The product adopts special water-resistant wire for motor winding, with excellent characteristics such as high frequency shock resistance, pulse peak voltage shock resistance and high temperature aging resistance. The frequency conversion winding design ensures the motor to operate smoothly between 1Hz and 50Hz for a long time, making the frequency conversion deep well pump more energy saving and longer service life.

We are honored to introduce our products, this product provides three-phase AC 380V power supply (tolerance of ± 5%), 50HZ voltage (tolerance of ± 1%). At the same time, our products require strict water quality requirements: water temperature is not higher than 20 °C; solid impurities content (mass ratio) is not greater than 0.01%; PH value (pH) is 6.5-8.5; hydrogen sulfide content is not greater than 1.5mg/L; chloride ion content is not greater than 400mg/L. The motor adopts closed or water-filled wet structure, which must be filled with clean water before use to prevent empty. Tighten the water charging and deflating bolts before use, otherwise, it is not allowed to use. The submersible pump must be completely immersed in water to work, the immersion depth shall not exceed 70 meters, and the distance between the bottom of the submersible pump and the bottom of the well shall not be less than 3 meters. The well water flow shall meet the output and continuous operation requirements of the submersible pump, and the output of the submersible pump shall be controlled at 0.7-1.2 times of the rated flow. The well must be vertical, and the submersible pump can not be used horizontally or inverted, but only vertically. The submersible pump must be equipped with cables according to requirements, and is equipped with external overload protection devices. It is strictly prohibited to conduct no-load tests on the pump without water. Our products guarantee to provide you with high quality and stable performance, while meeting your needs to ensure safe and reliable.

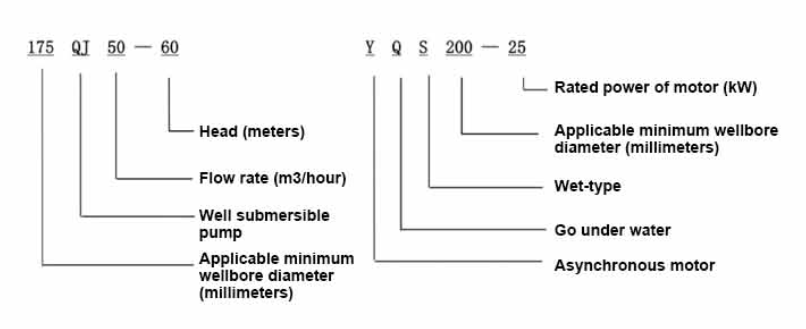

| Model | Akym (m3 / sag) | Baş (m) |

Aýlanma (üýtgetmek / nokat) |

Suw nasosy (%) | Çykyş diametri (mm) |

Gowy ulanylýar diametri (mm) |

Bahalandyryldy power(KW) |

Bahalandyryldy naprýa .eniýe (V) |

Bahalandyryldy häzirki (A) |

Motorefficiency (%) | power factorcosφ | Bölüm Radial Maksimu ululygy (mm) |

|||||||||

| 175QJ10-42 | 10 | 42 | 2850 | 53 | 50 | 175ýokarda | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ10-56 | 56 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-70 | 70 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-84 | 84 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ10-112 | 112 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-126 | 126 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-140 | 140 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ15-42 | 15 | 42 | 2850 | 58 | 50 | 175ýokarda | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ15-55 | 55 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-65 | 65 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-85 | 85 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ15-112 | 112 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 175ýokarda | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ20-39 | 39 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ20-52 | 52 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ20-78 | 78 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ20-91 | 91 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-104 | 104 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ20-130 | 130 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-156 | 156 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-182 | 187 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ20-208 | 208 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-247 | 247 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-273 | 273 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-299 | 299 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-325 | 325 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-364 | 364 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-26 | 25 | 26 | 2850 | 66 | 65 | 175ýokarda | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ25-39 | 39 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ25-65 | 25 | 65 | 2850 | 66 | 65 | 175ýokarda | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ25-78 | 78 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ25-91 | 91 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ25-104 | 104 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-130 | 130 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-156 | 156 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ25-182 | 182 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-208 | 208 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-221 | 221 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-247 | 247 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-260 | 260 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-299 | 299 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ30-30 | 30 | 30 | 2850 | 67 | 80 | 175ýokarda | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ30-40 | 40 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-24 | 32 | 24 | 2850 | 67 | 80 | 175ýokarda | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ32-36 | 36 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-48 | 48 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ32-60 | 60 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ32-72 | 72 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ32-84 | 84 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-96 | 96 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-120 | 120 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ32-144 | 144 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-168 | 168 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-180 | 180 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-192 | 192 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-204 | 204 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-240 | 240 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ35-60 | 35 | 60 | 2850 | 67 | 80 | 175ýokarda | 10 | 380 | 25.0 | 78.0 | 0.78 | 168 | |||||||||

| 175QJ35-75 | 75 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ35-100 | 100 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ40-24 | 40 | 24 | 2850 | 70 | 80 | 175ýokarda | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ40-30 | 30 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ40-36 | 36 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ40-48 | 48 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ40-60 | 60 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ40-72 | 72 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-84 | 84 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-96 | 96 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ40-120 | 120 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-132 | 132 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-144 | 144 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-156 | 156 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-168 | 168 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-192 | 192 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-24 | 50 | 24 | 2850 | 72 | 80 | 175ýokarda | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ50-36 | 36 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ50-48 | 48 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ50-70 | 70 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ50-84 | 84 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ50-96 | 96 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-108 | 108 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-120 | 120 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-132 | 132 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-144 | 144 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-156 | 156 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-22 | 63 | 22 | 2850 | 72 | 80 | 175ýokarda | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ63-44 | 44 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-55 | 55 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-66 | 66 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ63-77 | 77 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-88 | 88 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-99 | 63 | 99 | 2850 | 72 | 80 | 175ýokarda | 30 | 380 | 66.6 | 81.5 | 0.84 | 168 | |||||||||

| 175QJ63-110 | 110 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-132 | 132 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-9 | 80 | 9 | 2850 | 73 | 100 | 175ýokarda | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ80-18 | 18 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ80-27 | 27 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ80-36 | 36 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ80-45 | 45 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ80-54 | 54 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-63 | 63 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-72 | 72 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-81 | 81 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-90 | 90 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-98 | 98 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

This well submersible pump is a pump suitable for clean water. Digging new wells and pumping sediment and turbid water are strictly prohibited. The voltage grade of the well pump is 380V/50HZ. Submersible motors with other voltage grades need to be customized. Underground cables must use waterproof cables and must be equipped with starting equipment, such as distribution boxes, etc. The starting equipment should have common comprehensive motor protection functions, such as overload short circuit protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. In abnormal cases, the protection device should be tripped in time. During installation and use, the pump must be reliably grounded. It is prohibited to push and pull the switch when hands and feet are wet. The power supply must be cut off before installation and maintenance of the pump. The place where the pump is used must be set up with obvious "anti-electric shock" marks. Before going down the well or installation, the motor must be injected with distilled water or non-corrosive clear cold water in the inner cavity, and the intake/drain bolts must be tightened. When testing the pump on the ground, water must be injected into the pump chamber to lubricate the rubber bearings. The instant start time should not exceed one second to check whether the direction is correct. The same as the steering instructions. Pay attention to safety when the pump is upright to prevent tilting and injury. Strictly in accordance with the provisions of the pump lift and flow range, to prevent the pump flow at low lift or in high lift pull too large, resulting in extreme wear of thrust bearings and other components, the motor due to overload and burn. After put into the well, the measurement of the motor and the ground insulation resistance value, not less than 100M. After the start, regular observation of voltage and current, and check the motor winding insulation is in line with the requirements of the provisions. If the temperature of the storage site is below the freezing point, the water in the pump chamber should be drained to prevent the water in the motor chamber from freezing and damaging the motor due to low temperature.

Gurluşyň gysgaça girizilmegi: nasos bölegi esasan nasos ştatyndan, hereketlendirijiden, diwersiýa gabygyndan, rezin rulmadan, klapan korpusyndan (goşmaça böleklerden) we beýleki böleklerden durýar. Motor bölegi esasan esas, basyşy kadalaşdyryjy film, zyňylýan podşipnik, zyňylýan plastinka, aşaky gollanma oturgyjy, stator, rotor, ýokarky gollanma oturgyjy, gum halkasy, suw giriş bölümi, kabel we beýleki böleklerden durýar.

Önümiň esasy aýratynlyklary:

1.The motor is a water-filled wet submersible three-phase asynchronous motor, the motor cavity is full of clean water, used to cool the motor and lubricate the bearing, the pressure regulating film at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the water inside the body caused by the change of the temperature rise of the motor.

2.In order to prevent the sand in the well water from entering the motor, the upper end of the motor shaft is equipped with two oil seals, and a sand ring is installed to form a sand prevention structure.

3.In order to prevent the pump shaft from running up when starting, the pump shaft and the motor shaft are connected by a coupling, and an upper thrust bearing is installed at the lower part of the motor.

4.The lubrication of the motor and the pump bearing is water lubrication.

5.The motor stator winding is made of high quality submersible motor winding wire, with high insulation performance.

6.The pump is designed by computer CAD, with simple structure and good technical performance.

(1) Gurmakdan öň taýýarlyk:

1. Suwa çümýän nasosyň gollanmada görkezilen ulanyş şertlerine we gerimine laýyk gelýändigini barlaň.

2. Suwa çümýän nasosyň daşky diametrine deň bolan agyr obýekte ulanmak, guýynyň inneldiametriniň suwa çümýän nasosyna laýyk bolup biljekdigini ýa-da guýynyň çuňlugynyň gurnama talaplaryna laýyk gelýändigini ölçäň.

3. Guýynyň arassa bolandygyny ýa-da guýynyň suwunyň bulaşykdygyny barlaň. Suwa çümýän elektrik nasosyna wagtyndan öň zeper ýetmezligi üçin, garşylaýjy nasos palçyklaryny we gum suwlaryny ýuwmak üçin hiç wagt suwa çümýän elektrik nasosyny ulanmaň.

4. Kelleli gurnama gysgyjynyň ýagdaýynyň laýykdygyny ýa-da tutuş bölümiň hiline çydap biljekdigini barlaň

5. Gollanma gurnama diagrammasyna laýyklykda suwa çümýän nasos bölekleriniň doly we dogry gurlandygyny barlaň Süzgüç ekranyny aýyryň we çeýe aýlanýandygyny ýa-da ýokdugyny aýlaň.

6. Suw nurbatyny aýryň we motor boşlugyny arassa, poslamaýan suw bilen dolduryň (bellik ediň. 12 sagat suw sanjymyndan soň, 500V titreýän stol bilen ölçelende motoryň izolýasiýa garşylygy 150M Q-dan pes bolmaly däldir.

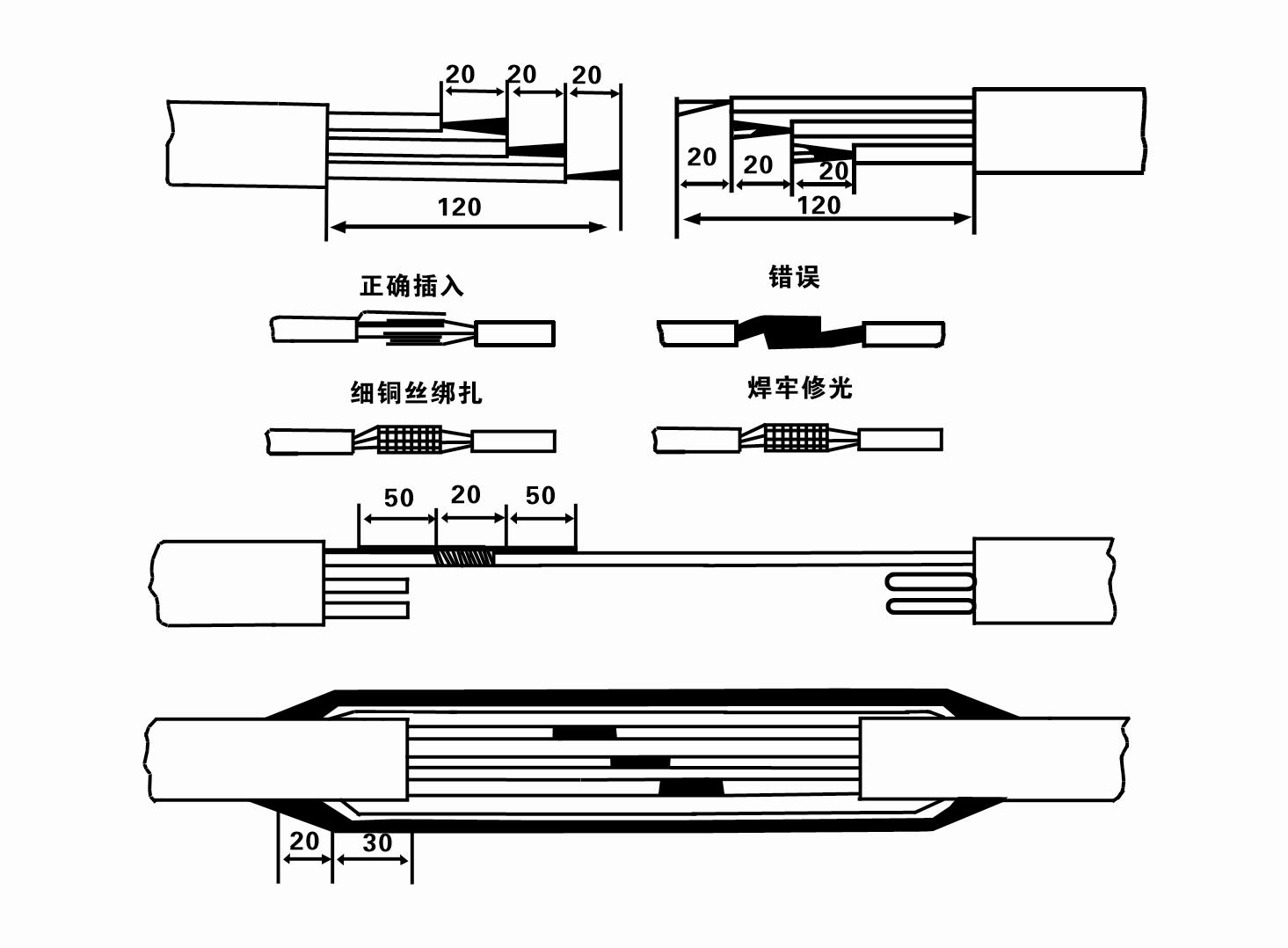

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Berkidilen kabel simleriniň diagrammasy aşakdaky ýaly:

8. Üç fazaly simleriň birikdirilendigini ýa-da DC garşylygynyň takmynan deňagramlydygyny ýa-da ýokdugyny barlamak üçin multimetr ulanyň.

9. Zynjyryň we transformatoryň kuwwatynyň aşa ýüklenendigini ýa-da ýokdugyny barlaň, soňra bolsa artykmaç gorag wyklýuçatelini ýa-da başlangyç enjamlary birikdiriň. Specificörite modeller üçin 2-nji tablisa serediň, soňra nasosdaky rezin podşipnikleri ýaglamak üçin suw nasosynyň rozetkasyndan bir bedre suw guýuň, soňra suwa çümýän elektrik nasosyny dik we durnukly ýerleşdiriň. Başlaň (bir sekuntdan köp bolmaly däl) we ruluň rul belgisine laýyk gelýändigini barlaň. Notok bolsa, üç fazaly kabeliň islendik iki birikdirijisini çalyşyň. Soňra süzgüçi guruň we guýynyň aşagyna gitmäge taýynlaň. Specialörite ýagdaýlarda (garymlar, garymlar, derýalar, howuzlar, howuzlar we ş.m.) ulanylsa, elektrik nasosy ygtybarly bolmaly.

(2) Gurnama enjamlary we gurallary:

1. Iki tonnadan gowrak göteriji zynjyr.

2. Dikligi dört metrden az bolmadyk üçburçluk.

3. Bir tonnadan gowrak agramy göterip bilýän iki sany asma ýüp (simli ýüpler) (suw nasoslarynyň doly toplumynyň agramyny göterip biler).

4. Iki jübüt gysgyç guruň.

5. Kirpikler, çekiçler, otwýortkalar, elektrik gurallary we gurallar we ş.m.

(3) Elektrik nasosyny oturtmak:

1. Suwa çümýän elektrik nasosynyň gurnama diagrammasy 2-nji suratda görkezilýär. Gurluşyň anyk ölçegleri 3-nji tablisada "Suwasty elektrik nasosynyň gurnama ölçegleriniň sanawy" görkezilýär.

2. Kellesi 30 metrden az bolan suwa çümdürilen elektrik nasoslary, ähli maşynyň, suw turbalarynyň we turbalardaky suwuň doly agramyny göterip bilýän şlanglar we sim arkanlary ýa-da beýleki kenep ýüpleri bilen göni guýa çykarylyp bilner.

3. 30 metrden gowrak kellesi bolan nasoslar polat turbalary ulanýarlar we gurnama yzygiderliligi aşakdaky ýaly:

Water Suw nasos böleginiň ýokarky ujuny gysmak üçin gysgyç ulanyň (motor we suw nasosy şu wagt birikdirildi), asylan zynjyr bilen galdyryň we guýynyň başyna gysgyç goýýançaňyz we haýallyk bilen guýa daňyň. asma zynjyr.

A Turbany gysmak, flanesden 15 sm uzaklykda asylan zynjyr bilen götermek we haýallyk bilen aşak düşürmek üçin başga bir gysgyç ulanyň. Turbanyň flanesleri bilen nasos flanesleriniň arasynda rezin paneli ýerleşdiriň we turbany berkidiň we boltlar, hozlar we pru springina ýuwujylar bilen deň derejede nasoslaň.

Sub Çökýän nasosy birneme ýokaryk galdyryň, suw nasosynyň ýokarky ujundaky gysgyçlary aýyryň, kabeli suw turbasyna plastmassa lenta bilen berkidiň we gysgyç guýynyň başyna goýulýança ýuwaş-ýuwaşdan daňyň.

Water waterhli suw turbalaryny guýa baglamak üçin şol bir usuly ulanyň.

Lead Gurluş kabeli dolandyryş wyklýuçateline birikdirilenden soň, üç fazaly elektrik üpjünçiligine birikdirilýär.

(4) Gurmak wagtynda bellemeli zatlar:

1. Sordurmak prosesinde dykyzlyk hadysasy tapylsa, dykylýan nokady ýeňip geçmek üçin suw turbasyny öwüriň ýa-da çekiň. Dürli çäreler henizem işlemeýän bolsa, suwa çümýän elektrik nasosyna we guýa zeper ýetmezligi üçin nasosy aşak mejbur etmäň.

2. Gurmak wagtynda her turbanyň flanesine rezin pad goýulmaly we deň derejede berkidilmeli.

3. Suw nasosy guýa düşürilende, nasosyň titremegine we motoryň süpürilmegine we ýanmagyna sebäp bolup, nasosyň guýynyň diwaryna uzak wagtlap işlemezligi üçin guýynyň turbasynyň ortasyna goýulmalydyr. .

4. Guýynyň akýan çäge we palçyk şertlerine görä guýynyň düýbüne suw nasosynyň çuňlugyny kesgitläň. Nasosy palçykda jaýlamaň. Suw nasosyndan guýynyň düýbüne çenli aralyk, adatça, 3 metrden az däl (2-nji surata serediň).

5. Suw nasosynyň suw giriş çuňlugy dinamiki suw derejesinden suw girelgesine çenli 1-1,5 metrden az bolmaly däldir (2-nji surata serediň). Otherwiseogsam, suw nasosynyň podşipnikleri aňsat zaýalanmagy mümkin.

6. Suw nasosynyň göterilmegi gaty pes bolup bilmez. Otherwiseogsam, uly akym tizligi sebäpli motoryň aşa köp ýüklenmeginiň we ýanmagynyň öňüni almak üçin, kesgitlenen akym nokadyndaky nasos akymyna gözegçilik etmek üçin guýy suw geçirijisine derwezeli klapan oturdylmalydyr.

7. Suw nasosy işleýän mahaly, suw çykarylyşy üznüksiz bolmaly we hatda tok durnukly bolmaly (bahalandyrylan iş şertlerinde, adatça bahalandyrylan tokyň 10% -inden köp bolmaly däldir) we yrgyldy ýa-da ses bolmaly däldir. Anormallik bar bolsa, sebäbini bilmek we ýok etmek üçin enjamy saklamaly.

8. Gurnanyňyzda, hereketlendirijiniň toprak siminiň sazlanmagyna üns beriň (2-nji surata serediň). Suw turbasy polat turba bolanda, ony guýy gysgyjyndan alyp gidiň; suw turbasy plastik turba bolanda, ony elektrik nasosynyň toprak belgisinden alyp çykyň.

- 1.After installing the submersible pump, recheck the insulation resistance and three-phase continuity switch, check whether there is any error in the connection between the instrument and the starting equipment.If there is no problem, you can start to test the machine. After starting, observe whether the indication reading of each instrument is correct.If the rated voltage and current specified on the nameplate are exceeded, please observe whether the pump has noise or vibration.If everything is normal, it can be put into operation. After the pump runs for the first time for four hours, the motor thermal insulation resistance should be closed and tested quickly. Its value should not be less than 0.5 megaohm. After the pump stops, it should be restarted after five minutes to prevent the water column in the pipeline from completely reversing, which will cause the motor to burn out due to excessive current.

- 2.After the pump is put into normal operation, in order to prolong its service life, it is necessary to check whether the supply voltage, working current and insulation resistance are normal regularly. If the following conditions are found, the machine should be stopped immediately to troubleshoot.

- 1.Under the rated working condition, the current exceeds 20%.

- 2.The dynamic water level drops to the water inlet section, resulting in intermittent water.

- 3.The submersible pump has severe vibration or noise.

- 4.The supply voltage is lower than 340 volts.

- 5.A fuse is burned out.

- 6.The water pipeline is damaged.

- 7.The motor's insulation resistance to the geothermal state is lower than 0.5 megaohm.

- 3.Unit disassembly:

- - Kabel galstugyny açyň, turbanyň bölegini aýryň we sim plastinkasyny aýryň.

- - screw down the water bolt, put out the water in the motor chamber.

- - süzgüçi aýyryň, hereketlendirijini düzmek üçin birikdirilen nurbady boşadyň.

- 4.screw down the bolt connecting the water inlet section with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the opposite order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

1, motor boşlugyna suw goýuň (esasanam gyşda motoryň doňmazlygy üçin) we kabeli gowy daňyň.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, uzak wagtlap ulanmak suwa çümýän nasoslaryň posynyň öňüni almaga üns bermelidir.

- Impeller

- Mil ýeňi

- Kauçuk ýeň

-

Möhür halkasy

01 Çuň guýynyň suwy

02 -okary gatly suw üpjünçiligi

03 dag suw üpjünçiligi

04 diň suwy

05 Oba hojalygyny suwarmak

06 bag suwaryş

07 derýa suwuny kabul etmek

08 içerki suw