This product is designed for underground hot water mining and is suitable for water temperatures below 100°C. It has high temperature resistance, corrosion resistance and aging resistance. This product is very suitable for use in underground hot water mining environments, which can effectively deal with high temperatures and corrosion of various chemical substances, while having good aging resistance, ensuring stable operation of equipment for a long time. Whether it is needed to be used in harsh mining environments or in the face of high water temperatures, this product can provide reliable protection, ensuring continuous operation and efficient work of equipment.

Product introduction: we recommend this product is equipped with three-phase AC 380V (tolerance + / - 1%), 50HZ (tolerance + / - 1%) power supply. Water quality requirements are strict, the water temperature shall not be higher than 20 °C, the content of solid impurities (mass ratio) shall not be greater than 0.01%; PH value (pH) between 6.5-8.5; hydrogen sulfide content shall not be greater than 1.5mg/L; chloride ion content shall not exceed 400mg/L. The product is equipped with a closed or water-cooled wet structure motor. Before use, the inner cavity of the submersible motor shall be filled with clean water to prevent empty. Then tighten the water injection and air exhaust screws, otherwise it is prohibited to use. The submersible pump must be completely immersed in water to operate, the penetration depth shall not exceed 70 meters, and the distance between the bottom of the submersible pump and the bottom of the well shall not be less than 3 meters. The inflow of well water shall meet the water output and continuous operation requirements of the submersible pump, and the water output of the pump shall be controlled between 0.7 and 1.2 times the rated flow. The well must be vertical, and the submersible pump can not be used horizontally or dumped, but only vertically. The submersible pump must be equipped with cables as required, and is equipped with external overload protection device. It is prohibited to test the pump without water and no load.

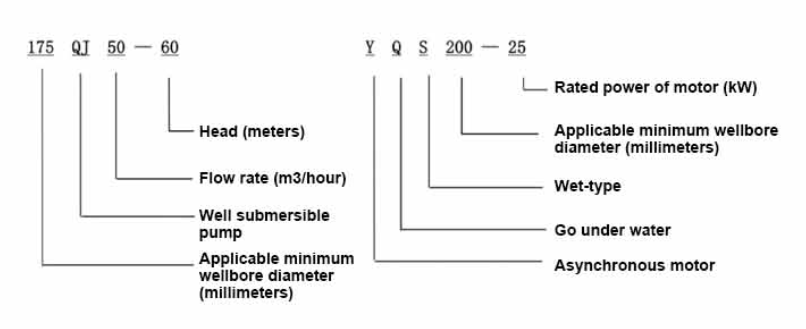

| Model | Vloei (m3/h) | Kop (m) |

Roterende spoed (verander/punt) |

Water pomp(%) | Uitlaat deursnee (mm) |

Goed toepaslik deursnee (mm) |

Gegradeer power(KW) |

Gegradeer spanning (V) |

Gegradeer stroom (A) |

Motordoeltreffendheid (%) | power factorcosφ | Eenheid Radiale maksimum grootte (mm) |

|||||||||

| 175QJ10-42 | 10 | 42 | 2850 | 53 | 50 | 175hierbo | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ10-56 | 56 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-70 | 70 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-84 | 84 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ10-112 | 112 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-126 | 126 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-140 | 140 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ15-42 | 15 | 42 | 2850 | 58 | 50 | 175hierbo | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ15-55 | 55 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-65 | 65 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-85 | 85 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ15-112 | 112 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 175hierbo | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ20-39 | 39 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ20-52 | 52 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ20-78 | 78 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ20-91 | 91 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-104 | 104 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ20-130 | 130 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-156 | 156 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-182 | 187 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ20-208 | 208 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-247 | 247 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-273 | 273 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-299 | 299 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-325 | 325 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-364 | 364 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-26 | 25 | 26 | 2850 | 66 | 65 | 175hierbo | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ25-39 | 39 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ25-65 | 25 | 65 | 2850 | 66 | 65 | 175hierbo | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ25-78 | 78 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ25-91 | 91 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ25-104 | 104 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-130 | 130 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-156 | 156 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ25-182 | 182 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-208 | 208 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-221 | 221 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-247 | 247 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-260 | 260 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-299 | 299 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ30-30 | 30 | 30 | 2850 | 67 | 80 | 175hierbo | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ30-40 | 40 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-24 | 32 | 24 | 2850 | 67 | 80 | 175hierbo | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ32-36 | 36 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-48 | 48 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ32-60 | 60 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ32-72 | 72 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ32-84 | 84 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-96 | 96 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-120 | 120 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ32-144 | 144 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-168 | 168 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-180 | 180 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-192 | 192 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-204 | 204 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-240 | 240 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ35-60 | 35 | 60 | 2850 | 67 | 80 | 175hierbo | 10 | 380 | 25.0 | 78.0 | 0.78 | 168 | |||||||||

| 175QJ35-75 | 75 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ35-100 | 100 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ40-24 | 40 | 24 | 2850 | 70 | 80 | 175hierbo | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ40-30 | 30 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ40-36 | 36 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ40-48 | 48 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ40-60 | 60 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ40-72 | 72 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-84 | 84 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-96 | 96 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ40-120 | 120 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-132 | 132 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-144 | 144 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-156 | 156 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-168 | 168 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-192 | 192 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-24 | 50 | 24 | 2850 | 72 | 80 | 175hierbo | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ50-36 | 36 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ50-48 | 48 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ50-70 | 70 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ50-84 | 84 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ50-96 | 96 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-108 | 108 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-120 | 120 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-132 | 132 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-144 | 144 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-156 | 156 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-22 | 63 | 22 | 2850 | 72 | 80 | 175hierbo | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ63-44 | 44 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-55 | 55 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-66 | 66 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ63-77 | 77 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-88 | 88 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-99 | 63 | 99 | 2850 | 72 | 80 | 175hierbo | 30 | 380 | 66.6 | 81.5 | 0.84 | 168 | |||||||||

| 175QJ63-110 | 110 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-132 | 132 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-9 | 80 | 9 | 2850 | 73 | 100 | 175hierbo | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ80-18 | 18 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ80-27 | 27 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ80-36 | 36 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ80-45 | 45 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ80-54 | 54 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-63 | 63 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-72 | 72 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-81 | 81 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-90 | 90 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-98 | 98 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, streng volgens die bepalings van die pomp hysbak, vloei reeks van gebruik, lae vloei of 'n hoë hysbak pomp krag, die druk laer en ander dele van die slytasie te voorkom, die motor oorlading verbrand

6, after the pump down the well, the measurement of the motor to the ground insulation resistance should not be less than 100M, after the start to observe the voltage and current, check the motor winding insulation, whether in line with the requirements; pump storage location temperature if less than freezing point, should be dry the motor cavity water, prevent the motor cavity water ice damage caused by low temperature.

Kort inleiding van struktuur: pompdeel bestaan hoofsaaklik uit pompas, stuwer, omleidingdop, rubberlager, terugslagklepliggaam (opsionele onderdele) en ander komponente.Motoronderdeel bestaan hoofsaaklik uit basis, drukregulerende film, stootlaer, stootplaat , onderste gidslaersitplek, stator, rotor, boonste gidslaersitplek, sandring, waterinlaatgedeelte, kabel en ander komponente.

Die belangrikste kenmerke van die produk sluit in:

1, Die motor is 'n watergevulde nat dompelbare driefase asinchrone motor, die motorholte is vol skoon water, word gebruik om die motor af te koel en die laer te smeer, die drukregulerende film aan die onderkant van die motor word gebruik om aan te pas die uitsetting en sametrekking druk verskil van die water binne die liggaam wat veroorsaak word deur die verandering van die temperatuur styging van die motor.

2, Om te verhoed dat die sand in die putwater die motor binnedring, is die boonste punt van die motoras toegerus met twee olieseëls, en 'n sandring word geïnstalleer om 'n sandvoorkomingstruktuur te vorm.

3, Om te verhoed dat die pompas aanloop wanneer dit begin word, word die pompas en die motoras deur 'n koppeling verbind, en 'n boonste stootlaer word aan die onderste deel van die motor geïnstalleer.

4, Die smering van die motor en die pomplager is watersmeer.

5, Die motorstatorwikkeling is gemaak van hoë kwaliteit dompelmotorwikkeldraad, met hoë isolasieprestasie.

6, Die pomp is ontwerp deur rekenaar CAD, met 'n eenvoudige struktuur en goeie tegniese werkverrigting.

(1) Voorbereiding voor installasie:

1. Kontroleer of die dompelpomp voldoen aan die gebruiksvoorwaardes en omvang gespesifiseer in die handleiding.

2. Gebruik 'n swaar voorwerp met 'n deursnee gelyk aan die maksimum buitenste deursnee van die dompelpomp, meet of die binnedeursnee van die boorput by die dompelpomp kan pas, en meet of die putdiepte aan die installasievereistes voldoen.

3. Kontroleer of die boorput skoon is en of die putwater troebel is. Moet nooit 'n dompelpomp gebruik om die welor pomp modder en sand water te was om voortydige skade aan die dompel elektriese pomp te vermy.

4. Kontroleer of die posisie van die putkopinstallasieklem geskik is en of dit die kwaliteit van die hele eenheid kan weerstaan

5. Kontroleer of die dompelpompkomponente volledig en behoorlik geïnstalleer is volgens die samestellingsdiagram in die handleiding Verwyder die filterskerm en draai die koppeling om te sien of dit buigsaam draai

6. Skroef die waterskroef los en vul die motorholte met skoon, nie-korrosiewe water (let wel. maak seker dat jy dit vol maak), draai dan die waterskroef vas. Na 12 uur se waterinspuiting moet die isolasieweerstand van die motor nie minder as 150M Q wees as dit gemeet word met 'n 500V skudtafel nie.

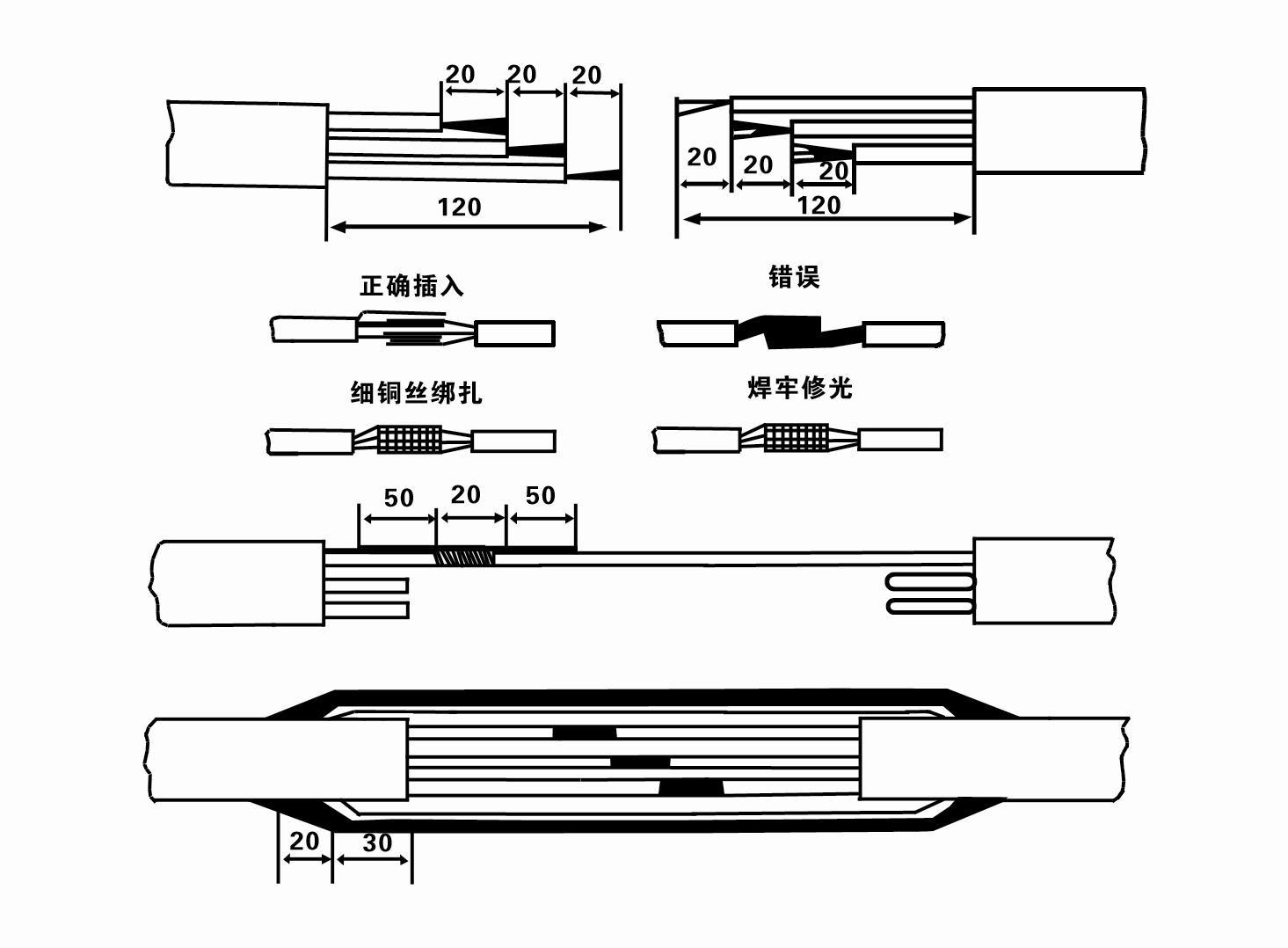

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Die aangehegte kabelbedradingsprosesdiagram is soos volg:

8. Gebruik 'n multimeter om te kyk of die driefase-drade verbind is en of die GS-weerstand ongeveer gebalanseerd is.

9. Kontroleer of die stroombaan en transformatorkapasiteit oorlaai is, en koppel dan die oorbelastingbeskermingskakelaar of aansittoerusting aan. Sien Tabel 2 vir spesifieke modelle, en Gooi dan 'n emmer water in die waterpomp vanaf die waterpompuitlaat om die rubberlaers in die pomp te smeer, en plaas dan die dompel elektriese pomp regop en bestendig.Begin (nie meer as een sekonde nie) en kyk of die stuurrigting ooreenstem met die stuurteken. Indien nie, ruil enige twee verbindings van die driefase-kabel om. Installeer dan die filter en maak gereed om in die put af te gaan. Indien dit in spesiale geleenthede gebruik word (soos slote, slote, riviere, damme, damme, ens.), moet die elektriese pomp betroubaar geaard wees.

(2) Installasie toerusting en gereedskap:

1. Een paar hyskettings vir meer as twee ton.

2. 'n Driepoot met 'n vertikale hoogte van nie minder nie as vier meter.

3. Twee hangtoue (draadtoue) wat 'n gewig van meer as een ton kan dra (kan die gewig van 'n volledige stel waterpompe dra).

4. Installeer twee pare klampe (spalke).

5. Sleutels, hamers, skroewedraaiers, elektriese gereedskap en instrumente, ens.

(3) Elektriese pompinstallasie:

1. Die installasiediagram van die dompel-elektriese pomp word in Figuur 2 getoon. Die spesifieke installasie-afmetings word in Tabel 3 "Lys van Installasie-afmetings van die dompel-elektriese pomp" getoon.

2. Dompelbare elektriese pompe met 'n hoogte van minder as 30 meter kan direk in die put gehys word deur gebruik te maak van slange en draadtoue of ander henneptoue wat die volle gewig van die hele masjien, waterpype en water in die pype kan dra.

3. Pompe met 'n hoogte van meer as 30 meter gebruik staalpype, en die installasievolgorde is soos volg:

①Gebruik 'n klem om die boonste punt van die waterpompdeel vas te klem (die motor en waterpomp is op hierdie tydstip gekoppel), lig dit met 'n hangketting en bind dit stadig in die put vas totdat Sit die klem op die putkop en verwyder die hang ketting.

② Gebruik nog 'n paar klampe om 'n pyp vas te klem, lig dit met 'n hangketting 15 cm weg van die flens af, en laat sak dit stadig. Tussen pypflens en pompflensSit die rubberkussing in plek en trek die pyp vas en pomp eweredig met boute, moere en veerringe.

③ Lig die dompelpomp effens op, verwyder die klem aan die boonste punt van die waterpomp, bind die kabel stewig aan die waterpyp vas met 'n plastiekband, en maak dit stadig vas totdat Die klem by die putkop geplaas is.

④Gebruik dieselfde metode om alle waterpype in die put vas te bind.

⑤ Nadat die uitloopkabel aan die beheerskakelaar gekoppel is, word dit aan die driefase-kragbron gekoppel.

(4) Dinge om op te let tydens installasie:

1. Indien 'n versteuringsverskynsel tydens die pompproses gevind word, draai of trek die waterpyp om die vassteekpunt te oorkom. As verskeie maatreëls steeds nie werk nie, moet asseblief nie die pomp af dwing om skade aan die dompelpomp en die put te voorkom nie.

2. Tydens installasie moet 'n rubberkussing by die flens van elke pyp geplaas word en eweredig vasgedraai word.

3. Wanneer die waterpomp in die put laat sak word, moet dit in die middel van die putpyp geplaas word om te verhoed dat die pomp vir 'n lang tyd teen die putwand loop, wat veroorsaak dat die pomp vibreer en die motor vee en brand .

4. Bepaal die diepte van die waterpomp tot by die bodem van die put volgens die vloeiende sand- en sliktoestande van die put. Moenie die pomp in die modder begrawe nie. Die afstand vanaf die waterpomp na die bodem van die put is oor die algemeen nie minder nie as 3 meter (sien Figuur 2).

5. Die watertoevoerdiepte van die waterpomp moet nie minder nie as 1-1,5 meter wees vanaf die dinamiese watervlak na die waterinlaatknooppunt (sien Figuur 2). Andersins kan die waterpomplaers maklik beskadig word.

6. Die hysbak van die waterpomp kan nie te laag wees nie. Andersins moet 'n hekklep op die putkopwaterpyplyn geïnstalleer word om die pompvloei by die aangewese vloeipunt te beheer om te verhoed dat die motor oorlaai en uitbrand as gevolg van groot vloeitempo's.

7. Wanneer die waterpomp aan die gang is, moet die wateruitset aaneenlopend en eweredig wees, die stroom moet stabiel wees (onder gegradeerde werksomstandighede, gewoonlik nie meer as 10% van die aangeslane stroom), en daar moet geen vibrasie of geraas wees nie. As daar enige abnormaliteit is, moet die masjien gestop word om die oorsaak uit te vind en dit uit te skakel.

8. Wanneer jy installeer, let op die instelling van die motor se aarddraad (sien Figuur 2). Wanneer die waterpyp 'n staalpyp is, lei dit uit die putkopklem; wanneer die waterpyp 'n plastiekpyp is, lei dit vanaf die aardmerk van die elektriese pomp.

- 1.After the submersible pump is installed, check the insulation resistance and three-phase conduction from the switch again, check whether the instrument and the connection of the start equipment are wrong, if there is no problem, the trial machine can be started, and observe whether the indicator readings of the instrument exceed the rated voltage and current specified on the nameplate after the start, and observe whether the pump has noise and vibration phenomenon. If everything is normal, it can be put into operation.

- 2. After the first operation of the pump for four hours, the motor should be shut down to test the thermal insulation resistance quickly, and its value should not be less than 0.5 megaohm.

- 3. After the pump is shut down, it should be started after five minutes to prevent the water column in the pipe from burning due to excessive motor current.

- 4. After the pump is running normally, in order to prolong its service life, it is necessary to check whether the power supply voltage, running current and insulation resistance are normal on a regular basis.If the following conditions are found, the equipment should be shut down immediately to eliminate the fault:

- - Under the rated working conditions, the current exceeds 20%.

- - The dynamic water level drops to the inlet section, resulting in intermittent drainage.

- - The submersible pump vibrates violently or emits noisy sounds.

- - The power supply voltage is lower than 340 volts.

- - There is a phase blown out in the fuse.

- - The water pipe is damaged.

- - The thermal insulation resistance between the motor and the ground is less than 0.5 megaohm.

- 5. Disassembly device:

- - Untie the cable, take off the pipe part and remove the line protection plate.

- - Unscrew the drain screw and exclude all water in the motor chamber.

- - Take out the filter and loosen the fixing screw on the coupling fixed to the motor shaft.

- - Unscrew the bolt connecting the water inlet section and the motor, and separate the pump and the motor (pay attention to the level of the device to prevent the bending of the pump shaft when separating).

- - The disassembly sequence of the pump is as follows: (see Figure 1) water inlet section, impeller, shunt shell, impeller, check valve body. When removing the impeller, use special tools to loosen the cone sleeve fixed to the impeller. In the process of disassembly, avoid bending the pump shaft and damaging various parts.

- - The disassembly process of the motor is as follows: (see Figure 1) place the motor on the platform, and remove the nuts, base, shaft head lock nut, thrust plate, key, lower guide bearing. seat, and tie rod bolts from the bottom of the motor in order (see Figure 1), and then take out the rotor (be careful not to damage the wiring harness) and finally take out the connector and upper guide bearing seat.

- - Assembly unit: before assembly, all parts should be cleaned of rust and dirt, and smear sealant on all the surfaces and fasteners, and then assemble in the opposite order of disassembly (the movement of the motor shaft after assembly is about 1 mm). After assembly, the coupling should be flexible, and then wear the filter for machine test. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

1, sit die water in die motorholte uit (veral in die winter om te verhoed dat die motor vries), en bind die kabel goed vas.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, langtermyn gebruik moet aandag gee aan die roes voorkoming van dompelpompe.

- Impeller

- Skaghuls

- Rubber skag huls

-

Seëlring

01 Diep put water inname

02 Hoë watervoorsiening

03 bergwatervoorsiening

04 toring water

05 Landboubesproeiing

06 tuinbesproeiing

07 rivier water inname

08 huishoudelike water