Suitable for underground hot water mining with water temperature below 100°C, with heat resistance, corrosion resistance, aging resistance and other characteristics

This product is a powerful three-phase AC 380V (tolerance ± 5%), 50HZ (tolerance ± 1%) electric pump, suitable for all kinds of occasions need high-power pump. Its design considers a variety of water quality factors, including water temperature not higher than 20 °C, solid impurities content is not greater than 0.01%, PH value is 6.5-8.5, hydrogen sulfide content is not greater than 1.5mg/L, chloride ion content is not greater than 400mg/L, etc. The product adopts a closed or water immersion wet structure of the motor, before use in the submersible motor chamber filled with clean water to prevent empty fill. Requirements in strict accordance with the requirements of the matching cable and equipped with external overload protection device. To ensure stable operation, the submersible pump must be completely immersed in water operation, the insertion depth shall not exceed 70 meters, and the distance from the bottom of the well shall not be less than 3 meters. In addition, the pump shall not be a no-load test before start. In general, this product has the characteristics of high efficiency and stability, suitable for a variety of pump tasks in harsh environment.

| Qauv | Dej ntws (m 3 / h) | Lub taub hau (m) |

Rotatingspeed (hloov / point) |

Lub tshuab nqus dej (%) | Qhov hluav taws xob txoj kab uas hla (mm) |

Siv tau zoo txoj kab uas hla (mm) |

Rated Lub zog (KW) |

Rated voltage (V) |

Rated tam sim no (A) |

Motorefficiency (%) | power factorcosφ | Chav tsev Radial Maximu loj (mm) |

Lus ceeb toom | |||||||||

| 125QJ5-34 | 5 | 34 | 2850 | 53 | 40 | 125saum toj no | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ5-51 | 51 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ5-68 | 68 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ5-85 | 85 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ5-102 | 102 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ5-119 | 119 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-24 | 10 | 24 | 2850 | 60 | 50 | 125saum toj no | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ10-32 | 32 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ10-48 | 48 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ10-56 | 56 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ10-72 | 72 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-80 | 80 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-104 | 104 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ10-120 | 10 | 120 | 2850 | 60 | 50 | 125saum toj no | 7.5 | 380 | 19.0 | 76.0 | 0.79 | 118 | ||||||||||

| 125QJ10-136 | 136 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ15-36 | 15 | 36 | 2850 | 63 | 50 | 125saum toj no | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ15-39 | 39 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ15-46 | 46 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-52 | 52 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-59 | 59 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-65 | 65 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-78 | 78 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-91 | 91 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-104 | 104 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ20-16 | 20 | 16 | 2850 | 64 | 50 | 125saum toj no | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ20-24 | 24 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ20-32 | 32 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-40 | 40 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-48 | 48 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-56 | 56 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-64 | 64 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-72 | 72 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-80 | 80 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ25-12 | 25 | 12 | 2850 | 64 | 65 | 125saum toj no | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ25-18 | 18 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ25-24 | 24 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-30 | 30 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-36 | 36 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ25-48 | 48 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ25-60 | 60 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ32-24 | 32 | 24 | 2850 | 64 | 80 | 125saum toj no | 4 | 380 | 10.53 | 74.0 | 0.78 | 118 | ||||||||||

| 125QJ32-30 | 30 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ32-42 | 42 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ32-54 | 54 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ5-240 | 5 | 240 | 2850 | 40 | 125saum toj no | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ5-280 | 280 | 13 | 30.87 | |||||||||||||||||||

| 125QJ5-320 | 320 | 15 | 35.62 | |||||||||||||||||||

| 125QJ10-180 | 10 | 180 | 2850 | 50 | 125saum toj no | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ10-210 | 210 | 13 | 30.87 | |||||||||||||||||||

| 125QJ10-240 | 240 | 15 | 35.62 | |||||||||||||||||||

| 125QJ15-120 | 15 | 120 | 2850 | 50 | 125saum toj no | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ15-142 | 142 | 13 | 30.87 | |||||||||||||||||||

| 125QJ15-162 | 162 | 15 | 35.62 | |||||||||||||||||||

| 125QJ20-100 | 20 | 100 | 2850 | 50 | 125saum toj no | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ20-120 | 120 | 13 | 30.87 | |||||||||||||||||||

| 125QJ20-136 | 136 | 15 | 35.62 | |||||||||||||||||||

| 125QJ25-82 | 25 | 82 | 2850 | 65 | 125saum toj no | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ25-97 | 97 | 13 | 30.87 | |||||||||||||||||||

| 125QJ25-110 | 110 | 15 | 35.62 | |||||||||||||||||||

| 125QJ32-68 | 32 | 68 | 2850 | 80 | 125saum toj no | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ32-80 | 80 | 13 | 30.87 | |||||||||||||||||||

| 125QJ32-92 | 92 | 15 | 35.62 | |||||||||||||||||||

| 125QJ40-46 | 40 | 46 | 2850 | 80 | 125saum toj no | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ40-54 | 54 | 13 | 30.87 | |||||||||||||||||||

| 125QJ40-62 | 62 | 15 | 35.62 | |||||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, strictly according to the provisions of the pump lift, flow range of use, to prevent low flow or high lift pumping force, the thrust bearing and other parts of the wear, the motor overload burned 6, after the pump down the well, the measurement of the motor to the ground insulation resistance should not be less than 100M, after the start to observe the voltage and current, check the motor winding insulation, whether in line with the requirements; pump storage location temperature if less than freezing point, should be dry the water in the motor cavity, prevent the motor cavity water ice damage caused by low temperature.

The pump parts are mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor part is mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand discharging ring, water inlet section, lead cable and other components. The motor is a water-filled submersible three-phase asynchronous motor, which is filled with water to cool the motor and lubricate the bearing. The pressure regulating diaphragm at the bottom is used to adjust the difference in internal water expansion and contraction pressure caused by the temperature rise of the motor. In order to prevent the sand in the well water from entering the motor, two oil seals are installed at the upper end of the motor shaft extension, and a sand discharging ring is installed to form a sand discharging structure. In order to prevent the pump shaft from jumping when starting, the pump shaft is connected with the motor shaft through a coupling, and a thrust bearing is installed at the lower part of the motor. The lubrication of the motor and the pump bearing is water lubrication. The stator winding of the motor adopts high quality submersible motor winding wire, with high insulation performance. The pump adopts computer CAD design, with simple structure and excellent technical performance.

(1) Kev npaj ua ntej installation:

1. Xyuas seb lub twj tso kua mis submersible puas ua tau raws li qhov kev siv thiab qhov tshwj xeeb hauv phau ntawv qhia.

2. Siv lub qhov hnyav obiect nrog txoj kab uas hla sib npaug rau qhov siab tshaj plaws sab nraud ntawm lub twj tso kua mis submersible, ntsuas seb qhov inneldiameter ntawm lub qhov dej puas tuaj yeem haum rau lub twj tso kua mis submersible, thiab ntsuas seb qhov dej tob puas ua tau raws li qhov yuav tsum tau ua.

3. Xyuas seb lub qhov dej puas huv si thiab seb cov dej hauv qhov dej puas yog turbid. Tsis txhob siv lub tshuab hluav taws xob submersible los ntxuav lub welor twj av nkos thiab dej xuab zeb kom tsis txhob muaj kev puas tsuaj ntxov rau lub tshuab hluav taws xob submersible.

4. Tshawb xyuas seb txoj haujlwm ntawm lub welhead installation clamp puas haum thiab seb nws puas tuaj yeem tiv taus qhov zoo ntawm tag nrho chav tsev.

5. Tshawb xyuas seb cov twj tso kua dej submersible puas ua tiav thiab teeb tsa kom raug raws li daim duab sib dhos hauv phau ntawv tshem tawm cov ntxaij lim dej thiab tig lub coupling kom pom tias nws tig tau yooj yim.

6. Unscrew cov dej ntsia hlau thiab sau cov kab noj hniav nrog cov dej huv, tsis muaj corrosive (ceeb toom. Nco ntsoov sau nws), tom qab ntawd ceev cov dej screws. Tom qab 12 teev ntawm kev txhaj tshuaj dej, qhov rwb thaiv tsev ntawm lub cev muaj zog yuav tsum tsis txhob tsawg dua 150M Q thaum ntsuas nrog 500V co lub rooj.

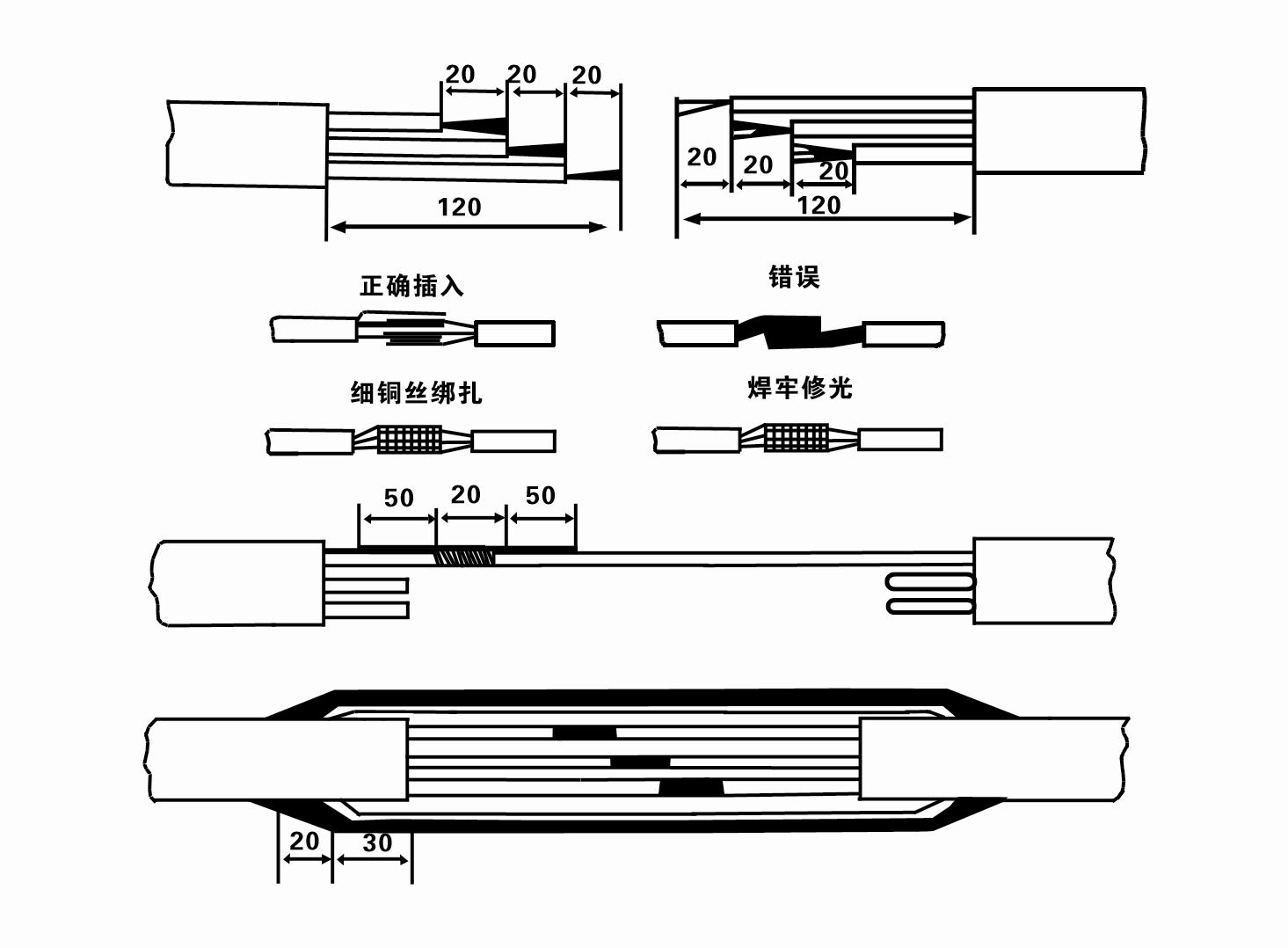

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Daim duab txuas cable thaiv txheej txheem yog raws li hauv qab no:

8. Siv multimeter los xyuas seb cov xov hlau peb-theem puas txuas thiab seb qhov DC tsis kam yog kwv yees li qhov sib npaug.

9. Xyuas seb puas muaj peev xwm ntawm lub Circuit Court thiab transformer yog overloaded, thiab ces txuas lub overload tiv thaiv hloov los yog pib cov khoom. Saib Table 2 rau cov qauv tshwj xeeb, thiab tom qab ntawd hliv ib lub thoob dej rau hauv lub twj tso kua mis los ntawm lub qhov dej twj tso kua mis kom lubricate cov roj hmab bearings hauv lub twj tso kua mis, thiab tom qab ntawd muab lub twj tso kua mis submersible fais fab tso ncaj thiab khov kho.Start (tsis pub ntau tshaj ib ob) thiab xyuas seb qhov kev taw qhia lub kauj tsheb puas zoo ib yam nrog lub kauj tsheb. Yog tias tsis yog, sib pauv ob qhov txuas ntawm peb-theem cable.Tom qab ntawd nruab lub lim thiab npaj mus rau hauv qhov dej. Yog tias siv rau lub sijhawm tshwj xeeb (xws li kwj dej, kwj dej, dej ntws, pas dej, pas dej, thiab lwm yam), lub twj tso kua mis hluav taws xob yuav tsum muaj kev ntseeg siab.

(2) Kev teeb tsa thiab cov cuab yeej siv:

1. Ib khub nqa cov hlua rau ntau tshaj ob tons.

2. Lub tripod nrog ib txoj kab ntsug qhov siab tsis pub tsawg tshaj plaub meters.

3. Ob txoj hlua dai (xov hlau hlua) uas tuaj yeem nqa tau qhov hnyav ntawm ntau tshaj ib tuj (tuaj yeem lav qhov hnyav ntawm cov twj tso kua dej tiav).

4. Nruab ob khub ntawm clamps (splnts).

5. Wrenches, hammers, ntswj ntsia hlau, cov cuab yeej hluav taws xob thiab cov twj paj nruag, thiab lwm yam.

(3) Hluav taws xob twj tso kua mis installation:

1. Daim duab qhia kev teeb tsa ntawm lub tshuab hluav taws xob submersible yog pom nyob rau hauv daim duab 2. Qhov tshwj xeeb installation qhov ntev yog qhia nyob rau hauv Table 3 "Daim Ntawv Teev Tseg Qhov Loj ntawm Submersible Electric Pump".

2. Cov twj siv hluav taws xob submersible nrog lub taub hau tsawg dua 30 meters tuaj yeem nqa ncaj qha mus rau hauv lub qhov dej siv cov hoses thiab cov hlua hlau lossis lwm cov hlua hemp uas tuaj yeem nqa tau qhov hnyav tag nrho ntawm lub tshuab, cov kav dej, thiab dej hauv cov kav dej.

3. Cov twj tso kua mis nrog lub taub hau ntau dua 30 meters siv cov kav dej steel, thiab cov txheej txheem kev teeb tsa yog raws li hauv qab no:

①Siv lub clamp los tuav lub siab kawg ntawm lub twj tso kua mis (lub cev muaj zog thiab lub twj tso kua dej tau txuas rau lub sijhawm no), nqa nws nrog cov hlua khi, thiab maj mam khi nws mus rau hauv lub qhov dej kom txog thaum muab lub clamp rau ntawm lub qhov dej thiab tshem tawm qhov saw caj dab.

② Siv lwm ob lub clamps los tuav cov yeeb nkab, nqa nrog ib txoj hlua dai 15 cm deb ntawm lub flange, thiab maj mam txo qis. Nruab nrab ntawm cov yeeb nkab flange thiab lub twj tso kua mis flange Muab cov roj hmab tso rau hauv qhov chaw thiab nruj cov yeeb nkab thiab twj tso kua mis sib npaug nrog bolts, ceev thiab lub caij nplooj ntoos hlav ntxhua.

③ Nqa lub twj tso kua mis submersible me ntsis, tshem lub clamp ntawm lub taub dej kawg ntawm lub twj tso kua mis, khi lub cable kom ruaj khov rau hauv cov kav dej nrog ib daim kab xev yas, thiab maj mam khi nws kom txog thaum lub clamp muab tso rau ntawm lub qhov dej.

④ Siv tib txoj kev los khi tag nrho cov kav dej rau hauv qhov dej.

⑤ Tom qab cov hlau lead-tawm txuas nrog rau kev tswj kev hloov, nws txuas nrog peb-theem fais fab mov.

(4) Tej yam yuav tsum nco ntsoov thaum lub installation:

1. Yog tias pom muaj qhov tshwm sim jamming thaum lub sij hawm siv cov txheej txheem, tig los yog rub cov yeeb nkab dej kom kov yeej qhov jamming point. Yog tias ntau yam kev ntsuas tseem tsis ua haujlwm, thov tsis txhob yuam lub twj tso kua mis kom tsis txhob muaj kev puas tsuaj rau lub tshuab hluav taws xob submersible thiab lub qhov dej.

2. Thaum lub sij hawm installation, yuav tsum tau muab tso rau ntawm ib tug roj hmab ncoo nyob rau hauv lub flange ntawm txhua lub yeeb nkab thiab nruj nreem sib npaug zos rau.

3. Thaum lub twj tso kua dej qis rau hauv lub qhov dej, nws yuav tsum tau muab tso rau hauv nruab nrab ntawm lub qhov dej kom tsis txhob lub twj tso kua mis khiav tawm ntawm lub qhov dej mus ntev, ua rau lub twj tso kua mis vibrate thiab lub cev muaj zog cheb thiab hlawv. .

4. Txiav txim siab qhov tob ntawm lub twj tso kua mis dej mus rau hauv qab ntawm lub qhov dej raws li cov xuab zeb ntws thiab cov av ntawm lub qhov dej. Tsis txhob faus lub twj tso kua mis hauv av nkos. Qhov kev ncua deb ntawm lub twj tso kua dej mus rau hauv qab ntawm lub qhov dej yog feem ntau tsis pub tsawg tshaj 3 meters (saib daim duab 2).

5. Qhov dej nkag qhov tob ntawm lub twj tso kua mis dej yuav tsum tsis pub tsawg tshaj 1-1.5 meters los ntawm cov dej dynamic mus rau qhov dej nkag ntawm qhov dej (saib daim duab 2). Txwv tsis pub, cov dej twj tso kua mis bearings yuav yooj yim puas.

6. Lub nqa ntawm lub twj tso kua dej tsis tuaj yeem qis dhau. Txwv tsis pub, lub rooj vag valve yuav tsum tau muab tso rau ntawm lub qhov dej hauv qhov dej los tswj lub twj tso kua mis ntawm qhov ntsuas qhov taw tes kom tsis txhob muaj lub cev muaj zog los ntawm overloaded thiab hlawv tawm vim qhov txaus txaus.

7. Thaum lub twj tso kua dej ua haujlwm, cov dej tso tawm yuav tsum tsis tu ncua thiab txawm tias, qhov tam sim no yuav tsum ruaj khov (raws li kev ntsuas kev ua haujlwm, feem ntau tsis pub tshaj 10% ntawm cov ntsuas tam sim no), thiab yuav tsum tsis muaj kev vibration lossis suab nrov. Yog tias muaj qhov txawv txav, lub tshuab yuav tsum tau nres kom paub qhov ua rau thiab tshem tawm nws.

8. Thaum txhim kho, xyuam xim rau qhov chaw ntawm lub cev muaj zog grounding hlau (saib daim duab 2). Thaum cov yeeb nkab dej yog cov yeeb nkab steel, coj nws los ntawm lub qhov dej zoo clamp; thaum cov yeeb nkab dej yog cov yeeb nkab yas, coj nws los ntawm cov cim hauv av ntawm lub tshuab hluav taws xob.

- (1)With the continuous development of modern technology, submersible pumps play a crucial role in the field of pumps. After installing the submersible pump, check the insulation resistance and three-phase continuity repeatedly to ensure that there are no errors in the connection between the instrument and the starting equipment. If everything is normal, the test equipment can be started. After starting, observe whether the indication readings of each instrument are correct. If the rated voltage and current specified on the nameplate are exceeded, pay attention to observe whether the pump has any noise or vibration. If everything is normal, it can be put into operation. After the pump runs for four hours for the first time, it should be closed and the thermal insulation resistance of the motor should be tested quickly, and its value should not be less than 0.5 megaohms. After stopping the pump, restart it after five minutes to prevent the water column in the pipeline from completely reversing, resulting in the motor burning due to overcurrent. After the pump is running normally, in order to prolong its service life, it is necessary to check regularly whether the supply voltage, working current and insulation resistance are normal. If the following conditions are found, the equipment should be shut down immediately to troubleshoot. The current exceeds 20% under the rated working conditions; the dynamic water level drops to the inlet section, resulting in intermittent drainage; the submersible pump vibrates violently or makes noisy sounds; the supply voltage is lower than 340 volts; any fuse is broken; the water pipe is damaged; The thermal insulation resistance between the motor and the ground is less than 0.5 megaohm.These recommended operating procedures and safety measures ensure the safe operation of the submersible pump, prolong the service life of the equipment, and provide users with a reliable pump choice.

- (2)Unit disassembly:

- 1 untie the cable tie, remove the pipeline part, remove the wire plate.

- 2 unscrew the water release bolt, put the water in the motor chamber.

- 3 remove the filter, loose the fixing screw of the motor shaft on the coupling.

- 4 unscrew the bolt connecting the water inlet section with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5 the disassembly sequence of the pump is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending the pump shaft and various bumps in the disassembly process.

- 6 the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nut, base, shaft head lock nut, thrust plate, key, lower guide bearing seat, double head bolt from the bottom of the motor in turn. Then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7 unit assembly: Before assembly, the rust and dirt of the parts should be cleaned, and the mating surfaces and fasteners should be coated with sealant. Then they should be assembled in the reverse order of disassembly (the up and down momentum of the motor shaft is about 1 mm after assembly). After assembly, the coupling should be flexible, and then the filter screen test machine.

- (3)The submersible pump should be dismantled and repaired according to Article 5 for each operation year, or less than one year, but the submersible time has reached two years, and the worn parts should be replaced.

1, muab cov dej tso rau hauv lub cav cav (tshwj xeeb tshaj yog nyob rau lub caij ntuj no los tiv thaiv lub cev tsis muaj zog), thiab khi lub cable zoo.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, kev siv mus sij hawm ntev yuav tsum tau them sai sai rau kev tiv thaiv xeb ntawm cov twj submersible.

- Impeller

- Ncej tes tsho

- Rubber ncej tes tsho

-

Lub nplhaib sealing

01 Lub qhov dej tob tob

02 High-rise water supply

03 roob dej

04 dej

05 Agricultural irrigation

06 vaj irrigation

07 dej haus

08 dej hauv tsev