Well-designed sand-proof large flow water system, using water-immersed motor, no oil after burning machine does not pollute water. Suitable for freshwater aquaculture extraction of river water, sea water oxygen. Flow range 100-1000m3/h, lift 3-100m, power 3-100KW.

1, mana lako: ʻekolu-phase AC 380V (hoʻomanawanui + / - 5%), 50HZ (hoʻomanawanui + / - 1%).

2, ka maikaʻi o ka wai:

(1) water temperature is not higher than 20 °C;

(2) ʻaʻole ʻoi aku ka nui o nā mea haumia paʻa (mass ratio) ma mua o 0.01%;

(3) Waiwai PH (pH) 6.5-8.5;

(4) ʻAʻole ʻoi aku ka nui o ka hydrogen sulfide ma mua o 1.5mg/L;

(5) ʻAʻole ʻoi aku ka nui o ka ʻona chloride ma mua o 400mg/L.

3, pani ʻia ka mīkini a i ʻole ka wai i piha i ka wai, ma mua o ka hoʻohana ʻana i ka lua kaʻa submersible pono e piha i ka wai maʻemaʻe, i mea e pale ai i ka hoʻopunipuni piha, a laila hoʻopaʻa i ka wai wai, hoʻokuʻu i nā bolts ea, inā ʻaʻole ʻae ʻia e hoʻohana.

4, pono e hoʻopiha piha ʻia ka pauma submersible i ka wai, ʻaʻole ʻoi aku ka hohonu o ka luʻu ʻana ma mua o 70m, ʻo ka lalo o ka paila submersible mai lalo o ka luawai ʻaʻole i emi iho ma mua o 3m.

5, hiki i ka wai punawai ke hoʻokō i ka hoʻopuka ʻana o ka wai paila submersible a me ka hoʻomau ʻana i ka hana, pono e hoʻokele ʻia ka hoʻopuka wai wai submersible ma 0.7 - 1.2 mau manawa o ka kahe i helu ʻia.

6, pono e pololei ka luawai, ʻaʻole hiki ke hoʻohana ʻia ka pauma submersible a hoʻolei ʻia, hoʻohana kū pololei wale nō.

7, pono e hoʻohālikelike ʻia ka pauma submersible me ke kaula e like me nā koi, a me ka ʻōnaehana pale overload waho. 8, pāpā loa ʻia ka paila me ka ʻole o ka mīkini hoʻāʻo wai ʻole

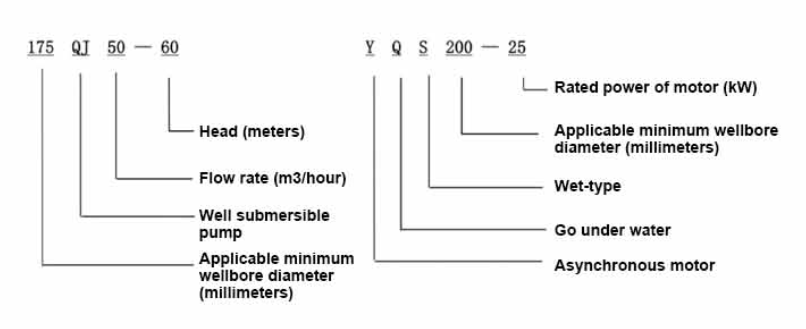

| 200 QS submersible pump hana papaaina ʻAʻole maʻamau i hoʻopilikino ʻia |

||||||||

| kumu hoʻohālike | kumu hoʻohālike | |||||||

| QS5-70-2.2KW | QS10-52-4KW | |||||||

| QS5-90-3KW | QS10-70-5.5KW | |||||||

| QS5-108-4KW | QS10-90-7.5KW | |||||||

| QS5-126-5.5KW | QS10-108-7.5KW | |||||||

| QS5-144-5.5KW | QS20-40-4KW | |||||||

| QS5-160-7.5KW | QS20-54-5.5KW | |||||||

| QS5-180-7.5KW | QS20-65-7.5KW | |||||||

| QS10-36-2.2KW | QS20-81-7.5KW | |||||||

| QS10-54-3KW | QS32-13-2.2KW | |||||||

| QS10-70-4KW | QS32-26-4KW | |||||||

| QS10-90-5.5KW | QS32-52-7.5KW | |||||||

| QS10-108-5.5KW | QS40-39-7.5KW | |||||||

| QS10-126-7.5KW | QS40-13-4KW | |||||||

| QS10-140-7.5KW | QS40-26-5.5KW | |||||||

| QS15-38-3KW | QS50-13-4KW | |||||||

| QS15-54-4KW | QS50-26-5.5KW | |||||||

| QS15-65-5.5KW | QS50-39-7.5KW | |||||||

| QS15-81-5.5KW | QS63-12-4KW | |||||||

| QS15-100-7.5KW | QS63-24-7.5KW | |||||||

| QS20-30-3KW | QS80-11-4KW | |||||||

| QS20-45-4KW | QS80-22-7.5KW | |||||||

| QS20-60-5.5KW | QS10-88-7.5KW | |||||||

| QS20-75-7.5KW | QS10-105-7.5KW | |||||||

| QS20-81-7.5KW | QS40-52-11KW | |||||||

| QS10-198-15KW | QS50-60-11KW | |||||||

| QS10-160-9.2KW | QS65-30-9.2KW | |||||||

| QS15-180-15KW | QS80-28-9.2KW | |||||||

| QS10-180-11KW | QS125-15-7.5KW | |||||||

This well submersible pump is a clean water pump. It is strictly prohibited to excavate new wells, discharge sediments and muddy water. The voltage rating of the pump is 380/50 hertz, and other voltage ratings are not allowed. The submersible motor needs to be customized, and the underground cable must be waterproof cable, and must be equipped with starting equipment, such as distribution box, etc. The starting equipment should have common motor comprehensive protection functions, such as short circuit overload protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. In order to prevent abnormal conditions, the protection device should be timely trip. During the installation and use process, the pump must be reliably grounded. It is strictly prohibited to push and pull the switch when hands and feet are wet. The power supply must be cut off before installation and maintenance of the pump. An obvious "anti-electric shock" sign must be set up where the pump is used. Before going down the well or installing, the motor must fill the inner cavity with distilled water or non-corrosive clean cold water, and the inlet and outlet bolts must be tightened. When testing the pump, the pump cavity must be filled with water to lubricate the rubber bearings, and the instant start time shall not exceed one second to check whether the direction is correct. Pay attention to safety when lifting, and prevent the overturning of the pump from causing injury. Strictly according to the provisions of the pump lift and flow range, to prevent the pump in low lift when the large flow or in high lift when the large pull, resulting in serious wear and tear of thrust bearings and other parts, causing motor overload and burnout. After the pump into the well, the insulation resistance between the motor and the ground should not be less than 100MΩ, after the start of regular observation of voltage and current, and check whether the motor winding insulation meets the requirements; if the pump storage temperature below freezing, the water in the motor cavity should be discharged to prevent the cold temperature caused by the motor cavity water icing and damage the motor due to low temperature.

ʻO ka hoʻomaka pōkole o ka hoʻolālā: ʻo ka ʻāpana pauma ka mea nui o ka pump shaft, impeller, diversion shell, rubber bearing, check valve body (nā ʻāpana koho) a me nā mea ʻē aʻe. ʻO ka ʻāpana kaʻa ka mea nui i hoʻokumu ʻia me ka base, kaomi hoʻoponopono kiʻiʻoniʻoni, pahu pahu, pahu pahu, ka noho alakaʻi haʻahaʻa haʻahaʻa, stator, rotor, alakaʻi alakaʻi i luna noho, one apo, ʻāpana wai komo, kelepona a me nā mea ʻē aʻe.

ʻO nā hiʻohiʻona nui o ka huahana:

1, ʻO ke kaʻa he wai piha piha i ka wai submersible ʻekolu-phase asynchronous motor, piha ka pahu kaʻa i ka wai maʻemaʻe, hoʻohana ʻia e hōʻoluʻolu i ka mīkini a lubricate i ka bearing, hoʻohana ʻia ke kiʻi hoʻoponopono kaomi ma lalo o ka kaʻa e hoʻoponopono. ka hoʻonui a me ka ʻokoʻa o ke kaomi ʻana o ka wai i loko o ke kino ma muli o ka hoʻololi ʻana o ka piʻi ʻana o ka wela o ke kaʻa.

2, I mea e pale aku ai i ke one i loko o ka wai punawai mai ke komo ʻana i ke kaʻa, ua hoʻolako ʻia ka ʻaoʻao o luna o ka pahu kaʻa me nā sila ʻaila ʻelua, a ua hoʻokomo ʻia kahi apo one e hana i kahi ʻano pale one.

3, I mea e pale ʻole ai i ka holo ʻana o ka pahu pāpaʻi i ka wā e hoʻomaka ai, ua hoʻopili ʻia ka pahu pāpaʻi a me ka pahu kaʻa e ka hui ʻana, a ua hoʻokomo ʻia kahi pahu pahu kiʻekiʻe ma ka ʻaoʻao haʻahaʻa o ke kaʻa.

4, ʻO ka lubrication o ka kaʻa a me ka pahū pahū he wai lubrication.

5, Hana ʻia ka wili kaʻa kaʻa stator me ke ʻano kiʻekiʻe o ka submersible motor winding wire, me ka hana insulation kiʻekiʻe.

6, Hoʻolālā ʻia ka paila e ka CAD kamepiula, me ka hana maʻalahi a me ka hana ʻenehana maikaʻi.

(1) Hoʻomākaukau ma mua o ke kau ʻana:

1. E nānā inā kūpono ka pauma submersible i nā kūlana hoʻohana a me ka laulā i ʻōlelo ʻia ma ka manual.

2. Ma ka hoʻohana ʻana i kahi obiect kaumaha me ke anawaena e like me ke anawaena o waho loa o ka pauma hoʻohaʻahaʻa, e ana inā hiki i ka inneldiameter o ka luawai ke hoʻokomo i ka pauma hoʻoheheʻe ʻia, a e ana i ka hoʻokō ʻana o ka hohonu i nā koi hoʻokomo.

3. E nānā i ka maʻemaʻe o ka luawai a me ka wai o ka pūnāwai. Mai hoʻohana i ka pauma uila e holoi ai i ka ʻōpala welor a me ka wai one no ka pale ʻana i ka pōʻino mua o ka pauma uila.

4. E nānā inā kūpono ke kūlana o ka hoʻopili welhead a inā hiki iā ia ke kū i ke kūlana o ka ʻāpana holoʻokoʻa.

5. E nānā inā ua paʻa a hoʻokomo pono ʻia nā ʻāpana pauma submersible e like me ke kiʻikuhi hui ma ka manual.

6. Wehe i ka wili wai a hoʻopiha i ka lua kaʻa me ka wai maʻemaʻe, ʻaʻole ʻino (e hoʻomaopopo. Ma hope o 12 mau hola o ka wai ʻana, ʻaʻole pono e emi ka pale insulation o ke kaʻa ma mua o 150M Q ke ana ʻia me kahi papa haʻalulu 500V.

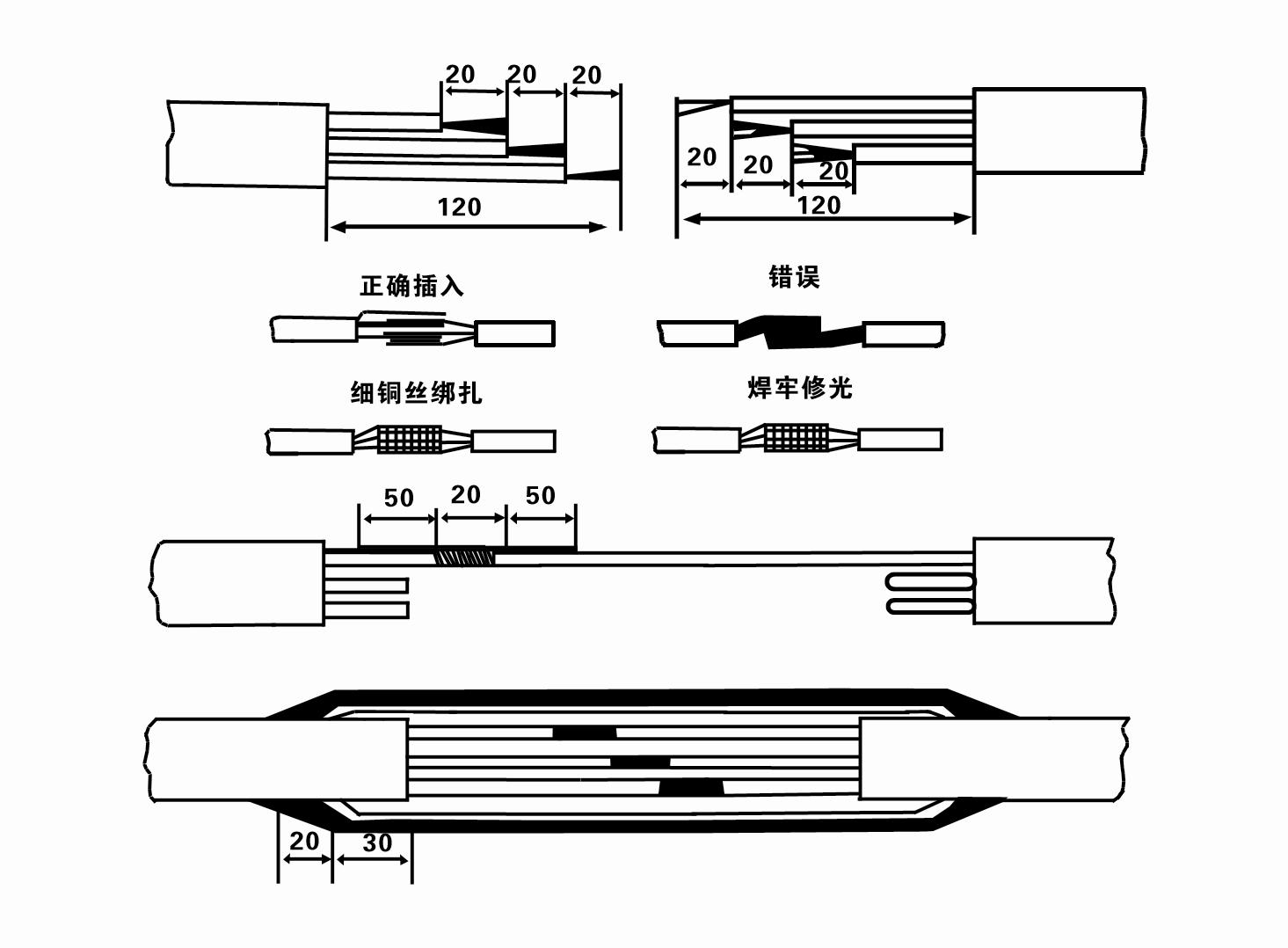

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

ʻO ke kiʻikuhi kaʻina hana uwila i hoʻopili ʻia penei:

8. E hoʻohana i ka multimeter no ka nānā ʻana inā pili ʻia nā uea ʻekolu ʻāpana a inā ʻaʻole kaulike ke kūpaʻa DC.

9. E nānā inā ua hoʻonui ʻia ka mana kaapuni a me ka mea hoʻololi, a laila hoʻohui i ke kī hoʻomalu overload a i ʻole nā mea hoʻomaka. E nānā i ka Papa 2 no nā hi'ohi'ona kiko'ī, a laila, e ninini i ka bākeke wai i loko o ka pā wai mai ka puka wai e ho'oma'ama'a i ka pahu pahu i loko o ka pama, a laila e kau i ka pauma uwila i lalo i luna a pa'a. a e nānā inā pili ka hoʻokele me ka hōʻailona hoʻokele. Inā ʻaʻole, e hoʻololi i nā mea hoʻohui ʻelua o ke kaula ʻekolu. Inā hoʻohana ʻia i nā hanana kūikawā (e like me nā ʻauwai, nā ʻauwai, nā muliwai, nā loko, nā loko, a me nā mea ʻē aʻe), pono e hoʻopaʻa ʻia ka paila uila.

(2) Mea hoʻokomo a me nā mea hana:

1. Hoʻokahi mau kaulahao hāpai no ʻelua mau tona.

2. ʻO kahi tripod me ke kiʻekiʻe kū i lalo o ʻehā mau mika.

3. ʻElua kaula kau (wire ropes) hiki ke kaumaha i ke kaumaha ma mua o hoʻokahi tona (hiki ke halihali i ke kaumaha o ka pahu wai piha).

4. E hoʻouka i ʻelua mau paʻi (splints).

5. Nā wrenches, hammers, screwdrivers, uila a me nā mea kani, etc.

(3) Hoʻokomo ʻia ka pauma uila:

1. Hōʻike ʻia ke kiʻikuhi hoʻonohonoho o ka pauma uila submersible ma ka Figure 2. Hōʻike ʻia nā ana hoʻonohonoho kikoʻī ma ka Papa 3 "List of Installation Dimensions of the Submersible Electric Pump".

2. Hiki ke hoʻokiʻekiʻe pololei ʻia nā paila uila me ke poʻo ma lalo o 30 mika i loko o ka pūnāwai me ka hoʻohana ʻana i nā paipu a me nā kaula uwea a i ʻole nā kaula hemp ʻē aʻe e hiki ai ke halihali i ke kaumaha piha o ka mīkini holoʻokoʻa, nā paipu wai, a me ka wai i loko o nā paipu.

3. ʻO nā pumps me ke poʻo i ʻoi aku ma mua o 30 mika e hoʻohana i nā paipu kila, a penei ka hoʻonohonoho ʻana:

①E hoʻohana i kahi pipili no ka hoʻopaʻa ʻana i ka ʻaoʻao o luna o ka ʻaoʻao o ka pauma wai (ua hoʻopili ʻia ke kaʻa a me ka pauma wai i kēia manawa), e hoʻokiʻekiʻe me ke kaulahao e kau ana, a nakinaki mālie i loko o ka luawai a kau i ka paʻi ma ke poʻo punawai a wehe i ke kaulahao. kaulahao e kau ana.

② E hoʻohana i nā paipu ʻē aʻe e hoʻopaʻa i ka paipu, e hoʻokiʻekiʻe me ke kaulahao e kau ana ma kahi mamao o 15 knm mai ka lehelehe, a e hoʻohaʻahaʻa mālie. Ma waena o ka flange paipu a me ka flange pump E hoʻopaʻa i ka pā hao a hoʻopaʻa i ka paipu a paʻa pono me nā bolts, nati a me nā mea holoi puna.

③ E hoʻokiʻekiʻe iki i ka pauma hoʻohaʻahaʻa, e wehe i ke kaula ma ka ʻaoʻao o luna o ka pā wai, e hoʻopaʻa paʻa i ke kaula i ka paipu wai me ka lipine plastik, a nakinaki mālie i lalo a kau ʻia ka paʻi ma ka luawai.

④E hoʻohana i ke ʻano like e hoʻopaʻa ai i nā paipu wai a pau i loko o ka pūnāwai.

⑤Ma hope o ka hoʻopili ʻia ʻana o ke kaula alakaʻi i waho i ka hoʻololi mana, ua hoʻopili ʻia i ka lako mana ʻekolu.

(4) Nā mea e nānā ai i ka wā e hoʻokomo ai:

1. Inā ʻike ʻia kahi mea hoʻopuʻi i ka wā o ka pahū ʻana, e hoʻohuli a huki paha i ka paipu wai no ka lanakila ʻana i ke kiko pahu. Inā ʻaʻole e holo nā ʻano hana like ʻole, e ʻoluʻolu, mai hoʻoikaika i ka pamu i lalo e pale aku i ka pōʻino o ka pauma uila a me ka luawai.

2. I ka wā o ka hoʻokomo ʻana, pono e kau ʻia kahi pā hao ma ka ʻaoʻao o kēlā me kēia paipu a paʻa pono.

3. Ke hoʻohaʻahaʻa ʻia ka paila wai i loko o ka pūnāwai, pono e hoʻokomo ʻia i waenakonu o ka paipu pūnāwai i mea e pale ai i ka holo ʻana o ka pamu i ka paia o ka pūnāwai no ka manawa lōʻihi, e hoʻonāwaliwali ai ka pamu a e kahili a wela ke kaʻa. .

4. E hoʻoholo i ka hohonu o ka paila wai a hiki i lalo o ka luawai e like me ke kahe ʻana o ke one a me ka lepo o ka luawai. Mai kanu i ka pamu i ka lepo. ʻO ka mamao mai ka pā wai a hiki i lalo o ka pūnāwai ʻaʻole i emi iho ma mua o 3 mika (e nānā i ke Kiʻi 2).

5. ʻAʻole emi ka hohonu o ke komo ʻana o ka wai ma lalo o 1-1.5 mika mai ke kiʻekiʻe o ka wai ikaika a hiki i ka node inlet wai (e nānā i ke Kiʻi 2). Inā ʻaʻole, hiki ke pohō maʻalahi nā bearings pump wai.

6. ʻAʻole hiki ke haʻahaʻa loa ka hāpai ʻana o ka paila wai. A i ʻole, pono e hoʻokomo ʻia kahi valve puka ma luna o ka pipeline wai punawai e hoʻomalu i ke kahe ʻana o ka paila ma ka helu kahe i helu ʻia e pale ai i ka hoʻonui ʻia ʻana o ke kaʻa a puhi ʻia ma muli o nā kahe kahe nui.

7. I ka holo ana o ka pauma wai, pono e hoomau ka puka ana o ka wai a me ke ano, pono ke kupaa (ma lalo o na kulana hana i heluia, ma ke ano, aole oi aku mamua o 10% o ka manawa i heluia), a aole e haalulu a walawala. Inā loaʻa kekahi mea ʻino, pono ke kāpae ʻia ka mīkini e ʻike i ke kumu a hoʻopau.

8. I ka wā e hoʻokomo ai, e hoʻolohe i ka hoʻonohonoho ʻana o ka uea hoʻopaʻa ʻia kaʻa (e nānā i ke Kiʻi 2). Inā he paipu kila ka paipu wai, e alakaʻi iā ia mai ka puʻu punawai; inā he paipu plastik ka paipu wai, e alakaʻi iā ia mai ka hōʻailona kumu o ka paila uila.

- 1.After the submersible electric pump is installed, recheck the insulation resistance and three-phase continuity from the switch, and check whether there are any errors in the connection of the instruments and starting equipment. If there are no problems, you can start the test machine. After starting, observe whether the indication readings of each instrument are correct. If the rated voltage and current specified on the nameplate are exceeded, observe whether the water pump has any noise or vibration. If everything is normal, it can be put into operation.

2. Four hours after the water pump is operated for the first time, the motor should be stopped and the thermal insulation resistance tested quickly. The value should be no less than 0.5 megohms.

3.After the water pump is stopped, it should be restarted after an interval of five minutes to prevent the water column in the pipe from flowing back completely and causing the motor to burn out due to excessive current.

4. After the water pump is put into normal operation, in order to extend its service life, it is necessary to regularly check whether the power supply voltage, operating current and insulation resistance are normal. If the following conditions are found, the machine should be shut down immediately to eliminate the fault.

①Under rated working conditions, the current exceeds 20%.

② The dynamic water level drops to the water inlet section, causing intermittent water discharge.

③The submersible pump vibrates violently or makes loud noise.

④The power supply voltage is lower than 340 volts.

⑤One phase of the fuse is burned out.

⑥The water pipe is damaged.

⑦The thermal insulation resistance of the motor to the ground is less than 0.5 megohms.

5. Unit disassembly:

① Untie the cable tether, remove the pipeline part, and remove the wire protection plate.

② Unscrew the water drain bolt and drain all the water in the motor cavity.

③Remove the filter and loosen the fixing screw on the coupling that fixes the motor shaft.

④ Unscrew the bolts connecting the water inlet section and the motor, and separate the water pump from the motor (pay attention to leveling the unit when separating to prevent the pump shaft from bending)

⑤The water pump disassembly sequence is: (see Figure 1) water inlet section, impeller, diversion shell, impeller... check valve body. When disassembling the impeller, use a special tool to first loosen the tapered sleeve that fixes the impeller. Avoid disassembly during the disassembly process. Bend the pump shaft and damage various parts.

⑥The motor disassembly process is: (See Figure 1) Place the motor on the platform, and remove the nuts, bases, shaft head locking nuts, thrust plates, keys, and lower guides on the stud bolts (tie rod bolts) in sequence from the bottom of the motor. bearing seat, stud bolts, and then take out the rotor (be careful not to

If the wire package is damaged), finally remove the connecting section and upper guide bearing seat.

⑦Unit assembly:

Before assembly, all parts should be cleaned of rust and dirt, and all mating surfaces and fasteners should be coated with sealant, and then assembled in the reverse order of disassembly (the amount of movement of the motor shaft after assembly is about one millimeter). After completion, the coupling should be flexible, and then put the filter on to test the machine.

6. Every time the submersible electric pump is operated for one year, or if it is operated for less than one year but has been submerged for two years, it should be disassembled and inspected in accordance with Article 5 to replace worn parts.

1, e hoʻoheheʻe i ka wai i loko o ka lua kaʻa (ʻoi loa i ka hoʻoilo e pale ai i ka hau mai ka hau), a nakinaki maikaʻi i ke kaula.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, pono ka hoʻohana lōʻihi e hoʻolohe i ka pale ʻana i ka ʻōpala o nā paila submersible.

- Mea hoʻolele

- Puʻu lima

- Ka lima lāʻau lāʻau

-

apo apo

01 Hoʻokomo wai hohonu

02 Waiwai kiʻekiʻe

03 lako wai mauna

04 hale kiaʻi wai

05 Ka wai mahiai

06 ka hoʻoulu ʻana i ka māla

07 hoʻokomo wai kahawai

08 wai hale