shaft.

- 4.screw down the bolt connecting the inlet junction with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) inlet junction, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising of the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the reverse order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

This product adopts advanced design and provides advanced storage suggestions to ensure long-term use effect.First of all, in winter, it is necessary to exhaust all the water to prevent freezing. In addition, the wire rolls should be placed well and tied up.Secondly, when storing, the environment without corrosive action and gas should be selected and the temperature should be kept below 40 °C. Finally, when not used for a long time, attention should be paid to prevent rust of submersible pump.These storage requirements will ensure that the product can maintain its performance status and prolong its service life for a long time.

- Impeller

- Kmiem tax-xaft

- Kmiem tax-xaft tal-gomma

-

Ċirku tas-siġillar

01 Intake ta 'ilma fil-fond

02 Provvista ta' ilma għoli

03 provvista ta 'ilma fil-muntanji

04 torri ilma

05 Tisqija agrikola

06 tisqija tal-ġnien

07 teħid ta 'ilma tax-xmara

08 ilma domestiku