The product adopts special water-resistant wire for motor winding, with excellent characteristics such as high frequency shock resistance, pulse peak voltage shock resistance and high temperature aging resistance. The frequency conversion winding design ensures the motor to operate smoothly between 1Hz and 50Hz for a long time, making the frequency conversion deep well pump more energy saving and longer service life.

We are honored to introduce our products, this product provides three-phase AC 380V power supply (tolerance of ± 5%), 50HZ voltage (tolerance of ± 1%). At the same time, our products require strict water quality requirements: water temperature is not higher than 20 °C; solid impurities content (mass ratio) is not greater than 0.01%; PH value (pH) is 6.5-8.5; hydrogen sulfide content is not greater than 1.5mg/L; chloride ion content is not greater than 400mg/L. The motor adopts closed or water-filled wet structure, which must be filled with clean water before use to prevent empty. Tighten the water charging and deflating bolts before use, otherwise, it is not allowed to use. The submersible pump must be completely immersed in water to work, the immersion depth shall not exceed 70 meters, and the distance between the bottom of the submersible pump and the bottom of the well shall not be less than 3 meters. The well water flow shall meet the output and continuous operation requirements of the submersible pump, and the output of the submersible pump shall be controlled at 0.7-1.2 times of the rated flow. The well must be vertical, and the submersible pump can not be used horizontally or inverted, but only vertically. The submersible pump must be equipped with cables according to requirements, and is equipped with external overload protection devices. It is strictly prohibited to conduct no-load tests on the pump without water. Our products guarantee to provide you with high quality and stable performance, while meeting your needs to ensure safe and reliable.

| Modèl | Koule (m3/h) | Tèt (m) |

Vitès wotasyon (chanje/pwen) |

Ponp dlo (%) | Debouche dyamèt (mm) |

Aplikab byen dyamèt (mm) |

Rated power(KW) |

Rated vòltaj (V) |

Rated aktyèl (A) |

Efikasite motè (%) | power factorcosφ | Inite Gwosè maksimòm radial (mm) |

|||||||||

| 175QJ10-42 | 10 | 42 | 2850 | 53 | 50 | 175pi wo a | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ10-56 | 56 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-70 | 70 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ10-84 | 84 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ10-112 | 112 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-126 | 126 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ10-140 | 140 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ15-42 | 15 | 42 | 2850 | 58 | 50 | 175pi wo a | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ15-55 | 55 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-65 | 65 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ15-85 | 85 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ15-112 | 112 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-26 | 20 | 26 | 2850 | 64 | 50 | 175pi wo a | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ20-39 | 39 | 4 | 10.1 | 76.0 | 0.79 | ||||||||||||||||

| 175QJ20-52 | 52 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ20-78 | 78 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ20-91 | 91 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ20-104 | 104 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ20-130 | 130 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-156 | 156 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ20-182 | 187 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ20-208 | 208 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-247 | 247 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ20-273 | 273 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-299 | 299 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-325 | 325 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ20-364 | 364 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-26 | 25 | 26 | 2850 | 66 | 65 | 175pi wo a | 3 | 380 | 7.8 | 74.0 | 0.79 | 168 | |||||||||

| 175QJ25-39 | 39 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ25-65 | 25 | 65 | 2850 | 66 | 65 | 175pi wo a | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ25-78 | 78 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ25-91 | 91 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ25-104 | 104 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-130 | 130 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ25-156 | 156 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ25-182 | 182 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-208 | 208 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ25-221 | 221 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-247 | 247 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-260 | 260 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ25-299 | 299 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ30-30 | 30 | 30 | 2850 | 67 | 80 | 175pi wo a | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ30-40 | 40 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-24 | 32 | 24 | 2850 | 67 | 80 | 175pi wo a | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ32-36 | 36 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ32-48 | 48 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ32-60 | 60 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ32-72 | 72 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ32-84 | 84 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-96 | 96 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ32-120 | 120 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ32-144 | 144 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-168 | 168 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ32-180 | 180 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-192 | 192 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-204 | 204 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ32-240 | 240 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ35-60 | 35 | 60 | 2850 | 67 | 80 | 175pi wo a | 10 | 380 | 25.0 | 78.0 | 0.78 | 168 | |||||||||

| 175QJ35-75 | 75 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ35-100 | 100 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ40-24 | 40 | 24 | 2850 | 70 | 80 | 175pi wo a | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ40-30 | 30 | 5.5 | 13.6 | 77.0 | 0.8 | ||||||||||||||||

| 175QJ40-36 | 36 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ40-48 | 48 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ40-60 | 60 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ40-72 | 72 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-84 | 84 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ40-96 | 96 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ40-120 | 120 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-132 | 132 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ40-144 | 144 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-156 | 156 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-168 | 168 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ40-192 | 192 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-24 | 50 | 24 | 2850 | 72 | 80 | 175pi wo a | 5.5 | 380 | 13.6 | 77.0 | 0.8 | 168 | |||||||||

| 175QJ50-36 | 36 | 9.2 | 22.1 | 78.0 | 0.81 | ||||||||||||||||

| 175QJ50-48 | 48 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ50-60 | 60 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ50-70 | 70 | 17 | 40.9 | 80.0 | 0.79 | ||||||||||||||||

| 175QJ50-84 | 84 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ50-96 | 96 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-108 | 108 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ50-120 | 120 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-132 | 132 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-144 | 144 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ50-156 | 156 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-22 | 63 | 22 | 2850 | 72 | 80 | 175pi wo a | 7.5 | 380 | 18.4 | 77.5 | 0.8 | 168 | |||||||||

| 175QJ63-44 | 44 | 13 | 30.1 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-55 | 55 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ63-66 | 66 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ63-77 | 77 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-88 | 88 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ63-99 | 63 | 99 | 2850 | 72 | 80 | 175pi wo a | 30 | 380 | 66.6 | 81.5 | 0.84 | 168 | |||||||||

| 175QJ63-110 | 110 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ63-132 | 132 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-9 | 80 | 9 | 2850 | 73 | 100 | 175pi wo a | 4 | 380 | 10.1 | 76.0 | 0.79 | 168 | |||||||||

| 175QJ80-18 | 18 | 7.5 | 18.4 | 77.5 | 0.8 | ||||||||||||||||

| 175QJ80-27 | 27 | 11 | 26.1 | 79.0 | 0.81 | ||||||||||||||||

| 175QJ80-36 | 36 | 15 | 34.7 | 80.0 | 0.82 | ||||||||||||||||

| 175QJ80-45 | 45 | 18.5 | 42.6 | 80.5 | 0.82 | ||||||||||||||||

| 175QJ80-54 | 54 | 22 | 49.7 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-63 | 63 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-72 | 72 | 25 | 56.5 | 81.0 | 0.83 | ||||||||||||||||

| 175QJ80-81 | 81 | 30 | 66.6 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-90 | 90 | 32 | 71.0 | 81.5 | 0.84 | ||||||||||||||||

| 175QJ80-98 | 98 | 37 | 82.1 | 81.5 | 0.84 | ||||||||||||||||

This well submersible pump is a pump suitable for clean water. Digging new wells and pumping sediment and turbid water are strictly prohibited. The voltage grade of the well pump is 380V/50HZ. Submersible motors with other voltage grades need to be customized. Underground cables must use waterproof cables and must be equipped with starting equipment, such as distribution boxes, etc. The starting equipment should have common comprehensive motor protection functions, such as overload short circuit protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. In abnormal cases, the protection device should be tripped in time. During installation and use, the pump must be reliably grounded. It is prohibited to push and pull the switch when hands and feet are wet. The power supply must be cut off before installation and maintenance of the pump. The place where the pump is used must be set up with obvious "anti-electric shock" marks. Before going down the well or installation, the motor must be injected with distilled water or non-corrosive clear cold water in the inner cavity, and the intake/drain bolts must be tightened. When testing the pump on the ground, water must be injected into the pump chamber to lubricate the rubber bearings. The instant start time should not exceed one second to check whether the direction is correct. The same as the steering instructions. Pay attention to safety when the pump is upright to prevent tilting and injury. Strictly in accordance with the provisions of the pump lift and flow range, to prevent the pump flow at low lift or in high lift pull too large, resulting in extreme wear of thrust bearings and other components, the motor due to overload and burn. After put into the well, the measurement of the motor and the ground insulation resistance value, not less than 100M. After the start, regular observation of voltage and current, and check the motor winding insulation is in line with the requirements of the provisions. If the temperature of the storage site is below the freezing point, the water in the pump chamber should be drained to prevent the water in the motor chamber from freezing and damaging the motor due to low temperature.

Brèf entwodiksyon nan estrikti: se pati ponp sitou ki konpoze de arbr ponp, roue, koki devyasyon, portant kawotchou, tcheke kò valv (pati si ou vle) ak lòt konpozan. Pati motè se sitou ki konpoze de baz, presyon reglemante fim, poussée portant, poussée plak, pi ba gid kote yo pote chèz, stator, rotor, anwo gid kote yo pote chèz, bag sab, seksyon inlet dlo, kab ak lòt konpozan.

Karakteristik prensipal yo nan pwodwi a gen ladan:

1.The motor is a water-filled wet submersible three-phase asynchronous motor, the motor cavity is full of clean water, used to cool the motor and lubricate the bearing, the pressure regulating film at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the water inside the body caused by the change of the temperature rise of the motor.

2.In order to prevent the sand in the well water from entering the motor, the upper end of the motor shaft is equipped with two oil seals, and a sand ring is installed to form a sand prevention structure.

3.In order to prevent the pump shaft from running up when starting, the pump shaft and the motor shaft are connected by a coupling, and an upper thrust bearing is installed at the lower part of the motor.

4.The lubrication of the motor and the pump bearing is water lubrication.

5.The motor stator winding is made of high quality submersible motor winding wire, with high insulation performance.

6.The pump is designed by computer CAD, with simple structure and good technical performance.

(1) Preparasyon anvan enstalasyon:

1. Tcheke si ponp lan submersible satisfè kondisyon itilizasyon yo ak dimansyon ki espesifye nan manyèl la.

2. Sèvi ak yon objè lou ki gen yon dyamèt ki egal a maksimòm dyamèt ekstèn ponp submersible a, mezire si wi ou non dyamèt inelbore a ka anfòm ponp submersible a, epi mezire si pwofondè pi a satisfè kondisyon enstalasyon yo.

3. Tcheke si twou a pwòp epi si dlo a twoub. Pa janm sèvi ak yon ponp elektrik submersible pou lave welor ponp labou ak dlo sab pou evite domaj twò bonè nan ponp elektrik submersible a.

4. Tcheke si pozisyon nan kranpon enstalasyon welhead la apwopriye epi si li ka kenbe tèt ak kalite a nan tout inite a.

5. Tcheke si konpozan ponp submersible yo konplè epi yo enstale byen dapre dyagram asanble a nan manyèl la Retire ekran filtre a epi vire kouple a pou wè si li vire fleksib.

6. Devise vis dlo a ak fillthe motè kavite ak dlo pwòp, ki pa korozivite (nòt. asire w ke ou fil li moute), Lè sa a, sere boulon waterscrew la. Apre 12 èdtan nan piki dlo, rezistans izolasyon motè a pa ta dwe mwens pase 150M Q lè yo mezire ak yon tab tranbleman 500V.

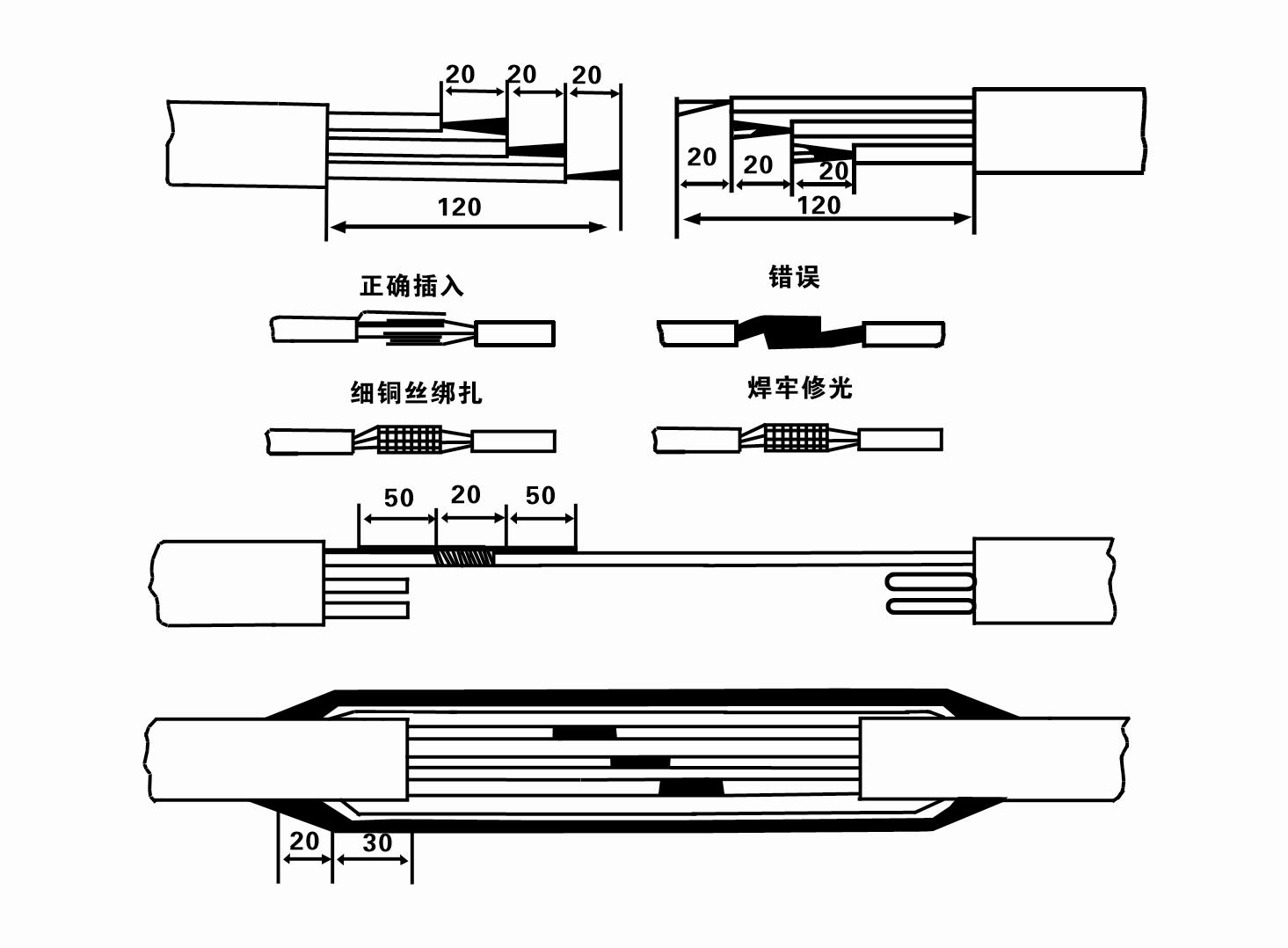

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Dyagram pwosesis fil elektrik kab atache a se jan sa a:

8. Sèvi ak yon miltimèt pou tcheke si wi ou non fil twa-faz yo konekte epi si rezistans DC a apeprè ekilibre.

9. Tcheke si sikwi a ak kapasite transfòmatè yo twò chaje, ak Lè sa a, konekte switch la pwoteksyon surcharge oswa ekipman kòmanse. Gade Tablo 2 pou modèl espesifik, ak Lè sa a, Vide yon bokit dlo nan ponp dlo a soti nan priz ponp dlo a wile BEARINGS kawotchou yo nan ponp lan, ak Lè sa a, mete ponp lan submersible elektrik dwat ak fiks. Kòmanse (pa plis pase yon segonn) epi tcheke si direksyon volan an konsistan avèk siy volan an. Si ou pa, chanje nenpòt ki de konektè nan twa-faz kab la. Lè sa a, enstale filtè a epi prepare yo desann pi a. Si yo itilize nan okazyon espesyal (tankou twou, twou, rivyè, etan, etan, elatriye), ponp elektrik la dwe fyab sou tè.

(2) Enstalasyon ekipman ak zouti:

1. Yon pè chenn leve pou plis pase de tòn.

2. Yon trépied ak yon wotè vètikal pa mwens pase kat mèt.

3. De kòd pandye (kòd fil) ki ka pote yon pwa ki gen plis pase yon tòn (ka pote pwa a nan yon seri konplè ponp dlo).

4. Enstale de pè kranpon (atèl).

5. Kle, mato, tournevis, zouti elektrik ak enstriman, elatriye.

(3) Enstalasyon ponp elektrik:

1. Dyagram enstalasyon ponp elektrik submersible a montre nan Figi 2. Dimansyon enstalasyon espesifik yo montre nan Tablo 3 "Lis Dimansyon Enstalasyon ponp elektrik Submersible a".

2. Ponp elektrik submersible ak yon tèt mwens pase 30 mèt ka leve dirèkteman nan pi a lè l sèvi avèk kawotchou ak kòd fil oswa lòt kòd chanv ki ka pote pwa a plen nan machin nan tout antye, tiyo dlo, ak dlo nan tiyo yo.

3. Ponp ak yon tèt ki gen plis pase 30 mèt itilize tiyo asye, ak sekans enstalasyon an se jan sa a:

①Sèvi ak yon kranpon pou sere pwent anwo nan pati ponp dlo a (motè a ak ponp dlo yo te konekte nan moman sa a), leve l ak yon chèn pandye, epi tou dousman mare l nan pi a jiskaske Mete kranpon an sou tèt pi a epi retire li. pandye chèn.

② Sèvi ak yon lòt pè kranpon pou sere yon tiyo, leve l ak yon chenn pandye 15 cm lwen bride a, epi bese l tou dousman. Ant bride tiyo ak bride ponp Mete pad kawotchou a an plas epi sere boulon tiyo a ak ponpe respire ak boulon, nwa ak rondelles prentan.

③ Leve ponp submersible a yon ti kras, retire kranpon an sou pwent anwo ponp dlo a, mare kab la byen fèm nan tiyo dlo a ak yon kasèt plastik, epi tou dousman mare li desann jiskaske kranpon an mete nan tèt pi a.

④Sèvi ak menm metòd pou mare tout tiyo dlo nan pi a.

⑤Apre kab plon an konekte ak switch kontwòl la, li konekte ak ekipman pou pouvwa twa faz la.

(4) Bagay ou dwe sonje pandan enstalasyon:

1. Si yo jwenn yon fenomèn blokis pandan pwosesis ponp lan, vire oswa rale tiyo dlo a simonte pwen an blocage. Si plizyè mezi toujou pa travay, tanpri pa fòse ponp lan desann pou evite domaj nan ponp elektrik submersible ak pi a.

2. Pandan enstalasyon, yo ta dwe mete yon pad kawotchou nan bride chak tiyo epi sere boulon respire.

3. Lè ponp dlo a bese nan pi a, li ta dwe mete l nan mitan tiyo a pou anpeche ponp lan kouri kont miray la byen pou yon tan long, sa ki lakòz ponp lan vibre ak motè a bale ak boule. .

4. Detèmine pwofondè ponp dlo a nan fon pi a dapre sab koule ak kondisyon limon nan pi a. Pa antere ponp lan nan labou. Distans ki soti nan ponp dlo a nan anba a nan pi a se jeneralman pa mwens pase 3 mèt (gade Figi 2).

5. Pwofondè dlo a antre nan ponp dlo a ta dwe pa mwens pase 1-1.5 mèt soti nan nivo dlo dinamik nan ne inlet dlo a (gade Figi 2). Sinon, bi ponp dlo yo ka fasil domaje.

6. Leve ponp dlo a pa ka twò ba. Sinon, yon tiyo pòtay bezwen yo dwe enstale sou tiyo dlo a pou kontwole koule ponp lan nan pwen an koule rated pou anpeche motè a twò chaje ak boule akòz gwo pousantaj koule.

7. Lè ponp dlo a ap kouri, pwodiksyon dlo a ta dwe kontinyèl e menm, aktyèl la ta dwe estab (anba kondisyon travay rated, jeneralman pa plis pase 10% aktyèl la nominal), epi pa ta dwe gen okenn vibrasyon oswa bri. Si gen nenpòt anòmal, yo ta dwe sispann machin nan pou chèche konnen kòz la epi elimine li.

8. Lè w ap enstale, peye atansyon sou anviwònman fil motè a (gade Figi 2). Lè tiyo dlo a se yon tiyo asye, mennen li soti nan kranpon nan wellhead; lè tiyo dlo a se yon tiyo plastik, mennen li soti nan mak baz la nan ponp elektrik la.

- 1.After installing the submersible pump, recheck the insulation resistance and three-phase continuity switch, check whether there is any error in the connection between the instrument and the starting equipment.If there is no problem, you can start to test the machine. After starting, observe whether the indication reading of each instrument is correct.If the rated voltage and current specified on the nameplate are exceeded, please observe whether the pump has noise or vibration.If everything is normal, it can be put into operation. After the pump runs for the first time for four hours, the motor thermal insulation resistance should be closed and tested quickly. Its value should not be less than 0.5 megaohm. After the pump stops, it should be restarted after five minutes to prevent the water column in the pipeline from completely reversing, which will cause the motor to burn out due to excessive current.

- 2.After the pump is put into normal operation, in order to prolong its service life, it is necessary to check whether the supply voltage, working current and insulation resistance are normal regularly. If the following conditions are found, the machine should be stopped immediately to troubleshoot.

- 1.Under the rated working condition, the current exceeds 20%.

- 2.The dynamic water level drops to the water inlet section, resulting in intermittent water.

- 3.The submersible pump has severe vibration or noise.

- 4.The supply voltage is lower than 340 volts.

- 5.A fuse is burned out.

- 6.The water pipeline is damaged.

- 7.The motor's insulation resistance to the geothermal state is lower than 0.5 megaohm.

- 3.Unit disassembly:

- - Demare mare kab la, retire pati tiyo a, epi retire plak fil la.

- - screw down the water bolt, put out the water in the motor chamber.

- - retire filtè a, lage vis fiks la sou kouple a pou ranje arbr motè a.

- 4.screw down the bolt connecting the water inlet section with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the opposite order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

1, mete dlo a nan kavite motè a (sitou nan sezon fredi pou anpeche motè a konjel), epi mare kab la byen.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, itilizasyon alontèm yo ta dwe peye atansyon sou prevansyon rouye ponp submersible yo.

- Impeller

- Manch manch arbr

- Kawotchou manch manch arbr

-

Bag sele

01 Konsomasyon dlo byen fon

02 Pwovizyon dlo ki wo

03 rezèv dlo mòn

04 gwo kay won dlo

05 Irigasyon agrikòl

06 irigasyon jaden

07 konsomasyon dlo rivyè

08 dlo domestik