This series of fountain pump is a special fountain pump developed by our factory. The pump motor core is made of high quality cold rolled silicon steel, which makes the pump more efficient, has good magnetic conductivity, and does not produce heat when starting frequently. The two ends of the motor rotor are equipped with alloy copper sleeves with water as lubricant. Stainless steel bushings replace ball bearings, avoiding the problems of easy rust of ball bearings and burnout of motor due to lack of oil and wear. Most suitable for music fountain, all models can be used horizontally.

1, ike ọkọnọ: atọ-adọ AC 380V ( ndidi + / - 5%), 50HZ ( ndidi + / - 1%).

2, ogo mmiri:

(1) water temperature is not higher than 20 °C;

(2) ọdịnaya adịghị ọcha siri ike (oke oke) adịghị elu karịa 0.01%;

(3) PH uru (pH) 6.5-8.5;

(4) hydrogen sulfide ọdịnaya abụghị ihe karịrị 1.5mg / L;

(5) Ọdịnaya ion chloride adịghị elu karịa 400mg/L.

3, moto na-emechi ma ọ bụ mmiri jupụtara mmiri Ọdịdị, tupu eji submersible moto oghere ga-ejupụta na mmiri dị ọcha, iji gbochie ụgha zuru, na mgbe ahụ ikesiike mmiri injection, ikuku ntọhapụ bolts, ma ọ bụghị ekwe ka iji.

4, mgbapụta mmiri na-agbapụta mmiri ga-ejupụta kpamkpam n'ime mmiri, omimi mmiri adịghị agafe 70m, ala nke mmiri na-esi na ala nke olulu mmiri adịghị erughị 3m.

5, mmiri mmiri nke ọma ga-enwe ike izute mmepụta mmiri na-emepụta mmiri na-arụ ọrụ na-arụ ọrụ na-aga n'ihu, a ga-achịkwa mmepụta mmiri na-emepụta mmiri na 0.7 - 1.2 ugboro nke a kwadoro.

6, olulu mmiri kwesịrị ịdị ogologo, enweghị ike iji ma ọ bụ tụfuo mgbapụta submersible, naanị iji kwụ ọtọ.

7, mgbapụta nke submersible ga-adaba na eriri dị ka ihe ndị a chọrọ, na ngwaọrụ nchebe nke mpụga.

8, a na-amachibido mgbapụta ahụ nke ọma na-enweghị igwe nyocha enweghị mmiri

| Nlereanya | Ọsọ (m3/h) | Isi (m) |

Ọsọ ntụgharị (mgbanwe/atụ) |

Mgbapu mmiri(%) | Mwepu dayameta (mm) |

Ọdabara nke ọma dayameta (mm) |

Enyere aha power(KW) |

Enyere aha voltaji (V) |

Enyere aha ugbu a (A) |

Ịrụ moto (%) | power factorcosφ | Nkeji Nha radial kacha (mm) |

kwuo | |||||||||

| 250QJ50-40 | 50 | 40 | 2875 | 72 | 80 | 250n'elu | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 233 | ||||||||||

| 250QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | |||||||||||||||||

| 250QJ50-80 | 80 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ50-100 | 100 | 22 | 47.9 | 83.0 | 0.84 | |||||||||||||||||

| 250QJ50-120 | 120 | 25 | 53.8 | 84.0 | 0.84 | |||||||||||||||||

| 250QJ50-140 | 140 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ50-160 | 160 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ50-200 | 200 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ50-240 | 240 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ50-280 | 280 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ50-320 | 320 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ50-400 | 400 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ50-440 | 440 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ63-40 | 63 | 40 | 2875 | 74 | 80 | 250n'elu | 11 | 380 | 25.8 | 79.0 | 0.82 | 233 | ||||||||||

| 250QJ63-60 | 60 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ63-80 | 80 | 22 | 47.9 | 83.0 | 0.84 | |||||||||||||||||

| 250QJ63-100 | 100 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ63-120 | 120 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ63-160 | 160 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ63-200 | 200 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ63-220 | 220 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ63-260 | 260 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ63-300 | 300 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ63-360 | 360 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ80-20 | 80 | 20 | 2875 | 75 | 100 | 250n'elu | 7.5 | 380 | 18.0 | 78.0 | 0.81 | 233 | ||||||||||

| 250QJ80-40 | 40 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 250QJ80-60 | 60 | 22 | 47.9 | 83.0 | 0.84 | |||||||||||||||||

| 250QJ80-80 | 80 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ80-100 | 100 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ80-120 | 120 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ80-160 | 80 | 160 | 2875 | 75 | 100 | 250n'elu | 55 | 380 | 114.3 | 86.0 | 0.85 | 233 | ||||||||||

| 250QJ80-180 | 180 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ80-200 | 200 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ80-240 | 240 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ80-280 | 280 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ100-18 | 100 | 18 | 2875 | 75 | 100 | 250n'elu | 7.5 | 380 | 18.0 | 78.0 | 0.81 | 233 | ||||||||||

| 250QJ100-36 | 36 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 250QJ100-54 | 54 | 25 | 53.8 | 84.0 | 0.84 | |||||||||||||||||

| 250QJ100-72 | 72 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ100-90 | 90 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ100-108 | 108 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ100-126 | 126 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ100-144 | 144 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ100-162 | 162 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ100-198 | 198 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ100-216 | 216 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-16 | 125 | 16 | 2875 | 76 | 125 | 250n'elu | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 233 | ||||||||||

| 250QJ125-32 | 32 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ125-48 | 48 | 25 | 53.8 | 84.0 | 0.84 | |||||||||||||||||

| 250QJ125-64 | 64 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ125-80 | 80 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ125-96 | 96 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ125-112 | 112 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ125-128 | 128 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-160 | 160 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-176 | 176 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-192 | 192 | 110 | 219.6 | 87.5 | 0.87 | |||||||||||||||||

| 250QJ140-15 | 140 | 15 | 2875 | 76 | 125 | 250n'elu | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 233 | ||||||||||

| 250QJ140-30 | 30 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ140-45 | 45 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ140-60 | 60 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ140-75 | 45 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ140-90 | 90 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ140-105 | 140 | 105 | 2875 | 76 | 125 | 250n'elu | 63 | 380 | 131.0 | 86.0 | 0.85 | 233 | ||||||||||

| 250QJ140-120 | 120 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ140-150 | 150 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ140-165 | 165 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ140-180 | 180 | 110 | 219.6 | 87.5 | 0.87 | |||||||||||||||||

| 250QJ200-20 | 200 | 20 | 2875 | 75 | 150 | 250n'elu | 18.5 | 380 | 40.8 | 82.0 | 0.84 | 233 | ||||||||||

| 250QJ200-40 | 40 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ200-60 | 60 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ200-80 | 80 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ200-100 | 100 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ200-120 | 120 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ200-140 | 140 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, n'ụzọ doro anya dị ka ndokwa nke mgbapụta ebuli, eruba nso nke ojiji, iji gbochie ala eruba ma ọ bụ elu ebuli pumping ike, mkpali ibu na akụkụ ndị ọzọ nke eyi, moto bufee ọkụ.

6, after the pump down the well, the measurement of the motor to the ground insulation resistance should not be less than 100M, after the start to observe the voltage and current, check the motor winding insulation, whether in line with the requirements; pump storage location temperature if less than freezing point, should be dry the motor cavity water, prevent the motor cavity water ice damage caused by low temperature.

The introduction and structure of this pump product mainly include pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor part is mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand ring, water inlet section, lead cable and other components. The main characteristics of this pump product include the use of water-cooled wet submersible three-phase asynchronous motor, the motor cavity is filled with clean water to cool the motor and lubricate the bearing, the pressure regulating diaphragm at the bottom is used to adjust the expansion and contraction pressure difference of the internal water caused by the change of the temperature rise of the motor. In order to prevent the sand particles in the well water from entering the motor, two oil seals are installed on the upper end of the motor shaft extension, and the sand ring is installed to form a sand prevention structure. In order to avoid the pump shaft jumping at startup, the pump shaft and the motor shaft are connected together through the coupling, and the thrust bearing is installed at the lower part of the motor. The motor and pump bearing lubrication adopts water lubrication. The stator winding of the motor adopts high quality submersible motor winding, with high insulation performance. The pump adopts computer CAD design, simple structure and superior technical performance.

(1) Nkwadebe tupu echichi:

1. Lelee ma mgbapụta submersible na-ezute ọnọdụ ojiji yana oke akọwapụtara na ntuziaka.

2. Iji obiect dị arọ nke nwere dayameta hà nhata kachasị elu nke mgbapụta mmiri na-ekpuchi mmiri, tụọ ma inneldiameter nke olulu mmiri ahụ nwere ike dabara na mgbapụta mmiri, ma tụọ ma omimi nke ọma na-emezu ihe achọrọ nrụnye.

3. Lelee ma olulu mmiri ahụ ọ dị ọcha ma mmiri olulu mmiri ahụ ọ na-asọ oyi. Ejila mgbapụta ọkụ eletrik na-eme ka mmiri na-asachapụ apịtị welor na mmiri ájá ka ịzenarị mmebi nke mgbapụta ọkụ eletrik n'oge.

4. Lelee ma ọnọdụ nke welhead echichi mwekota dabara na ma ọ nwere ike iguzogide qualty nke dum unit.

5. Lelee ma ọ bụrụ na akụrụngwa mgbapụta submersible zuru ezu ma wụnye ya nke ọma dị ka eserese mgbakọ na mwepụ na akwụkwọ ntuziaka Wepụ ihuenyo nzacha ma gbanwee njikọ ahụ iji hụ ma ọ na-agbagharị na-agbanwe agbanwe.

6. Kpochapụ ihe nkedo mmiri ma jupụta oghere moto na mmiri dị ọcha, nke na-adịghị emebi emebi (dee. jide n'aka na ị ga-agbanye ya), wee mee ka mmiri sie ike. Mgbe awa 12 nke ịgbanye mmiri gasịrị, nguzogide mkpuchi nke moto ekwesịghị ịbụ ihe na-erughị 150M Q mgbe a tụrụ ya na tebụl ịma jijiji 500V.

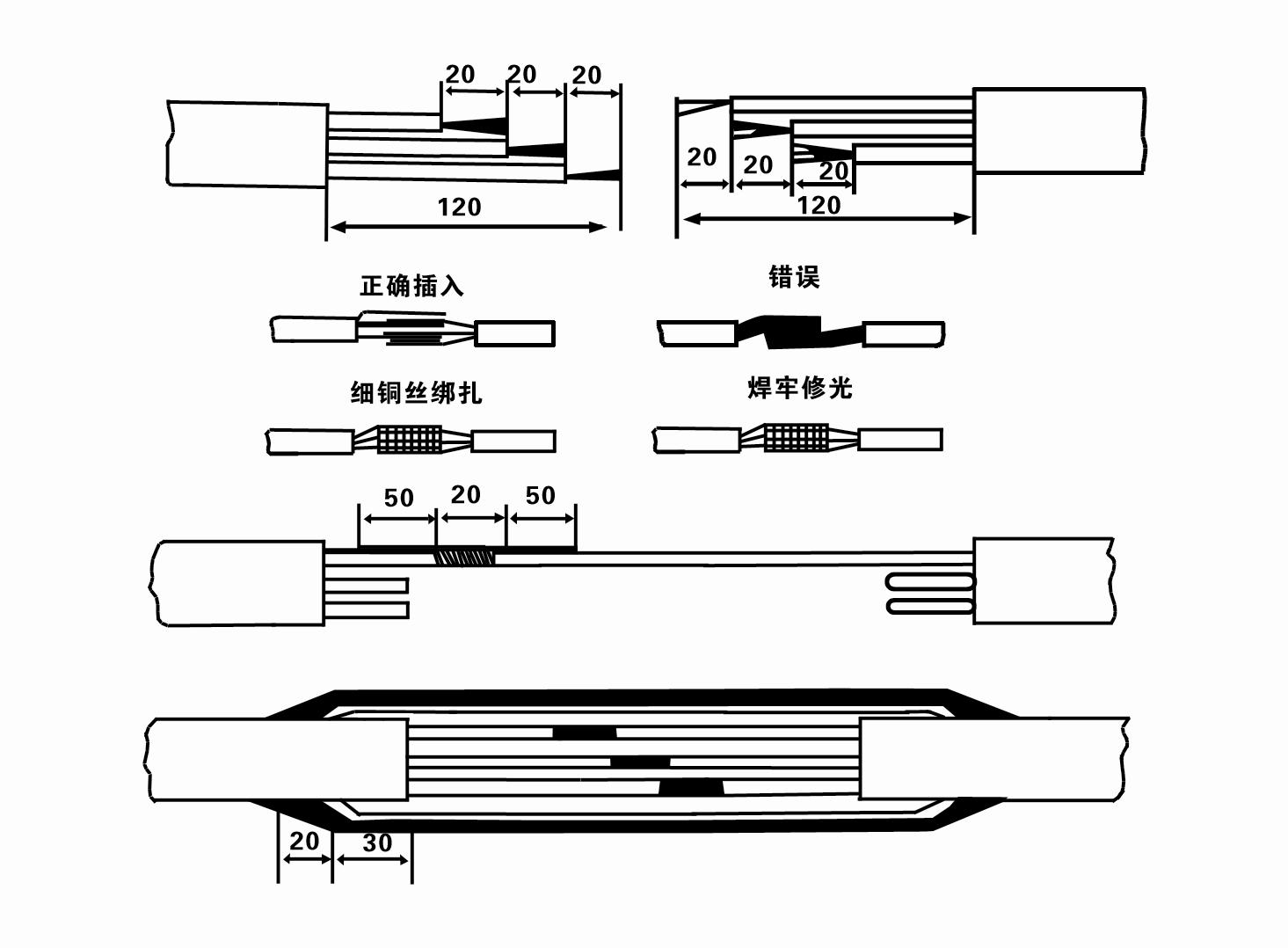

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Eserese usoro wiring cable nke agbakwunyere bụ nke a:

8. Jiri multimeter chọpụta ma ejikọrọ wires nke atọ na ma nkwụsi ike DC ọ dị oke nhata.

9. Lelee ma ikike sekit na transformer bubigara ibu, wee jikọọ ihe ngbanwe mkpuchi ibufe ma ọ bụ akụrụngwa mmalite. Hụ Tebụl 2 maka ụdị ụdị dị iche iche, wee wụsa ịwụ mmiri n'ime mgbapụta mmiri si na mmiri mgbapụta mmiri iji mee ka mmanu rọba dị na mgbapụta ahụ, wee debe mgbapụta ọkụ eletrik nke nwere ike ime ka ọ kwụ ọtọ na kwụ ọtọ. Malite (ọ bụghị ihe karịrị otu sekọnd) ma lelee ma ntụzịaka stereị ọ dabara na akara stereị. Ọ bụrụ na ọ bụghị, gbanwee njikọ abụọ ọ bụla nke eriri ụzọ atọ. Mgbe ahụ wụnye nzacha ma kwadebe ka ị gbadaa n'olulu mmiri ahụ. Ọ bụrụ na ejiri ya n'oge pụrụ iche (dịka ọwa mmiri, ọwa mmiri, osimiri, ọdọ mmiri, ọdọ mmiri, wdg), mgbapụta ọkụ eletrik ga-agbanyerịrị nke ọma.

(2) Akụrụngwa na akụrụngwa ntinye:

1. Otu ụzọ na-ebuli agbụ maka ihe karịrị tọn abụọ.

2. A tripod nwere ogologo kwụ ọtọ na-erughị mita anọ.

3. Ụdọ abụọ kwụgidere (ụdọ waya) nke nwere ike ibu ibu ihe karịrị otu ton (nwere ike ibu ibu nke nfuli mmiri zuru ezu).

4. Wụnye ụzọ abụọ nke clamps (splints).

5. Wrenches, hammers, screwdrivers, eletriki ngwaọrụ na ngwá, wdg.

(3) Nwụnye mgbapụta ọkụ eletrik:

1. E gosipụtara eserese nrụnye nke mgbapụta ọkụ eletrik submersible na eserese 2. A na-egosipụta akụkụ ntinye kpọmkwem na Tebụl 3 "Ndepụta nke nrụnye akụkụ nke mgbapụta ọkụ eletrik".

2. Enwere ike ibunye nfuli eletriki na-ekpuchi isi na isi ihe na-erughị mita 30 ozugbo n'ime olulu mmiri site na iji ụdọ na eriri waya ma ọ bụ eriri hemp ndị ọzọ nwere ike iburu igwe zuru oke nke igwe dum, ọkpọkọ mmiri na mmiri na ọkpọkọ.

3. Nfuli nke nwere isi ihe karịrị mita 30 na-eji ọkpọkọ ígwè, na usoro ntinye bụ nke a:

① Jiri ihe nkedo iji kpoo njedebe elu nke akụkụ mgbapụta mmiri (a na-ejikọta moto na mmiri mgbapụta n'oge a), bulite ya na agbụ nke nghọta, ma jiri nwayọọ nwayọọ kechie ya n'ime olulu mmiri ruo mgbe ịtinye ihe nkedo na isi mmiri ma wepụ ya. nghọta yinye.

② Jiri ụzọ mkpị ọzọ kụchie ọkpọkọ, were yinye kwụgidere 15 cm pụọ na flange, wee wetuo ya nwayọ. N'etiti ọkpọkọ flange na mgbapụta flange Tinye ihe mgbochi rọba n'ebe ma mee ka ọkpọkọ ahụ sie ike ma gbapụta ya nke ọma na bolts, mkpụrụ na mmiri mmiri.

③ Welite obere mgbapụta submersible, wepụ ihe nkedo dị na nsọtụ elu nke mgbapụta mmiri ahụ, kechie eriri ahụ nke ọma na ọkpọkọ mmiri na teepu rọba, ma jiri nwayọọ nwayọọ kechie ya ruo mgbe etinyere mkpọ ahụ n'isi olulu mmiri.

④ Jiri otu usoro ahụ kee ọkpọkọ mmiri niile n'ime olulu mmiri.

⑤ Mgbe ejikọtara eriri na-eduga na njikwa njikwa, a na-ejikọta ya na ọkụ ọkụ nke atọ.

(4) Ihe ị ga-ahụ n'oge echichi:

1. Ọ bụrụ na achọpụtara ihe mgbagwoju anya n'oge usoro mgbapụta ahụ, tụgharịa ma ọ bụ dọrọ ọkpọkọ mmiri iji merie ebe nkwụsị. Ọ bụrụ na usoro dị iche iche ka na-arụ ọrụ, biko Amanyela mgbapụta ahụ ka ọ ghara imebi mgbapụta ọkụ eletrik na olulu mmiri.

2. N'oge echichi, a ga-etinye ihe mkpuchi rọba na flange nke ọkpọkọ ọ bụla ma mee ka ọ sie ike.

3. Mgbe a na-agbanye mmiri mmiri n'ime olulu mmiri ahụ, a ga-etinye ya n'etiti ọkpọkọ nke ọma iji gbochie mgbapụta ahụ na-agba ọsọ megide mgbidi olulu mmiri ruo ogologo oge, na-eme ka mgbapụta ahụ na-ama jijiji na moto na-ekpochapụ ma gbaa ọkụ. .

4. Kpebie omimi nke mgbapụta mmiri na ala nke olulu mmiri dịka ájá na-asọ asọ na ọnọdụ silt nke olulu mmiri ahụ. Eliela mgbapụta n'ime apịtị. Ebe dị anya site na mgbapụta mmiri na ala nke olulu mmiri n'ozuzu ọ bụghị ihe na-erughị mita 3 (lee foto 2).

5. Ihe omimi ntinye mmiri nke mgbapụta mmiri kwesịrị ịbụ ihe na-erughị 1-1.5 mita site na mmiri dị ike na ọnụ mmiri ntinye mmiri (lee foto 2). Ma ọ bụghị ya, a ga-emebi bearings mgbapụta mmiri n'ụzọ dị mfe.

6. Ebuli nke mgbapụta mmiri enweghị ike ịdị ala. Ma ọ bụghị ya, ekwesịrị itinye valvụ ọnụ ụzọ ámá na pipeline mmiri nke ọma iji chịkwaa mgbapụta mgbapụta na ebe a na-agbapụta agbapụta iji gbochie moto ahụ ka ọ ghara ibufe ma gbaa ọkụ n'ihi nnukwu ọnụọgụ mmiri.

7. Mgbe mgbapụta mmiri na-agba ọsọ, mmepụta mmiri kwesịrị ịdị na-aga n'ihu na ọbụna, nke dị ugbu a kwesịrị ịdị na-eguzosi ike (n'okpuru ọnọdụ ọrụ a kwadoro, n'ozuzu ọ dịghị ihe karịrị 10% nke akara ugbu a), na e kwesịghị inwe mkpọtụ ma ọ bụ mkpọtụ. Ọ bụrụ na enwere ihe na-adịghị mma, a ga-akwụsị igwe ahụ iji chọpụta ihe kpatara ya ma kpochapụ ya.

8. Mgbe ị na-etinye ya, ṅaa ntị na ntọala nke waya mgbanaka moto (lee foto 2). Mgbe ọkpọkọ mmiri bụ ọkpọkọ ígwè, dupụta ya site na mkpọchi olulu mmiri; mgbe ọkpọkọ mmiri bụ ọkpọkọ plastik, duga ya site na akara ala nke mgbapụta eletrik.

After the installation of the underwater pump, the insulation resistance and three-phase continuity of the switch face should be rechecked, and the connection between the instrument and the start device should be checked for any errors. If there is no problem, you can start to test the machine. After the start, observe whether the indication readings of each instrument are correct. If the rated voltage and current specified on the nameplate are exceeded, observe whether the pump has noise or vibration. If everything is normal, it can be put into operation. After the first operation of the pump for four hours, the motor should be shut down and tested for thermal insulation resistance quickly. Its value should not be less than 0.5 megaohm. After stopping the pump, it should be restarted after an interval of five minutes to prevent the water column in the pipeline from completely reversing and causing the motor to burn out due to excessive current. After the pump is put into normal operation, in order to prolong its service life, it is necessary to check regularly whether the supply voltage, running current and insulation resistance are normal. If the following conditions are found, the machine should be shut down immediately to eliminate the fault: the current exceeds 20% under rated working conditions; the dynamic water level drops to the inlet section, resulting in intermittent drainage; the underwater pump becomes violently vibrating or making noise; the supply voltage is lower than 340 volts; a fuse is blown out; the water pipe is damaged; the motor's thermal insulation resistance to the earth is less than 0.5 megaohm. The sequence of disassembly is: untie the cable fastening, remove the pipeline part, remove the line protection plate, screw down the water discharge bolt and discharge all the water in the motor chamber, remove the filter and loosen the coupling fixing screw of the motor shaft. The sequence of disassembly of the pump is: (see Figure 1) inlet section, impeller, guide housing, impeller, check the valve body. When removing the impeller, use special tools to loosen the taper sleeve of the impeller. Avoid bending the pump shaft and damaging the components throughout the process. The disassembly process of the motor is: (see Figure 1) put the motor on the platform, and remove the bolts, base, shaft head lock nut, thrust plate, key, lower guide plate (transverse bolt), bearing seat, screw knife seat from the bottom of the motor in order (take care not to damage the winding), and finally remove the connecting part and the upper guide bearing seat. Before assembling the unit, the rust and dirt of each part should be cleaned, and the sealant should be applied to each mating surface and fastener, and then assembled in reverse order of disassembly (the movement of the motor shaft after assembly is about one millimeter). After assembly, the coupling should be rotated flexibly and put on the filter for test. Once a year, or if less than a year of operation but has been immersed for two years, the underwater electric pump must be disassembled for maintenance in accordance with Article 5 and replace worn parts to ensure the normal operation and durability of the pump.

1, wepụta mmiri n'ime oghere moto (karịsịa n'oge oyi iji gbochie moto ahụ ka ọ ghara ịnwụ), ma kee eriri ahụ nke ọma.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, ogologo oge ojiji kwesịrị ịṅa ntị na nchara mgbochi nke submersible nfuli.

- impeller

- Ogwe aka

- Roba aro ogwe aka

-

mgbanaka akara

01 Mmiri olulu mmiri miri emi

02 Mmiri mmiri dị elu

03 mmiri mmiri ugwu

04 ụlọ elu mmiri

05 Agricultural ogbugba mmiri n'ubi

06 ogbugba mmiri n'ubi

07 oriri mmiri osimiri

08 mmiri ụlọ