Suitable for underground hot water mining with water temperature below 100°C, with heat resistance, corrosion resistance, aging resistance and other characteristics

This product is a powerful three-phase AC 380V (tolerance ± 5%), 50HZ (tolerance ± 1%) electric pump, suitable for all kinds of occasions need high-power pump. Its design considers a variety of water quality factors, including water temperature not higher than 20 °C, solid impurities content is not greater than 0.01%, PH value is 6.5-8.5, hydrogen sulfide content is not greater than 1.5mg/L, chloride ion content is not greater than 400mg/L, etc. The product adopts a closed or water immersion wet structure of the motor, before use in the submersible motor chamber filled with clean water to prevent empty fill. Requirements in strict accordance with the requirements of the matching cable and equipped with external overload protection device. To ensure stable operation, the submersible pump must be completely immersed in water operation, the insertion depth shall not exceed 70 meters, and the distance from the bottom of the well shall not be less than 3 meters. In addition, the pump shall not be a no-load test before start. In general, this product has the characteristics of high efficiency and stability, suitable for a variety of pump tasks in harsh environment.

| Model | Flow (m3/h) | Head (m) |

Rotatingspeed (change/point) |

Waterpump(%) | Outlet diameter (mm) |

Applicable well diameter(mm) |

Rated power(KW) |

Rated voltage(V) |

Rated current(A) |

Motorefficiency (%) | power factorcosφ | Unit Radial Maximu size(mm) |

Remark | |||||||||

| 125QJ5-34 | 5 | 34 | 2850 | 53 | 40 | 125above | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ5-51 | 51 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ5-68 | 68 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ5-85 | 85 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ5-102 | 102 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ5-119 | 119 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-24 | 10 | 24 | 2850 | 60 | 50 | 125above | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ10-32 | 32 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ10-48 | 48 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ10-56 | 56 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ10-72 | 72 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-80 | 80 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-104 | 104 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ10-120 | 10 | 120 | 2850 | 60 | 50 | 125above | 7.5 | 380 | 19.0 | 76.0 | 0.79 | 118 | ||||||||||

| 125QJ10-136 | 136 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ15-36 | 15 | 36 | 2850 | 63 | 50 | 125above | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ15-39 | 39 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ15-46 | 46 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-52 | 52 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-59 | 59 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-65 | 65 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-78 | 78 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-91 | 91 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-104 | 104 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ20-16 | 20 | 16 | 2850 | 64 | 50 | 125above | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ20-24 | 24 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ20-32 | 32 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-40 | 40 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-48 | 48 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-56 | 56 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-64 | 64 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-72 | 72 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-80 | 80 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ25-12 | 25 | 12 | 2850 | 64 | 65 | 125above | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ25-18 | 18 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ25-24 | 24 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-30 | 30 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-36 | 36 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ25-48 | 48 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ25-60 | 60 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ32-24 | 32 | 24 | 2850 | 64 | 80 | 125above | 4 | 380 | 10.53 | 74.0 | 0.78 | 118 | ||||||||||

| 125QJ32-30 | 30 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ32-42 | 42 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ32-54 | 54 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ5-240 | 5 | 240 | 2850 | 40 | 125above | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ5-280 | 280 | 13 | 30.87 | |||||||||||||||||||

| 125QJ5-320 | 320 | 15 | 35.62 | |||||||||||||||||||

| 125QJ10-180 | 10 | 180 | 2850 | 50 | 125above | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ10-210 | 210 | 13 | 30.87 | |||||||||||||||||||

| 125QJ10-240 | 240 | 15 | 35.62 | |||||||||||||||||||

| 125QJ15-120 | 15 | 120 | 2850 | 50 | 125above | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ15-142 | 142 | 13 | 30.87 | |||||||||||||||||||

| 125QJ15-162 | 162 | 15 | 35.62 | |||||||||||||||||||

| 125QJ20-100 | 20 | 100 | 2850 | 50 | 125above | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ20-120 | 120 | 13 | 30.87 | |||||||||||||||||||

| 125QJ20-136 | 136 | 15 | 35.62 | |||||||||||||||||||

| 125QJ25-82 | 25 | 82 | 2850 | 65 | 125above | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ25-97 | 97 | 13 | 30.87 | |||||||||||||||||||

| 125QJ25-110 | 110 | 15 | 35.62 | |||||||||||||||||||

| 125QJ32-68 | 32 | 68 | 2850 | 80 | 125above | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ32-80 | 80 | 13 | 30.87 | |||||||||||||||||||

| 125QJ32-92 | 92 | 15 | 35.62 | |||||||||||||||||||

| 125QJ40-46 | 40 | 46 | 2850 | 80 | 125above | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ40-54 | 54 | 13 | 30.87 | |||||||||||||||||||

| 125QJ40-62 | 62 | 15 | 35.62 | |||||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, strictly according to the provisions of the pump lift, flow range of use, to prevent low flow or high lift pumping force, the thrust bearing and other parts of the wear, the motor overload burned 6, after the pump down the well, the measurement of the motor to the ground insulation resistance should not be less than 100M, after the start to observe the voltage and current, check the motor winding insulation, whether in line with the requirements; pump storage location temperature if less than freezing point, should be dry the water in the motor cavity, prevent the motor cavity water ice damage caused by low temperature.

The pump parts are mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor part is mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand discharging ring, water inlet section, lead cable and other components. The motor is a water-filled submersible three-phase asynchronous motor, which is filled with water to cool the motor and lubricate the bearing. The pressure regulating diaphragm at the bottom is used to adjust the difference in internal water expansion and contraction pressure caused by the temperature rise of the motor. In order to prevent the sand in the well water from entering the motor, two oil seals are installed at the upper end of the motor shaft extension, and a sand discharging ring is installed to form a sand discharging structure. In order to prevent the pump shaft from jumping when starting, the pump shaft is connected with the motor shaft through a coupling, and a thrust bearing is installed at the lower part of the motor. The lubrication of the motor and the pump bearing is water lubrication. The stator winding of the motor adopts high quality submersible motor winding wire, with high insulation performance. The pump adopts computer CAD design, with simple structure and excellent technical performance.

(1)Preparation before installation:

1. Check whether the submersible pump meets the usage conditions and scope specifed in the manual.

2. Using a heavy obiect with a diameter equal to the maximum outer diameter of the submersible pump, measure whether the inneldiameter of the wellbore can fit the submersible pump, and measure whether the well depth meets the installation requirements.

3. Check whether the wellbore is clean and whether the well water is turbid. Never use a submersible electric pump to wash the welor pump mud and sand water to avoid premature damage to the submersible electric pump.

4. Check whether the position of the welhead installation clamp is suitable and whether it can withstand the qualty of the entire unit

5. Check if the submersible pump components are complete and installed properly according to the assembly diagram in the manualRemove the filter screen and rotate the coupling to see if it rotates flexibly

6. Unscrew the water screw and fillthe motor cavity with clean, non corrosive water (note. be sure to fil it up), then tighten the waterscrew. After 12 hours of water injection, the insulation resistance of the motor should not be less than 150M Q when measured witha 500V shaking table.

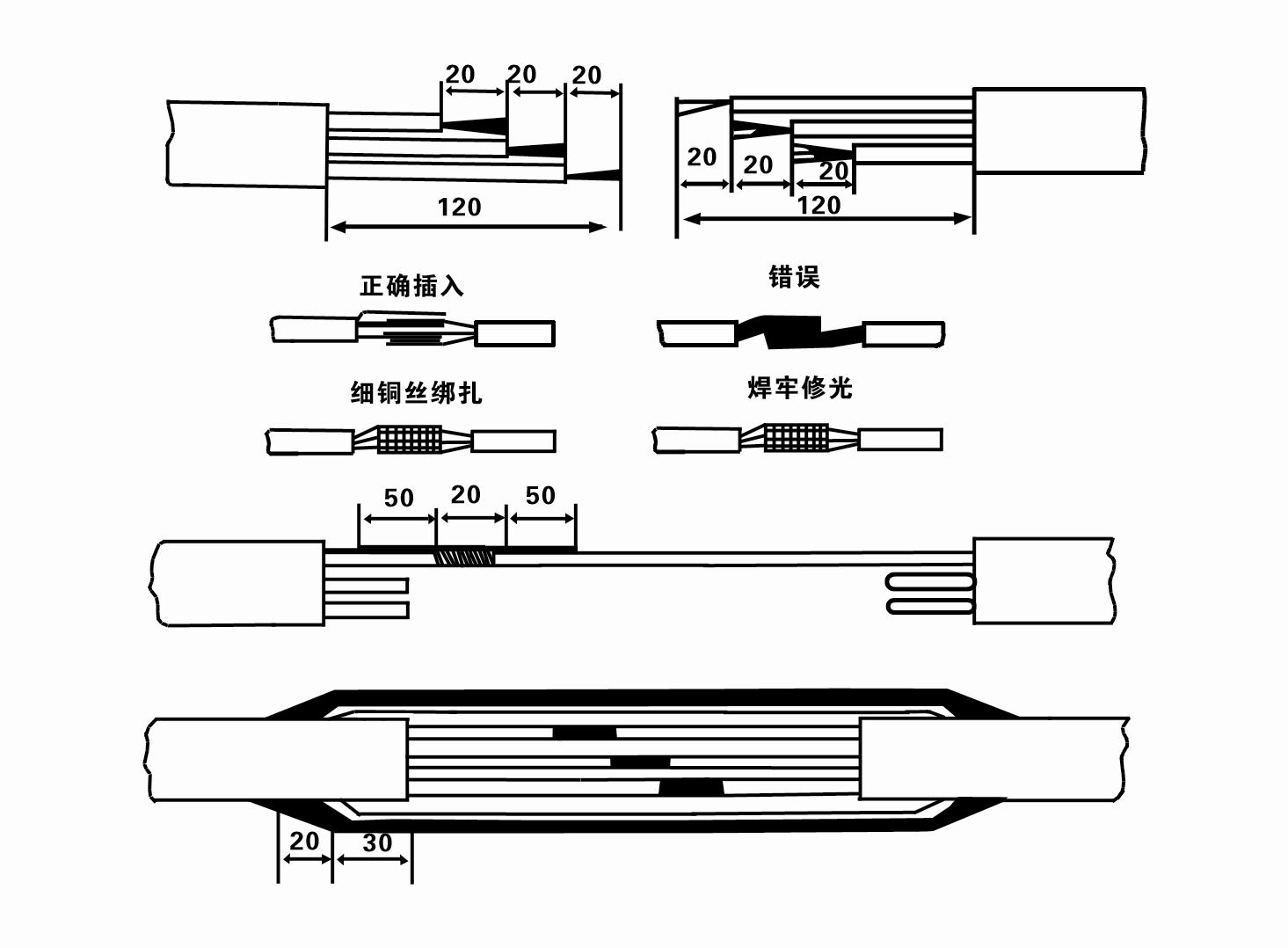

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

The attached cable wiring process diagram is as follows:

8. Use a multimeter to check whether the three-phase wires are connected and whether the DC resistance is approximately balanced.

9. Check whether the circuit and transformer capacity are overloaded, and then connect the overload protection switch or starting equipment. See Table 2 for specific models, and thenPour a bucket of water into the water pump from the water pump outlet to lubricate the rubber bearings in the pump, and then place the submersible electric pump upright and steady.Start (no more than one second) and check whether the steering direction is consistent with the steering sign. If not, swap any two connectors of the three-phase cable.Then install the filter and prepare to go down the well. If used in special occasions (such as ditches, ditches, rivers, ponds, ponds, etc.), the electric pump must be reliably grounded.

(2)Installation equipment and tools:

1. One pair of lifting chains for more than two tons.

2. A tripod with a vertical height of no less than four meters.

3. Two hanging ropes (wire ropes) that can bear a weight of more than one ton (can bear the weight of a complete set of water pumps).

4. Install two pairs of clamps (splints).

5. Wrenches, hammers, screwdrivers, electrical tools and instruments, etc.

(3)Electric pump installation:

1. The installation diagram of the submersible electric pump is shown in Figure 2. The specific installation dimensions are shown in Table 3 "List of Installation Dimensions of the Submersible Electric Pump".

2. Submersible electric pumps with a head less than 30 meters can be hoisted directly into the well using hoses and wire ropes or other hemp ropes that can bear the full weight of the entire machine, water pipes, and water in the pipes.

3. Pumps with a head of more than 30 meters use steel pipes, and the installation sequence is as follows:

①Use a clamp to clamp the upper end of the water pump part (the motor and water pump have been connected at this time), lift it with a hanging chain, and slowly tie it into the well untilPut the clamp on the wellhead and remove the hanging chain.

② Use another pair of clamps to clamp a pipe, lift it with a hanging chain 15 cm away from the flange, and lower it slowly. Between pipe flange and pump flangePut the rubber pad in place and tighten the pipe and pump evenly with bolts, nuts and spring washers.

③ Lift the submersible pump slightly, remove the clamp on the upper end of the water pump, tie the cable firmly to the water pipe with a plastic tape, and slowly tie it down until The clamp is placed at the wellhead.

④Use the same method to tie all water pipes into the well.

⑤After the lead-out cable is connected to the control switch, it is connected to the three-phase power supply.

(4)Things to note during installation:

1. If a jamming phenomenon is found during the pumping process, turn or pull the water pipe to overcome the jamming point. If various measures still do not work, pleaseDo not force the pump down to avoid damage to the submersible electric pump and the well.

2. During installation, a rubber pad should be placed at the flange of each pipe and tightened evenly.

3. When the water pump is lowered into the well, it should be placed in the middle of the well pipe to prevent the pump from running against the well wall for a long time, causing the pump to vibrate and the motor to sweep and burn.

4. Determine the depth of the water pump to the bottom of the well according to the flowing sand and silt conditions of the well. Do not bury the pump in the mud. The distance from the water pump to the bottom of the well is generally not less than 3 meters (see Figure 2).

5. The water entry depth of the water pump should be no less than 1-1.5 meters from the dynamic water level to the water inlet node (see Figure 2). Otherwise, the water pump bearings may be easily damaged.

6. The lift of the water pump cannot be too low. Otherwise, a gate valve needs to be installed on the wellhead water pipeline to control the pump flow at the rated flow point to prevent the motor from being overloaded and burned out due to large flow rates.

7. When the water pump is running, the water output should be continuous and even, the current should be stable (under rated working conditions, generally no more than 10% of the rated current), and there should be no vibration or noise. If there is any abnormality, the machine should be stopped to find out the cause and eliminate it.

8. When installing, pay attention to the setting of the motor grounding wire (see Figure 2). When the water pipe is a steel pipe, lead it from the wellhead clamp; when the water pipe is a plastic pipe, lead it from the grounding mark of the electric pump.

- (1)With the continuous development of modern technology, submersible pumps play a crucial role in the field of pumps. After installing the submersible pump, check the insulation resistance and three-phase continuity repeatedly to ensure that there are no errors in the connection between the instrument and the starting equipment. If everything is normal, the test equipment can be started. After starting, observe whether the indication readings of each instrument are correct. If the rated voltage and current specified on the nameplate are exceeded, pay attention to observe whether the pump has any noise or vibration. If everything is normal, it can be put into operation. After the pump runs for four hours for the first time, it should be closed and the thermal insulation resistance of the motor should be tested quickly, and its value should not be less than 0.5 megaohms. After stopping the pump, restart it after five minutes to prevent the water column in the pipeline from completely reversing, resulting in the motor burning due to overcurrent. After the pump is running normally, in order to prolong its service life, it is necessary to check regularly whether the supply voltage, working current and insulation resistance are normal. If the following conditions are found, the equipment should be shut down immediately to troubleshoot. The current exceeds 20% under the rated working conditions; the dynamic water level drops to the inlet section, resulting in intermittent drainage; the submersible pump vibrates violently or makes noisy sounds; the supply voltage is lower than 340 volts; any fuse is broken; the water pipe is damaged; The thermal insulation resistance between the motor and the ground is less than 0.5 megaohm.These recommended operating procedures and safety measures ensure the safe operation of the submersible pump, prolong the service life of the equipment, and provide users with a reliable pump choice.

- (2)Unit disassembly:

- 1 untie the cable tie, remove the pipeline part, remove the wire plate.

- 2 unscrew the water release bolt, put the water in the motor chamber.

- 3 remove the filter, loose the fixing screw of the motor shaft on the coupling.

- 4 unscrew the bolt connecting the water inlet section with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5 the disassembly sequence of the pump is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending the pump shaft and various bumps in the disassembly process.

- 6 the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nut, base, shaft head lock nut, thrust plate, key, lower guide bearing seat, double head bolt from the bottom of the motor in turn. Then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7 unit assembly: Before assembly, the rust and dirt of the parts should be cleaned, and the mating surfaces and fasteners should be coated with sealant. Then they should be assembled in the reverse order of disassembly (the up and down momentum of the motor shaft is about 1 mm after assembly). After assembly, the coupling should be flexible, and then the filter screen test machine.

- (3)The submersible pump should be dismantled and repaired according to Article 5 for each operation year, or less than one year, but the submersible time has reached two years, and the worn parts should be replaced.

1, put out the water in the motor cavity (especially in winter to prevent the motor from freezing), and tie the cable well.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, long-term use should pay attention to the rust prevention of submersible pumps.

- Impeller

- Shaft sleeve

- Rubber shaft sleeve

-

Sealing ring

01 Deep well water intake

02 High-rise water supply

03 mountain water supply

04 tower water

05 Agricultural irrigation

06 garden irrigation

07 river water intake

08 domestic water