The product adopts special water-resistant wire for motor winding, with excellent characteristics such as high frequency shock resistance, pulse peak voltage shock resistance and high temperature aging resistance. The frequency conversion winding design ensures the motor to operate smoothly between 1Hz and 50Hz for a long time, making the frequency conversion deep well pump more energy saving and longer service life.

We are honored to introduce our products, this product provides three-phase AC 380V power supply (tolerance of ± 5%), 50HZ voltage (tolerance of ± 1%). At the same time, our products require strict water quality requirements: water temperature is not higher than 20 °C; solid impurities content (mass ratio) is not greater than 0.01%; PH value (pH) is 6.5-8.5; hydrogen sulfide content is not greater than 1.5mg/L; chloride ion content is not greater than 400mg/L. The motor adopts closed or water-filled wet structure, which must be filled with clean water before use to prevent empty. Tighten the water charging and deflating bolts before use, otherwise, it is not allowed to use. The submersible pump must be completely immersed in water to work, the immersion depth shall not exceed 70 meters, and the distance between the bottom of the submersible pump and the bottom of the well shall not be less than 3 meters. The well water flow shall meet the output and continuous operation requirements of the submersible pump, and the output of the submersible pump shall be controlled at 0.7-1.2 times of the rated flow. The well must be vertical, and the submersible pump can not be used horizontally or inverted, but only vertically. The submersible pump must be equipped with cables according to requirements, and is equipped with external overload protection devices. It is strictly prohibited to conduct no-load tests on the pump without water. Our products guarantee to provide you with high quality and stable performance, while meeting your needs to ensure safe and reliable.

| Mfano | Mtiririko (m3/h) | Kichwa (m) |

Kasi ya mzunguko (badilisha / uhakika) |

Pampu ya maji(%) | Kituo kipenyo (mm) |

Inatumika vizuri kipenyo(mm) |

Imekadiriwa power(KW) |

Imekadiriwa voltage (V) |

Imekadiriwa sasa (A) |

Ufanisi (%) | power factorcosφ | Kitengo Ukubwa wa juu wa radial(mm) |

|||||||||

| 175QJ10-42 | 10 | 42 | 2850 | 53 | 50 | 175juu | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ10-56 | 56 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-70 | 70 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-84 | 84 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ10-112 | 112 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-126 | 126 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-140 | 140 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ15-42 | 15 | 42 | 2850 | 58 | 50 | 175juu | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ15-55 | 55 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-65 | 65 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-85 | 85 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ15-112 | 112 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 175juu | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ20-39 | 39 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ20-52 | 52 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ20-78 | 78 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ20-91 | 91 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-104 | 104 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ20-130 | 130 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-156 | 156 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-182 | 187 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ20-208 | 208 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-247 | 247 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-273 | 273 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-299 | 299 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-325 | 325 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-364 | 364 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-26 | 25 | 26 | 2850 | 66 | 65 | 175juu | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ25-39 | 39 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ25-65 | 25 | 65 | 2850 | 66 | 65 | 175juu | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ25-78 | 78 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ25-91 | 91 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ25-104 | 104 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-130 | 130 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-156 | 156 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ25-182 | 182 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-208 | 208 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-221 | 221 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-247 | 247 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-260 | 260 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-299 | 299 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ30-30 | 30 | 30 | 2850 | 67 | 80 | 175juu | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ30-40 | 40 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-24 | 32 | 24 | 2850 | 67 | 80 | 175juu | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ32-36 | 36 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-48 | 48 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ32-60 | 60 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ32-72 | 72 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ32-84 | 84 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-96 | 96 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-120 | 120 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ32-144 | 144 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-168 | 168 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-180 | 180 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-192 | 192 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-204 | 204 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-240 | 240 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ35-60 | 35 | 60 | 2850 | 67 | 80 | 175juu | 10 | 380 | 25.0 | 78.0 | 0.78 | 168 | |||||||||

| 175QJ35-75 | 75 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ35-100 | 100 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ40-24 | 40 | 24 | 2850 | 70 | 80 | 175juu | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ40-30 | 30 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ40-36 | 36 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ40-48 | 48 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ40-60 | 60 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ40-72 | 72 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-84 | 84 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-96 | 96 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ40-120 | 120 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-132 | 132 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-144 | 144 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-156 | 156 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-168 | 168 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-192 | 192 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-24 | 50 | 24 | 2850 | 72 | 80 | 175juu | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ50-36 | 36 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ50-48 | 48 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ50-70 | 70 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ50-84 | 84 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ50-96 | 96 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-108 | 108 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-120 | 120 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-132 | 132 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-144 | 144 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-156 | 156 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-22 | 63 | 22 | 2850 | 72 | 80 | 175juu | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ63-44 | 44 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-55 | 55 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-66 | 66 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ63-77 | 77 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-88 | 88 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-99 | 63 | 99 | 2850 | 72 | 80 | 175juu | 30 | 380 | 66.6 | 81.5 | 0.84 | 168 | |||||||||

| 175QJ63-110 | 110 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-132 | 132 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-9 | 80 | 9 | 2850 | 73 | 100 | 175juu | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ80-18 | 18 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ80-27 | 27 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ80-36 | 36 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ80-45 | 45 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ80-54 | 54 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-63 | 63 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-72 | 72 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-81 | 81 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-90 | 90 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-98 | 98 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

This well submersible pump is a pump suitable for clean water. Digging new wells and pumping sediment and turbid water are strictly prohibited. The voltage grade of the well pump is 380V/50HZ. Submersible motors with other voltage grades need to be customized. Underground cables must use waterproof cables and must be equipped with starting equipment, such as distribution boxes, etc. The starting equipment should have common comprehensive motor protection functions, such as overload short circuit protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. In abnormal cases, the protection device should be tripped in time. During installation and use, the pump must be reliably grounded. It is prohibited to push and pull the switch when hands and feet are wet. The power supply must be cut off before installation and maintenance of the pump. The place where the pump is used must be set up with obvious "anti-electric shock" marks. Before going down the well or installation, the motor must be injected with distilled water or non-corrosive clear cold water in the inner cavity, and the intake/drain bolts must be tightened. When testing the pump on the ground, water must be injected into the pump chamber to lubricate the rubber bearings. The instant start time should not exceed one second to check whether the direction is correct. The same as the steering instructions. Pay attention to safety when the pump is upright to prevent tilting and injury. Strictly in accordance with the provisions of the pump lift and flow range, to prevent the pump flow at low lift or in high lift pull too large, resulting in extreme wear of thrust bearings and other components, the motor due to overload and burn. After put into the well, the measurement of the motor and the ground insulation resistance value, not less than 100M. After the start, regular observation of voltage and current, and check the motor winding insulation is in line with the requirements of the provisions. If the temperature of the storage site is below the freezing point, the water in the pump chamber should be drained to prevent the water in the motor chamber from freezing and damaging the motor due to low temperature.

Utangulizi mfupi wa muundo: sehemu ya pampu inaundwa hasa na shimoni la pampu, impela, ganda la diversion, kuzaa kwa mpira, angalia mwili wa valve (sehemu za hiari) na vipengele vingine. Sehemu ya motor inaundwa na msingi, filamu inayosimamia shinikizo, fani ya kutia, sahani ya kutia, kiti cha chini cha kubeba mwongozo, stator, rotor, kiti cha kuzaa mwongozo, pete ya mchanga, sehemu ya ghuba ya maji, kebo na vifaa vingine.

Makala kuu ya bidhaa ni pamoja na:

1.The motor is a water-filled wet submersible three-phase asynchronous motor, the motor cavity is full of clean water, used to cool the motor and lubricate the bearing, the pressure regulating film at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the water inside the body caused by the change of the temperature rise of the motor.

2.In order to prevent the sand in the well water from entering the motor, the upper end of the motor shaft is equipped with two oil seals, and a sand ring is installed to form a sand prevention structure.

3.In order to prevent the pump shaft from running up when starting, the pump shaft and the motor shaft are connected by a coupling, and an upper thrust bearing is installed at the lower part of the motor.

4.The lubrication of the motor and the pump bearing is water lubrication.

5.The motor stator winding is made of high quality submersible motor winding wire, with high insulation performance.

6.The pump is designed by computer CAD, with simple structure and good technical performance.

(1) Maandalizi kabla ya ufungaji:

1. Angalia ikiwa pampu inayoweza kuzama inakidhi masharti ya matumizi na upeo uliobainishwa kwenye mwongozo.

2. Kwa kutumia kipenyo kizito chenye kipenyo sawa na kipenyo cha juu zaidi cha nje cha pampu inayoweza kuzamishwa, pima ikiwa kipenyo cha ndani cha kisima kinaweza kutoshea pampu inayoweza kuzamishwa, na kupima kama kina cha kisima kinakidhi mahitaji ya usakinishaji.

3. Angalia kama kisima ni safi na kama maji ya kisima ni machafu. Kamwe usitumie pampu ya umeme inayoweza kuzama ili kuosha tope la pampu ya kisima na maji ya mchanga ili kuepuka uharibifu wa mapema wa pampu ya umeme inayoweza kuzamishwa.

4. Angalia ikiwa nafasi ya bani ya usakinishaji ya welhead inafaa na ikiwa inaweza kuhimili ubora wa kitengo kizima.

5. Angalia ikiwa vijenzi vya pampu inayoweza kuzamishwa vimekamilika na kusakinishwa ipasavyo kulingana na mchoro wa kusanyiko kwenye mwongozoOndoa skrini ya kichujio na uzungushe kiunganishi ili kuona kama kinazunguka kwa urahisi.

6. Fungua skrubu ya skrubu ya maji na ujaze tundu la moshi kwa maji safi, yasiyo na babuzi (kumbuka. hakikisha umeichuja), kisha kaza screw ya maji. Baada ya masaa 12 ya sindano ya maji, upinzani wa insulation ya motor haipaswi kuwa chini ya 150M Q inapopimwa na meza ya 500V ya kutikisa.

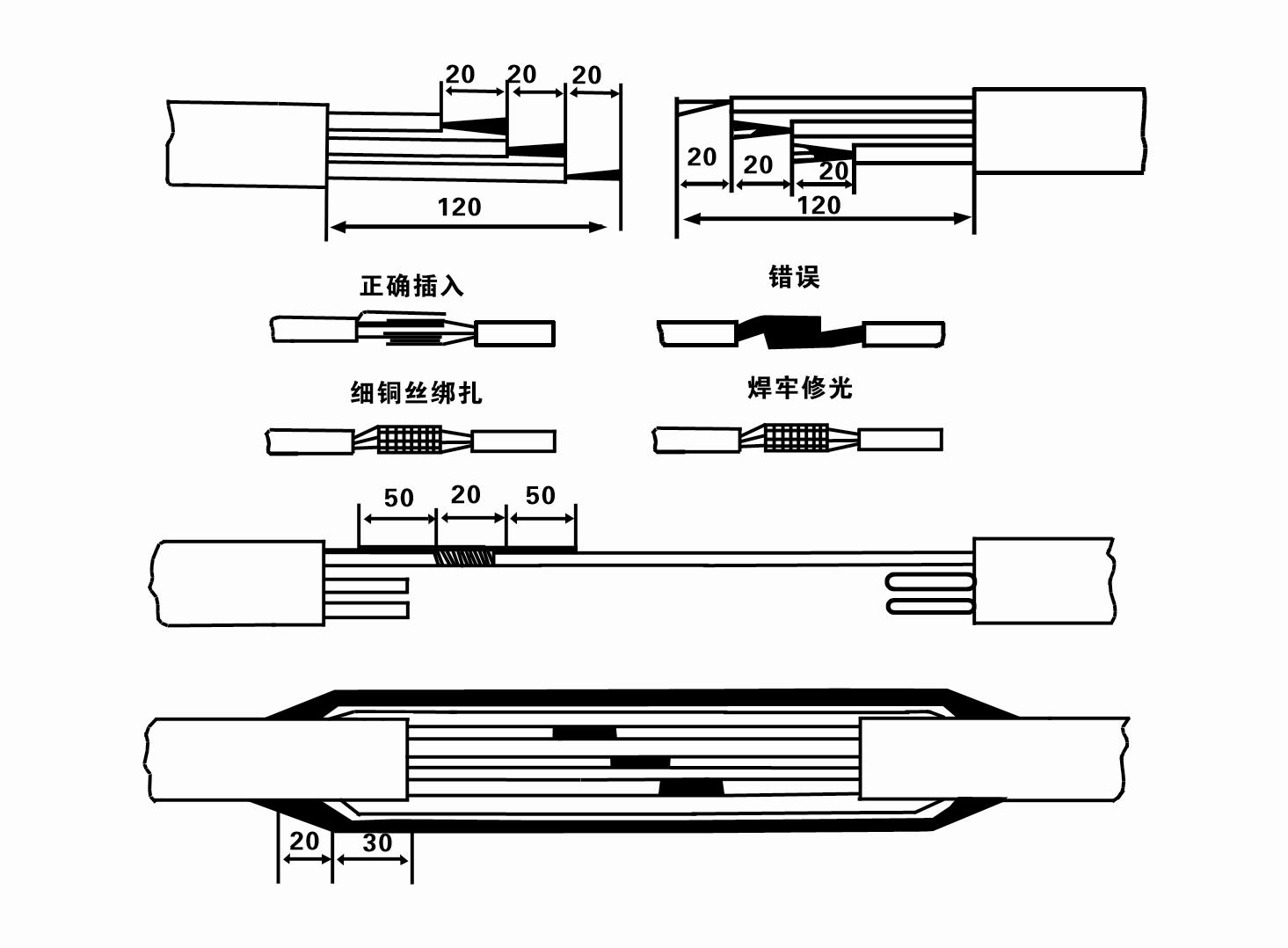

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Mchoro wa mchakato wa wiring cable ni kama ifuatavyo:

8. Tumia multimeter ili uangalie ikiwa waya za awamu tatu zimeunganishwa na ikiwa upinzani wa DC ni takriban usawa.

9. Angalia ikiwa saketi na uwezo wa kibadilishaji umeme umejaa kupita kiasi, na kisha unganisha swichi ya ulinzi wa upakiaji au vifaa vya kuanzia. Tazama Jedwali la 2 kwa miundo mahususi, kisha Mimina ndoo ya maji kwenye pampu ya maji kutoka kwa pampu ya maji ili kulainisha fani za mpira kwenye pampu, na kisha uweke pampu ya umeme inayoweza kuzamishwa wima na thabiti. Anza (si zaidi ya sekunde moja) na uangalie ikiwa mwelekeo wa usukani unalingana na ishara ya usukani. Ikiwa sivyo, badilisha viunganishi vyovyote viwili vya kebo ya awamu ya tatu.Kisha sakinisha kichujio na ujiandae kwenda chini ya kisima. Ikiwa inatumiwa katika matukio maalum (kama vile mitaro, mifereji, mito, mabwawa, mabwawa, nk), pampu ya umeme lazima iwekwe chini kwa uhakika.

(2) Vifaa na zana za usakinishaji:

1. Jozi moja ya minyororo ya kuinua kwa zaidi ya tani mbili.

2. Tripod yenye urefu wa wima wa si chini ya mita nne.

3. Kamba mbili za kunyongwa (kamba za waya) zinazoweza kubeba uzito wa zaidi ya tani moja (zinaweza kubeba uzito wa seti kamili ya pampu za maji).

4. Weka jozi mbili za clamps (splints).

5. Wrenches, nyundo, screwdrivers, zana za umeme na vyombo, nk.

(3) Ufungaji wa pampu ya umeme:

1. Mchoro wa ufungaji wa pampu ya umeme ya chini ya maji umeonyeshwa kwenye Mchoro 2. Vipimo maalum vya ufungaji vinaonyeshwa kwenye Jedwali la 3 "Orodha ya Vipimo vya Ufungaji wa Pumpu ya Umeme ya Submersible".

2. Pampu za umeme zinazozamishwa na kichwa chini ya mita 30 zinaweza kuinuliwa moja kwa moja kwenye kisima kwa kutumia mabomba na kamba za waya au kamba nyingine za katani ambazo zinaweza kubeba uzito kamili wa mashine nzima, mabomba ya maji, na maji katika mabomba.

3. Pampu zilizo na kichwa cha zaidi ya mita 30 hutumia mabomba ya chuma, na mlolongo wa ufungaji ni kama ifuatavyo:

①Tumia kibano kubana ncha ya juu ya sehemu ya pampu ya maji (motor na pampu ya maji vimeunganishwa kwa wakati huu), inua kwa mnyororo wa kuning'inia, na polepole uifunge ndani ya kisima hadi Weka bani kwenye kichwa cha kisima na uondoe. mnyororo wa kunyongwa.

② Tumia vibano vingine ili kubana bomba, linyanyue kwa mnyororo wa kuning'inia umbali wa sm 15 kutoka kwenye ubao, na uushushe polepole. Kati ya flange ya bomba na flange ya pampuWeka pedi ya mpira mahali pake na kaza bomba na pampu sawasawa na bolts, karanga na washers wa spring.

③ Inua pampu inayoweza kuzama kidogo, ondoa kibano kwenye ncha ya juu ya pampu ya maji, funga kebo kwa uthabiti kwenye bomba la maji kwa mkanda wa plastiki, na uifunge polepole chini hadi Kinano kiwekwe kwenye kisima.

④Tumia njia sawa kufunga mabomba yote ya maji kwenye kisima.

⑤Baada ya kebo ya kuongoza kuunganishwa kwenye swichi ya kudhibiti, inaunganishwa kwenye usambazaji wa umeme wa awamu tatu.

(4) Mambo ya kuzingatia wakati wa usakinishaji:

1. Ikiwa jambo la jamming linapatikana wakati wa mchakato wa kusukuma, pindua au kuvuta bomba la maji ili kuondokana na hatua ya jamming. Ikiwa hatua mbalimbali bado hazifanyi kazi, tafadhaliUsilazimishe pampu chini ili kuepuka uharibifu wa pampu ya umeme inayozama na kisima.

2. Wakati wa ufungaji, pedi ya mpira inapaswa kuwekwa kwenye flange ya kila bomba na kuimarishwa sawasawa.

3. Wakati pampu ya maji inaposhushwa ndani ya kisima, inapaswa kuwekwa katikati ya bomba la kisima ili kuzuia pampu kukimbia dhidi ya ukuta wa kisima kwa muda mrefu, na kusababisha pampu kutetemeka na motor kufagia na kuwaka. .

4. Tambua kina cha pampu ya maji hadi chini ya kisima kulingana na mchanga unaopita na hali ya silt ya kisima. Usizike pampu kwenye matope. Umbali kutoka kwa pampu ya maji hadi chini ya kisima kwa ujumla sio chini ya mita 3 (ona Mchoro 2).

5. Kina cha kuingilia maji cha pampu ya maji haipaswi kuwa chini ya mita 1-1.5 kutoka ngazi ya maji yenye nguvu hadi nodi ya ingizo la maji (ona Mchoro 2). Vinginevyo, fani za pampu za maji zinaweza kuharibiwa kwa urahisi.

6. Kuinua kwa pampu ya maji hawezi kuwa chini sana. Vinginevyo, vali ya lango inahitaji kusakinishwa kwenye bomba la maji la kisima ili kudhibiti mtiririko wa pampu kwenye sehemu iliyokadiriwa ya mtiririko ili kuzuia injini isijazwe na kuteketezwa kwa sababu ya viwango vikubwa vya mtiririko.

7. Wakati pampu ya maji inapoendesha, pato la maji linapaswa kuendelea na hata, sasa inapaswa kuwa imara (chini ya hali ya kazi iliyopimwa, kwa ujumla si zaidi ya 10% ya sasa iliyopimwa), na haipaswi kuwa na vibration au kelele. Ikiwa kuna hali isiyo ya kawaida, mashine inapaswa kusimamishwa ili kujua sababu na kuiondoa.

8. Wakati wa kufunga, makini na mpangilio wa waya wa kutuliza motor (angalia Mchoro 2). Wakati bomba la maji ni bomba la chuma, liongoze kutoka kwenye kisima cha kisima; wakati bomba la maji ni bomba la plastiki, liongoze kutoka kwa alama ya kutuliza pampu ya umeme.

- 1.After installing the submersible pump, recheck the insulation resistance and three-phase continuity switch, check whether there is any error in the connection between the instrument and the starting equipment.If there is no problem, you can start to test the machine. After starting, observe whether the indication reading of each instrument is correct.If the rated voltage and current specified on the nameplate are exceeded, please observe whether the pump has noise or vibration.If everything is normal, it can be put into operation. After the pump runs for the first time for four hours, the motor thermal insulation resistance should be closed and tested quickly. Its value should not be less than 0.5 megaohm. After the pump stops, it should be restarted after five minutes to prevent the water column in the pipeline from completely reversing, which will cause the motor to burn out due to excessive current.

- 2.After the pump is put into normal operation, in order to prolong its service life, it is necessary to check whether the supply voltage, working current and insulation resistance are normal regularly. If the following conditions are found, the machine should be stopped immediately to troubleshoot.

- 1.Under the rated working condition, the current exceeds 20%.

- 2.The dynamic water level drops to the water inlet section, resulting in intermittent water.

- 3.The submersible pump has severe vibration or noise.

- 4.The supply voltage is lower than 340 volts.

- 5.A fuse is burned out.

- 6.The water pipeline is damaged.

- 7.The motor's insulation resistance to the geothermal state is lower than 0.5 megaohm.

- 3.Unit disassembly:

- - Fungua kebo, ondoa sehemu ya bomba na uondoe bati la waya.

- - screw down the water bolt, put out the water in the motor chamber.

- - ondoa chujio, fungua screw fasta kwenye kuunganisha ili kurekebisha shaft motor.

- 4.screw down the bolt connecting the water inlet section with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the opposite order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

1, kuweka maji katika cavity motor (hasa katika majira ya baridi ili kuzuia motor kutoka kufungia), na kufunga cable vizuri.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, matumizi ya muda mrefu lazima makini na kuzuia kutu ya pampu submersible.

- Msukumo

- Sleeve ya shimoni

- Sleeve ya shimoni ya mpira

-

Pete ya kuziba

01 Unywaji wa maji ya kisima kirefu

02 Ugavi wa maji wa hali ya juu

03 usambazaji wa maji wa mlima

04 maji ya mnara

05 Umwagiliaji wa kilimo

06 umwagiliaji wa bustani

07 ulaji wa maji ya mto

08 maji ya nyumbani