Frequency conversion winding design, ensure the motor in 1HZ-50HZ long-term stable conversion operation. Energy saving, longer service life.

1, te mana hiko: toru-waahanga AC 380V (te manawanui + / - 5%), 50HZ (te manawanui + / - 1%).

2, kounga wai:

(1) water temperature is not higher than 20 °C;

(2) karekau e nui ake i te 0.01% te ihirangi poke totoka (owehenga papatipu);

(3) Uara PH (pH) 6.5-8.5;

(4) Ko te ihirangi hauwai sulfide kaua e nui ake i te 1.5mg/L;

(5) Ko te ihirangi katote pūhaumāota kaore e nui ake i te 400mg/L.

3, ka kati te motuka, ka whakakiia ranei ki te wai te hanganga maku, i mua i te whakamahi me whakakiia te kohao motopaika ruku ki te wai ma, kia kore ai e ki tonu te teka, katahi ka whakapakeke i te werohanga wai, nga kati tuku hau, ki te kore e whakaaetia kia whakamahia.

4, me tino rukuhia te papu ruku ki te wai, ko te hohonutanga o te ruku kaua e nui ake i te 70m, ko te raro o te papu ruku mai i raro o te puna kaua e iti iho i te 3m.

5, me kaha te rere o te wai puna ki te whakatau i te whakaputanga wai papu ruku me te mahi tonu, me whakahaere te whakaputanga wai papu ruku ki te 0.7 - 1.2 nga wa o te rere whakatau.

6, kia tika te puna, e kore e taea te whakamahi i te papu ruku, ka makahia ranei, ko te whakamahi poutū anake.

7, me rite te papu submersible ki te taura kia rite ki nga whakaritenga, me te taputapu tiaki taumaha o waho. 8, ka tino aukatihia te papu me te kore he wai miihini miihini whakamatautau

| Tauira | Rere (m3/h) | Upoko (m) |

Rotating speed(change/point) | Puma wai(%) | Putanga diameter (mm) |

E tika ana diameter(mm) |

Whakatauria mana(KW) |

Rated voltage(V) | Ratedcurrent(A) | Te Motika (%) | power factorcosφ | Waeine Rahi Morahi Radial(mm) |

Korero | |||||||||

| 125QJ5-34 | 5 | 34 | 2850 | 53 | 40 | 125runga | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ5-51 | 51 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ5-68 | 68 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ5-85 | 85 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ5-102 | 102 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ5-119 | 119 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-24 | 10 | 24 | 2850 | 60 | 50 | 125runga | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ10-32 | 32 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ10-48 | 48 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ10-56 | 56 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ10-72 | 72 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-80 | 80 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-104 | 104 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ10-120 | 10 | 120 | 2850 | 60 | 50 | 125runga | 7.5 | 380 | 19.0 | 76.0 | 0.79 | 118 | ||||||||||

| 125QJ10-136 | 136 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ15-36 | 15 | 36 | 2850 | 63 | 50 | 125runga | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ15-39 | 39 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ15-46 | 46 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-52 | 52 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-59 | 59 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-65 | 65 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-78 | 78 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-91 | 91 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-104 | 104 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ20-16 | 20 | 16 | 2850 | 64 | 50 | 125runga | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ20-24 | 24 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ20-32 | 32 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-40 | 40 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-48 | 48 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-56 | 56 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-64 | 64 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-72 | 72 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-80 | 80 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ25-12 | 25 | 12 | 2850 | 64 | 65 | 125runga | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ25-18 | 18 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ25-24 | 24 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-30 | 30 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-36 | 36 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ25-48 | 48 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ25-60 | 60 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ32-24 | 32 | 24 | 2850 | 64 | 80 | 125runga | 4 | 380 | 10.53 | 74.0 | 0.78 | 118 | ||||||||||

| 125QJ32-30 | 30 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ32-42 | 42 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ32-54 | 54 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ5-240 | 5 | 240 | 2850 | 40 | 125runga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ5-280 | 280 | 13 | 30.87 | |||||||||||||||||||

| 125QJ5-320 | 320 | 15 | 35.62 | |||||||||||||||||||

| 125QJ10-180 | 10 | 180 | 2850 | 50 | 125runga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ10-210 | 210 | 13 | 30.87 | |||||||||||||||||||

| 125QJ10-240 | 240 | 15 | 35.62 | |||||||||||||||||||

| 125QJ15-120 | 15 | 120 | 2850 | 50 | 125runga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ15-142 | 142 | 13 | 30.87 | |||||||||||||||||||

| 125QJ15-162 | 162 | 15 | 35.62 | |||||||||||||||||||

| 125QJ20-100 | 20 | 100 | 2850 | 50 | 125runga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ20-120 | 120 | 13 | 30.87 | |||||||||||||||||||

| 125QJ20-136 | 136 | 15 | 35.62 | |||||||||||||||||||

| 125QJ25-82 | 25 | 82 | 2850 | 65 | 125runga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ25-97 | 97 | 13 | 30.87 | |||||||||||||||||||

| 125QJ25-110 | 110 | 15 | 35.62 | |||||||||||||||||||

| 125QJ32-68 | 32 | 68 | 2850 | 80 | 125runga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ32-80 | 80 | 13 | 30.87 | |||||||||||||||||||

| 125QJ32-92 | 92 | 15 | 35.62 | |||||||||||||||||||

| 125QJ40-46 | 40 | 46 | 2850 | 80 | 125runga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ40-54 | 54 | 13 | 30.87 | |||||||||||||||||||

| 125QJ40-62 | 62 | 15 | 35.62 | |||||||||||||||||||

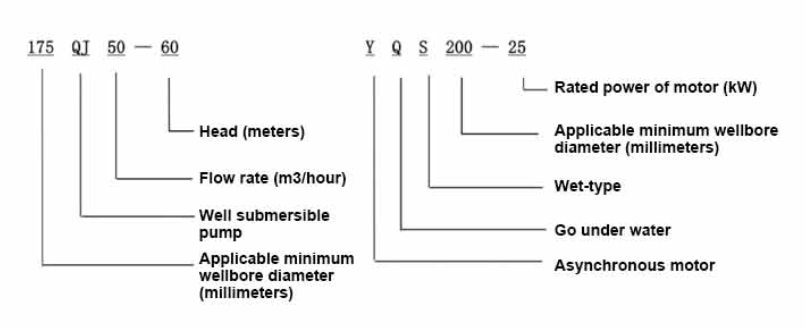

The well submersible pump is a pump suitable for clear water. It is strictly prohibited to dig new wells and pump out mud and sand. The voltage grade of the well pump is 380V/50HZ, and other voltage grades of the submersible motor need to be customized. Underground cables must be waterproof cables and must be equipped with starting equipment, such as distribution box, etc. The starting equipment should have common motor comprehensive protection functions, such as short circuit overload protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. In abnormal cases, the protective device should be tripped in time. When installing and using the pump, it must be firmly grounded. It is prohibited to push and pull the switch when the hands and feet are wet. The power supply must be cut off before installing and maintaining the pump. An obvious "anti-electric shock" sign must be set up where the pump is used. Before going down the well or installing the motor, the inner cavity must be filled with distilled water or non-corrosive clean cold water, and the water injection/drainage bolts must be tightened. Fill the pump with water for ground test to lubricate the rubber bearings. The instant start time shall not exceed one second to check whether the direction is correct and consistent with the direction indication. Be sure to pay attention to safety when placing the pump upright to prevent overturning and causing injury. Strictly in accordance with the provisions of the pump lift and flow range of use, to prevent the pump flow at low lift or excessive pull at high lift, resulting in extreme wear of thrust bearings and other components, resulting in motor overload burn. After the pump into the well, the insulation resistance between the motor and the ground shall be measured, which shall not be less than 100MΩ. After the start, observe the voltage and current regularly, and check the motor winding insulation, to see if it meets the requirements; if the pump storage temperature is below the freezing point, the water in the motor cavity should be discharged, so as to avoid the water in the motor cavity freezing and damaging the motor due to low temperature.

Ko nga ahuatanga matua o te hua ko:

1.The motor is a water-loaded wet submersible three-phase asynchronous motor,and the motor cavity is filled with clean water for cooling the motor and lubricating the bearing.The regulating diaphragm at the bottom of the motor is used to adjust the expansion and contraction pressure difference inside and outside the body caused by the temperature rise of the motor.

2.In order to prevent the sand particles in the well water from entering the motor,two oil seals are installed at the extension end of the motor shaft,and the sand ring is installed to form a sand prevention structure.

3.In order to prevent the pump shaft from jumping when starting,the pump shaft is connected with the motor shaft through a coupling,and the thrust bearing is installed at the bottom of the motor.

4.The lubrication of the motor and the pump bearing is water lubrication.

5.The stator winding of the motor adopts high-quality submersible motor winding wire,with excellent insulation performance.

6.The pump is designed by computer CAD,with simple structure and excellent technical performance.

(1) Whakaritenga i mua i te whakaurunga:

1. Tirohia mehemea ka tutuki te papu ruku ki nga tikanga whakamahi me te whanuitanga kua tohua ki te pukapuka.

2. Ma te whakamahi i te obiect taumaha me te diameter e rite ana ki te teitei o te diameter o waho o te papu ruku, ine mehemea ka uru te inneldiameter o te poka wai ki te papu ruku, me te ine mena ka tutuki te hohonutanga o te puna ki nga whakaritenga whakaurunga.

3. Tirohia mehemea he ma te rua o te puna me te wai pokarekare ranei. Kaua rawa e whakamahia he papu hiko ruku ki te horoi i te paru welor papu me te wai kirikiri kia kore e pakaru wawe te papu hiko ruku.

4. Tirohia mehemea he pai te tuunga o te rawhi whakaurunga welhead me te kaha ki te tu ki te kounga o te waahanga katoa.

5. Tirohia mehemea kua oti te whakaurunga o nga waahanga papu ruku me te tika kia rite ki te hoahoa huinga i roto i te pukapuka Tangohia te mata tātari ka huri i te hononga kia kite mena ka huri ngawari.

6. Wewetehia te wiri wai ka whakakiia te kohao motopaika ki te wai ma, kaua e pirau (tohu. me whakakiia ki runga), katahi ka whakakaha i te kopa wai. I muri i nga haora 12 o te werohia o te wai, kaua e iti iho i te 150M Q te parenga whakamarumaru o te motini ka ine ki te tepu wiri 500V.

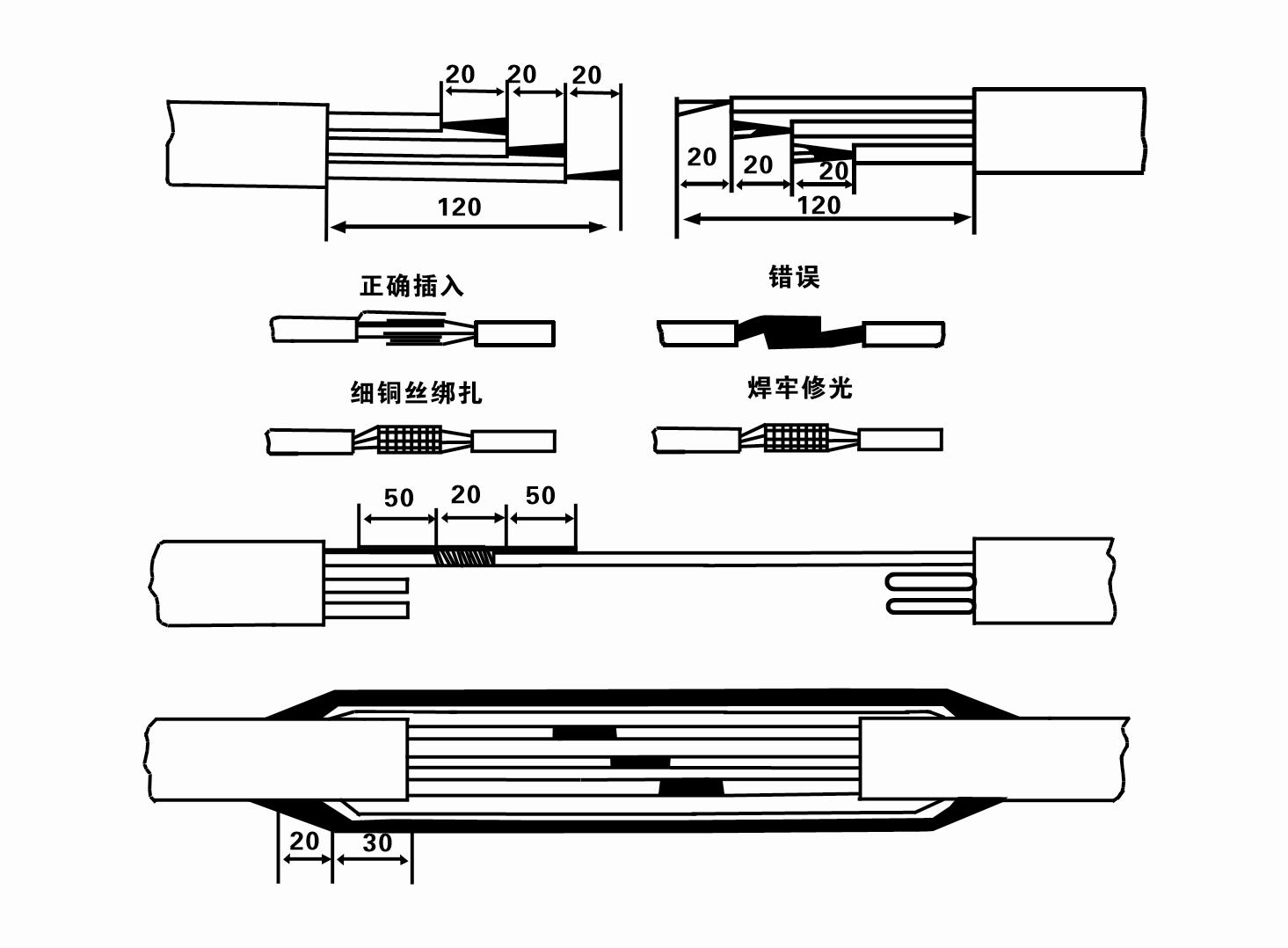

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.

After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Ko te hoahoa tukanga waea waea kua honoa e whai ake nei:

8. Whakamahi i te mita maha ki te tirotiro mena kei te hono nga waea-waa-toru me te ahua taurite te parenga DC.

9. Check whether the circuit and transformer capacity are overloaded, and then connect the overload protection switch or starting equipment. See Table 2 for specific models, and then

Pour a bucket of water into the water pump from the water pump outlet to lubricate the rubber bearings in the pump, and then place the submersible electric pump upright and steady.

Start (no more than one second) and check whether the steering direction is consistent with the steering sign. If not, swap any two connectors of the three-phase cable.

Then install the filter and prepare to go down the well. If used in special occasions (such as ditches, ditches, rivers, ponds, ponds, etc.), the electric pump must be reliably grounded.

(2) Nga taputapu me nga taputapu whakauru:

1. Kotahi te rua o nga mekameka hiki mo te neke atu i te rua tana.

2. He tripod me te teitei poutū kaua e iti iho i te wha mita.

3. E rua nga taura iri (wire ropes) ka taea te kawe i te taumaha neke atu i te kotahi tana (ka taea te kawe i te taumaha o te huinga katoa o nga papu wai).

4. Tāutahia kia rua ngā rawhi (splints).

5. Nga wrenches, hama, wiriwiri, taputapu hiko me nga taputapu, aha atu.

(3)Tautanga papu hiko:

1. Ko te hoahoa whakaurunga o te papu hiko ruku e whakaatuhia ana i te Whakaaturanga 2. Ko nga rahinga whakaurunga motuhake e whakaatuhia ana i te Ripanga 3 "Rarangi o nga Rarangi Whakamutunga o te Pump Hiko Rakau".

2. Ko nga papu hiko ruku me te upoko iti iho i te 30 mita ka taea te whakairi tika ki roto i te puna ma te whakamahi i nga ngongo me nga taura waea, etahi atu taura hemp ranei ka taea te kawe i te taumaha katoa o te miihini, nga paipa wai, me te wai i roto i nga paipa.

3. Ko nga papu me te upoko neke atu i te 30 mita te whakamahi paipa maitai, a ko te raupapa whakaurunga e whai ake nei:

①Use a clamp to clamp the upper end of the water pump part (the motor and water pump have been connected at this time), lift it with a hanging chain, and slowly tie it into the well until

Put the clamp on the wellhead and remove the hanging chain.

② Use another pair of clamps to clamp a pipe, lift it with a hanging chain 15 cm away from the flange, and lower it slowly. Between pipe flange and pump flange

Put the rubber pad in place and tighten the pipe and pump evenly with bolts, nuts and spring washers.

③ Whakaarahia te papu ruuma kia paku, tangohia te rawhi i te pito o runga o te papu wai, herea te taura ki te paipa wai me te riipene kirihou, ka ata herea ki raro kia tuu te rawhi ki te upoko puna.

④Whakamahia taua tikanga ki te here i nga paipa wai katoa ki roto i te puna.

⑤I muri i te hono o te taura arataki ki te pana whakahaere, ka hono atu ki te hiko hiko e toru nga wahanga.

(4) Nga mea hei tohu i te wa o te whakaurunga:

1. If a jamming phenomenon is found during the pumping process, turn or pull the water pipe to overcome the jamming point. If various measures still do not work, please

Do not force the pump down to avoid damage to the submersible electric pump and the well.

2. I te wa o te whakaurunga, me whakanoho he papa rapa ki te taha o ia paipa me te whakakaha kia rite.

3. Ka tukuna te papu wai ki roto i te puna, me tuu ki waenganui o te paipa puna kia kore ai e rere te papu ki te pakitara o te puna mo te wa roa, ka wiri te papu, ka tahia, ka wera te motini. .

4. Whakatauhia te hohonutanga o te papu wai ki raro o te puna i runga i te rere o te onepu me te parapara o te puna. Kaua e tanu te papu ki te paru. Ko te tawhiti mai i te papu wai ki raro o te puna ko te tikanga kaua e iti iho i te 3 mita (tirohia te Whakaahua 2).

5. Ko te hohonutanga o te urunga wai o te papu wai kia kaua e iti iho i te 1-1.5 mita mai i te taumata wai hihiri ki te kohanga uru wai (tirohia te Whakaahua 2). Ki te kore, ka ngawari te pakaru o nga papa papu wai.

6. Ko te hiki o te papu wai e kore e iti rawa. Ki te kore, me whakauru he paera kuaha ki runga i te paipa wai o te upoko o te puna ki te whakahaere i te rere o te papu ki te waahi rere reiti kia kore ai te motini e nui te utaina me te wera na te nui o te rere.

7. I te wa e rere ana te papu wai, me noho tonu te whakaputanga wai me te ara, kia mau tonu te naianei (i raro i nga tikanga mahi kua whakatauhia, ko te tikanga kaua e neke atu i te 10% o te waa kua tohua), kaore he wiri, he haruru ranei. Mena he mate kino, me whakamutu te miihini kia kitea te take me te whakakore.

8. I te wa e whakauru ana, whakarongo ki te whakatakotoranga o te waea motika motika (tirohia te Whakaahua 2). Ina he paipa rino te paipa wai, arahina mai i te rawhi o te upoko puna; ina he paipa kirihou te paipa wai, arahina mai i te tohu whenua o te papu hiko.

- 1.I muri i te whakaurunga o te papu ruuma, tirohia te parenga whakaahuru me te kawe i nga wahanga e toru mai i te whakawhiti, tirohia mehemea kei te he te taputapu me te hononga o nga taputapu tiimata, mena kaore he raru, ka taea te timata te miihini whakamatautau, me te titiro mehemea ka nui ake nga panui tohu o te taputapu i te ngaohiko reiti me te naianei kua tohua ki runga i te papa ingoa i muri i te tiimatanga, ka tirohia mena he haruru me te wiri te ahua o te papu, ka mahi mena he mea noa nga mea katoa.

- 2.I muri i te mahi tuatahi o te papu mo nga haora e wha, me tutakina te motini ki te whakamatautau wawe i te parenga waiariki, a kaua e iti iho i te 0.5 megaohm tona uara.

- 3. I muri i te katinga o te papu, me timata i muri i te rima meneti kia kore ai e rere te wai o roto o te putorino me te nui o te motini me te wera.

- 4.I muri i te tuunga o te papu ki te mahi noa, kia roa ai tona oranga mahi, he mea tika kia tirohia mena he rite tonu te ngaohiko tuku, te mahi o naianei me te aukati i nga wa katoa. Mena ka kitea nga tikanga e whai ake nei, me tutakina tonu te papu ki te rapu raruraru.

- 1 In the rated condition, the current exceeds 20%.

- 2 Ka heke te taumata o te wai hihiri ki te wahanga uru wai, ka puta he wai mokowhiti.

- 3 He nui te wiri, te haruru ranei o te papu ruku.

- 4 He iti ake te ngaohiko tuku i te 340 volts.

- 5 Kua wera te ngongo.

- 6 Kua pakaru te paipa tuku wai.

- 7 The motor's thermal insulation resistance is lower than 0.5 megaohm.

- Unit disassembly:

- 1.Untie the cable tie, remove the pipeline part, and remove the wire plate.

- 2.screw down the water bolt, put the water in the motor chamber.

- 3.remove the filter, loose the fixed screw on the coupling to fix the motor shaft.

- 4.screw down the bolt connecting the water inlet section with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the opposite order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

This product is an efficient and durable submersible electric pump, suitable for a variety of environments and applications.In order to ensure the long-term use and stable performance of the product, we suggest that users pay special attention to drying the water in the motor cavity in winter to avoid freezing; in addition, the cable is coiled and tied, and properly stored in an environment without corrosive substances and gases, with a temperature below 40 °C. If the product is not used for a long time, attention should be paid to rust prevention treatment to ensure the life cycle and performance of the product.Whether for industrial use or for home use, this submersible electric pump can provide you with reliable pump service.

-

- Kaipupuri

- Karekau kakau

- Karekau rakau rapa

-

mowhiti hiri

01 Te urunga wai hohonu

02 Te tuku wai teitei

03 wai maunga

04 wai pourewa

05 Te whakamakuku ahuwhenua

06 te whakamakuku maara

07 te urunga wai o te awa

08 wai whare