QJP series fountain pump is a special pump for fountain developed by our factory.The pump motor core is made of high quality cold rolled silicon steel, which makes the pump more efficient, good magnetic conductivity, and frequent start will not fever.Both ends of the motor rotor use water as lubricant alloy copper sleeve.Stainless steel sleeve instead of ball bearings, to avoid the problem of easy rust ball bearings and lack of oil wear and tear the motor.The most suitable for music fountain use, all models can be used.

This product is a three-phase AC 380V (tolerance + / - 5%), 50HZ (tolerance + / - 1%) power supply system. Applicable water quality conditions include water temperature not exceeding 20 °C, solid impurities content (mass ratio) is not greater than 0.01%, PH value (pH) is 6.5-8.5, hydrogen sulfide content is not greater than 1.5mg/L, chloride ion content is not greater than 400mg/L. The motor is a closed or water-filled wet structure. Before use, it must be filled with clean water to prevent false filling, and then tighten the water injection and exhaust bolts, otherwise it is not allowed to use. The submersible pump must be completely immersed in water, and the penetration depth shall not exceed 70m. The distance between the submersible pump base and the bottom of the well shall not be less than 3m. The well flow shall be able to meet the water output and continuous operation of the submersible pump. The water output of the submersible pump shall be controlled at 0.7-1.2 times of the rated flow. The well shall be vertical, and the submersible pump can not be used horizontally or upside down, but only vertically. The submersible pump shall be equipped with cables and external overload protection devices as required. The pump is strictly prohibited from no-load test without water.

| Umzekelo | Ukuhamba (m3/h) | Intloko (m) |

Isantya sokujikeleza (tshintsha/inqaku) |

Impompo yamanzi(%) | Indawo yokuphuma ububanzi (mm) |

Isebenza kakuhle ububanzi(mm) |

Ikaliwe power(KW) |

Ikaliwe amandla ombane (V) |

Ikaliwe yangoku (A) |

Ukusebenza kakuhle (%) | power factorcosφ | Iyunithi Ubungakanani beRadial Maximum (mm) |

|||||||||

| 175QJ10-42 | 10 | 42 | 2850 | 53 | 50 | 175ngaphezulu | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ10-56 | 56 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-70 | 70 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-84 | 84 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ10-112 | 112 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-126 | 126 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-140 | 140 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ15-42 | 15 | 42 | 2850 | 58 | 50 | 175ngaphezulu | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ15-55 | 55 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-65 | 65 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-85 | 85 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ15-112 | 112 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 175ngaphezulu | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ20-39 | 39 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ20-52 | 52 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ20-78 | 78 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ20-91 | 91 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-104 | 104 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ20-130 | 130 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-156 | 156 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-182 | 187 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ20-208 | 208 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-247 | 247 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-273 | 273 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-299 | 299 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-325 | 325 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-364 | 364 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-26 | 25 | 26 | 2850 | 66 | 65 | 175ngaphezulu | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ25-39 | 39 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ25-65 | 25 | 65 | 2850 | 66 | 65 | 175ngaphezulu | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ25-78 | 78 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ25-91 | 91 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ25-104 | 104 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-130 | 130 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-156 | 156 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ25-182 | 182 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-208 | 208 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-221 | 221 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-247 | 247 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-260 | 260 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-299 | 299 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ30-30 | 30 | 30 | 2850 | 67 | 80 | 175ngaphezulu | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ30-40 | 40 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-24 | 32 | 24 | 2850 | 67 | 80 | 175ngaphezulu | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ32-36 | 36 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-48 | 48 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ32-60 | 60 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ32-72 | 72 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ32-84 | 84 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-96 | 96 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-120 | 120 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ32-144 | 144 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-168 | 168 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-180 | 180 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-192 | 192 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-204 | 204 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-240 | 240 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ35-60 | 35 | 60 | 2850 | 67 | 80 | 175ngaphezulu | 10 | 380 | 25.0 | 78.0 | 0.78 | 168 | |||||||||

| 175QJ35-75 | 75 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ35-100 | 100 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ40-24 | 40 | 24 | 2850 | 70 | 80 | 175ngaphezulu | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ40-30 | 30 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ40-36 | 36 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ40-48 | 48 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ40-60 | 60 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ40-72 | 72 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-84 | 84 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-96 | 96 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ40-120 | 120 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-132 | 132 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-144 | 144 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-156 | 156 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-168 | 168 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-192 | 192 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-24 | 50 | 24 | 2850 | 72 | 80 | 175ngaphezulu | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ50-36 | 36 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ50-48 | 48 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ50-70 | 70 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ50-84 | 84 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ50-96 | 96 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-108 | 108 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-120 | 120 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-132 | 132 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-144 | 144 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-156 | 156 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-22 | 63 | 22 | 2850 | 72 | 80 | 175ngaphezulu | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ63-44 | 44 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-55 | 55 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-66 | 66 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ63-77 | 77 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-88 | 88 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-99 | 63 | 99 | 2850 | 72 | 80 | 175ngaphezulu | 30 | 380 | 66.6 | 81.5 | 0.84 | 168 | |||||||||

| 175QJ63-110 | 110 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-132 | 132 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-9 | 80 | 9 | 2850 | 73 | 100 | 175ngaphezulu | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ80-18 | 18 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ80-27 | 27 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ80-36 | 36 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ80-45 | 45 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ80-54 | 54 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-63 | 63 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-72 | 72 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-81 | 81 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-90 | 90 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-98 | 98 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, ngokungqongqo ngokwemiqathango yokunyuswa kwempompo, uluhlu lokuhamba kokusetyenziswa, ukuthintela ukuhamba okuphantsi okanye amandla okumpompa aphezulu, ukunyanzeliswa kwe-thrust kunye nezinye iindawo zokunxiba, ukugcwala kwemoto kutshiswe.

6, after the pump down the well, the measurement of the motor to the ground insulation resistance should not be less than 100M, after the start to observe the voltage and current, check the motor winding insulation, whether in line with the requirements; pump storage location temperature if less than freezing point, should be dry the motor cavity water, prevent the motor cavity water ice damage caused by low temperature.

The pump part is mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor part mainly includes base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand ring, water inlet section, lead cable and other components. The main features of the product include: the motor is a water immersed wet three-phase asynchronous motor, the motor cavity is full of water, used to cool the motor and lubricate the bearing; the pressure regulating film at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the internal water caused by the change of temperature; in order to prevent the sand particles in the well water from entering the motor, two oil seals are installed on the upper end of the motor shaft extension, and a sand control structure is formed by installing the sand ring; in order to prevent the pump shaft from jumping at startup, the pump shaft is connected with the motor shaft through a coupling, and the thrust bearing is installed under the motor; the lubrication of the motor and the pump bearing is water lubrication; the stator winding of the motor is made of high quality submersible motor winding, with high insulation performance; the pump is designed by computer CAD, with simple structure and excellent technical performance.

(1)Ulungiselelo phambi kofakelo:

1. Jonga ukuba impompo engaphantsi kwamanzi iyahlangabezana nemiqathango yokusetyenziswa kunye nobubanzi obuchazwe kwincwadana.

2. Ukusebenzisa i-obiect enzima ene-diameter elingana nobukhulu obungaphandle bedayamitha yempompo engaphantsi kwamanzi, linganisa ukuba i-inneldiameter ye-wellbore ingafanelana nempompo engaphantsi kwamanzi, kwaye ulinganise ukuba ubunzulu bomthombo buhlangabezana neemfuno zokufakela.

3. Jonga ukuba iqula licocekile na kunye nokuba amanzi amgxobhozo na. Ungaze usebenzise impompo yombane engaphantsi kwamanzi ukuhlamba udaka lwempompo ye-welor kunye namanzi esanti ukunqanda umonakalo ophambi kwexesha kwimpompo yombane engaphantsi kwamanzi.

4. Khangela ukuba indawo ye-welhead yokufakela i-clamp ifanelekile kwaye ingaba inokumelana nomgangatho weyunithi yonke.

5. Khangela ukuba izixhobo zempompo eziphantsi kwamanzi zigqityiwe kwaye zifakwe ngokufanelekileyo ngokwedayagram yendibano kwincwadana Susa isikrini sokucoca kwaye ujikelezise ukudibanisa ukuze ubone ukuba ijikeleza ngokuguquguqukayo.

6. Khupha isikrufu samanzi uze ugcwalise umngxuma wemoto ngamanzi acocekileyo, angadlekiyo (qaphela. qiniseka ukuba uyasifafa), uze uqinise isikrufu samanzi. Emva kweeyure ezili-12 zenaliti yamanzi, ukuxhathisa kwe-insulation ye-motor akufanele kube ngaphantsi kwe-150M Q xa kulinganiswa netafile yokungcangcazela ye-500V.

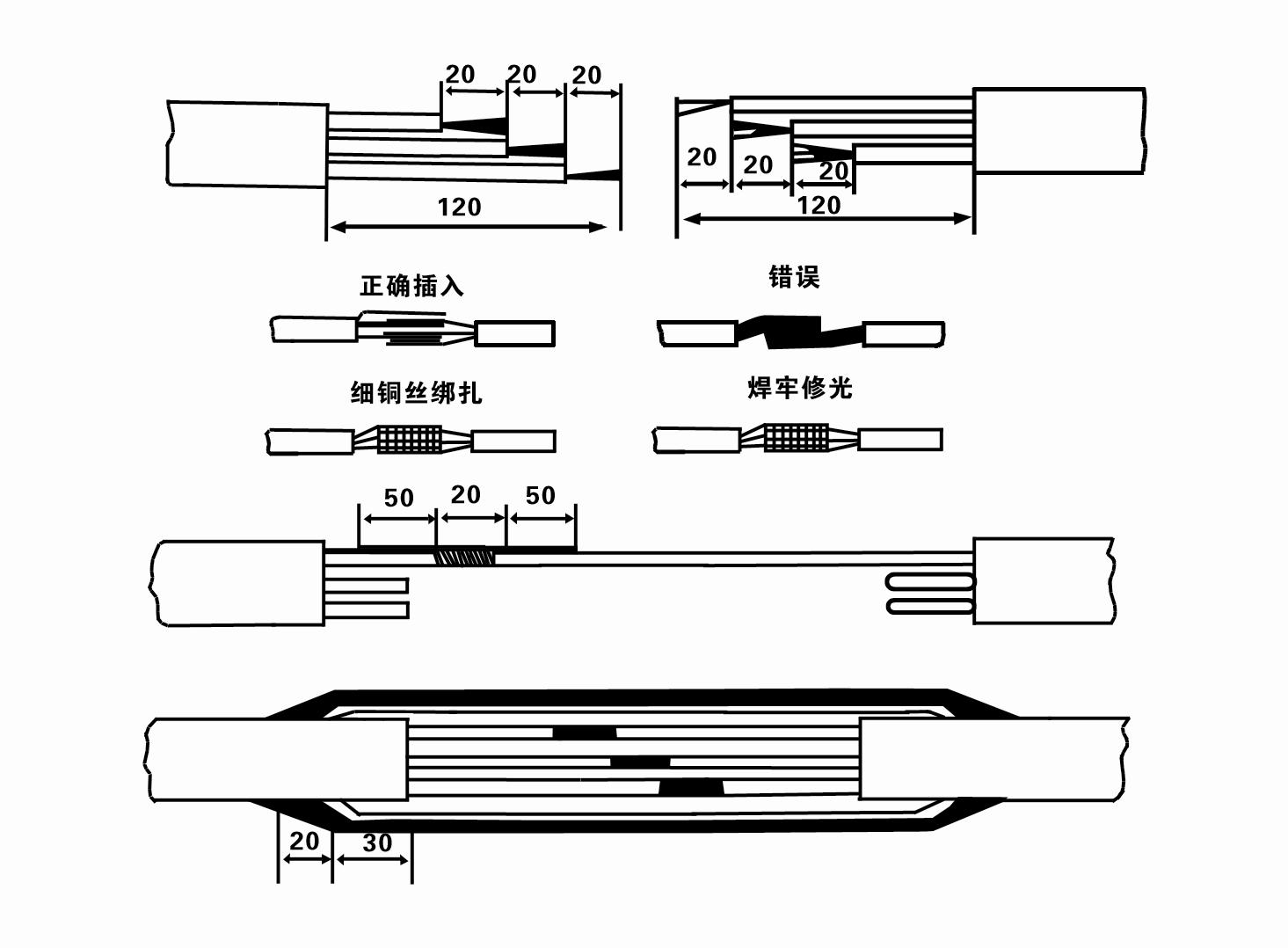

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Umzobo oqhotyoshelweyo wenkqubo yokufaka iintambo zentambo umi ngolu hlobo lulandelayo:

8. Sebenzisa i-multimeter ukujonga ukuba ngaba iingcingo zesigaba sesithathu zidibaniswe kunye nokuba ukuchasana kwe-DC kuphantse kulinganiswe.

9. Khangela ukuba isekethe kunye nomthamo we-transformer ugcwele kakhulu, kwaye emva koko uqhagamshele i-switch yokukhusela okanye uqalise izixhobo. Jonga iTheyibhile yesi-2 kwiimodeli ezithile, kwaye emva koko galela ibhakethi lamanzi kwimpompo yamanzi ukusuka kwindawo yokupompoza amanzi ukuthambisa iibheringi zerabha kwimpompo, kwaye emva koko ubeke impompo yombane entywilayo ngokuthe tye kwaye izinzile.Qala (ungabi ngaphezu komzuzwana omnye) kwaye ujonge ukuba ngaba ulwalathiso lokuqhuba luyahambelana nophawu lokuqhuba. Ukuba akunjalo, tshintsha naziphi na izihlanganisi ezibini zesigaba sesithathu sentambo. Emva koko faka isihluzo kwaye ulungiselele ukuhla equleni. Ukuba isetyenziswe ngezihlandlo ezikhethekileyo (ezifana nemijelo, imisele, imilambo, amachibi, amachibi, njl. njl.), impompo yombane kufuneka isekelwe ngokuthembekileyo.

(2)Izixhobo zofakelo kunye nezixhobo:

1. Ipere enye yamatyathanga okuphakamisa ngaphezulu kweetoni ezimbini.

2. I-tripod enobude obuthe nkqo obungekho ngaphantsi kweemitha ezine.

3. Iintambo ezimbini ezijingayo (iintambo zocingo) ezinokuthwala ubunzima obungaphezu kwetoni enye (zinokuthwala ubunzima beseti epheleleyo yeempompo zamanzi).

4. Fakela izibini ezimbini zeeclamps (i-splints).

5. Izitshixo, izando, i-screwdrivers, izixhobo zombane kunye nezixhobo, njl.

(3)Ufakelo lwempompo yombane:

1. Umzobo wofakelo lwempompo yombane engaphantsi kwamanzi iboniswe kuMzobo 2. Imilinganiselo ethile yokufakela iboniswe kwiThebhile 3 "Uluhlu lweMilinganiselo yokuFakela iPump yoMbane ongaphantsi kwamanzi".

2. Iimpompo zombane ezingaphantsi kwamanzi ezinentloko engaphantsi kweemitha ezingama-30 zinokunyuswa ngokuthe ngqo equleni kusetyenziswa imibhobho kunye neentambo zocingo okanye ezinye iintambo zehemp ezinokuthwala ubunzima obupheleleyo bomatshini wonke, imibhobho yamanzi, kunye namanzi kwimibhobho.

3. Iipompo ezinentloko yeemitha ezingaphezu kwe-30 zisebenzisa iipayipi zensimbi, kwaye ulandelelwano lofakelo lulandelayo:

①Sebenzisa ibamba ukucinezela isiphelo esiphezulu sempompo yamanzi (injini kunye nempompo yamanzi sele idityanisiwe ngeli xesha), yiphakamise ngetsheyini ejingayo, kwaye uyibophe ngokukhawuleza equleni de ubeke isibambiso entloko kwaye uyisuse. ikhonkco elijingayo.

② Sebenzisa enye ipere yeziqhoboshi ukuqhobosha umbhobho, uwuphakamise ngetyathanga elijingayo 15 cm kude neflange, kwaye uwuhlise kancinane. Phakathi kweflange yombhobho kunye neflange yepompoFaka ipadi yerabha endaweni kwaye uqinise umbhobho kwaye umpompe ngokulinganayo ngeebholiti, iinati kunye newasher zasentwasahlobo.

③ Phakamisa kancinane impompo entywilayo emanzini, susa isithinteli esikwisiphelo esiphezulu sempompo yamanzi, qhina intambo ngokuqinileyo kumbhobho wamanzi ngeteyiphu yeplastiki, kwaye uyibophe kancinane de Ibamba libekwe emthonjeni.

④Sebenzisa indlela efanayo ukubopha yonke imibhobho yamanzi equleni.

⑤Emva kokuba ikhebula elikhokelayo liqhagamshelwe kwisitshixo solawulo, liqhagamshelwe kunikezelo lwamandla amanqanaba amathathu.

(4)Izinto ekufuneka uziqwalasele ngexesha lofakelo:

1. Ukuba i-jamming phenomenon ifunyenwe ngexesha lenkqubo yokupompa, jika okanye utsale umbhobho wamanzi ukuze unqobe i-jamming point. Ukuba imilinganiselo eyahlukeneyo ayisebenzi, nceda unganyanzeli impompo phantsi ukunqanda umonakalo kwimpompo yombane engaphantsi kwamanzi kunye nequla.

2. Ngethuba lofakelo, i-rubber pad kufuneka ifakwe kwi-flange yombhobho ngamnye kwaye iqiniswe ngokulinganayo.

3. Xa impompo yamanzi ithotywa equleni, kufuneka ibekwe embindini wombhobho wequla ukuthintela ukuba impompo ihambe ngaphaya kodonga lwequla ixesha elide, nto leyo ebangela ukuba impompo ingcangcazele kwaye imotor itshayele kwaye itshise. .

4. Qinisekisa ubunzulu bempompo yamanzi ukuya ezantsi kwequla ngokwesanti equkuqelayo kunye neemeko zentlenge equleni. Musa ukungcwaba impompo eludakeni. Umgama ukusuka kumpompo wamanzi ukuya ezantsi kwequla awukho ngaphantsi kweemitha ezi-3 (jonga umfanekiso 2).

5. Ubunzulu bokungena kwamanzi kwimpompo yamanzi kufuneka bungabi ngaphantsi kwe-1-1.5 yeemitha ukusuka kwinqanaba lamanzi aguquguqukayo ukuya kwindawo yokungena kwamanzi (jonga uMfanekiso 2). Ngaphandle koko, iibheringi zempompo zamanzi zinokonakala lula.

6. Ukunyuswa kwempompo yamanzi akunakuba phantsi kakhulu. Kungenjalo, ivalve yesango kufuneka ifakwe kumbhobho wamanzi osentloko yomthombo ukulawula ukuhamba kwempompo kwindawo yokuqukuqela ehleliweyo ukuthintela ukugcwala okugqithisileyo kwemoto kwaye itshiswe ngenxa yamazinga amakhulu okuhamba.

7. Xa umpompo wamanzi usebenza, ukukhutshwa kwamanzi kufuneka kuqhubeke kwaye nokuba, okwangoku kufuneka kuzinzile (phantsi kweemeko zokusebenza ezilinganisiweyo, ngokuqhelekileyo akukho ngaphezu kwe-10% ye-current rated current), kwaye akufanele kubekho ukungcangcazela okanye ingxolo. Ukuba kukho nakuphi na ukungaqhelekanga, umatshini kufuneka umiswe ukufumanisa unobangela kwaye upheliswe.

8. Xa ufaka, qwa lasela ukusetwa kwe-motor grounding wire (jonga umfanekiso 2). Xa umbhobho wamanzi ungumbhobho wentsimbi, yiholele kwi-clamp ye-wellhead clamp; xa umbhobho wamanzi ungumbhobho weplastiki, ukhokele ukusuka kwindawo yokubeka ipompo yombane.

- 1.After installing the submersible pump, recheck the insulation resistance and the three-phase continuity at the switch, and check whether there are errors in the connection of the instrument and the starting equipment.If there are no problems, you can start to test the machine. After starting, observe whether the indication readings of each instrument are correct. If the rated voltage and current specified on the nameplate are exceeded, observe whether the pump emits any noise or vibration. If everything is normal, it can be put into operation.

- 2. After the pump runs for the first four hours, the thermal insulation resistance of the motor should be closed and tested quickly.Its value should not be less than 0.5 megaohm.After the pump stops, it should be restarted after an interval of five minutes to prevent the water column in the pipeline from completely reversing and burning the motor due to excessive current.

- 3. After the pump is put into normal operation, in order to prolong its service life, it is necessary to check regularly whether the supply voltage, working current and insulation resistance are normal. If the following conditions are found, the machine should be stopped immediately to troubleshoot.

- 1 Kwimeko yokusebenza elinganisiweyo, okwangoku kudlula i-20%.

- 2 Umgangatho wamanzi oguquguqukayo wehla ukuya kwindawo yokungena kwamanzi, okubangela ukuba amanzi aphumle.

- 3 Impompo entywilayo phantsi inongcangcazelo olumandla okanye ingxolo.

- 4 Umbane wokubonelela ungaphantsi kwe-340 volts.

- 5 Ifuse iyatshiswa.

- 6 Umbhobho wonikezelo lwamanzi wonakalisiwe.

- 7 Ukumelana nokugquma kwemotor kwimeko ye-geothermal ingaphantsi kune-0.5 megaohm.

- Unit disassembly:

- 1.untie cable rope, remove the pipeline part, remove the wire plate.

- 2.screw down the water bolt, put the water in the motor chamber.

- 3.remove the filter, loose the fixed screw on the coupling to fix the motor shaft.

- 4.screw down the bolt connecting the inlet junction with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) inlet junction, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising of the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the reverse order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

This product adopts advanced design and provides advanced storage suggestions to ensure long-term use effect.First of all, in winter, it is necessary to exhaust all the water to prevent freezing. In addition, the wire rolls should be placed well and tied up.Secondly, when storing, the environment without corrosive action and gas should be selected and the temperature should be kept below 40 °C. Finally, when not used for a long time, attention should be paid to prevent rust of submersible pump.These storage requirements will ensure that the product can maintain its performance status and prolong its service life for a long time.

- Impeller

- Umkhono weshaft

- Umkhono weshaft yerabha

-

Umsesane wokutywina

01 Ukusela amanzi kwiqula elinzulu

02 Ubonelelo lwamanzi olukwizinga eliphezulu

03 unikezelo lwamanzi entabeni

04 amanzi enqaba

05 Ukunkcenkceshela kwezolimo

06 ukunkcenkceshela egadini

07 amanzi omlambo

08 amanzi asekhaya