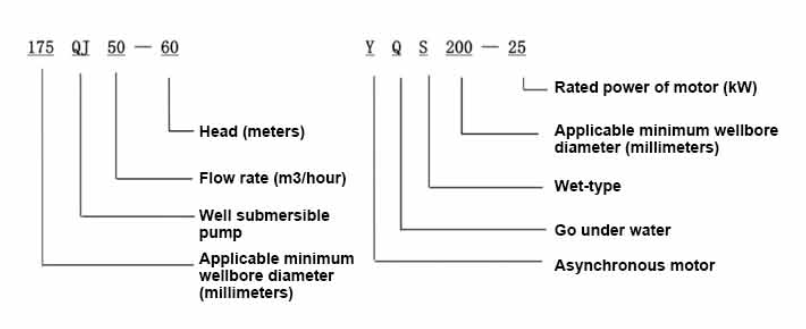

This series of fountain pump is a special fountain pump developed by our factory. The pump motor core is made of high quality cold rolled silicon steel, which makes the pump more efficient, has good magnetic conductivity, and does not produce heat when starting frequently. The two ends of the motor rotor are equipped with alloy copper sleeves with water as lubricant. Stainless steel bushings replace ball bearings, avoiding the problems of easy rust of ball bearings and burnout of motor due to lack of oil and wear. Most suitable for music fountain, all models can be used horizontally.

1, te mana hiko: toru-waahanga AC 380V (te manawanui + / - 5%), 50HZ (te manawanui + / - 1%).

2, kounga wai:

(1) water temperature is not higher than 20 °C;

(2) karekau e nui ake i te 0.01% te ihirangi poke totoka (owehenga papatipu);

(3) Uara PH (pH) 6.5-8.5;

(4) Ko te ihirangi hauwai sulfide kaua e nui ake i te 1.5mg/L;

(5) Ko te ihirangi katote pūhaumāota kaore e nui ake i te 400mg/L.

3, ka kati te motuka, ka whakakiia ranei ki te wai te hanganga maku, i mua i te whakamahi me whakakiia te kohao motopaika ruku ki te wai ma, kia kore ai e ki tonu te teka, katahi ka whakapakeke i te werohanga wai, nga kati tuku hau, ki te kore e whakaaetia kia whakamahia.

4, me tino rukuhia te papu ruku ki te wai, ko te hohonutanga o te ruku kaua e nui ake i te 70m, ko te raro o te papu ruku mai i raro o te puna kaua e iti iho i te 3m.

5, me kaha te rere o te wai puna ki te whakatau i te whakaputanga wai papu ruku me te mahi tonu, me whakahaere te whakaputanga wai papu ruku ki te 0.7 - 1.2 nga wa o te rere whakatau.

6, kia tika te puna, e kore e taea te whakamahi i te papu ruku, ka makahia ranei, ko te whakamahi poutū anake.

7, me rite te papu submersible ki te taura kia rite ki nga whakaritenga, me te taputapu whakamarumaru o waho.

8, ka tino rahuitia te papu me te kore he wai miihini whakamatautau

| Tauira | Rere (m3/h) | Upoko (m) |

Tere hurihuri (hurihia/tohu) |

Puma wai(%) | Putanga diameter (mm) |

E tika ana diameter(mm) |

Whakatauria power(KW) |

Whakatauria ngaohiko(V) |

Whakatauria nāianei(A) |

Te Motika (%) | power factorcosφ | Waeine Rahi Morahi Radial(mm) |

Korero | |||||||||

| 250QJ50-40 | 50 | 40 | 2875 | 72 | 80 | 250runga | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 233 | ||||||||||

| 250QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | |||||||||||||||||

| 250QJ50-80 | 80 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ50-100 | 100 | 22 | 47.9 | 83.0 | 0.84 | |||||||||||||||||

| 250QJ50-120 | 120 | 25 | 53.8 | 84.0 | 0.84 | |||||||||||||||||

| 250QJ50-140 | 140 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ50-160 | 160 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ50-200 | 200 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ50-240 | 240 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ50-280 | 280 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ50-320 | 320 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ50-400 | 400 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ50-440 | 440 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ63-40 | 63 | 40 | 2875 | 74 | 80 | 250runga | 11 | 380 | 25.8 | 79.0 | 0.82 | 233 | ||||||||||

| 250QJ63-60 | 60 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ63-80 | 80 | 22 | 47.9 | 83.0 | 0.84 | |||||||||||||||||

| 250QJ63-100 | 100 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ63-120 | 120 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ63-160 | 160 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ63-200 | 200 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ63-220 | 220 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ63-260 | 260 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ63-300 | 300 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ63-360 | 360 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ80-20 | 80 | 20 | 2875 | 75 | 100 | 250runga | 7.5 | 380 | 18.0 | 78.0 | 0.81 | 233 | ||||||||||

| 250QJ80-40 | 40 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 250QJ80-60 | 60 | 22 | 47.9 | 83.0 | 0.84 | |||||||||||||||||

| 250QJ80-80 | 80 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ80-100 | 100 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ80-120 | 120 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ80-160 | 80 | 160 | 2875 | 75 | 100 | 250runga | 55 | 380 | 114.3 | 86.0 | 0.85 | 233 | ||||||||||

| 250QJ80-180 | 180 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ80-200 | 200 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ80-240 | 240 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ80-280 | 280 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ100-18 | 100 | 18 | 2875 | 75 | 100 | 250runga | 7.5 | 380 | 18.0 | 78.0 | 0.81 | 233 | ||||||||||

| 250QJ100-36 | 36 | 15 | 33.9 | 81.0 | 0.83 | |||||||||||||||||

| 250QJ100-54 | 54 | 25 | 53.8 | 84.0 | 0.84 | |||||||||||||||||

| 250QJ100-72 | 72 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ100-90 | 90 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ100-108 | 108 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ100-126 | 126 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ100-144 | 144 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ100-162 | 162 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ100-198 | 198 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ100-216 | 216 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-16 | 125 | 16 | 2875 | 76 | 125 | 250runga | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 233 | ||||||||||

| 250QJ125-32 | 32 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ125-48 | 48 | 25 | 53.8 | 84.0 | 0.84 | |||||||||||||||||

| 250QJ125-64 | 64 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ125-80 | 80 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ125-96 | 96 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ125-112 | 112 | 63 | 131.0 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ125-128 | 128 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-160 | 160 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-176 | 176 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ125-192 | 192 | 110 | 219.6 | 87.5 | 0.87 | |||||||||||||||||

| 250QJ140-15 | 140 | 15 | 2875 | 76 | 125 | 250runga | 9.2 | 380 | 21.7 | 78.5 | 0.82 | 233 | ||||||||||

| 250QJ140-30 | 30 | 18.5 | 40.8 | 82.0 | 0.84 | |||||||||||||||||

| 250QJ140-45 | 45 | 30 | 64.2 | 84.5 | 0.84 | |||||||||||||||||

| 250QJ140-60 | 60 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ140-75 | 45 | 45 | 94.1 | 85.5 | 0.85 | |||||||||||||||||

| 250QJ140-90 | 90 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ140-105 | 140 | 105 | 2875 | 76 | 125 | 250runga | 63 | 380 | 131.0 | 86.0 | 0.85 | 233 | ||||||||||

| 250QJ140-120 | 120 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ140-150 | 150 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ140-165 | 165 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ140-180 | 180 | 110 | 219.6 | 87.5 | 0.87 | |||||||||||||||||

| 250QJ200-20 | 200 | 20 | 2875 | 75 | 150 | 250runga | 18.5 | 380 | 40.8 | 82.0 | 0.84 | 233 | ||||||||||

| 250QJ200-40 | 40 | 37 | 77.8 | 85.0 | 0.85 | |||||||||||||||||

| 250QJ200-60 | 60 | 55 | 114.3 | 86.0 | 0.85 | |||||||||||||||||

| 250QJ200-80 | 80 | 75 | 152.3 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ200-100 | 100 | 90 | 182.8 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ200-120 | 120 | 100 | 203.1 | 87.0 | 0.86 | |||||||||||||||||

| 250QJ200-140 | 140 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

1, well submersible pump for clean water pump, prohibit the new well, pumping sediment and muddy water,

2, well water pump voltage grade of 380/50HZ, the use of other voltage grades of submersible motors need to be customized. The underground cable must use waterproof cable, must be equipped with starting equipment, such as distribution box, start not ready should have commonly used motor comprehensive protection function, such as short circuit overload protection, phase protection, undervoltage protection, grounding protection, idling protection, in case of abnormal conditions, the protection device should be timely action trip.

3, the installation and use of the pump must be reliably grounded, prohibit the push and pull switch when the hands and feet are wet, the installation and maintenance of the pump must be cut off the power supply, the use of the pump place to set up "to prevent electric shock" obvious signs:

4, down the well or before installation, the motor cavity must be filled with distilled water or non-corrosive clean cold boiling water, tighten the / water bolt, the pump on the ground test run, must be to the pump chamber water lubrication rubber bearings, instant start not more than a second, see whether the steering is the same as the steering instructions. When the pump is upright, pay attention to safety, prevent overturning injury.

5, kia rite tonu ki nga tikanga o te ara o te papu, te awhe rere o te whakamahi, ki te aukati i te iti o te rere, te teitei ranei o te kaha o te kumara, te peera me etahi atu waahanga o te kakahu, ka wera te motuka motuka.

6, after the pump down the well, the measurement of the motor to the ground insulation resistance should not be less than 100M, after the start to observe the voltage and current, check the motor winding insulation, whether in line with the requirements; pump storage location temperature if less than freezing point, should be dry the motor cavity water, prevent the motor cavity water ice damage caused by low temperature.

The introduction and structure of this pump product mainly include pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor part is mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand ring, water inlet section, lead cable and other components. The main characteristics of this pump product include the use of water-cooled wet submersible three-phase asynchronous motor, the motor cavity is filled with clean water to cool the motor and lubricate the bearing, the pressure regulating diaphragm at the bottom is used to adjust the expansion and contraction pressure difference of the internal water caused by the change of the temperature rise of the motor. In order to prevent the sand particles in the well water from entering the motor, two oil seals are installed on the upper end of the motor shaft extension, and the sand ring is installed to form a sand prevention structure. In order to avoid the pump shaft jumping at startup, the pump shaft and the motor shaft are connected together through the coupling, and the thrust bearing is installed at the lower part of the motor. The motor and pump bearing lubrication adopts water lubrication. The stator winding of the motor adopts high quality submersible motor winding, with high insulation performance. The pump adopts computer CAD design, simple structure and superior technical performance.

(1) Whakaritenga i mua i te whakaurunga:

1. Tirohia mehemea ka tutuki te papu ruku ki nga tikanga whakamahi me te whanuitanga kua tohua ki te pukapuka.

2. Ma te whakamahi i te obiect taumaha me te diameter e rite ana ki te teitei o te diameter o waho o te papu ruku, ine mehemea ka uru te inneldiameter o te poka wai ki te papu ruku, me te ine mena ka tutuki te hohonutanga o te puna ki nga whakaritenga whakaurunga.

3. Tirohia mehemea he ma te rua o te puna me te wai pokarekare ranei. Kaua rawa e whakamahia he papu hiko ruku ki te horoi i te paru welor papu me te wai kirikiri kia kore e pakaru wawe te papu hiko ruku.

4. Tirohia mehemea he pai te tuunga o te rawhi whakaurunga welhead me te kaha ki te tu ki te kounga o te waahanga katoa.

5. Tirohia mehemea kua oti te whakaurunga o nga waahanga papu ruku me te tika kia rite ki te hoahoa huinga i roto i te pukapuka Tangohia te mata tātari ka huri i te hononga kia kite mena ka huri ngawari.

6. Wewetehia te wiri wai ka whakakiia te kohao motopaika ki te wai ma, kaua e pirau (tohu. me whakakiia ki runga), katahi ka whakakaha i te kopa wai. I muri i nga haora 12 o te werohia o te wai, kaua e iti iho i te 150M Q te parenga whakamarumaru o te motini ka ine ki te tepu wiri 500V.

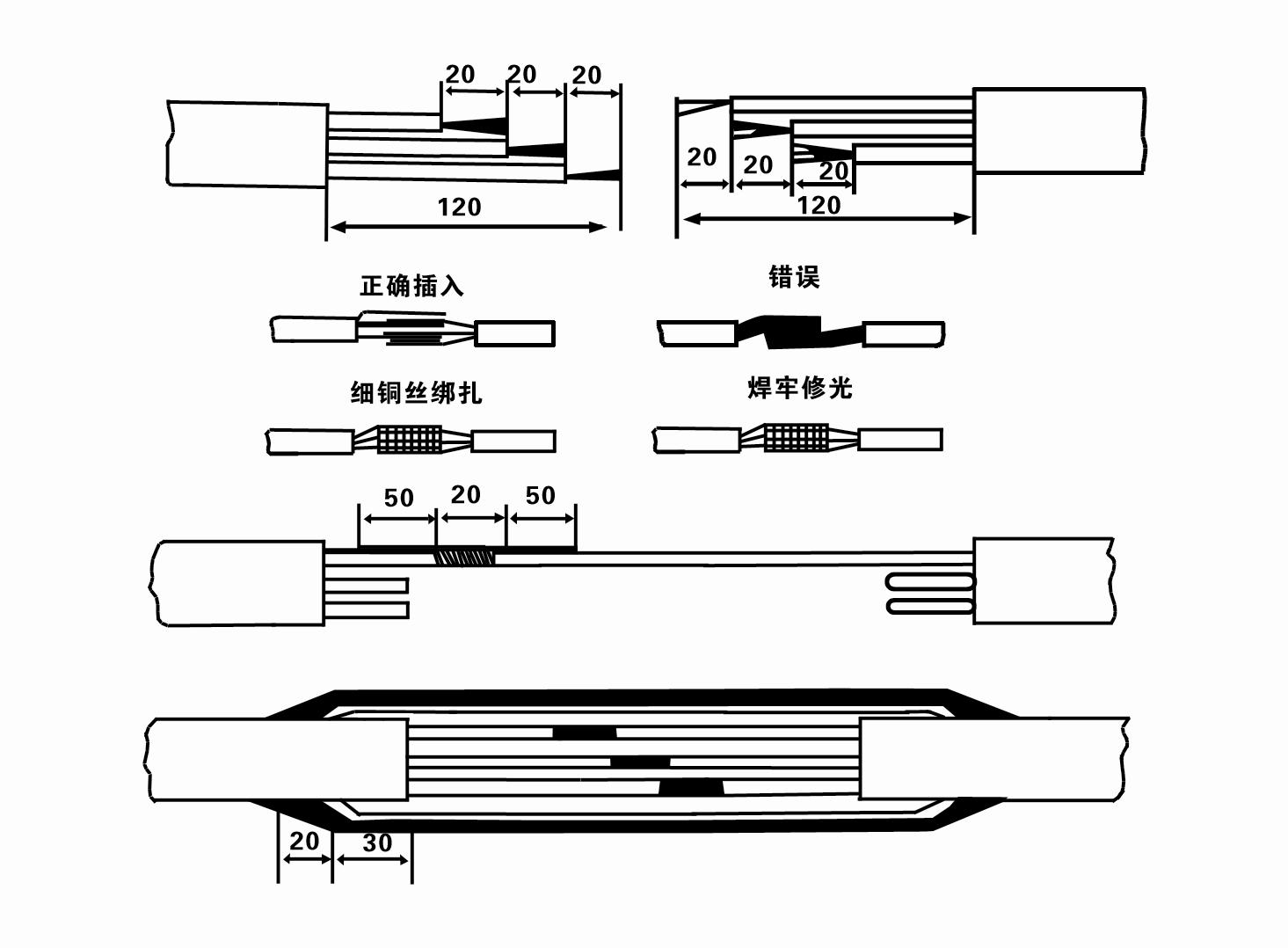

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Ko te hoahoa tukanga waea waea kua honoa e whai ake nei:

8. Whakamahi i te mita maha ki te tirotiro mena kei te hono nga waea-waa-toru me te ahua taurite te parenga DC.

9. Tirohia mehemea kua taumaha te ara iahiko me te kaha o te hurihanga, katahi ka hono atu i te pana whakamaru i te taumaha, i nga taputapu tiimata ranei. Tirohia te Ripanga 2 mo nga tauira motuhake, katahi ka ringihia he peere wai ki roto i te papu wai mai i te putanga papu wai hei whakahinuhinu i nga rapa rapa i roto i te papu, katahi ka tuu te papu hiko ruku ki runga kia mau. ka tirohia mehemea e rite ana te ahunga urungi ki te tohu urungi. Ki te kore, whakawhitia nga hononga e rua o te taura e toru-waahanga. Katahi ka whakauruhia te tātari ka takatu ki te heke ki raro i te puna. Mena ka whakamahia i roto i nga waahi motuhake (penei i nga awaawa, i nga awaawa, i nga awa, i nga harotoroto, i nga harotoroto, me etahi atu), me tika te turanga o te papu hiko.

(2) Nga taputapu me nga taputapu whakauru:

1. Kotahi te rua o nga mekameka hiki mo te neke atu i te rua tana.

2. He tripod me te teitei poutū kaua e iti iho i te wha mita.

3. E rua nga taura iri (wire ropes) ka taea te kawe i te taumaha neke atu i te kotahi tana (ka taea te kawe i te taumaha o te huinga katoa o nga papu wai).

4. Tāutahia kia rua ngā rawhi (splints).

5. Nga wrenches, hama, wiriwiri, taputapu hiko me nga taputapu, aha atu.

(3)Tautanga papu hiko:

1. Ko te hoahoa whakaurunga o te papu hiko ruku e whakaatuhia ana i te Whakaaturanga 2. Ko nga rahinga whakaurunga motuhake e whakaatuhia ana i te Ripanga 3 "Rarangi o nga Rarangi Whakamutunga o te Pump Hiko Rakau".

2. Ko nga papu hiko ruku me te upoko iti iho i te 30 mita ka taea te whakairi tika ki roto i te puna ma te whakamahi i nga ngongo me nga taura waea, etahi atu taura hemp ranei ka taea te kawe i te taumaha katoa o te miihini, nga paipa wai, me te wai i roto i nga paipa.

3. Ko nga papu me te upoko neke atu i te 30 mita te whakamahi paipa maitai, a ko te raupapa whakaurunga e whai ake nei:

①Whakamahia he rawhi hei rawhi i te pito o runga o te wahanga papu wai (kua honoa te motini me te papu wai i tenei wa), hikitia me te mekameka iri, ka ata herea ki roto i te puna tae noa ki te kuhua te rawhi ki te upoko o te puna ka tango mekameka iri.

② Whakamahia etahi atu rawhi hei rawhi i te paipa, hikitia me te mekameka iri kia 15 cm te tawhiti atu i te flange, ka ata whakaheke. I waenganui i te flange paipa me te flange papu Whakanohoia te papa rapa ki te waahi ka whakakoia te paipa me te papu kia rite ki nga tutaki, nati me nga horoi puna.

③ Whakaarahia te papu ruuma kia paku, tangohia te rawhi i te pito o runga o te papu wai, herea te taura ki te paipa wai me te riipene kirihou, ka ata herea ki raro kia tuu te rawhi ki te upoko puna.

④Whakamahia taua tikanga ki te here i nga paipa wai katoa ki roto i te puna.

⑤I muri i te hono o te taura arataki ki te pana whakahaere, ka hono atu ki te hiko hiko e toru nga wahanga.

(4) Nga mea hei tohu i te wa o te whakaurunga:

1. Mēnā ka kitea he āhuatanga tāmii i te wā e mahi ana te kumara, huri, kumea ranei te paipa wai kia pai ai te taunga. Ki te kore tonu e mahi nga momo mahi, tena koaKaua e tohe te papu ki raro kia kore ai e pakaru te papu hiko ruku me te puna.

2. I te wa o te whakaurunga, me whakanoho he papa rapa ki te taha o ia paipa me te whakakaha kia rite.

3. Ka tukuna te papu wai ki roto i te puna, me tuu ki waenganui o te paipa puna kia kore ai e rere te papu ki te pakitara o te puna mo te wa roa, ka wiri te papu, ka tahia, ka wera te motini. .

4. Whakatauhia te hohonutanga o te papu wai ki raro o te puna i runga i te rere o te onepu me te parapara o te puna. Kaua e tanu te papu ki te paru. Ko te tawhiti mai i te papu wai ki raro o te puna ko te tikanga kaua e iti iho i te 3 mita (tirohia te Whakaahua 2).

5. Ko te hohonutanga o te urunga wai o te papu wai kia kaua e iti iho i te 1-1.5 mita mai i te taumata wai hihiri ki te kohanga uru wai (tirohia te Whakaahua 2). Ki te kore, ka ngawari te pakaru o nga papa papu wai.

6. Ko te hiki o te papu wai e kore e iti rawa. Ki te kore, me whakauru he paera kuaha ki runga i te paipa wai o te upoko o te puna ki te whakahaere i te rere o te papu ki te waahi rere reiti kia kore ai te motini e nui te utaina me te wera na te nui o te rere.

7. I te wa e rere ana te papu wai, me noho tonu te whakaputanga wai me te ara, kia mau tonu te naianei (i raro i nga tikanga mahi kua whakatauhia, ko te tikanga kaua e neke atu i te 10% o te waa kua tohua), kaore he wiri, he haruru ranei. Mena he mate kino, me whakamutu te miihini kia kitea te take me te whakakore.

8. I te wa e whakauru ana, whakarongo ki te whakatakotoranga o te waea motika motika (tirohia te Whakaahua 2). Ina he paipa rino te paipa wai, arahina mai i te rawhi o te upoko puna; ina he paipa kirihou te paipa wai, arahina mai i te tohu whenua o te papu hiko.

After the installation of the underwater pump, the insulation resistance and three-phase continuity of the switch face should be rechecked, and the connection between the instrument and the start device should be checked for any errors. If there is no problem, you can start to test the machine. After the start, observe whether the indication readings of each instrument are correct. If the rated voltage and current specified on the nameplate are exceeded, observe whether the pump has noise or vibration. If everything is normal, it can be put into operation. After the first operation of the pump for four hours, the motor should be shut down and tested for thermal insulation resistance quickly. Its value should not be less than 0.5 megaohm. After stopping the pump, it should be restarted after an interval of five minutes to prevent the water column in the pipeline from completely reversing and causing the motor to burn out due to excessive current. After the pump is put into normal operation, in order to prolong its service life, it is necessary to check regularly whether the supply voltage, running current and insulation resistance are normal. If the following conditions are found, the machine should be shut down immediately to eliminate the fault: the current exceeds 20% under rated working conditions; the dynamic water level drops to the inlet section, resulting in intermittent drainage; the underwater pump becomes violently vibrating or making noise; the supply voltage is lower than 340 volts; a fuse is blown out; the water pipe is damaged; the motor's thermal insulation resistance to the earth is less than 0.5 megaohm. The sequence of disassembly is: untie the cable fastening, remove the pipeline part, remove the line protection plate, screw down the water discharge bolt and discharge all the water in the motor chamber, remove the filter and loosen the coupling fixing screw of the motor shaft. The sequence of disassembly of the pump is: (see Figure 1) inlet section, impeller, guide housing, impeller, check the valve body. When removing the impeller, use special tools to loosen the taper sleeve of the impeller. Avoid bending the pump shaft and damaging the components throughout the process. The disassembly process of the motor is: (see Figure 1) put the motor on the platform, and remove the bolts, base, shaft head lock nut, thrust plate, key, lower guide plate (transverse bolt), bearing seat, screw knife seat from the bottom of the motor in order (take care not to damage the winding), and finally remove the connecting part and the upper guide bearing seat. Before assembling the unit, the rust and dirt of each part should be cleaned, and the sealant should be applied to each mating surface and fastener, and then assembled in reverse order of disassembly (the movement of the motor shaft after assembly is about one millimeter). After assembly, the coupling should be rotated flexibly and put on the filter for test. Once a year, or if less than a year of operation but has been immersed for two years, the underwater electric pump must be disassembled for maintenance in accordance with Article 5 and replace worn parts to ensure the normal operation and durability of the pump.

1, whakawetohia te wai ki roto i te kohao motopaika (ina koa i te takurua kia kore ai te motini e makariri), kia pai te here i te taura.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, me aro te whakamahi mo te wa roa ki te aukati waikura o nga papu totohu.

- Kaipupuri

- Karekau kakau

- Karekau rakau rapa

-

mowhiti hiri

01 Te urunga wai hohonu

02 Te tuku wai teitei

03 wai maunga

04 wai pourewa

05 Te whakamakuku ahuwhenua

06 te whakamakuku maara

07 te urunga wai o te awa

08 wai whare