Frequency conversion winding design, ensure the motor in 1HZ-50HZ long-term stable conversion operation. Energy saving, longer service life.

1, kragtoevoer: driefase-wisselstroom 380V (toleransie + / - 5%), 50HZ (toleransie + / - 1%).

2, waterkwaliteit:

(1) water temperature is not higher than 20 °C;

(2) vaste onsuiwerhede inhoud (massa verhouding) is nie groter as 0,01%;

(3) PH-waarde (pH) 6,5-8,5;

(4) waterstofsulfiedinhoud nie groter as 1.5mg/L is nie;

(5) chloried-iooninhoud is nie meer as 400mg/L nie.

3, die motor is gesluit of water gevulde nat struktuur, voor gebruik moet die dompelmotorholte vol skoon water wees, om vals vol te voorkom, en draai dan die waterinspuiting, lugvrystellingboute vas, anders mag dit nie gebruik word nie

4, dompelpomp moet heeltemal in die water gedompel word, die duikdiepte is nie groter as 70m nie, die onderkant van die dompelpomp vanaf die bodem van die put is nie minder nie as 3m.

5, moet die put water vloei in staat wees om te voldoen aan die dompelpomp water uitset en deurlopende werking, moet die dompelpomp water uitset beheer word op 0,7 - 1,2 keer die gegradeerde vloei.

6, die put moet reguit wees, die dompelpomp kan nie gebruik of gestort word nie, slegs vertikale gebruik.

7, moet die dompelpomp ooreenstem met die kabel volgens die vereistes, en die eksterne oorladingsbeskermingstoestel. 8, die pomp is streng verbode sonder water-nie-laai toetsmasjien

| Model | Vloei (m3/h) | Kop (m) |

Rotating speed(change/point) | Water pomp(%) | Uitlaat deursnee (mm) |

Goed toepaslik deursnee (mm) |

Gegradeer drywing (KW) |

Rated voltage(V) | Ratedcurrent(A) | Motordoeltreffendheid (%) | power factorcosφ | Eenheid Radiale maksimum grootte (mm) |

Opmerking | |||||||||

| 125QJ5-34 | 5 | 34 | 2850 | 53 | 40 | 125hierbo | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ5-51 | 51 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ5-68 | 68 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ5-85 | 85 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ5-102 | 102 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ5-119 | 119 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-24 | 10 | 24 | 2850 | 60 | 50 | 125hierbo | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ10-32 | 32 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ10-48 | 48 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ10-56 | 56 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ10-72 | 72 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-80 | 80 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-104 | 104 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ10-120 | 10 | 120 | 2850 | 60 | 50 | 125hierbo | 7.5 | 380 | 19.0 | 76.0 | 0.79 | 118 | ||||||||||

| 125QJ10-136 | 136 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ15-36 | 15 | 36 | 2850 | 63 | 50 | 125hierbo | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ15-39 | 39 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ15-46 | 46 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-52 | 52 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-59 | 59 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-65 | 65 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-78 | 78 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-91 | 91 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-104 | 104 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ20-16 | 20 | 16 | 2850 | 64 | 50 | 125hierbo | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ20-24 | 24 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ20-32 | 32 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-40 | 40 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-48 | 48 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-56 | 56 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-64 | 64 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-72 | 72 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-80 | 80 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ25-12 | 25 | 12 | 2850 | 64 | 65 | 125hierbo | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ25-18 | 18 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ25-24 | 24 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-30 | 30 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-36 | 36 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ25-48 | 48 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ25-60 | 60 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ32-24 | 32 | 24 | 2850 | 64 | 80 | 125hierbo | 4 | 380 | 10.53 | 74.0 | 0.78 | 118 | ||||||||||

| 125QJ32-30 | 30 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ32-42 | 42 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ32-54 | 54 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ5-240 | 5 | 240 | 2850 | 40 | 125hierbo | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ5-280 | 280 | 13 | 30.87 | |||||||||||||||||||

| 125QJ5-320 | 320 | 15 | 35.62 | |||||||||||||||||||

| 125QJ10-180 | 10 | 180 | 2850 | 50 | 125hierbo | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ10-210 | 210 | 13 | 30.87 | |||||||||||||||||||

| 125QJ10-240 | 240 | 15 | 35.62 | |||||||||||||||||||

| 125QJ15-120 | 15 | 120 | 2850 | 50 | 125hierbo | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ15-142 | 142 | 13 | 30.87 | |||||||||||||||||||

| 125QJ15-162 | 162 | 15 | 35.62 | |||||||||||||||||||

| 125QJ20-100 | 20 | 100 | 2850 | 50 | 125hierbo | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ20-120 | 120 | 13 | 30.87 | |||||||||||||||||||

| 125QJ20-136 | 136 | 15 | 35.62 | |||||||||||||||||||

| 125QJ25-82 | 25 | 82 | 2850 | 65 | 125hierbo | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ25-97 | 97 | 13 | 30.87 | |||||||||||||||||||

| 125QJ25-110 | 110 | 15 | 35.62 | |||||||||||||||||||

| 125QJ32-68 | 32 | 68 | 2850 | 80 | 125hierbo | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ32-80 | 80 | 13 | 30.87 | |||||||||||||||||||

| 125QJ32-92 | 92 | 15 | 35.62 | |||||||||||||||||||

| 125QJ40-46 | 40 | 46 | 2850 | 80 | 125hierbo | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ40-54 | 54 | 13 | 30.87 | |||||||||||||||||||

| 125QJ40-62 | 62 | 15 | 35.62 | |||||||||||||||||||

The well submersible pump is a pump suitable for clear water. It is strictly prohibited to dig new wells and pump out mud and sand. The voltage grade of the well pump is 380V/50HZ, and other voltage grades of the submersible motor need to be customized. Underground cables must be waterproof cables and must be equipped with starting equipment, such as distribution box, etc. The starting equipment should have common motor comprehensive protection functions, such as short circuit overload protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. In abnormal cases, the protective device should be tripped in time. When installing and using the pump, it must be firmly grounded. It is prohibited to push and pull the switch when the hands and feet are wet. The power supply must be cut off before installing and maintaining the pump. An obvious "anti-electric shock" sign must be set up where the pump is used. Before going down the well or installing the motor, the inner cavity must be filled with distilled water or non-corrosive clean cold water, and the water injection/drainage bolts must be tightened. Fill the pump with water for ground test to lubricate the rubber bearings. The instant start time shall not exceed one second to check whether the direction is correct and consistent with the direction indication. Be sure to pay attention to safety when placing the pump upright to prevent overturning and causing injury. Strictly in accordance with the provisions of the pump lift and flow range of use, to prevent the pump flow at low lift or excessive pull at high lift, resulting in extreme wear of thrust bearings and other components, resulting in motor overload burn. After the pump into the well, the insulation resistance between the motor and the ground shall be measured, which shall not be less than 100MΩ. After the start, observe the voltage and current regularly, and check the motor winding insulation, to see if it meets the requirements; if the pump storage temperature is below the freezing point, the water in the motor cavity should be discharged, so as to avoid the water in the motor cavity freezing and damaging the motor due to low temperature.

Die belangrikste kenmerke van die produk sluit in:

1.The motor is a water-loaded wet submersible three-phase asynchronous motor,and the motor cavity is filled with clean water for cooling the motor and lubricating the bearing.The regulating diaphragm at the bottom of the motor is used to adjust the expansion and contraction pressure difference inside and outside the body caused by the temperature rise of the motor.

2.In order to prevent the sand particles in the well water from entering the motor,two oil seals are installed at the extension end of the motor shaft,and the sand ring is installed to form a sand prevention structure.

3.In order to prevent the pump shaft from jumping when starting,the pump shaft is connected with the motor shaft through a coupling,and the thrust bearing is installed at the bottom of the motor.

4.The lubrication of the motor and the pump bearing is water lubrication.

5.The stator winding of the motor adopts high-quality submersible motor winding wire,with excellent insulation performance.

6.The pump is designed by computer CAD,with simple structure and excellent technical performance.

(1) Voorbereiding voor installasie:

1. Kontroleer of die dompelpomp voldoen aan die gebruiksvoorwaardes en omvang gespesifiseer in die handleiding.

2. Gebruik 'n swaar voorwerp met 'n deursnee gelyk aan die maksimum buitenste deursnee van die dompelpomp, meet of die binnedeursnee van die boorput by die dompelpomp kan pas, en meet of die putdiepte aan die installasievereistes voldoen.

3. Kontroleer of die boorput skoon is en of die putwater troebel is. Moet nooit 'n dompelpomp gebruik om die welor pomp modder en sand water te was om voortydige skade aan die dompel elektriese pomp te vermy.

4. Kontroleer of die posisie van die putkopinstallasieklem geskik is en of dit die kwaliteit van die hele eenheid kan weerstaan

5. Kontroleer of die dompelpompkomponente volledig en behoorlik geïnstalleer is volgens die samestellingsdiagram in die handleiding Verwyder die filterskerm en draai die koppeling om te sien of dit buigsaam draai

6. Skroef die waterskroef los en vul die motorholte met skoon, nie-korrosiewe water (let wel. maak seker dat jy dit vol maak), draai dan die waterskroef vas. Na 12 uur se waterinspuiting moet die isolasieweerstand van die motor nie minder as 150M Q wees as dit gemeet word met 'n 500V skudtafel nie.

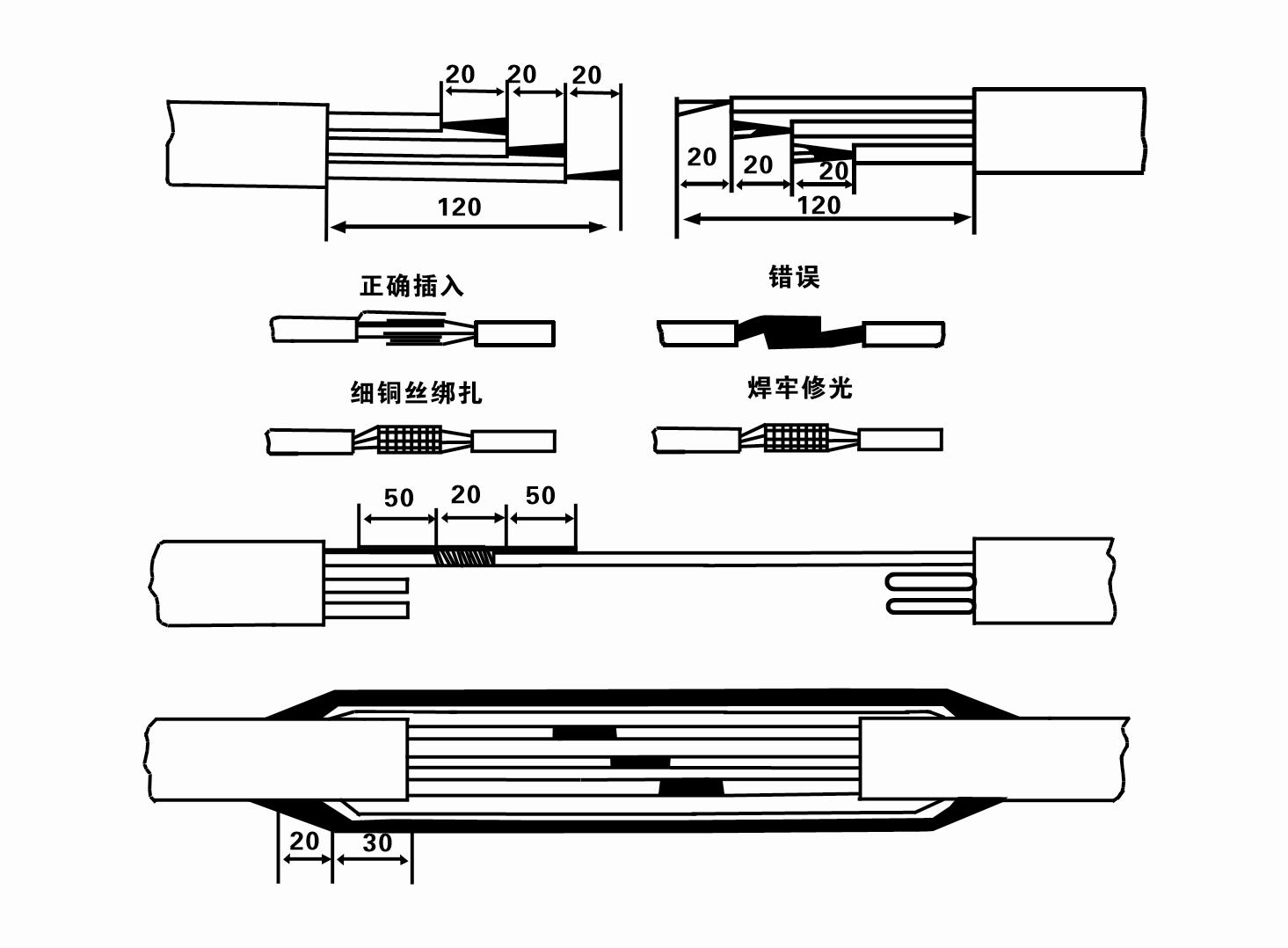

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.

After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Die aangehegte kabelbedradingsprosesdiagram is soos volg:

8. Gebruik 'n multimeter om te kyk of die driefase-drade verbind is en of die GS-weerstand ongeveer gebalanseerd is.

9. Check whether the circuit and transformer capacity are overloaded, and then connect the overload protection switch or starting equipment. See Table 2 for specific models, and then

Pour a bucket of water into the water pump from the water pump outlet to lubricate the rubber bearings in the pump, and then place the submersible electric pump upright and steady.

Start (no more than one second) and check whether the steering direction is consistent with the steering sign. If not, swap any two connectors of the three-phase cable.

Then install the filter and prepare to go down the well. If used in special occasions (such as ditches, ditches, rivers, ponds, ponds, etc.), the electric pump must be reliably grounded.

(2) Installasie toerusting en gereedskap:

1. Een paar hyskettings vir meer as twee ton.

2. 'n Driepoot met 'n vertikale hoogte van nie minder nie as vier meter.

3. Twee hangtoue (draadtoue) wat 'n gewig van meer as een ton kan dra (kan die gewig van 'n volledige stel waterpompe dra).

4. Installeer twee pare klampe (spalke).

5. Sleutels, hamers, skroewedraaiers, elektriese gereedskap en instrumente, ens.

(3) Elektriese pompinstallasie:

1. Die installasiediagram van die dompel-elektriese pomp word in Figuur 2 getoon. Die spesifieke installasie-afmetings word in Tabel 3 "Lys van Installasie-afmetings van die dompel-elektriese pomp" getoon.

2. Dompelbare elektriese pompe met 'n hoogte van minder as 30 meter kan direk in die put gehys word deur gebruik te maak van slange en draadtoue of ander henneptoue wat die volle gewig van die hele masjien, waterpype en water in die pype kan dra.

3. Pompe met 'n hoogte van meer as 30 meter gebruik staalpype, en die installasievolgorde is soos volg:

①Use a clamp to clamp the upper end of the water pump part (the motor and water pump have been connected at this time), lift it with a hanging chain, and slowly tie it into the well until

Put the clamp on the wellhead and remove the hanging chain.

② Use another pair of clamps to clamp a pipe, lift it with a hanging chain 15 cm away from the flange, and lower it slowly. Between pipe flange and pump flange

Put the rubber pad in place and tighten the pipe and pump evenly with bolts, nuts and spring washers.

③ Lig die dompelpomp effens op, verwyder die klem aan die boonste punt van die waterpomp, bind die kabel stewig aan die waterpyp vas met 'n plastiekband, en maak dit stadig vas totdat Die klem by die putkop geplaas is.

④Gebruik dieselfde metode om alle waterpype in die put vas te bind.

⑤ Nadat die uitloopkabel aan die beheerskakelaar gekoppel is, word dit aan die driefase-kragbron gekoppel.

(4) Dinge om op te let tydens installasie:

1. If a jamming phenomenon is found during the pumping process, turn or pull the water pipe to overcome the jamming point. If various measures still do not work, please

Do not force the pump down to avoid damage to the submersible electric pump and the well.

2. Tydens installasie moet 'n rubberkussing by die flens van elke pyp geplaas word en eweredig vasgedraai word.

3. Wanneer die waterpomp in die put laat sak word, moet dit in die middel van die putpyp geplaas word om te verhoed dat die pomp vir 'n lang tyd teen die putwand loop, wat veroorsaak dat die pomp vibreer en die motor vee en brand .

4. Bepaal die diepte van die waterpomp tot by die bodem van die put volgens die vloeiende sand- en sliktoestande van die put. Moenie die pomp in die modder begrawe nie. Die afstand vanaf die waterpomp na die bodem van die put is oor die algemeen nie minder nie as 3 meter (sien Figuur 2).

5. Die watertoevoerdiepte van die waterpomp moet nie minder nie as 1-1,5 meter wees vanaf die dinamiese watervlak na die waterinlaatknooppunt (sien Figuur 2). Andersins kan die waterpomplaers maklik beskadig word.

6. Die hysbak van die waterpomp kan nie te laag wees nie. Andersins moet 'n hekklep op die putkopwaterpyplyn geïnstalleer word om die pompvloei by die aangewese vloeipunt te beheer om te verhoed dat die motor oorlaai en uitbrand as gevolg van groot vloeitempo's.

7. Wanneer die waterpomp aan die gang is, moet die wateruitset aaneenlopend en eweredig wees, die stroom moet stabiel wees (onder gegradeerde werksomstandighede, gewoonlik nie meer as 10% van die aangeslane stroom), en daar moet geen vibrasie of geraas wees nie. As daar enige abnormaliteit is, moet die masjien gestop word om die oorsaak uit te vind en dit uit te skakel.

8. Wanneer jy installeer, let op die instelling van die motor se aarddraad (sien Figuur 2). Wanneer die waterpyp 'n staalpyp is, lei dit uit die putkopklem; wanneer die waterpyp 'n plastiekpyp is, lei dit vanaf die aardmerk van die elektriese pomp.

- 1.Nadat die dompelpomp geïnstalleer is, kontroleer die isolasieweerstand en driefasegeleiding van die skakelaar weer, kyk of die instrument en die verbinding van die aansittoerusting verkeerd is, as daar geen probleem is nie, kan die proefmasjien begin word, en let op of die aanwyserlesings van die instrument die nominale spanning en stroom wat op die naamplaat gespesifiseer is na die aansit oorskry, en kyk of die pomp geraas- en vibrasieverskynsel het, en in werking tree as alles normaal is.

- 2.Na die eerste werking van die pomp vir vier uur, moet die motor afgeskakel word om die termiese isolasieweerstand vinnig te toets, en die waarde daarvan moet nie minder as 0,5 megaohm wees nie.

- 3.Nadat die pomp afgeskakel is, moet dit na vyf minute aangeskakel word om te verhoed dat die waterkolom in die pyp heeltemal hervloei en oormatige motorstroom en uitbranding veroorsaak.

- 4.Nadat die pomp in normale werking gestel is, om sy lewensduur te verleng, is dit nodig om gereeld na te gaan of die toevoerspanning, werkstroom en isolasieweerstand normaal is. As die volgende toestande gevind word, moet die pomp onmiddellik afgeskakel word om die probleem op te los.

- 1 In the rated condition, the current exceeds 20%.

- 2 Die dinamiese watervlak daal na die waterinlaatgedeelte, wat onderbroke water veroorsaak.

- 3 Die dompelpomp het erge vibrasie of geraas.

- 4 Die toevoerspanning is laer as 340 volt.

- 5 'n Sekering is uitgebrand.

- 6 Die watertoevoerpyp is beskadig.

- 7 The motor's thermal insulation resistance is lower than 0.5 megaohm.

- Unit disassembly:

- 1.Untie the cable tie, remove the pipeline part, and remove the wire plate.

- 2.screw down the water bolt, put the water in the motor chamber.

- 3.remove the filter, loose the fixed screw on the coupling to fix the motor shaft.

- 4.screw down the bolt connecting the water inlet section with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the opposite order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

This product is an efficient and durable submersible electric pump, suitable for a variety of environments and applications.In order to ensure the long-term use and stable performance of the product, we suggest that users pay special attention to drying the water in the motor cavity in winter to avoid freezing; in addition, the cable is coiled and tied, and properly stored in an environment without corrosive substances and gases, with a temperature below 40 °C. If the product is not used for a long time, attention should be paid to rust prevention treatment to ensure the life cycle and performance of the product.Whether for industrial use or for home use, this submersible electric pump can provide you with reliable pump service.

-

- Impeller

- Skaghuls

- Rubber skag huls

-

Seëlring

01 Diep put water inname

02 Hoë watervoorsiening

03 bergwatervoorsiening

04 toring water

05 Landboubesproeiing

06 tuinbesproeiing

07 rivier water inname

08 huishoudelike water