This product adopts a variable frequency winding design, ensuring the motor's smooth conversion operation between 1HZ and 50HZ for a long time. This innovative design not only saves energy and prolongs service life, but also provides lasting and reliable performance in the work process. Whether in a home or industrial environment, this product will provide users with excellent efficiency and reliability, making it an indispensable tool in the manufacturing and production process.

1, magetsi: matatu-chikamu AC 380V (kushivirira + / - 5%), 50HZ (kushivirira + / - 1%).

2, kunaka kwemvura:

(1) water temperature is not higher than 20 °C;

(2) kusvibiswa kwakasimba kwemukati (huwandu hwehuwandu) haisi yakakura kudarika 0.01%;

(3) PH kukosha (pH) 6.5-8.5;

(4) hydrogen sulfide content haisi yakakura kudarika 1.5mg/L;

(5) chloride ion yemukati haina kupfuura 400mg/L.

3, mota yakavharwa kana yakazadzwa nemvura yakanyorova chimiro, usati washandisa iyo submersible mota mhango inofanira kunge izere nemvura yakachena, kudzivirira manyepo akazara, uye ipapo simbisa jekiseni remvura, mabhaudhi ekuburitsa mhepo, neimwe nzira isingabvumirwe kushandisa.

4, submersible pump must be completely submerged in the water, the diving depth is not greater than 70m, the bottom of the submersible pump from the bottom of the well is not less than 3m. 5, the well water flow should be able to meet the submersible pump water output and continuous operation, the submersible pump water output should be controlled at 0.7 - 1.2 times the rated flow.

6, tsime rinofanira kunge rakatwasuka, pombi inonyudza haigone kushandiswa kana kuraswa, inongomira yakamira chete.

7, pombi inodzika inofanira kufananidzwa netambo zvinoenderana nezvinodiwa, uye mudziyo wekunze wekudzivirira wakawandisa.

8, pombi inorambidzwa zvachose pasina mvura isina-mutoro bvunzo muchina

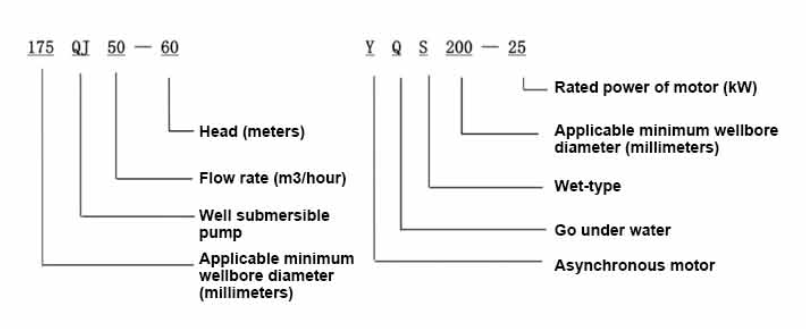

| Model | Kuyerera (m3/h) | Head (m) |

Rotatingspeed (chinja/point) |

Pombi yemvura(%) | Outlet dhayamita (mm) |

Inoshanda zvakanaka dhayamita(mm) |

Rated power(KW) |

Rated voltage (V) |

Rated ikozvino (A) |

Motorefficiency (%) | power factorcosφ | Unit Radial Maximu size(mm) |

Remark | |||||||||

| 300QJ200-40 | 200 | 40 | 2900 | 76 | 150 | 300kumusoro | 37 | 380 | 77.8 | 85.0 | 0.85 | 281 | ||||||||||

| 300QJ200-60 | 60 | 55 | 115 | 85.5 | 0.85 | |||||||||||||||||

| 300QJ200-80 | 80 | 75 | 154.1 | 86.0 | 0.86 | |||||||||||||||||

| 300QJ200-100 | 100 | 90 | 183.8 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ200-120 | 120 | 100 | 204.3 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ200-140 | 140 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

| 300QJ200-160 | 160 | 140 | 277.8 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-180 | 180 | 160 | 317.5 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-200 | 200 | 185 | 367.2 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-240 | 240 | 220 | 436.6 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ320-30 | 320 | 30 | 2900 | 77 | 200 | 300kumusoro | 45 | 380 | 94.6 | 85.0 | 0.85 | 281 | ||||||||||

| 300QJ320-60 | 60 | 90 | 183.8 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ320-90 | 90 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

| 300QJ320-120 | 120 | 160 | 317.5 | 88.0 | 0.87 | |||||||||||||||||

This well submersible pump is a pump suitable for clean water. It is strictly prohibited to dig new wells and pump dirty water containing sediment. The voltage grade of the pump is 380/50HZ, and other submersible motors with different voltage grades need to be customized. Underground cables must be waterproof cables and must be equipped with starting equipment, such as distribution boxes, etc. The starting equipment should have common comprehensive motor protection functions, such as short circuit overload protection, dephase protection, undervoltage protection, grounding protection and idling protection, etc., in order to prevent timely tripping when abnormal conditions occur. During the installation and use process, the pump must have reliable grounding. It is strictly prohibited to push and pull the switch when your hands and feet are wet. The power supply must be cut off before installation and maintenance of the pump. An obvious sign "anti-electric shock" must be set up where the pump is used. Before going down the well or installation, the motor must be filled with distilled water or non-corrosive clean cold water, and the water inlet and outlet bolts must be tightened. When testing the pump on the ground, water must be filled into the pump chamber to lubricate the rubber bearings. The instant start time shall not exceed one second to check whether the steering is correct. Pay attention to safety when the pump is upright to prevent toppling and injury. Strictly in accordance with the provisions of the pump lift and flow range, to prevent the pump with a large flow at low lift or produce a large pull at high lift, resulting in extreme wear of thrust bearings and other parts, the motor overload and burn. After the pump into the well, the measurement of the motor to the ground insulation resistance should not be less than 100MΩ. After starting, regularly observe the voltage and current, and check whether the motor winding insulation meets the requirements; if the pump storage temperature below freezing point, should be drained to prevent the water in the motor cavity from freezing and cause the motor damage due to low temperature.

The pump part is mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor part is mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand ring, water inlet section, lead cable and other components.

Izvo zvakakosha zvechigadzirwa zvinosanganisira:

- 1.The motor is a water-filled wet submersible three-phase asynchronous motor. The motor cavity is filled with clean water, used to cool the motor and lubricate the bearing. The pressure regulating diaphragm at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the water in the body caused by the temperature rise of the motor.

- 2. In order to prevent the sand particles from entering the motor, two sand seals are installed at the upper end of the motor shaft extension, and a sand control structure is formed by installing the sand ring.

- 3. In order to prevent the pump shaft from jumping when starting, the pump shaft is connected with the motor shaft through a coupling, and the thrust bearing is installed at the bottom of the motor.

- 4. The lubrication method of the motor and the pump bearing is water lubrication.

- 5. The stator winding of the motor adopts high quality submersible motor winding wire with high insulation performance.

- 6. The pump is designed by computer CAD, with simple structure and excellent technical performance.

(1) Gadziriro isati yaiswa:

1. Tarisa kana pombi inodzika inosangana nemamiriro ekushandiswa uye chiyero chakatsanangurwa mubhuku rekushandisa.

2. Uchishandisa inorema obiect ine dhayamita yakaenzana nehupamhi hwekunze dhayamita yepombi inonyura, yera kana innediameter yemugodhi inogona kukwana pombi yepasi, uye kuyera kana kudzika kwetsime kunosangana nezvinodiwa zvekuisa.

3. Tarisa kuti chibhorani chakachena here uye kuti mvura yemutsime ine tsvina here. Usambofa washandisa pombi yemagetsi inonyura kugeza madhaka epombi yewelor nemvura yejecha kudzivirira kukuvara kusati kwasvika kwepombi yemagetsi inonyura.

4. Tarisa kana chinzvimbo cheiyo welhead yekumisikidza chisimbi chakakodzera uye kana ichikwanisa kumira nemhando yechikamu chose.

5. Tarisa kana zvikamu zvepombi zvinopinda mumvura zvakakwana uye zvakaiswa zvakanaka maererano nedhiyagiramu yegungano iri mubhukuBvisa sikirini yekusefa uye tenderedza coupling kuti uone kana ichitenderera zviri nyore.

6. Sunungura siruu yemvura wozadza monitivha nemvura yakachena, isingaore (noti. iva nechokwadi chekuinyora), wobva wasunga simbi yemvura. Mushure memaawa gumi nemaviri ejekiseni remvura, kudzivirira kwekudzivirira kwemota hakufanirwe kunge kuri pasi pe150M Q kana kuyerwa ne500V tafura yekuzunza.

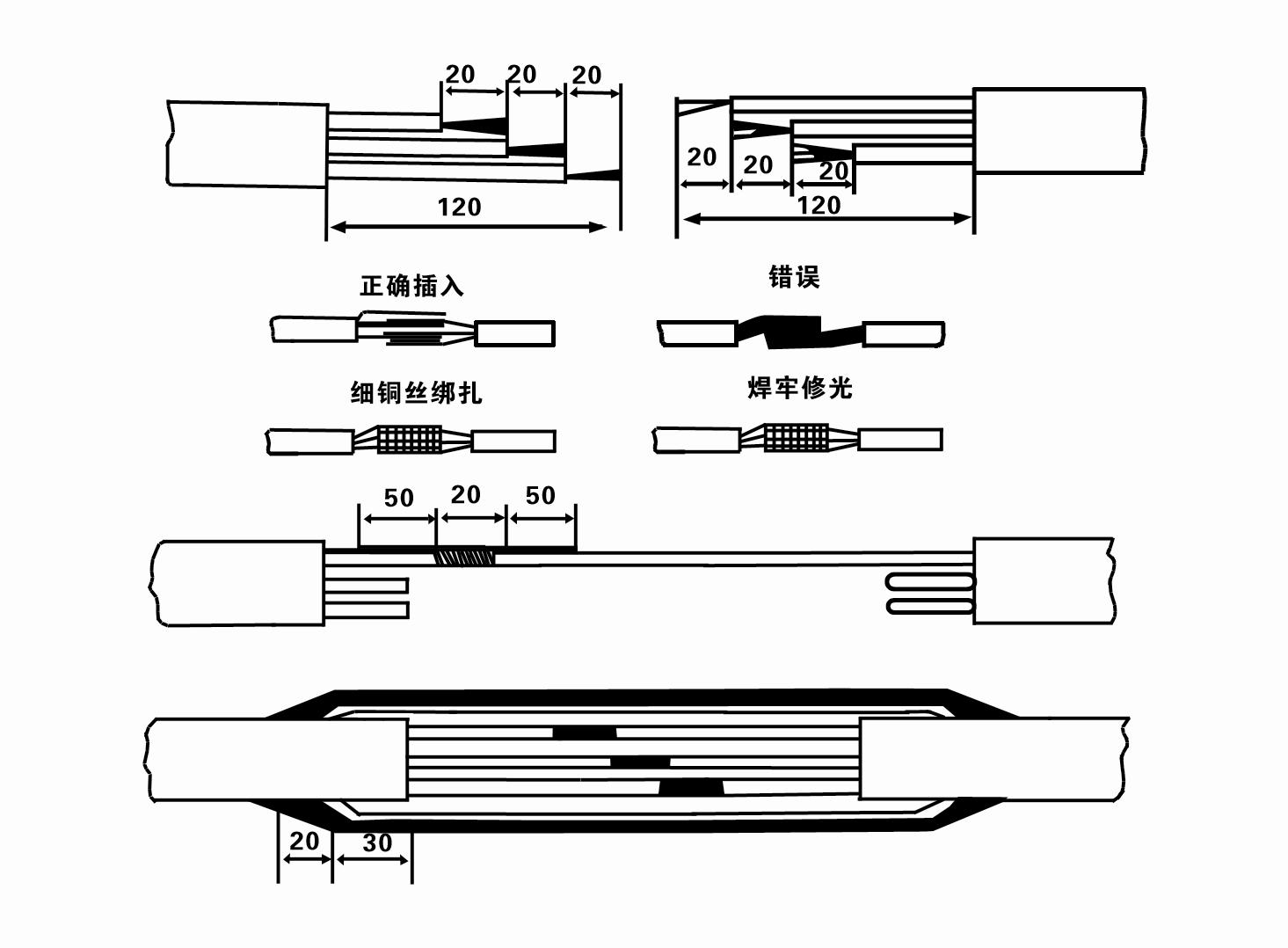

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Iyo yakasungirirwa cable wiring process diagraph yakaita seiyi:

8. Shandisa multimeter kuti utarise kana mawaya matatu-chikamu akabatana uye kana iyo DC inopikisa inenge yakaenzana.

9. Tarisa kana dunhu neshanduko simba rakawandisa, uye wozobatanidza iyo overload kudzivirira switch kana kutanga michina. Ona Tafura 2 yemhando dzakanangana, wozoDurura mugomo wemvura mupombi yemvura kubva papombi yemvura kuti uise mabearings erabha mupombi, wobva waisa pombi yemagetsi inonyura yakamira uye yakatsiga. Tanga (pasingapfuuri sekondi imwe) uye tarisa kana gwara rekutungamirira richienderana nechiratidzo chekutungamirira. Kana zvisina kudaro, chinjanisa chero zvibatanidza zviviri zvetatu-phase cable. Wobva waisa sefa uye gadzirira kudzika pasi mutsime. Kana yakashandiswa muzviitiko zvakakosha (zvakadai semigero, migero, nzizi, madziva, madziva, nezvimwewo), pombi yemagetsi inofanira kunge yakavimbika pasi.

(2) Midziyo yekuisa uye zvishandiso:

1. Imwe peya yekusimudza maketani anopfuura matani maviri.

2. Chitatu chine hurefu hwakamira husingasviki mamita mana.

3. Tambo mbiri dzakarembera (tambo dzetambo) dzinogona kutakura huremu hunodarika tani imwe (dzinogona kutakura huremu hweseti yakakwana yemapombi emvura).

4. Isai mapeya maviri emagetsi (splints).

5. Wrenches, sando, screwdrivers, midziyo yemagetsi uye zviridzwa, nezvimwewo.

(3) Kuiswa kwepombi yemagetsi:

1. Dhidhiyo yekuisa yepombi yemagetsi inoputika inoratidzwa muMufananidzo 2. Izvo zviyero zvekuisa zvakananga zvinoratidzwa muTebhu 3 "Rondedzero yeKuisa Dimensions ye Submersible Electric Pump".

2. Pombi dzemagetsi dzinonyura dzine musoro usingasviki mamita makumi matatu dzinogona kusimudzwa zvakananga mugomba uchishandisa hose netambo dzewaya kana dzimwe tambo dzehemp dzinogona kutakura huremu hwakazara hwemuchina wese, pombi dzemvura, uye mvura mumapombi.

3. Mapombi ane musoro weanopfuura mamita makumi matatu anoshandisa pombi dzesimbi, uye kutevedzana kwekugadzika kunotevera:

①Shandisa chibatiso kusungirira kumucheto kwekumusoro kwepombi yemvura (motor nepombi yemvura zvabatanidzwa panguva ino), isimudze neketani inorembera, woisungirira zvishoma nezvishoma mugomba kusvikira Isa chirambi patsime wobvisa. hanging chain.

② Shandisa imwe peya yezvisungo kusungirira pombi, woisimudza necheni yakaturika masendimita gumi nemashanu kubva paflange, woidzikisa zvishoma nezvishoma. Pakati pepombi flange nepombi flangeIsa pedhi rerabha panzvimbo uye simbisa pombi uye pomba zvakaenzana nemabhaudhi, nzungu uye mawachi echirimo.

③ Simudza pombi inonyura zvishoma, bvisa chinosungirira chiri kumucheto kwepombi yemvura, sunga tambo zvakasimba papombi yemvura netepi yepurasitiki, woisunga zvishoma nezvishoma kusvikira Chisungiso chaiswa patsime.

④Shandisa nzira imwechete kusungira pombi dzose dzemvura mutsime.

⑤Mushure metambo yekutungamirira-kunze yakabatanidzwa kune chinja chekutonga, chakabatanidzwa kune matatu-phase simba rekupa.

(4) Zvinhu zvekucherechedza panguva yekuisa:

1. Kana chiitiko chejamming chinowanikwa panguva yekupomba, shandura kana kudhonza pombi yemvura kuti ukunde nzvimbo yekumisa. Kana matanho akasiyana-siyana achiri kusashanda, ndapota Usamanikidza pombi pasi kuti udzivise kukuvadzwa kwepombi yemagetsi inonyudza uye tsime.

2. Panguva yekuisa, rubber pad inofanira kuiswa paflange yepombi imwe neimwe uye yakasimbiswa zvakafanana.

3. Kana pombi yemvura yadzikiswa mugomba, inofanira kuiswa pakati pepombi yetsime kudzivirira kuti pombi isamhanye nemudhuri wetsime kwenguva yakareba, zvichiita kuti pombi izununguke uye injini kutsvaira nekutsva. .

4. Sarudza kudzika kwepombi yemvura kusvika pasi petsime maererano nejecha rinoyerera uye silt mamiriro emutsime. Usavige pombi mumatope. Nhambwe kubva papombi yemvura kusvika pasi petsime kazhinji haisviki mamita matatu (ona Mufananidzo 2).

5. Kudzika kwemvura yepombi yemvura hakufanirwe kunge kuri pasi pe1-1.5 metres kubva padanho remvura rine simba kusvika painopinza mvura (ona Mufananidzo 2). Zvikasadaro, pombi yemvura inotakura inogona kukuvara nyore.

6. Kusimudzwa kwepombi yemvura hakugoni kuderera zvakanyanya. Zvikasadaro, vharuvhu yegedhi inoda kuiswa papombi yemvura yemugodhi kudzora kuyerera kwepombi panzvimbo yakayerwa yekuyerera kudzivirira mota kuti isaremerwe nekupiswa nekuda kwekuyerera kukuru.

7. Apo pombi yemvura iri kushanda, kubuda kwemvura kunofanira kuenderera mberi uye kunyange, ikozvino inofanira kunge yakagadzikana (pasi pemamiriro ekushanda akarongwa, kazhinji haapfuuri 10% yehuwandu hwemazuva ano), uye hapafaniri kuva nekudengenyeka kana ruzha. Kana paine abnormality, muchina uyu unofanirwa kumiswa kuti uzive chikonzero uye kubvisa.

8. Paunenge uchiisa, teerera kugadzika kwemoto wepasi waya (ona Mufananidzo 2). Kana pombi yemvura iri pombi yesimbi, itungamire kubva patsime remusoro; apo pombi yemvura iri pombi yepurasitiki, itungamirire kubva painogadzika chiratidzo chepombi yemagetsi.

- 1.After the submersible pump is installed, check the insulation resistance and three-phase conduction from the switch again, check whether the instrument and the connection of the start equipment are wrong, if there is no problem, the trial machine can be started, and observe whether the indicator readings of the instrument exceed the rated voltage and current specified on the nameplate after the start, and observe whether the pump has noise and vibration phenomenon. If everything is normal, it can be put into operation.

- 2. After the first operation of the pump for four hours, the motor should be shut down to test the thermal insulation resistance quickly, and its value should not be less than 0.5 megaohm.

- 3. After the pump is shut down, it should be started after five minutes to prevent the water column in the pipe from being completely reflowed and causing excessive motor current and burnout.

- 4.After the pump is running normally, in order to prolong its service life, it is necessary to check the power supply voltage, running current and insulation resistance regularly to see if they are normal.If the following conditions are found, the equipment should be shut down immediately to troubleshoot.

- (1)Under the rated working conditions, the current exceeds 20% of the rated value.

- (2)The dynamic water level drops to the inlet part, resulting in intermittent water discharge.

- (3)The submersible pump vibrates violently or emits noisy noise.

- (4)The power supply voltage is lower than 340 volts.

- (5)A fuse is burned out.

- (6)The water pipe is damaged.

- (7)The thermal insulation resistance of the motor to the ground is less than 0.5 megaohm.

- These inspections will help to ensure the normal operation of the pump, improve its reliability and stability, so as to ensure its durability and service life.

- 5.unit disassembly:

- - untie cable rope, remove the pipeline part, remove the wire plate.

- - pukuta bhaudhi remvura, isa mvura mukamuri yemota.

- - remove the filter, loose the fixed screw on the coupling fixed motor shaft.

- - screw down the bolt connected with the motor at the inlet junction, separate the pump and the motor (pay attention to the unit cushion when separating, prevent the bending of the pump shaft)

- - pump disassembly sequence is: (see figure 1) inlet junction, impeller, guide housing, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, avoid bending the pump shaft and each part in the disassembly process.

- - motor disassembly process is: (see figure 1) place the motor on the platform, remove the nut, base, shaft head lock nut, thrust plate, key, lower guide bearing seat, double head bolt from the bottom of the motor in turn, then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- - unit assembly: Before assembly, the rust and dirt of the parts should be cleaned, and the mating surfaces and fasteners should be coated with sealant. Then they should be assembled in the reverse order of disassembly (the up and down momentum of the motor shaft is about 1 mm after assembly). After assembly, the coupling should be flexible, and then the filter screen test machine.

- 6.The submersible pump should be dismantled and repaired according to Article 5 for each operation year, or less than one year, but the submersible time has reached two years, and the worn parts should be replaced.

1, bvisa mvura mumugodhi wemota (kunyanya munguva yechando kudzivirira mota kubva kuchando), uye sunga tambo zvakanaka.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, kushandiswa kwenguva refu kunofanira kutarisisa kudzivirira ngura kwemapombi anodzika.

- Impeller

- Shaft sleeve

- Rubber shaft sleeve

-

Chisimbiso mhete

01 Kunwa mvura mutsime rakadzika

02 Mvura yakakwirira-inokwira

03 mvura yemugomo

04 shongwe yemvura

05 Kudiridzira kwekurima

06 kudiridza mubindu

07 kunwa mvura yerwizi

08 mvura yemumba