QJP series fountain pump is a special pump for fountain developed by our factory.The pump motor core is made of high quality cold rolled silicon steel, which makes the pump more efficient, good magnetic conductivity, and frequent start will not fever.Both ends of the motor rotor use water as lubricant alloy copper sleeve.Stainless steel sleeve instead of ball bearings, to avoid the problem of easy rust ball bearings and lack of oil wear and tear the motor.The most suitable for music fountain use, all models can be used.

This product is a three-phase AC 380V (tolerance + / - 5%), 50HZ (tolerance + / - 1%) power supply system. Applicable water quality conditions include water temperature not exceeding 20 °C, solid impurities content (mass ratio) is not greater than 0.01%, PH value (pH) is 6.5-8.5, hydrogen sulfide content is not greater than 1.5mg/L, chloride ion content is not greater than 400mg/L. The motor is a closed or water-filled wet structure. Before use, it must be filled with clean water to prevent false filling, and then tighten the water injection and exhaust bolts, otherwise it is not allowed to use. The submersible pump must be completely immersed in water, and the penetration depth shall not exceed 70m. The distance between the submersible pump base and the bottom of the well shall not be less than 3m. The well flow shall be able to meet the water output and continuous operation of the submersible pump. The water output of the submersible pump shall be controlled at 0.7-1.2 times of the rated flow. The well shall be vertical, and the submersible pump can not be used horizontally or upside down, but only vertically. The submersible pump shall be equipped with cables and external overload protection devices as required. The pump is strictly prohibited from no-load test without water.

| MODELY | Fikoriana (m3/h) | LOHA (m) |

Rotatingspeed (fiovana/ teboka) |

Paompy rano(%) | fivoahan'ny savaivony (mm) |

Azo ampiharina tsara savaivony (mm) |

naoty power(KW) |

naoty malefaka (V) |

naoty ankehitriny (A) |

Fahombiazan'ny motera (%) | power factorcosφ | Unit Radial Habe ambony (mm) |

|||||||||

| 175QJ10-42 | 10 | 42 | 2850 | 53 | 50 | 175AMBONY | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ10-56 | 56 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-70 | 70 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-84 | 84 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ10-112 | 112 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-126 | 126 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-140 | 140 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ15-42 | 15 | 42 | 2850 | 58 | 50 | 175AMBONY | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ15-55 | 55 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-65 | 65 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-85 | 85 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ15-112 | 112 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 175AMBONY | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ20-39 | 39 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ20-52 | 52 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ20-78 | 78 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ20-91 | 91 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-104 | 104 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ20-130 | 130 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-156 | 156 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-182 | 187 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ20-208 | 208 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-247 | 247 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-273 | 273 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-299 | 299 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-325 | 325 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-364 | 364 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-26 | 25 | 26 | 2850 | 66 | 65 | 175AMBONY | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ25-39 | 39 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ25-65 | 25 | 65 | 2850 | 66 | 65 | 175AMBONY | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ25-78 | 78 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ25-91 | 91 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ25-104 | 104 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-130 | 130 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-156 | 156 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ25-182 | 182 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-208 | 208 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-221 | 221 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-247 | 247 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-260 | 260 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-299 | 299 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ30-30 | 30 | 30 | 2850 | 67 | 80 | 175AMBONY | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ30-40 | 40 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-24 | 32 | 24 | 2850 | 67 | 80 | 175AMBONY | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ32-36 | 36 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-48 | 48 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ32-60 | 60 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ32-72 | 72 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ32-84 | 84 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-96 | 96 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-120 | 120 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ32-144 | 144 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-168 | 168 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-180 | 180 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-192 | 192 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-204 | 204 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-240 | 240 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ35-60 | 35 | 60 | 2850 | 67 | 80 | 175AMBONY | 10 | 380 | 25.0 | 78.0 | 0.78 | 168 | |||||||||

| 175QJ35-75 | 75 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ35-100 | 100 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ40-24 | 40 | 24 | 2850 | 70 | 80 | 175AMBONY | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ40-30 | 30 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ40-36 | 36 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ40-48 | 48 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ40-60 | 60 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ40-72 | 72 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-84 | 84 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-96 | 96 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ40-120 | 120 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-132 | 132 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-144 | 144 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-156 | 156 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-168 | 168 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-192 | 192 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-24 | 50 | 24 | 2850 | 72 | 80 | 175AMBONY | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ50-36 | 36 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ50-48 | 48 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ50-70 | 70 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ50-84 | 84 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ50-96 | 96 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-108 | 108 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-120 | 120 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-132 | 132 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-144 | 144 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-156 | 156 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-22 | 63 | 22 | 2850 | 72 | 80 | 175AMBONY | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ63-44 | 44 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-55 | 55 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-66 | 66 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ63-77 | 77 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-88 | 88 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-99 | 63 | 99 | 2850 | 72 | 80 | 175AMBONY | 30 | 380 | 66.6 | 81.5 | 0.84 | 168 | |||||||||

| 175QJ63-110 | 110 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-132 | 132 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-9 | 80 | 9 | 2850 | 73 | 100 | 175AMBONY | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ80-18 | 18 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ80-27 | 27 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ80-36 | 36 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ80-45 | 45 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ80-54 | 54 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-63 | 63 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-72 | 72 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-81 | 81 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-90 | 90 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-98 | 98 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, hentitra araka ny fepetra ny paompy fanandratana, mikoriana isan-karazany ny fampiasana, mba hisorohana ny fikorianan'ny ambany na ny fiakarana avo pumping hery, ny fanosehana mitondra sy ny ampahany hafa amin'ny fitafy, ny maotera be loatra may.

6, after the pump down the well, the measurement of the motor to the ground insulation resistance should not be less than 100M, after the start to observe the voltage and current, check the motor winding insulation, whether in line with the requirements; pump storage location temperature if less than freezing point, should be dry the motor cavity water, prevent the motor cavity water ice damage caused by low temperature.

The pump part is mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor part mainly includes base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand ring, water inlet section, lead cable and other components. The main features of the product include: the motor is a water immersed wet three-phase asynchronous motor, the motor cavity is full of water, used to cool the motor and lubricate the bearing; the pressure regulating film at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the internal water caused by the change of temperature; in order to prevent the sand particles in the well water from entering the motor, two oil seals are installed on the upper end of the motor shaft extension, and a sand control structure is formed by installing the sand ring; in order to prevent the pump shaft from jumping at startup, the pump shaft is connected with the motor shaft through a coupling, and the thrust bearing is installed under the motor; the lubrication of the motor and the pump bearing is water lubrication; the stator winding of the motor is made of high quality submersible motor winding, with high insulation performance; the pump is designed by computer CAD, with simple structure and excellent technical performance.

(1) Fiomanana alohan'ny fametrahana:

1. Hamarino raha mahafeno ny fepetra fampiasana sy ny habaka voafaritra ao amin'ny boky ny paompy submersible.

2. Mampiasa obiect mavesatra miaraka amin'ny savaivony mitovy amin'ny savaivony ivelany ambony indrindra amin'ny paompy submersible, refeso raha mety hifanaraka amin'ny paompy submersible ny savaivony amin'ny lavaka fantsakana, ary refesina raha mahafeno ny fepetra takiana amin'ny fametrahana ny halaliny.

3. Hamarino raha madio ny lavaka fantsakana ary ny rano fantsakana dia feno rano. Aza mampiasa paompy elektrika azo atsoboka mihitsy mba hanasana ny fotaka sy ny rano fasika mba hisorohana ny fahasimbana aloha loatra amin'ny paompy elektrika.

4. Hamarino raha mety ny toerana misy ny clamp fametrahana welhead ary mahatanty ny kalitaon'ny vondrona manontolo.

5. Hamarino raha toa ka feno sy apetraka araka ny tokony ho izy ny singa ao amin'ny paompy submersible araka ny kisarisary ao amin'ny boky torolalana.

6. Esory ny visy ary fenoy rano madio tsy misy korontanina ny lavaky ny môtô (mariho. Ataovy azo antoka ny famenoana azy), ary henjana ny vy. Taorian'ny 12 ora ny tsindrona rano, ny insulation fanoherana ny maotera dia tsy tokony ho latsaky ny 150M Q rehefa refesina amin'ny 500V nihozongozona latabatra.

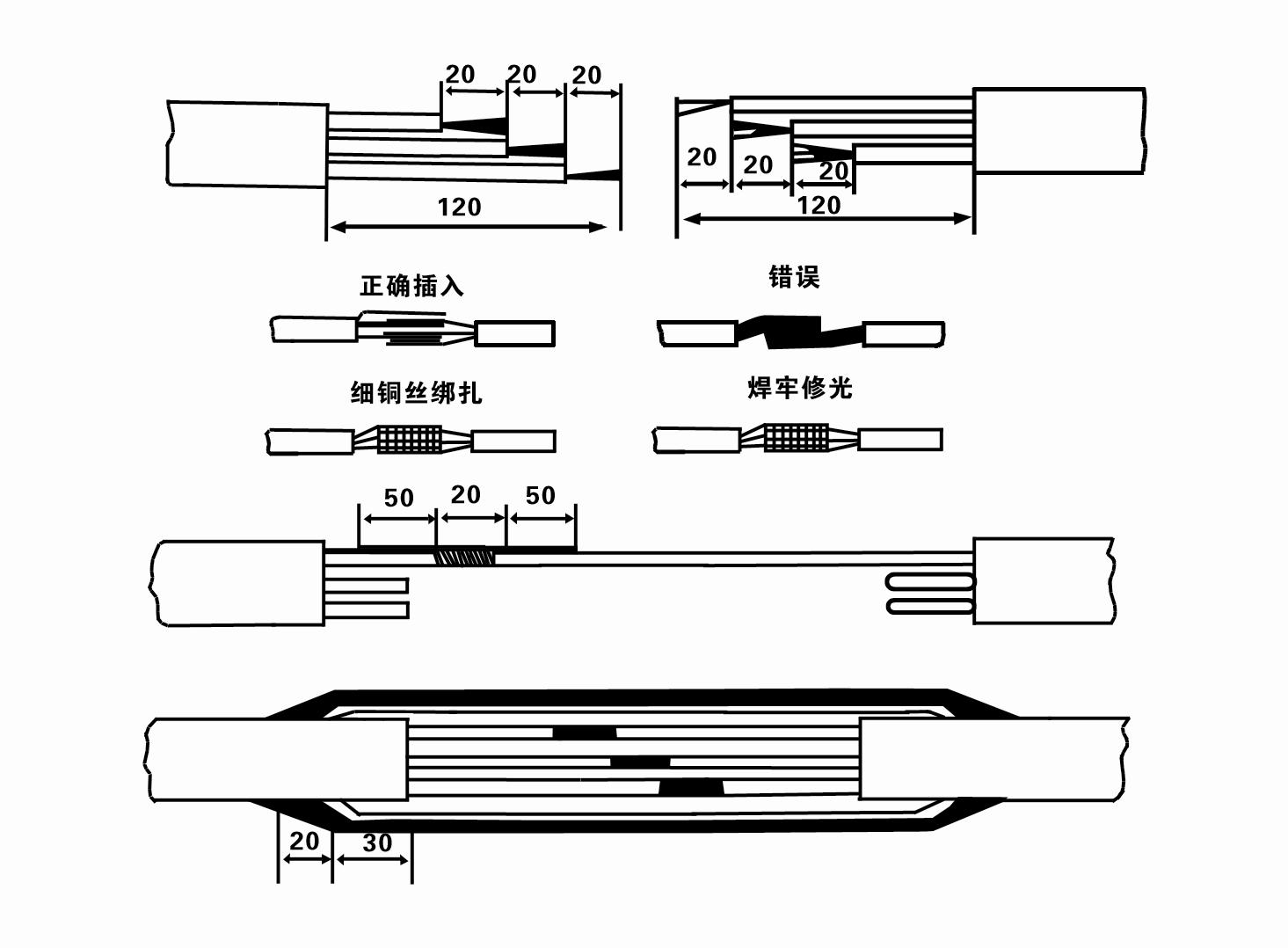

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Toy izao manaraka izao ny diagrama fizotry ny fizotry ny tariby tariby mifamatotra:

8. Mampiasà multimeter mba hijerena raha mifandray ny tariby telo-dingana ary sao dia mifandanja ny fanoherana DC.

9. Jereo raha be loatra ny fahaizan'ny circuit sy ny transformer, ary ampifandraiso amin'ny fiatoana fiarovana na fitaovana fanombohana avy eo. Jereo ny tabilao 2 ho an'ny maodely manokana, ary avy eo dia arotsaho ao anaty paompy rano avy amin'ny fivoahan'ny paompy rano ny siny mba hanesorana ny fingotra ao amin'ny paompy, ary avy eo dia apetraho mitsangana sy miorim-paka ny paompy elektrika an-drano. ary jereo raha mifanaraka amin'ny famantarana ny familiana ny fitarihana. Raha tsy izany dia ampifamadiho ny mpampitohy roa amin'ny tariby misy dingana telo. Avy eo apetraho ny sivana ary miomàna hidina amin'ny fantsakana. Raha ampiasaina amin'ny fotoana manokana (toy ny tatatra, tatatra, renirano, dobo, dobo, sns.), Ny paompy elektrika dia tsy maintsy miorina tsara.

(2) Fametrahana fitaovana sy fitaovana:

1. Rojo fanandratana roa mihoatra ny roa taonina.

2. Tripod misy haavo mitsangana tsy latsaky ny efatra metatra.

3. Tady mihantona roa (tady tariby) izay mahazaka lanja mihoatra ny iray taonina (mahazaka ny lanjan'ny paompin-drano feno).

4. Mametraka clamp roa (splints).

5. Wrenches, tantanana, screwdrivers, fitaovana elektrika sy fitaovana, sns.

(3) Fametrahana paompy elektrika:

1. Ny sarin'ny fametrahana ny paompy elektrika an-tsokosoko dia aseho amin'ny sary 2. Ny refy fametrahana manokana dia aseho amin'ny tabilao 3 "Lisitry ny haben'ny fametrahana ny paompy elektrika azo ampiasaina".

2. Ny paompy elektrika azo atsoboka amin'ny lohany latsaky ny 30 metatra dia azo atsangana mivantana ao amin'ny fantsakana amin'ny fampiasana hoses sy tady tariby na tady hemp hafa izay mahazaka ny lanjan'ny milina iray manontolo, ny fantson-drano ary ny rano ao anaty fantsona.

3. Ny paompy manana loha mihoatra ny 30 metatra dia mampiasa fantsona vy, ary ny filaharan'ny fametrahana dia toy izao manaraka izao:

①Mampiasà clamp hanintonana ny tendrony ambony amin'ny ampahany amin'ny paompy rano (efa mifandray ny motera sy ny paompy rano amin'izao fotoana izao), atsangano amin'ny rojo mihantona, ary afehezo tsikelikely ao anaty lavaka fantsakana mandra-pametraka ny fametahana eo amin'ny lohan'ny fantsakana ary esory rojo mihantona.

② Mampiasà fametahana roa hafa hamehezana sodina, atsangano amin'ny rojo mihantona eo amin'ny 15 sm miala ny flange, ary ampidino tsikelikely. Eo anelanelan'ny flange pipe sy flange paompyApetraho eo amin'ny toerany ny pad fingotra ary henjana ny sodina ary paompy mitovy amin'ny bolt, voanjo ary mpanasa lohataona.

③ Asandrato kely ny paompin-drano, esory ny fametahana eo amin'ny tendrony ambony amin'ny paompy rano, afehezo mafy amin'ny fantsona plastika ny tariby, ary afehezo tsikelikely mandra-pametraka ny fametahana eo amin'ny lohan'ny fantsakana.

④Mampiasà fomba mitovy amin'ny famatorana ny fantsona rehetra ao anaty lavaka fantsakana.

⑤Rehefa mifandray amin'ny tariby fanaraha-maso ny tariby mitarika, dia mifandray amin'ny famatsiana herinaratra amin'ny dingana telo izany.

(4) Zavatra tokony homarihina mandritra ny fametrahana:

1. Raha toa ka misy trangan-javatra misy fitohanana hita mandritra ny fizotry ny paompy, atodiho na sintonina ny fantson-drano mba hialana amin'ny teboka mikorontana. Raha mbola tsy mandeha ny fepetra isan-karazany, azafadyAza terena hidina ny paompy mba hisorohana ny fahasimban'ny paompy elektrika sy ny fantsakana.

2. Mandritra ny fametrahana dia tokony hapetraka eo amin'ny sisin'ny sodina tsirairay ny pad fingotra ary hamafisina tsara.

3. Rehefa ampidinina ao anaty fantsakana ny paompy rano, dia tokony hapetraka eo afovoan'ny fantsakana izany mba hisorohana ny paompy tsy hianjera amin'ny rindrin'ny fantsakana mandritra ny fotoana maharitra, ka mahatonga ny paompy hihovitrovitra ary ny motera hifafa sy handoro. .

4. Farito ny halalin'ny paompin-drano mankany amin'ny fanambanin'ny fantsakana araka ny toetry ny fasika mikoriana sy ny fotaka. Aza alevina ao anaty fotaka ny paompy. Ny halaviran'ny paompin-drano mankany amin'ny fanambanin'ny fantsakana amin'ny ankapobeny dia tsy latsaky ny 3 metatra (jereo ny sary 2).

5. Ny halalin'ny rano miditra amin'ny paompy dia tsy tokony ho latsaky ny 1-1,5 metatra avy amin'ny haavon'ny rano mavitrika mankany amin'ny node fampidirana rano (jereo ny sary 2). Raha tsy izany dia mety ho simba mora foana ny paompy rano.

6. Tsy tokony ho ambany loatra ny fiakaran'ny paompy rano. Raha tsy izany, mila asiana valva vavahady eo amin'ny fantson-drano amin'ny lohan'ny fantsakana mba hifehezana ny fikorianan'ny paompy eo amin'ny toerana misy naoty mba hisorohana ny motera tsy ho be loatra sy ho may noho ny tahan'ny fikorianan'ny rivotra.

7. Rehefa mandeha ny paompy rano, ny fivoahan'ny rano dia tokony ho mitohy ary na dia, ny ankehitriny dia tokony ho marin-toerana (eo ambanin'ny fepetra miasa, amin'ny ankapobeny tsy mihoatra ny 10% ny naoty ankehitriny), ary tsy tokony hisy hovitrovitra na tabataba. Raha misy tsy mety dia tokony hajanona ny milina mba hahitana ny antony sy hanafoanana izany.

8. Rehefa mametraka, tandremo tsara ny fametrahana ny tariby fanodinkodinana maotera (jereo ny sary 2). Raha sodina vy ny fantsona rano, dia tariho avy amin'ny fantson-drano; rehefa fantsona plastika ny fantsona rano dia tariho avy amin'ny marika fototra amin'ny paompy elektrika.

- 1.After installing the submersible pump, recheck the insulation resistance and the three-phase continuity at the switch, and check whether there are errors in the connection of the instrument and the starting equipment.If there are no problems, you can start to test the machine. After starting, observe whether the indication readings of each instrument are correct. If the rated voltage and current specified on the nameplate are exceeded, observe whether the pump emits any noise or vibration. If everything is normal, it can be put into operation.

- 2. After the pump runs for the first four hours, the thermal insulation resistance of the motor should be closed and tested quickly.Its value should not be less than 0.5 megaohm.After the pump stops, it should be restarted after an interval of five minutes to prevent the water column in the pipeline from completely reversing and burning the motor due to excessive current.

- 3. After the pump is put into normal operation, in order to prolong its service life, it is necessary to check regularly whether the supply voltage, working current and insulation resistance are normal. If the following conditions are found, the machine should be stopped immediately to troubleshoot.

- 1 Amin'ny toe-javatra miasa naoty, ny ankehitriny dia mihoatra ny 20%.

- 2 Ny haavon'ny rano mavitrika dia midina any amin'ny faritra fidirana amin'ny rano, ka miteraka rano miato.

- 3 Ny paompy submersible dia misy vibration na tabataba mafy.

- 4 Ny voltase famatsiana dia ambany noho ny 340 volts.

- 5 May ny fuse iray.

- 6 Simba ny fantsona famatsian-drano.

- 7 Ny fanoherana insulation ny maotera amin'ny fanjakana geothermal dia ambany noho ny 0,5 megaohm.

- Unit disassembly:

- 1.untie cable rope, remove the pipeline part, remove the wire plate.

- 2.screw down the water bolt, put the water in the motor chamber.

- 3.remove the filter, loose the fixed screw on the coupling to fix the motor shaft.

- 4.screw down the bolt connecting the inlet junction with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) inlet junction, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising of the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the reverse order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

This product adopts advanced design and provides advanced storage suggestions to ensure long-term use effect.First of all, in winter, it is necessary to exhaust all the water to prevent freezing. In addition, the wire rolls should be placed well and tied up.Secondly, when storing, the environment without corrosive action and gas should be selected and the temperature should be kept below 40 °C. Finally, when not used for a long time, attention should be paid to prevent rust of submersible pump.These storage requirements will ensure that the product can maintain its performance status and prolong its service life for a long time.

- Impeller

- Shaft tanany

- Fingotra tanany

-

Peratra famehezana

01 Fantsakana rano lalina

02 Famatsiana rano avo

03 famatsiana rano an-tendrombohitra

04 rano tilikambo

05 Fanondrahana fambolena

06 fanondrahana zaridaina

07 rano fisotro madio

08 rano ao an-trano