The product adopts special water-resistant wire for motor winding, with excellent characteristics such as high frequency shock resistance, pulse peak voltage shock resistance and high temperature aging resistance. The frequency conversion winding design ensures the motor to operate smoothly between 1Hz and 50Hz for a long time, making the frequency conversion deep well pump more energy saving and longer service life.

We are honored to introduce our products, this product provides three-phase AC 380V power supply (tolerance of ± 5%), 50HZ voltage (tolerance of ± 1%). At the same time, our products require strict water quality requirements: water temperature is not higher than 20 °C; solid impurities content (mass ratio) is not greater than 0.01%; PH value (pH) is 6.5-8.5; hydrogen sulfide content is not greater than 1.5mg/L; chloride ion content is not greater than 400mg/L. The motor adopts closed or water-filled wet structure, which must be filled with clean water before use to prevent empty. Tighten the water charging and deflating bolts before use, otherwise, it is not allowed to use. The submersible pump must be completely immersed in water to work, the immersion depth shall not exceed 70 meters, and the distance between the bottom of the submersible pump and the bottom of the well shall not be less than 3 meters. The well water flow shall meet the output and continuous operation requirements of the submersible pump, and the output of the submersible pump shall be controlled at 0.7-1.2 times of the rated flow. The well must be vertical, and the submersible pump can not be used horizontally or inverted, but only vertically. The submersible pump must be equipped with cables according to requirements, and is equipped with external overload protection devices. It is strictly prohibited to conduct no-load tests on the pump without water. Our products guarantee to provide you with high quality and stable performance, while meeting your needs to ensure safe and reliable.

| Icyitegererezo | Gutemba (m3 / h) | Umutwe (m) |

Kwihuta (guhindura / ingingo) |

Amazi meza (%) | Gusohoka diameter (mm) |

Bikurikizwa neza diameter (mm) |

Ikigereranyo power(KW) |

Ikigereranyo voltage (V) |

Ikigereranyo ikigezweho (A) |

Imashanyarazi (%) | power factorcosφ | Igice Ingano ya radiyo nini (mm) |

|||||||||

| 175QJ10-42 | 10 | 42 | 2850 | 53 | 50 | 175hejuru | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ10-56 | 56 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-70 | 70 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-84 | 84 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ10-112 | 112 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-126 | 126 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-140 | 140 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ15-42 | 15 | 42 | 2850 | 58 | 50 | 175hejuru | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ15-55 | 55 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-65 | 65 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-85 | 85 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ15-112 | 112 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 175hejuru | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ20-39 | 39 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ20-52 | 52 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ20-78 | 78 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ20-91 | 91 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-104 | 104 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ20-130 | 130 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-156 | 156 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-182 | 187 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ20-208 | 208 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-247 | 247 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-273 | 273 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-299 | 299 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-325 | 325 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-364 | 364 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-26 | 25 | 26 | 2850 | 66 | 65 | 175hejuru | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ25-39 | 39 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ25-65 | 25 | 65 | 2850 | 66 | 65 | 175hejuru | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ25-78 | 78 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ25-91 | 91 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ25-104 | 104 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-130 | 130 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-156 | 156 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ25-182 | 182 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-208 | 208 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-221 | 221 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-247 | 247 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-260 | 260 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-299 | 299 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ30-30 | 30 | 30 | 2850 | 67 | 80 | 175hejuru | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ30-40 | 40 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-24 | 32 | 24 | 2850 | 67 | 80 | 175hejuru | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ32-36 | 36 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-48 | 48 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ32-60 | 60 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ32-72 | 72 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ32-84 | 84 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-96 | 96 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-120 | 120 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ32-144 | 144 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-168 | 168 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-180 | 180 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-192 | 192 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-204 | 204 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-240 | 240 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ35-60 | 35 | 60 | 2850 | 67 | 80 | 175hejuru | 10 | 380 | 25.0 | 78.0 | 0.78 | 168 | |||||||||

| 175QJ35-75 | 75 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ35-100 | 100 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ40-24 | 40 | 24 | 2850 | 70 | 80 | 175hejuru | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ40-30 | 30 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ40-36 | 36 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ40-48 | 48 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ40-60 | 60 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ40-72 | 72 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-84 | 84 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-96 | 96 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ40-120 | 120 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-132 | 132 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-144 | 144 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-156 | 156 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-168 | 168 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-192 | 192 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-24 | 50 | 24 | 2850 | 72 | 80 | 175hejuru | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ50-36 | 36 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ50-48 | 48 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ50-70 | 70 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ50-84 | 84 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ50-96 | 96 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-108 | 108 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-120 | 120 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-132 | 132 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-144 | 144 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-156 | 156 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-22 | 63 | 22 | 2850 | 72 | 80 | 175hejuru | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ63-44 | 44 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-55 | 55 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-66 | 66 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ63-77 | 77 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-88 | 88 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-99 | 63 | 99 | 2850 | 72 | 80 | 175hejuru | 30 | 380 | 66.6 | 81.5 | 0.84 | 168 | |||||||||

| 175QJ63-110 | 110 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-132 | 132 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-9 | 80 | 9 | 2850 | 73 | 100 | 175hejuru | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ80-18 | 18 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ80-27 | 27 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ80-36 | 36 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ80-45 | 45 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ80-54 | 54 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-63 | 63 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-72 | 72 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-81 | 81 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-90 | 90 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-98 | 98 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

This well submersible pump is a pump suitable for clean water. Digging new wells and pumping sediment and turbid water are strictly prohibited. The voltage grade of the well pump is 380V/50HZ. Submersible motors with other voltage grades need to be customized. Underground cables must use waterproof cables and must be equipped with starting equipment, such as distribution boxes, etc. The starting equipment should have common comprehensive motor protection functions, such as overload short circuit protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. In abnormal cases, the protection device should be tripped in time. During installation and use, the pump must be reliably grounded. It is prohibited to push and pull the switch when hands and feet are wet. The power supply must be cut off before installation and maintenance of the pump. The place where the pump is used must be set up with obvious "anti-electric shock" marks. Before going down the well or installation, the motor must be injected with distilled water or non-corrosive clear cold water in the inner cavity, and the intake/drain bolts must be tightened. When testing the pump on the ground, water must be injected into the pump chamber to lubricate the rubber bearings. The instant start time should not exceed one second to check whether the direction is correct. The same as the steering instructions. Pay attention to safety when the pump is upright to prevent tilting and injury. Strictly in accordance with the provisions of the pump lift and flow range, to prevent the pump flow at low lift or in high lift pull too large, resulting in extreme wear of thrust bearings and other components, the motor due to overload and burn. After put into the well, the measurement of the motor and the ground insulation resistance value, not less than 100M. After the start, regular observation of voltage and current, and check the motor winding insulation is in line with the requirements of the provisions. If the temperature of the storage site is below the freezing point, the water in the pump chamber should be drained to prevent the water in the motor chamber from freezing and damaging the motor due to low temperature.

Intangiriro yerekana imiterere: igice cya pompe kigizwe ahanini na pompe ya pompe, impeller, shell diverion, reberi, kugenzura umubiri wa valve (ibice bidahitamo) nibindi bice. Igice cya moteri kigizwe ahanini na base, igitutu kigenga firime, gutwara ibyuma, gusunika isahani, icyerekezo cyo hasi cyicara, stator, rotor, icyerekezo cyo hejuru cyicara, impeta yumucanga, igice cyinjira mumazi, insinga nibindi bice.

Ibintu nyamukuru biranga ibicuruzwa birimo:

1.The motor is a water-filled wet submersible three-phase asynchronous motor, the motor cavity is full of clean water, used to cool the motor and lubricate the bearing, the pressure regulating film at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the water inside the body caused by the change of the temperature rise of the motor.

2.In order to prevent the sand in the well water from entering the motor, the upper end of the motor shaft is equipped with two oil seals, and a sand ring is installed to form a sand prevention structure.

3.In order to prevent the pump shaft from running up when starting, the pump shaft and the motor shaft are connected by a coupling, and an upper thrust bearing is installed at the lower part of the motor.

4.The lubrication of the motor and the pump bearing is water lubrication.

5.The motor stator winding is made of high quality submersible motor winding wire, with high insulation performance.

6.The pump is designed by computer CAD, with simple structure and good technical performance.

(1) Kwitegura mbere yo kwishyiriraho:

1. Reba niba pompe yarohamye yujuje imiterere yimikoreshereze nubunini bugaragara mu gitabo.

2. Ukoresheje obiect iremereye ifite diameter ingana na diameter ntarengwa yo hanze ya pompe yarohamye, bapima niba inneldiameter ya riba ishobora guhuza pompe irohama, hanyuma upime niba ubujyakuzimu bwujuje ibyangombwa bisabwa.

3. Reba niba iriba rifite isuku kandi niba iriba ryuzuye. Ntuzigere ukoresha pompe yamashanyarazi yogejwe kugirango ukarabe pompe ya welor icyondo namazi yumucanga kugirango wirinde kwangirika hakiri kare pompe yamashanyarazi.

4. Reba niba imyanya ya clamp yo kwishyiriraho ikwiye kandi niba ishobora kwihanganira ubuziranenge bwigice cyose

5. Reba niba ibice bya pompe byamazi byuzuye kandi byashyizweho neza ukurikije igishushanyo cyinteko kiri mu gitabo Kuramo akayunguruzo ka ecran hanyuma uzenguruke hamwe kugirango urebe niba izunguruka byoroshye.

6. Kuramo umugozi wamazi hanyuma wuzuze umwobo wa moteri amazi meza, adashobora kwangirika (icyitonderwa. Witondere kuyuzuza), hanyuma ukomereze kumazi. Nyuma yamasaha 12 yo guterwa amazi, kurwanya moteri ya moteri ntigomba kuba munsi ya 150M Q mugihe upimye hamwe nameza 500V yo kunyeganyega.

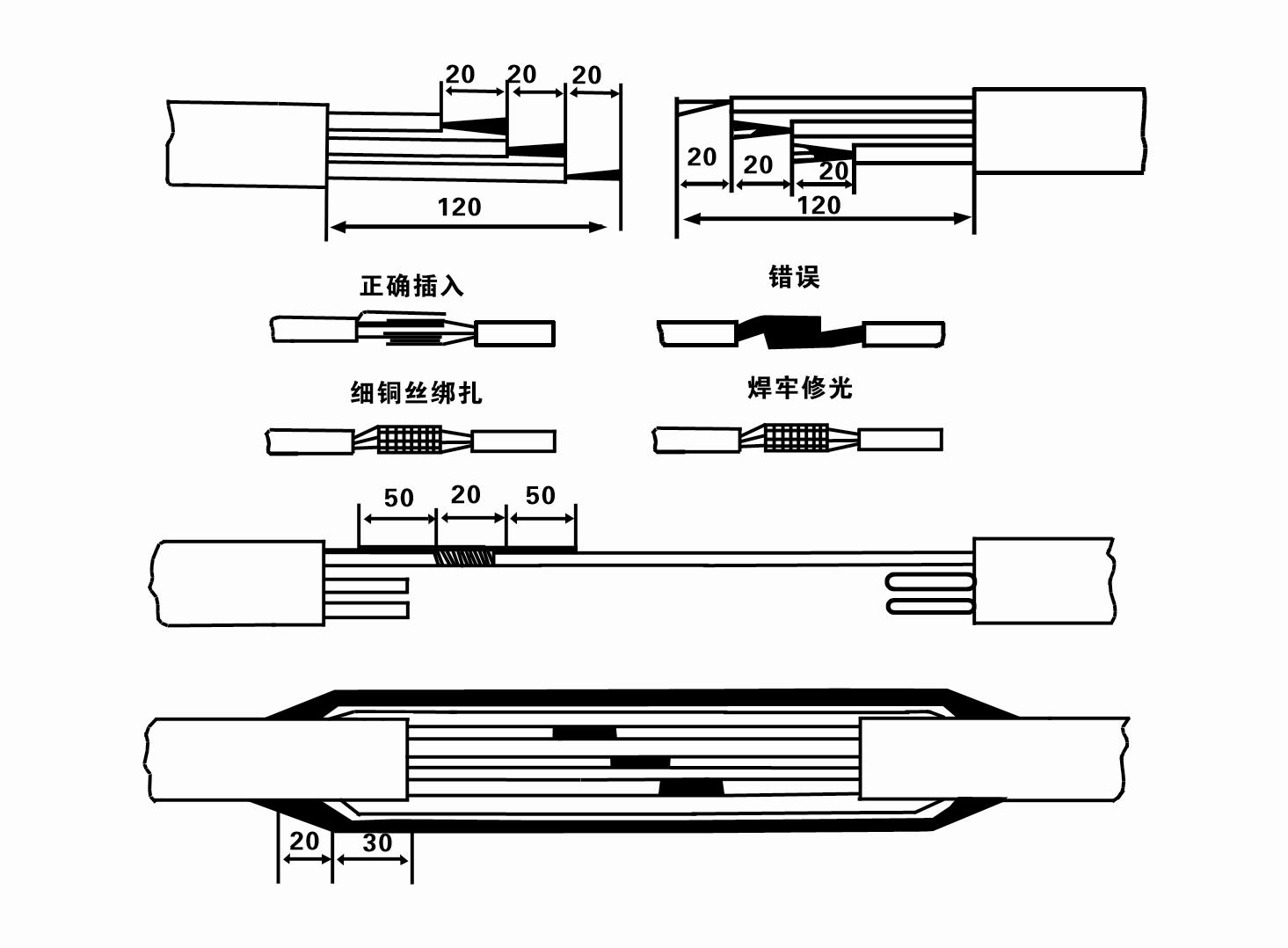

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Igishushanyo cyometse kumugozi wigishushanyo nuburyo bukurikira:

8. Koresha multimeter kugirango urebe niba insinga z'ibyiciro bitatu zahujwe kandi niba DC irwanya hafi.

9. Reba niba ubushobozi bwumuzunguruko na transformateur burenze, hanyuma uhuze uburyo bwo kurinda ibintu birenze cyangwa ibikoresho byo gutangira. Reba Imbonerahamwe ya 2 kuri moderi yihariye, hanyuma Suka indobo y'amazi muri pompe y'amazi uva mumasoko y'amazi kugirango usige amavuta ya reberi muri pompe, hanyuma ushyire pompe y'amashanyarazi yibiza neza kandi bihamye. Tangira (bitarenze isegonda imwe) hanyuma urebe niba icyerekezo kiyobora gihuye nikimenyetso cyo kuyobora. Niba atariyo, hinduranya ibice bibiri bihuza umugozi wibyiciro bitatu. Noneho shyiramo akayunguruzo hanyuma witegure kumanuka kuriba. Niba ikoreshejwe mugihe kidasanzwe (nk'imyobo, imyobo, inzuzi, ibyuzi, ibyuzi, nibindi), pompe y'amashanyarazi igomba kuba ihagaze neza.

(2) Ibikoresho n'ibikoresho byo kwishyiriraho:

1. Ihuriro rimwe ryo guterura iminyururu kuri toni zirenga ebyiri.

2. Inyabutatu ifite uburebure buhagaritse butari munsi ya metero enye.

3. Umugozi ibiri umanitse (umugozi winsinga) ushobora kwihanganira uburemere burenze toni imwe (irashobora kwihanganira uburemere bwamazi yuzuye ya pompe).

4. Shyiramo ibice bibiri bya clamps (splints).

5. Wrenches, inyundo, screwdrivers, ibikoresho byamashanyarazi nibikoresho, nibindi.

(3) Gushyira pompe y'amashanyarazi:

1. Igishushanyo cyo kwishyiriraho pompe yamashanyarazi irengerwa irerekanwa mumashusho 2. Ibipimo byihariye byo kwishyiriraho bigaragara mu mbonerahamwe ya 3 "Urutonde rwibipimo byubushakashatsi bwa pompe yamashanyarazi".

2. Amashanyarazi yamashanyarazi afite umutwe uri munsi ya metero 30 arashobora kuzamurwa mu iriba akoresheje imiyoboro hamwe n’umugozi w’insinga cyangwa indi migozi y’imisozi ishobora kwihanganira uburemere bwuzuye bwimashini yose, imiyoboro y'amazi, n'amazi mu miyoboro.

3. Amapompe afite umutwe wa metero zirenga 30 koresha imiyoboro yicyuma, kandi gahunda yo kuyishyiraho nuburyo bukurikira:

① Koresha clamp kugirango ufate impera yo hejuru yigice cya pompe yamazi (pompe na pompe yamazi byahujwe muriki gihe), ubizamure numunyururu umanitse, hanyuma ubihambire buhoro buhoro kuriba kugeza ushyire clamp kumuriba hanyuma ukureho kumanika urunigi.

② Koresha irindi jambo rya clamp kugirango ufate umuyoboro, uzamure numunyururu umanitse kuri cm 15 uvuye kuri flange, hanyuma umanure buhoro. Hagati ya flange ya pompe na pompe flange Shyira reberi mumwanya wawe hanyuma uhambire umuyoboro hanyuma uvome neza hamwe na bolts, nuts hamwe nogeshe isoko.

Kuzamura pompe yarohamye gato, kura clamp kumpera yo hejuru ya pompe yamazi, guhambira umugozi neza kumuyoboro wamazi hamwe na kaseti ya plastike, hanyuma ubihambire buhoro buhoro kugeza igihe clamp ishyizwe kumuriba.

④ Koresha uburyo bumwe bwo guhuza imiyoboro yose y'amazi mu iriba.

⑤Nyuma ya kabili yo kuyobora-ihujwe no kugenzura ibintu, ihuzwa n'amashanyarazi y'ibice bitatu.

(4) Ibintu ugomba kwitondera mugihe cyo kwishyiriraho:

1. Niba ikintu cyo kuvanga kiboneka mugihe cyo kuvoma, hindura cyangwa ukure umuyoboro wamazi kugirango utsinde aho bahurira. Niba ingamba zitandukanye zitagikora, nyamuneka Ntugahate pompe hasi kugirango wirinde kwangirika kwa pompe yamashanyarazi niriba.

2. Mugihe cyo kwishyiriraho, reberi igomba gushyirwa kuri flange ya buri muyoboro kandi igakomera neza.

3. Iyo pompe yamazi yamanuwe mwiriba, igomba gushyirwa hagati yumuyoboro wiriba kugirango irinde pompe kutiruka kurukuta rwiriba igihe kirekire, bigatuma pompe ihinda umushyitsi kandi moteri irahanagura kandi yaka .

4. Menya ubujyakuzimu bwa pompe yamazi munsi yiziba ukurikije umusenyi utemba hamwe nubutaka bwiriba. Ntugashyingure pompe mucyondo. Intera kuva pompe y'amazi kugeza hepfo y'iriba muri rusange ntabwo iri munsi ya metero 3 (reba Ishusho 2).

5. Ubujyakuzimu bw’amazi ya pompe yamazi ntibugomba kuba munsi ya metero 1-1,5 kuva kurwego rwamazi afite imbaraga kugeza aho amazi yinjira (reba Ishusho 2). Bitabaye ibyo, imiyoboro y'amazi irashobora kwangirika byoroshye.

6. Kuzamura pompe yamazi ntibishobora kuba hasi cyane. Bitabaye ibyo, hagomba gushyirwaho umuyoboro w’irembo ku muyoboro w’amazi kugira ngo ugenzure imigendekere ya pompe ku kigero cyagenwe kugira ngo moteri itaremerwa kandi igatwikwa kubera umuvuduko mwinshi.

7. Iyo pompe yamazi ikora, ibisohoka byamazi bigomba guhoraho kandi niyo, umuyoboro ugomba kuba uhagaze neza (mugihe cyakazi cyagenwe, mubisanzwe ntibirenza 10% byumuvuduko wagenwe), kandi ntihakagombye kubaho kunyeganyega cyangwa urusaku. Niba hari ibintu bidasanzwe, imashini igomba guhagarikwa kugirango imenye icyabimuteye.

8. Mugihe ushyiraho, witondere gushiraho insinga za moteri (reba Ishusho 2). Iyo umuyoboro w'amazi ari umuyoboro w'icyuma, iyiyobore uhereye kumatiba y'iriba; iyo umuyoboro wamazi ari umuyoboro wa pulasitike, iyiyobore uhereye ku kimenyetso cya pompe yamashanyarazi.

- 1.After installing the submersible pump, recheck the insulation resistance and three-phase continuity switch, check whether there is any error in the connection between the instrument and the starting equipment.If there is no problem, you can start to test the machine. After starting, observe whether the indication reading of each instrument is correct.If the rated voltage and current specified on the nameplate are exceeded, please observe whether the pump has noise or vibration.If everything is normal, it can be put into operation. After the pump runs for the first time for four hours, the motor thermal insulation resistance should be closed and tested quickly. Its value should not be less than 0.5 megaohm. After the pump stops, it should be restarted after five minutes to prevent the water column in the pipeline from completely reversing, which will cause the motor to burn out due to excessive current.

- 2.After the pump is put into normal operation, in order to prolong its service life, it is necessary to check whether the supply voltage, working current and insulation resistance are normal regularly. If the following conditions are found, the machine should be stopped immediately to troubleshoot.

- 1.Under the rated working condition, the current exceeds 20%.

- 2.The dynamic water level drops to the water inlet section, resulting in intermittent water.

- 3.The submersible pump has severe vibration or noise.

- 4.The supply voltage is lower than 340 volts.

- 5.A fuse is burned out.

- 6.The water pipeline is damaged.

- 7.The motor's insulation resistance to the geothermal state is lower than 0.5 megaohm.

- 3.Unit disassembly:

- - Kuramo umugozi wa kabili, kura igice cyumuyoboro, hanyuma ukureho icyuma.

- - screw down the water bolt, put out the water in the motor chamber.

- - kuvanaho akayunguruzo, kurekura umugozi uhamye kuri guhuza kugirango ukosore moteri.

- 4.screw down the bolt connecting the water inlet section with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the opposite order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

1, shyira amazi mu cyuho cya moteri (cyane cyane mu gihe cy'itumba kugirango moteri idakonja), hanyuma uhambire umugozi neza.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, gukoresha igihe kirekire bigomba kwitondera kwirinda ingese zo kwirinda pompe zirohama.

- Impeller

- Ikiboko

- Rubber shaft

-

Impeta

01 Amazi meza

02 Amazi maremare

03 amazi yo mumisozi

04 umunara

Kuhira imyaka

Kuvomera ubusitani

Amazi yo mu ruzi

08 amazi yo murugo