The variable frequency winding design ensures the motor's long-term smooth conversion operation between 1HZ-50HZ, energy saving and longer service life. This product stands out for its advanced technology and efficient performance, which can achieve energy-saving and environmentally friendly operation, while ensuring the stability and reliability of the motor for long-term use. Not only that, its design makes the product with a longer life, bringing more value to users. Whether in home applications or industrial fields, this motor can provide you with excellent performance to meet a variety of needs.

1,Power supply: three-phase AC 380V (tolerance + / - 5%), 50HZ (tolerance + / - 1%).

2, ikhwalithi yamanzi:

(1) water temperature is not higher than 20 °C;

(2) okuqukethwe kokungcola okuqinile (isilinganiso sobuningi) akukho ngaphezu kuka-0.01%;

(3) PH inani (pH) 6.5-8.5;

(4) okuqukethwe kwe-hydrogen sulfide akukhulu kuno-1.5mg/L;

(5) okuqukethwe kwe-chloride ion akukhulu kuno-400mg/L.

3, the motor is a closed or water-filled wet structure, before use the submersible motor cavity must be full of clean water, to prevent false full, and then tighten the water injection, air release bolts, otherwise not allowed to use

4, the submersible pump must be completely submerged in the water, the diving depth is not greater than 70m, the bottom of the submersible pump from the bottom of the well is not less than 3m.

5, ukugeleza kwamanzi omthombo kufanele kukwazi ukuhlangabezana nokuphuma kwamanzi kwepompo engaphansi kwamanzi nokusebenza okuqhubekayo, ukuphuma kwamanzi empompi engaphansi kwamanzi kufanele kulawulwe izikhathi ezingu-0.7 - 1.2 zokugeleza okulinganiselwe.

I-6, umthombo kufanele uqonde, ipompo ye-submersible ayikwazi ukusetshenziswa noma ilahlwe, ukusetshenziswa okuqondile kuphela.

7, iphampu engaphansi kwamanzi kufanele ifaniswe nekhebula ngokwezidingo, kanye nedivayisi yokuvikela ukugcwala ngokweqile kwangaphandle.

8, the pump is strictly prohibited without water no-load test machine.

| Imodeli | Ukugeleza (m3/h) | Ikhanda (m) |

Isivinini sokuzungeza (shintsha/iphuzu) |

Iphampu yamanzi(%) | I-Outlet ububanzi (mm) |

Isebenza kahle ububanzi(mm) |

Ikaliwe amandla (KW) |

Ikaliwe i-voltage(V) |

Ikaliwe yamanje (A) |

Ukusebenza kahle (%) | power factorcosφ | Iyunithi Usayizi weRadial Maximu(mm) |

Phawula | |||||||||

| 135QJ5-34 | 5 | 34 | 2850 | 40 | 135ngenhla | 1.5 | 380 | 4.23 | 128 | |||||||||||||

| 135QJ5-51 | 51 | 2.2 | 6.03 | |||||||||||||||||||

| 135QJ5-68 | 68 | 3 | 8.01 | |||||||||||||||||||

| 135QJ5-85 | 85 | 4 | 10.53 | |||||||||||||||||||

| 135QJ5-102 | 102 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ5-119 | 119 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ5-240 | 240 | 11 | 26.28 | |||||||||||||||||||

| 135QJ5-280 | 5 | 280 | 2850 | 40 | 135ngenhla | 13 | 380 | 30.87 | 128 | |||||||||||||

| 135QJ5-320 | 320 | 15 | 35.62 | |||||||||||||||||||

| 135QJ10-24 | 10 | 24 | 2850 | 50 | 135ngenhla | 1.5 | 380 | 4.23 | 128 | |||||||||||||

| 135QJ10-32 | 32 | 2.2 | 6.03 | |||||||||||||||||||

| 135QJ10-48 | 48 | 3 | 8.01 | |||||||||||||||||||

| 135QJ10-56 | 56 | 4 | 10.53 | |||||||||||||||||||

| 135QJ10-72 | 72 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ10-80 | 80 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ10-104 | 104 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ10-120 | 120 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ10-136 | 136 | 9.2 | 22.7 | |||||||||||||||||||

| 135QJ10-180 | 180 | 11 | 26.28 | |||||||||||||||||||

| 135QJ10-210 | 210 | 13 | 30.87 | |||||||||||||||||||

| 135QJ10-240 | 240 | 15 | 35.62 | |||||||||||||||||||

| 135QJ10-300 | 300 | 18.5 | 43.12 | |||||||||||||||||||

| 135QJ15-36 | 15 | 36 | 2850 | 50 | 135ngenhla | 2.2 | 380 | 6.03 | 128 | |||||||||||||

| 135QJ15-39 | 39 | 3 | 8.01 | |||||||||||||||||||

| 135QJ15-46 | 46 | 4 | 10.53 | |||||||||||||||||||

| 135QJ15-52 | 52 | 4 | 10.53 | |||||||||||||||||||

| 135QJ15-59 | 59 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ15-65 | 65 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ15-78 | 78 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ15-91 | 91 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ15-104 | 104 | 9.2 | 22.7 | |||||||||||||||||||

| 135QJ15-120 | 120 | 11 | 26.28 | |||||||||||||||||||

| 135QJ15-142 | 142 | 13 | 30.87 | |||||||||||||||||||

| 135QJ15-162 | 162 | 15 | 35.62 | |||||||||||||||||||

| 135QJ15-200 | 200 | 18.5 | 43.12 | |||||||||||||||||||

| 135QJ20-16 | 20 | 16 | 2850 | 50 | 135above | 2.2 | 380 | 6.03 | 128 | |||||||||||||

| 135QJ20-24 | 24 | 3 | 8.01 | |||||||||||||||||||

| 135QJ20-32 | 32 | 4 | 10.53 | |||||||||||||||||||

| 135QJ20-40 | 40 | 4 | 10.53 | |||||||||||||||||||

| 135QJ20-48 | 48 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ20-56 | 56 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ20-64 | 64 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ20-72 | 72 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ20-80135QJ20-100 | 80 | 9.2 | 22.7 | |||||||||||||||||||

| 100 | 11 | 26.28 | ||||||||||||||||||||

| 135QJ20-120 | 120 | 13 | 30.87 | |||||||||||||||||||

| 135QJ20-136 | 136 | 15 | 35.62 | |||||||||||||||||||

| 135QJ20-168135QJ25-12 | 168 | 18.5 | 43.12 | |||||||||||||||||||

| 25 | 12 | 2850 | 65 | 135ngenhla | 2.2 | 380 | 6.03 | 128 | ||||||||||||||

| 135QJ25-18 | 18 | 3 | 8.01 | |||||||||||||||||||

| 135QJ25-24 | 24 | 4 | 10.53 | |||||||||||||||||||

| 135QJ25-30 | 30 | 4 | 10.53 | |||||||||||||||||||

| 135QJ25-36 | 36 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ25-48 | 48 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ25-60 | 60 | 9.2 | 22.7 | |||||||||||||||||||

| 135QJ25-82 | 82 | 11 | 26.28 | |||||||||||||||||||

| 135QJ25-97 | 97 | 13 | 30.87 | |||||||||||||||||||

| 135QJ25-110 | 110 | 15 | 35.62 | |||||||||||||||||||

| 135QJ25-130 | 130 | 18.5 | 43.12 | |||||||||||||||||||

| 135QJ32-24 | 32 | 24 | 2850 | 80 | 135ngenhla | 4 | 380 | 10.53 | 128 | |||||||||||||

| 135QJ32-30 | 30 | 5.5 | 14.1 | |||||||||||||||||||

| 135QJ32-42 | 42 | 7.5 | 19.0 | |||||||||||||||||||

| 135QJ32-54 | 54 | 9.2 | 22.7 | |||||||||||||||||||

| 135QJ32-68 | 68 | 11 | 26.28 | |||||||||||||||||||

| 135QJ32-80 | 80 | 13 | 30.87 | |||||||||||||||||||

| 135QJ32-92 | 92 | 15 | 35.62 | |||||||||||||||||||

| 135QJ32-104 | 104 | 18.5 | 43.12 | |||||||||||||||||||

| 135QJ40-46 | 40 | 46 | 2850 | 80 | 135ngenhla | 11 | 380 | 26.28 | 128 | |||||||||||||

| 135QJ40-54 | 54 | 13 | 30.87 | |||||||||||||||||||

| 135QJ40-62 | 62 | 15 | 35.62 | |||||||||||||||||||

| 135QJ40-84 | 84 | 18.5 | 43.12 | |||||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, ngokuqinile ngokuvumelana nezinhlinzeko zokuphakanyiswa kwephampu, ububanzi bokugeleza bokusetshenziswa, ukuvimbela ukugeleza okuphansi noma amandla okumpompa aphakeme kakhulu, i-thrust bear nezinye izingxenye zokugqokwa, ukulayishwa kwemoto kushiswe 6, ngemva kokuba iphampu yehle emthonjeni, ukukalwa kwe-motor kuya kokumelana nokufakwa komhlabathi akufanele kube ngaphansi kuka-100M, ngemuva kokuqala ukubheka i-voltage kanye namanje, hlola ukufakwa kwama-motor winding, kungakhathaliseki ukuthi kuhambisana nezidingo; futha isitoreji izinga lokushisa uma esingaphansi iphuzu umnkantsha, kufanele ome motor cavity amanzi, ukuvimbela motor cavity amanzi ice umonakalo okubangelwa lokushisa aphansi.

The pump parts are mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor parts are mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand discharging ring, water inlet section, and lead cable.

Izici eziyinhloko zomkhiqizo zihlanganisa:

The main characteristic of the product is that the pump is a water-immersed three-phase asynchronous motor, and the motor cavity is full of water for cooling the motor and lubricating the bearing. The pressure regulating diaphragm at the bottom of the motor is used to adjust the expansion-contraction pressure difference of the water inside the body caused by the change of temperature. At the same time, in order to prevent the sand particles in the well water from entering the motor, two oil seals are installed at the end of the motor shaft, and the sand discharging ring is installed to form a sand control structure. In order to prevent the pump shaft from beating when starting up, the pump shaft and the motor shaft are connected by a coupling, and the thrust bearing is installed at the bottom of the motor. In addition, the motor and the pump bearing are water-lubricated, and the stator winding of the motor uses high-quality submersible motor winding to ensure high insulation performance. The overall design is made of computer CAD, with simple structure and superior technical performance.

(1) Ukulungiselela ngaphambi kokufakwa:

1. Hlola ukuthi ingabe iphampu engaphansi kwamanzi iyahlangabezana yini nezimo zokusetshenziswa kanye nobubanzi obushiwo kubhukwana.

2. Usebenzisa i-obiect esindayo enobubanzi obulingana nobukhulu bedayamitha yangaphandle yephampu engaphansi kwamanzi, linganisa ukuthi i-inneldiameter yomthombo ingalingana nephampu engaphansi kwamanzi, futhi ulinganise ukuthi ukujula komthombo kuyahlangabezana yini nezidingo zokufakwa.

3. Hlola ukuthi umthombo uhlanzekile yini nokuthi amanzi omthombo anodaka. Ungalokothi usebenzise iphampu kagesi engaphansi kwamanzi ukugeza udaka lwepompo le-welor namanzi esihlabathi ukuze ugweme ukulimala ngaphambi kwesikhathi kwepompo kagesi engaphansi kwamanzi.

4. Hlola ukuthi indawo ye-welhead yokufaka i-welhead ifanelekile yini nokuthi ingakwazi yini ukumelana nekhwalithi yayo yonke iyunithi.

5. Hlola ukuthi izingxenye zepompo ezingaphansi kwamanzi ziphelele yini futhi zifakwe ngendlela efanele ngokomdwebo womhlangano osebhukwini Susa isikrini sokuhlunga bese uzungezisa ukuhlanganisa ukuze ubone ukuthi siyazungeza yini

6. Khipha isikulufu samanzi bese ugcwalisa imbobo yesithuthuthu ngamanzi ahlanzekile, angagqwali (qaphela. qiniseka ukuthi uyasigcwalisa), bese uqinisa isikrufu samanzi. Ngemuva kwamahora ayi-12 omjovo wamanzi, ukumelana nokufakwa kwenjini akufanele kube ngaphansi kuka-150M Q uma kulinganiswa netafula lokunyakazisa elingu-500V.

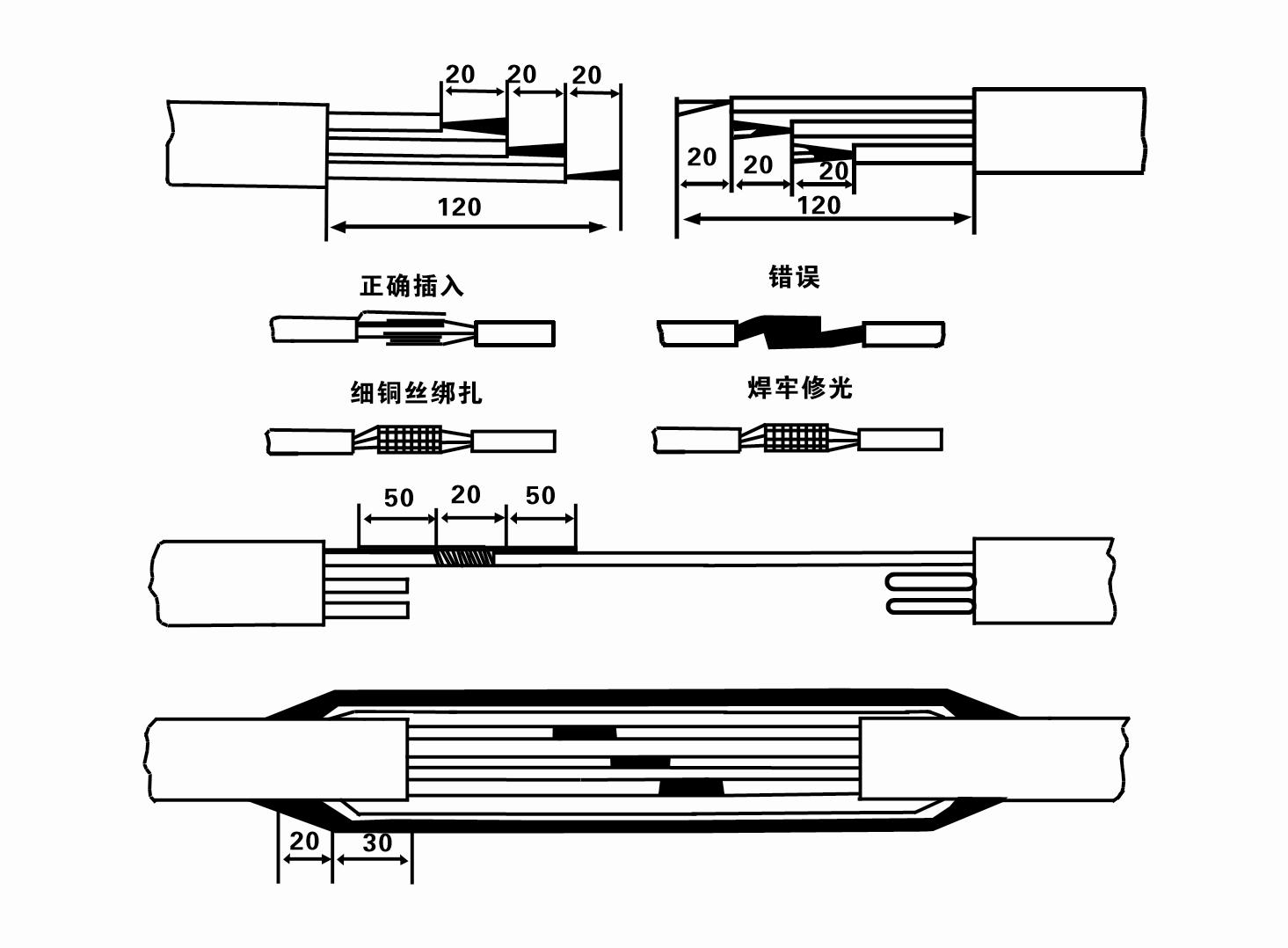

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Umdwebo wenqubo yokufaka izintambo zekhebula umi kanje:

8. Sebenzisa i-multimeter ukuze uhlole ukuthi izintambo zezigaba ezintathu zixhumekile yini nokuthi ukumelana ne-DC cishe kulinganiselwe.

9. Hlola ukuthi umthamo wesekethe kanye ne-transformer ugcwele ngokweqile, bese uxhuma iswishi yokuvikela ukulayisha ngokweqile noma okokusebenza kokuqala. Bheka Ithebula 2 ukuze uthole amamodeli athile, bese uThela ibhakede lamanzi empompini yamanzi usuka endaweni yepompo yamanzi ukuze ugcobe amabheringi erabha epompo, bese ubeka iphampu kagesi engaphansi kwamanzi iqonde futhi inganyakazi.Qala (ingabi ngaphezu komzuzwana owodwa) futhi uhlole ukuthi isiqondiso sokuqondisa siyahambisana yini nophawu lokuqondisa. Uma kungenjalo, shintsha noma yiziphi izixhumi ezimbili zekhebula lezigaba ezintathu.Bese ufaka isihlungi bese ulungiselela ukwehla ngomthombo. Uma isetshenziswa ngezikhathi ezikhethekile (njengemisele, imisele, imifula, amachibi, amachibi, njll.), iphampu kagesi kufanele ibekwe phansi ngendlela enokwethenjelwa.

(2)Imishini yokufaka namathuluzi:

1. Ipheya elilodwa lamaketango okuphakamisa amathani angaphezu kwamabili.

2. I-tripod enobude obuqondile obungekho ngaphansi kwamamitha amane.

3. Izintambo ezimbili ezilengayo (izintambo zocingo) ezingathwala isisindo esingaphezu kwethani elilodwa (zingathwala isisindo sesethi ephelele yamaphampu amanzi).

4. Faka amapheya amabili ezinsimbi (ama-splint).

5. Izikele, izando, izikulufu, amathuluzi kagesi nezinsimbi, njll.

(3)Ukufakwa kwephampu kagesi:

1. Umdwebo wokufakwa kwephampu kagesi engaphansi kwamanzi uboniswa kuMfanekiso 2. Ubukhulu obuthile bokufaka buboniswa kuThebula lesi-3 "Uhlu Lobukhulu Bokufakwa Kwephampu Kagesi Engaphansi".

2. Amaphampu kagesi angaphansi kwamanzi anekhanda elingaphansi kwamamitha angu-30 angaphakanyiselwa ngqo emthonjeni kusetshenziswa amapayipi nezintambo zocingo noma ezinye izintambo ze-hemp ezingathwala isisindo esigcwele sawo wonke umshini, amapayipi amanzi, namanzi emapayipini.

3. Amaphampu anekhanda elingaphezu kwamamitha angu-30 asebenzisa amapayipi ensimbi, futhi ukulandelana kokufakwayo kungokulandelayo:

①Sebenzisa i-clamp ukuze ubambe ingxenye engenhla yengxenye yepompo yamanzi (injini nepompo yamanzi kuxhunyiwe ngalesi sikhathi), yiphakamise ngeketango elilengayo, bese uyibopha kancane kancane emthonjeni uze ufake i-clamp ekhanda lomthombo bese ukhipha iketango elilengayo.

② Sebenzisa amanye ama-clamp ukuze ubambe ipayipi, uliphakamise ngeketango elilengayo eliqhele ngamasentimitha angu-15 ukusuka ku-flange, bese ulehlisa kancane. Phakathi kwe-flange yepayipi ne-pump flangeFaka iphedi yenjoloba endaweni bese uqinisa ipayipi bese umpompa ngokulinganayo ngamabhawodi, amantongomane namawasha asentwasahlobo.

③ Phakamisa iphampu engaphansi kwamanzi kancane, khipha intambo engxenyeni engenhla yepompo yamanzi, bopha intambo ngokuqinile epayipini lamanzi ngetheyiphu yepulasitiki, bese uyibopha kancane kancane kuze kube yilapho I-clamp ibekwe emthonjeni.

④Sebenzisa indlela efanayo ukubopha wonke amapayipi amanzi emthonjeni.

⑤Ngemva kokuthi ikhebuli ephumayo ixhunywe kusiwishi sokulawula, ixhunywa ekunikezeni amandla kwezigaba ezintathu.

(4) Izinto okufanele uziqaphele ngesikhathi sokufakwa:

1. Uma i-jamming itholakala phakathi nenqubo yokumpompa, vula noma udonse ipayipi lamanzi ukuze unqobe indawo yokuma. Uma izinyathelo ezihlukahlukene zingasebenzi, sicelaUngaphoqeleli iphampu phansi ukuze ugweme ukulimala kwepompo kagesi engaphansi kwamanzi kanye nomthombo.

2. Ngesikhathi sokufakwa, i-rubber pad kufanele ibekwe ku-flange yepayipi ngayinye futhi iqiniswe ngokulinganayo.

3. Lapho iphampu yamanzi yehliselwa emthonjeni, kufanele ibekwe phakathi nepayipi lomthombo ukuze ivimbele ukuthi iphampu ingagijimi odongeni lomthombo isikhathi eside, okubangela ukuba iphampu inyakaze futhi injini ishanele futhi ishise. .

4. Thola ukujula kwepompo yamanzi ukuya phansi komthombo ngokwesihlabathi esigelezayo kanye nezimo zodaka lomthombo. Ungangcwabi iphampu odakeni. Ibanga ukusuka empompini ukuya phansi komthombo ngokuvamile alikho ngaphansi kwamamitha amathathu (bheka uMdwebo 2).

5. Ukujula kokungena kwamanzi kwephampu yamanzi kufanele kungabi ngaphansi kwamamitha angu-1-1.5 ukusuka ezingeni lamanzi aguquguqukayo kuya endaweni yokungena kwamanzi (bheka uMdwebo 2). Uma kungenjalo, ama-bearings epompo yamanzi angase alimale kalula.

6. Ukuphakanyiswa kwepompo yamanzi angeke kube phansi kakhulu. Uma kungenjalo, i-valve yesango idinga ukufakwa epayipini lamanzi elisemthonjeni ukuze kulawulwe ukugeleza kwepompo endaweni elinganiselwe yokugeleza ukuze kuvinjwe injini ukuthi ingagcwali kakhulu futhi ishiswe ngenxa yamazinga amakhulu okugeleza.

7. Lapho ipompo yamanzi isebenza, ukuphuma kwamanzi kufanele kuqhubeke futhi ngisho, okwamanje kufanele kuzinzile (ngaphansi kwezimo zokusebenza ezilinganiselwe, ngokuvamile kungabi ngaphezu kuka-10% wamanje olinganiselwe), futhi akufanele kube nokudlidliza noma umsindo. Uma kukhona okungahambi kahle, umshini kufanele umiswe ukuze kutholwe imbangela futhi kuqedwe.

8. Lapho ufaka, naka ukumiswa kocingo lwe-motor grounding wire (bheka Umfanekiso 2). Uma ipayipi lamanzi liyipayipi lensimbi, lihole kusukela ku-wellhead clamp; lapho ipayipi lamanzi liyipayipi lepulasitiki, lihole ukusuka endaweni yokubeka phansi yepompo kagesi.

- 1.After the submersible pump is installed, check the insulation resistance and three-phase conduction from the switch again, check whether the instrument and the connection of the start equipment are wrong, if there is no problem, the trial machine can be started, and after the start, observe whether the indicator readings of the instrument exceed the rated voltage and current specified on the nameplate, observe whether the pump has noise and vibration phenomenon, and put into operation if everything is normal.

- 2. After the first operation of the pump for four hours, the motor should be stopped to test the thermal insulation resistance quickly, and its value should not be less than 0.5 megaohm.

- 3. After the pump is stopped, it should be started after five minutes to prevent the water column in the pipe from being completely reflowed and causing the motor to burn out due to excessive current.

- 4. Our pump is designed to provide efficient, reliable and lasting pumping solutions.After normal operation, in order to prolong the service life of the pump, it is necessary to check the power supply voltage, running current and insulation resistance regularly to ensure that they are normal.

- If the following conditions are found, the machine should be shut down immediately to eliminate the fault:

- - the current exceeds 20% under the rated working conditions;

- - the dynamic water level drops to the inlet section, resulting in intermittent drainage;

- - the submersible pump vibrates violently or emits noisy sounds;

- - the power supply voltage is lower than 340 volts;

- - one phase of a fuse is blown out;

- - the water pipe is damaged;

- - the thermal insulation resistance of the motor to the ground is less than 0.5 megaohm.

- The steps of disassembling the unit include unlocking the cable holder, taking off the pipe part, removing the line protection plate, rotating the drain screw and emptying all the water in the motor chamber, taking out the filter and loosening the screw of the coupling fixed to the motor shaft.Unscrew the bolt connecting the water inlet section and the motor, and separate the pump and the motor (note that the unit should be placed horizontally when separating to prevent the bending of the pump shaft).

- 5. The disassembly sequence of the pump includes: water inlet part, impeller, shunt shell, impeller, check valve body.When removing the impeller, use a special tool to loosen the cone sleeve fixing the impeller.During the disassembly process, avoid bending the pump shaft and damaging various parts.The disassembly process of the motor includes: placing the motor on the platform, and then removing the nuts on the studs, base, shaft head lock nut, thrust plate, key, lower guide rail, bearing seat and bolt from the bottom of the motor, then removing the rotor (be careful not to damage the winding), and finally removing the connecting parts and upper guide bearing seat. Before assembling the unit, it is necessary to clean the rust and dirt of each part, and apply sealant on each mating surface and fastener, and then assemble it in the opposite order of disassembly.After assembly, the coupling should be flexibly rotated, and then the filter should be put on to test the machine. Our pump products are designed to provide superior performance and reliability to meet your pumping needs.

- 6. Submersible pumps operating every year, or less than a year of operation but the submersible time has reached two years, should be taken out of the well according to the 5th dismantled maintenance, replacement of worn parts.

1, khipha amanzi ku-motor cavity (ikakhulukazi ebusika ukuvimbela injini ukuba ingaqhwa), futhi ubophe ikhebula kahle.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, ukusetshenziswa isikhathi eside kufanele sinake ukuvimbela nokugqwala amaphampu submersible.

- Impeller

- Umkhono we-shaft

- Umkhono we-rubber shaft

- Indandatho yokuvala

01 Ukuphuza amanzi omthombo ojulile

02 Ukuhlinzekwa kwamanzi asezingeni eliphezulu

03 amanzi asezintabeni

04 amanzi ombhoshongo

05 Ukuchelela kwezolimo

06 ukuchelela engadini

07 amanzi omfula

08 amanzi asekhaya