This hot water pump adopts the motor made of 50W400 grade high quality cold rolled silicon steel, which is stamped by high speed punch press. It has the advantages of low stator iron loss and low self-heating. The motor winding is designed for hot water pump, high temperature resistance and anti-aging. The winding has water resistance, and adopts 3CR13 stainless steel blade shaft, high temperature resistant bushing and other high quality accessories to enable it to operate for a long time at high temperature, and can be used with frequency converter, so as to automatically adjust according to the amount of water used. This hot water pump is the ideal choice for your hot water equipment, which can operate stably and efficiently, providing you with a lasting hot water supply.

The product is a three-phase AC 380V (tolerance + / - 5%), 50HZ (tolerance + / - 1%) power supply submersible pump. With water quality requirements: water temperature is not higher than 20 °C; solid impurities content (mass ratio) is not more than 0.01%; PH value (pH) is 6.5-8.5; hydrogen sulfide content is not more than 1.5mg/L; chloride ion content is not more than 400mg/L. The electric pump adopts closed or water sealed wet structure, before use must be submersible motor inner cavity filled with clean water to prevent empty, and then tighten the water and air bolts, otherwise not to use. Its work should be completely immersed in water, immersion depth is not more than 70 meters, the distance between the bottom of the pump and the bottom of the well is not less than 3 meters. Well water inflow quantity should be able to meet the electric pump water output and continuous operation, the output water quantity should be controlled at 0.7-1.2 times of the rated flow. The well should be vertical, the electric pump can not be used horizontally or inclined, only vertically placed. The electric pump must be equipped with cables and external overload protection device as required. It is strictly prohibited to conduct no-load test under no water condition.

| Nlereanya | Ọsọ (m3/h) | Isi (m) |

Ọsọ ntụgharị (mgbanwe/atụ) |

Mgbapu mmiri(%) | Mwepu dayameta (mm) |

Ọdabara nke ọma dayameta (mm) |

Enyere aha power(KW) |

Enyere aha voltaji (V) |

Enyere aha ugbu a (A) |

Ịrụ moto (%) | power factorcosφ | Nkeji Nha radial kacha (mm) |

kwuo | |||||||||

| 300QJ200-40 | 200 | 40 | 2900 | 76 | 150 | 300n'elu | 37 | 380 | 77.8 | 85.0 | 0.85 | 281 | ||||||||||

| 300QJ200-60 | 60 | 55 | 115 | 85.5 | 0.85 | |||||||||||||||||

| 300QJ200-80 | 80 | 75 | 154.1 | 86.0 | 0.86 | |||||||||||||||||

| 300QJ200-100 | 100 | 90 | 183.8 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ200-120 | 120 | 100 | 204.3 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ200-140 | 140 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

| 300QJ200-160 | 160 | 140 | 277.8 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-180 | 180 | 160 | 317.5 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-200 | 200 | 185 | 367.2 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-240 | 240 | 220 | 436.6 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ320-30 | 320 | 30 | 2900 | 77 | 200 | 300n'elu | 45 | 380 | 94.6 | 85.0 | 0.85 | 281 | ||||||||||

| 300QJ320-60 | 60 | 90 | 183.8 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ320-90 | 90 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

| 300QJ320-120 | 120 | 160 | 317.5 | 88.0 | 0.87 | |||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, n'ụzọ doro anya dị ka ndokwa nke mgbapụta ebuli, eruba nso nke ojiji, iji gbochie ala eruba ma ọ bụ elu ebuli pumping ike, mkpali ibu na akụkụ ndị ọzọ nke eyi, moto bufee ọkụ.

6, mgbe mgbapụta gbadaa olulu mmiri ahụ, nha nke moto na nguzogide mkpuchi ala ekwesịghị ịbụ ihe na-erughị 100M, mgbe mmalite na-ekiri voltaji na ugbu a, lelee mkpuchi mkpuchi moto, ma ọ dabara na ihe ndị a chọrọ; mgbapụta nchekwa ọnọdụ okpomọkụ ma ọ bụrụ na-erughị kefriza ebe, kwesịrị akọrọ mmiri na moto oghere, gbochie moto oghere mmiri ice mebiri mere site ala okpomọkụ.

The pump part is mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor part is mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand discharging ring, water inlet section, lead cable and other components. The main characteristic of this product is that the motor is a water-cooled submersible three-phase asynchronous motor, and the motor cavity is filled with water to cool the motor and lubricate the bearing. The pressure regulating diaphragm at the bottom is used to adjust the expansion-contraction pressure difference in the body caused by the change of the temperature rise of the motor. In order to prevent the sand particles in the well water from entering the motor, two oil seals are installed at the upper end of the motor shaft extension, and a sand discharging ring is installed to form a sand discharging structure. In order to prevent the pump shaft from jumping when starting, the pump shaft and the motor shaft are connected together through a coupling, and a thrust bearing is installed at the bottom of the motor. The lubrication of the motor and the pump bearing is realized through water lubrication. The stator winding of the motor is made of high-quality well motor winding wire, with high insulation performance. The pump is designed by computer CAD, with simple structure and good technical performance.

(1) Nkwadebe tupu echichi:

1. Lelee ma mgbapụta submersible na-ezute ọnọdụ ojiji yana oke akọwapụtara na ntuziaka.

2. Iji obiect dị arọ nke nwere dayameta hà nhata kachasị elu nke mgbapụta mmiri na-ekpuchi mmiri, tụọ ma inneldiameter nke olulu mmiri ahụ nwere ike dabara na mgbapụta mmiri, ma tụọ ma omimi nke ọma na-emezu ihe achọrọ nrụnye.

3. Lelee ma olulu mmiri ahụ ọ dị ọcha ma mmiri olulu mmiri ahụ ọ na-asọ oyi. Ejila mgbapụta ọkụ eletrik na-eme ka mmiri na-asachapụ apịtị welor na mmiri ájá ka ịzenarị mmebi nke mgbapụta ọkụ eletrik n'oge.

4. Lelee ma ọnọdụ nke welhead echichi mwekota dabara na ma ọ nwere ike iguzogide qualty nke dum unit.

5. Lelee ma ọ bụrụ na akụrụngwa mgbapụta submersible zuru ezu ma wụnye ya nke ọma dị ka eserese mgbakọ na mwepụ na akwụkwọ ntuziaka Wepụ ihuenyo nzacha ma gbanwee njikọ ahụ iji hụ ma ọ na-agbagharị na-agbanwe agbanwe.

6. Kpochapụ ihe nkedo mmiri ma jupụta oghere moto na mmiri dị ọcha, nke na-adịghị emebi emebi (dee. jide n'aka na ị ga-agbanye ya), wee mee ka mmiri sie ike. Mgbe awa 12 nke ịgbanye mmiri gasịrị, nguzogide mkpuchi nke moto ekwesịghị ịbụ ihe na-erughị 150M Q mgbe a tụrụ ya na tebụl ịma jijiji 500V.

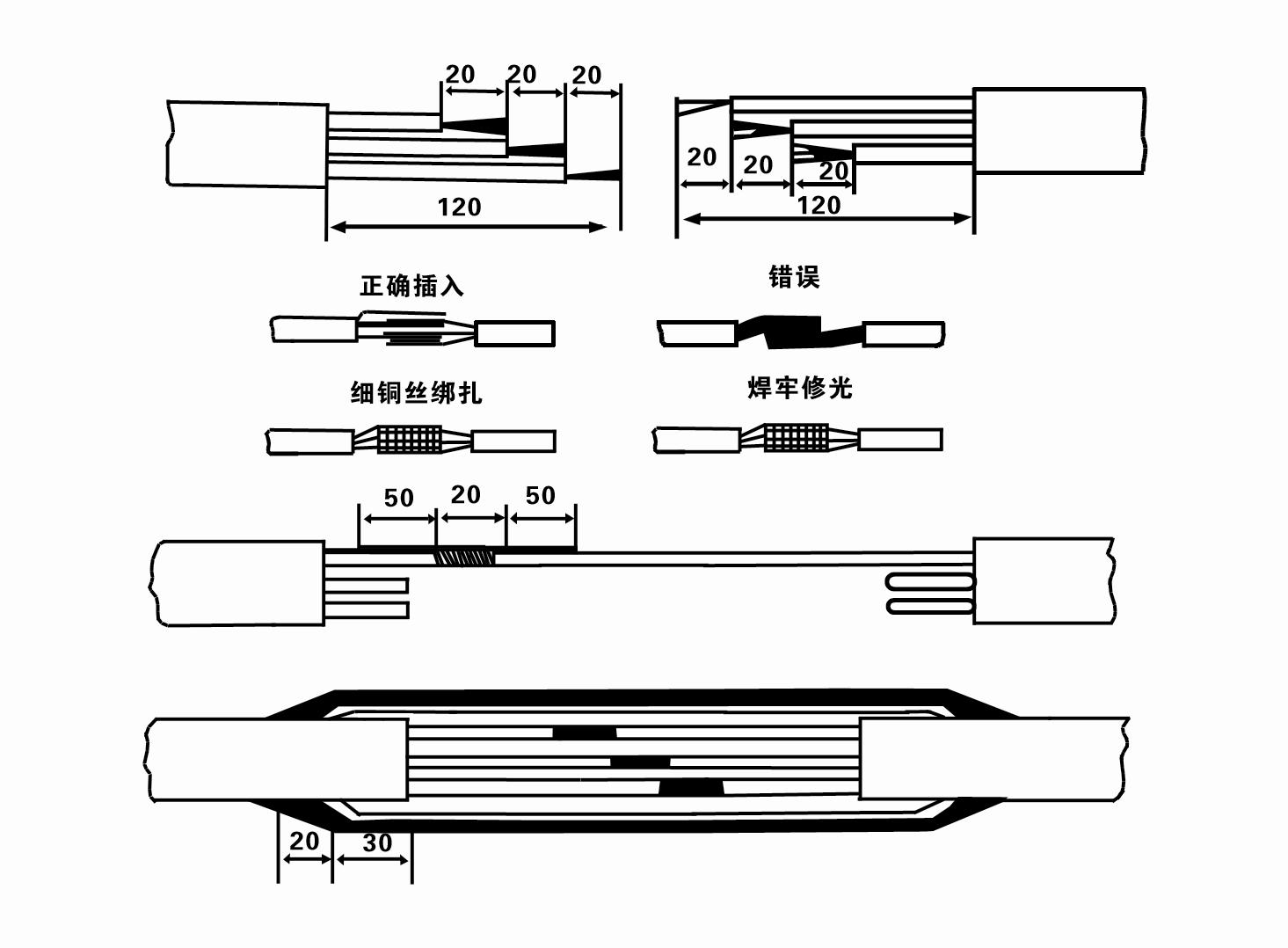

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Eserese usoro wiring cable nke agbakwunyere bụ nke a:

8. Jiri multimeter chọpụta ma ejikọrọ wires nke atọ na ma nkwụsi ike DC ọ dị oke nhata.

9. Lelee ma ikike sekit na transformer bubigara ibu, wee jikọọ ihe ngbanwe mkpuchi ibufe ma ọ bụ akụrụngwa mmalite. Hụ Tebụl 2 maka ụdị ụdị dị iche iche, wee wụsa ịwụ mmiri n'ime mgbapụta mmiri si na mmiri mgbapụta mmiri iji mee ka mmanu rọba dị na mgbapụta ahụ, wee debe mgbapụta ọkụ eletrik nke nwere ike ime ka ọ kwụ ọtọ na kwụ ọtọ. Malite (ọ bụghị ihe karịrị otu sekọnd) ma lelee ma ntụzịaka stereị ọ dabara na akara stereị. Ọ bụrụ na ọ bụghị, gbanwee njikọ abụọ ọ bụla nke eriri ụzọ atọ. Mgbe ahụ wụnye nzacha ma kwadebe ka ị gbadaa n'olulu mmiri ahụ. Ọ bụrụ na ejiri ya n'oge pụrụ iche (dịka ọwa mmiri, ọwa mmiri, osimiri, ọdọ mmiri, ọdọ mmiri, wdg), mgbapụta ọkụ eletrik ga-agbanyerịrị nke ọma.

(2) Akụrụngwa na akụrụngwa ntinye:

1. Otu ụzọ na-ebuli agbụ maka ihe karịrị tọn abụọ.

2. A tripod nwere ogologo kwụ ọtọ na-erughị mita anọ.

3. Ụdọ abụọ kwụgidere (ụdọ waya) nke nwere ike ibu ibu ihe karịrị otu ton (nwere ike ibu ibu nke nfuli mmiri zuru ezu).

4. Wụnye ụzọ abụọ nke clamps (splints).

5. Wrenches, hammers, screwdrivers, eletriki ngwaọrụ na ngwá, wdg.

(3) Nwụnye mgbapụta ọkụ eletrik:

1. E gosipụtara eserese nrụnye nke mgbapụta ọkụ eletrik submersible na eserese 2. A na-egosipụta akụkụ ntinye kpọmkwem na Tebụl 3 "Ndepụta nke nrụnye akụkụ nke mgbapụta ọkụ eletrik".

2. Enwere ike ibunye nfuli eletriki na-ekpuchi isi na isi ihe na-erughị mita 30 ozugbo n'ime olulu mmiri site na iji ụdọ na eriri waya ma ọ bụ eriri hemp ndị ọzọ nwere ike iburu igwe zuru oke nke igwe dum, ọkpọkọ mmiri na mmiri na ọkpọkọ.

3. Nfuli nke nwere isi ihe karịrị mita 30 na-eji ọkpọkọ ígwè, na usoro ntinye bụ nke a:

① Jiri ihe nkedo iji kpoo njedebe elu nke akụkụ mgbapụta mmiri (a na-ejikọta moto na mmiri mgbapụta n'oge a), bulite ya na agbụ nke nghọta, ma jiri nwayọọ nwayọọ kechie ya n'ime olulu mmiri ruo mgbe ịtinye ihe nkedo na isi mmiri ma wepụ ya. nghọta yinye.

② Jiri ụzọ mkpị ọzọ kụchie ọkpọkọ, were yinye kwụgidere 15 cm pụọ na flange, wee wetuo ya nwayọ. N'etiti ọkpọkọ flange na mgbapụta flange Tinye ihe mgbochi rọba n'ebe ma mee ka ọkpọkọ ahụ sie ike ma gbapụta ya nke ọma na bolts, mkpụrụ na mmiri mmiri.

③ Welite obere mgbapụta submersible, wepụ ihe nkedo dị na nsọtụ elu nke mgbapụta mmiri ahụ, kechie eriri ahụ nke ọma na ọkpọkọ mmiri na teepu rọba, ma jiri nwayọọ nwayọọ kechie ya ruo mgbe etinyere mkpọ ahụ n'isi olulu mmiri.

④ Jiri otu usoro ahụ kee ọkpọkọ mmiri niile n'ime olulu mmiri.

⑤ Mgbe ejikọtara eriri na-eduga na njikwa njikwa, a na-ejikọta ya na ọkụ ọkụ nke atọ.

(4) Ihe ị ga-ahụ n'oge echichi:

1. Ọ bụrụ na achọpụtara ihe mgbagwoju anya n'oge usoro mgbapụta ahụ, tụgharịa ma ọ bụ dọrọ ọkpọkọ mmiri iji merie ebe nkwụsị. Ọ bụrụ na usoro dị iche iche ka na-arụ ọrụ, biko Amanyela mgbapụta ahụ ka ọ ghara imebi mgbapụta ọkụ eletrik na olulu mmiri.

2. N'oge echichi, a ga-etinye ihe mkpuchi rọba na flange nke ọkpọkọ ọ bụla ma mee ka ọ sie ike.

3. Mgbe a na-agbanye mmiri mmiri n'ime olulu mmiri ahụ, a ga-etinye ya n'etiti ọkpọkọ nke ọma iji gbochie mgbapụta ahụ na-agba ọsọ megide mgbidi olulu mmiri ruo ogologo oge, na-eme ka mgbapụta ahụ na-ama jijiji na moto na-ekpochapụ ma gbaa ọkụ. .

4. Kpebie omimi nke mgbapụta mmiri na ala nke olulu mmiri dịka ájá na-asọ asọ na ọnọdụ silt nke olulu mmiri ahụ. Eliela mgbapụta n'ime apịtị. Ebe dị anya site na mgbapụta mmiri na ala nke olulu mmiri n'ozuzu ọ bụghị ihe na-erughị mita 3 (lee foto 2).

5. Ihe omimi ntinye mmiri nke mgbapụta mmiri kwesịrị ịbụ ihe na-erughị 1-1.5 mita site na mmiri dị ike na ọnụ mmiri ntinye mmiri (lee foto 2). Ma ọ bụghị ya, a ga-emebi bearings mgbapụta mmiri n'ụzọ dị mfe.

6. Ebuli nke mgbapụta mmiri enweghị ike ịdị ala. Ma ọ bụghị ya, ekwesịrị itinye valvụ ọnụ ụzọ ámá na pipeline mmiri nke ọma iji chịkwaa mgbapụta mgbapụta na ebe a na-agbapụta agbapụta iji gbochie moto ahụ ka ọ ghara ibufe ma gbaa ọkụ n'ihi nnukwu ọnụọgụ mmiri.

7. Mgbe mgbapụta mmiri na-agba ọsọ, mmepụta mmiri kwesịrị ịdị na-aga n'ihu na ọbụna, nke dị ugbu a kwesịrị ịdị na-eguzosi ike (n'okpuru ọnọdụ ọrụ a kwadoro, n'ozuzu ọ dịghị ihe karịrị 10% nke akara ugbu a), na e kwesịghị inwe mkpọtụ ma ọ bụ mkpọtụ. Ọ bụrụ na enwere ihe na-adịghị mma, a ga-akwụsị igwe ahụ iji chọpụta ihe kpatara ya ma kpochapụ ya.

8. Mgbe ị na-etinye ya, ṅaa ntị na ntọala nke waya mgbanaka moto (lee foto 2). Mgbe ọkpọkọ mmiri bụ ọkpọkọ ígwè, dupụta ya site na mkpọchi olulu mmiri; mgbe ọkpọkọ mmiri bụ ọkpọkọ plastik, duga ya site na akara ala nke mgbapụta eletrik.

After installation of the underwater pump, it is necessary to recheck the insulation resistance and three-phase continuity of the switch, and check whether the connection between the instrument and the starting equipment is wrong. If there is no problem, you can start the test machine. After starting, observe whether the indication reading of each instrument is correct. If the rated voltage and current specified on the nameplate are exceeded, observe whether the pump has any noise or vibration. If everything is normal, it can be put into operation. Four hours after the first operation of the pump, it should be turned off and the thermal insulation resistance of the motor should be quickly tested, and its value should not be less than 0.5 megaohm. After stopping the pump, it should be restarted after an interval of five minutes to prevent the water column in the pipeline from completely reversing, resulting in the motor burning due to excessive current. After the pump is put into normal operation, in order to prolong its service life, it is necessary to check regularly whether the supply voltage, working current and insulation resistance are normal. If the following conditions are found, the machine should be stopped immediately to eliminate the fault:

1 the current exceeds 20% under the rated working condition.

2 the dynamic water level drops to the inlet section, resulting in intermittent drainage.

3 the underwater pump vibrates violently or emits huge noise.

4 the supply voltage is lower than 340 volts.

5 a fuse is burned.

6 the water pipe is damaged.

7 the thermal insulation resistance of the motor to the ground is less than 0.5 megaohm.

When disassembling the device, it is necessary to untie the cable bundle and remove the pipeline part and the line protection plate. Remove the drain bolt and exclude all water in the motor chamber. Remove the filter element and loosen the screw on the coupling fixed to the motor shaft. Unscrew the bolt connecting the water inlet section and the motor, and separate the pump and the motor (pay attention to placing the device horizontally when separating to prevent the bending of the pump shaft). The sequence of disassembling the pump is as follows: (see Figure 1) water inlet section, impeller, water inlet shell, impeller. Check the valve body, and use a special tool to loosen the cone sleeve fixed to the impeller when removing the impeller. In the process of disassembly, avoid bending the pump shaft and damaging various components. The disassembly process of the motor is as follows: (see Figure 1) put the motor on the platform, and remove the nuts on the screw (pull rod bolt), base, shaft head lock nut, thrust plate, key and lower guide rail - bearing seat, bolt, and then remove the rotor (be careful not to damage the wiring harness), and finally remove the connecting parts and upper guide bearing seat. Unit assembly: before assembly, the rust and dirt of each component should be cleaned, and the sealant should be coated on each mating surface and fastener, and then assembled in the opposite order of disassembly (the movement of the motor shaft after assembly is about one millimeter), after the assembly is completed, the coupling should be flexibly rotated, and then the filter element should be placed for testing. Each time the underwater electric pump has been used for one year, or less than one year but has been immersed for two years, it must be disassembled and inspected in accordance with Article 5 and replace the worn parts.

1, wepụta mmiri n'ime oghere moto (karịsịa n'oge oyi iji gbochie moto ahụ ka ọ ghara ịnwụ), ma kee eriri ahụ nke ọma.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, ogologo oge ojiji kwesịrị ịṅa ntị na nchara mgbochi nke submersible nfuli.

- impeller

- Ogwe aka

- Roba aro ogwe aka

-

mgbanaka akara

01 Mmiri olulu mmiri miri emi

02 Mmiri mmiri dị elu

03 mmiri mmiri ugwu

04 ụlọ elu mmiri

05 Agricultural ogbugba mmiri n'ubi

06 ogbugba mmiri n'ubi

07 oriri mmiri osimiri

08 mmiri ụlọ